Darth Vader....Your LSx Stroker is ready!!

#81

Nice work Tony! I"m curious how this setup will perform with no issues. For even a big inch street motor, it's hard to argue with a good cathedral head. Even if a similar setup with ported rectangle ports makes similar power, it likely won't have as good of part throttle & under-the-curve power. For a street motor, it seems many still don't take this into enough consideration.

Good luck with traction...

Jason

Good luck with traction...

Jason

And Im with you on the rect port stuff.

The better heads always gets you the big flow numbers but Im usually slightly disappointed at most of the actual dyno curves I see (be it engine or chassis). Based on the head flow you would expect even more in peak power and the curves are never especially flat (torque curves looking more like a hill). The good cathedral stuff builds up close to peak torque quickly, then hangs and usually has another small ramp up before rolling over.....the better the engine the flatter the curve, but in general, the low/midrange grunt of the optimized cathedral set-ups are far more impressive IMO. And it makes sense....longer runners with smaller CSA in general will typically do that, plus a better exhaust port location helps that a bit (far less shrouded than any of the LS3/LS7 style heads).

Some of this is related to the intake as well....I would take a guess the cathedral FAST runners are two inches longer than the FAST square port stuff and that makes a huge difference in low/midrange torque. Admittedly its probably a little more challenging to put up a BIG number with a cathedral set-up but if you set it up properly the end results speak for themselves.

Even if the average enthusiast copied my recipe without all the extra bells and whistles, and say landed around 675 peak, that peak number would also include a really fat power/torque curve to boot and the part throttle response and tip in from a cathedral set-up would be alot sharper as you noted also.

BTW, I'm going back to the dyno next month looking for more....

I have been spending a a fair bit of time (many late nights in the last week or so) on the "Mad hatter" plan I mentioned a few posts back and it looks like the time I'm investing will likely pay off assuming the flowbench has a say in the matter and it usually does. The small set-back I experienced with the single piston ring has given me the opportunity to push this combination even more and at this point I'm actually glad I had to disassemble the engine again because it opened Pandora's box allowing me to think long and hard about what I could try to do in an effort to improve it even further and capitalize on the downtime. Putting it back together and not changing something in an effort to find more was not an option.

This engine should be an absolute blast to drive in my Vette and obviously somewhat dangerous as well if not managed properly. But fun is the name of the game and if traction issues and not putting the car sideways into the guardrail are my biggest problems at the end of the day I'm not complaining. I think if the work I'm doing now pays off and everything falls into place how I hope, my Vette might be awfully close to 140 trap speeds N/A....a goal of mine I have had for a long time but one I never dreamed possible in a normally aspirated cathedral head combination and a FAST intake manifold.

Cheers,

Tony

Last edited by Tony Mamo @ AFR; 08-17-2011 at 01:07 AM.

#83

And I got caught up in the GM hype about how much "better" it was.....better for them as it probably cost them a third of what the "batwing" pan cost to manufacture.

After I took it out of the box I was extremely disappointed but prior to it arriving was also warming up to the idea I could install and remove the engine from the top of the car and it would leave more room for a future turbo project I also had rattling around in my brain at one point.

After receiving it and being semi mentally committed I realized I could probably fabricate a tray to make a crappy design a whole lot more effective. Of course that turned into a rocket launch as these kinds of projects always do but at the end of the day (more like week) I was really happy how everything turned out and the fact I could more easily install/remove the engine with the straight rear sump LS2 pan.

Bottom line to anyone who has a batwing style pan now, keep it....it's the best oil pan GM ever made for a production car IMO....at least as far as a wetsump goes. Great oil control for drag racing as well as road racing....a very versatile design.

-Tony

#84

TECH Enthusiast

iTrader: (5)

Join Date: Apr 2008

Location: Hemet

Posts: 663

Likes: 0

Received 0 Likes

on

0 Posts

Brainfade....LOL

After I took it out of the box I was extremely disappointed but prior to it arriving was also warming up to the idea I could install and remove the engine from the top of the car and it would leave more room for a future turbo project I also had rattling around in my brain at one point.

-Tony

After I took it out of the box I was extremely disappointed but prior to it arriving was also warming up to the idea I could install and remove the engine from the top of the car and it would leave more room for a future turbo project I also had rattling around in my brain at one point.

-Tony

#86

TECH Resident

iTrader: (4)

Join Date: Nov 2004

Location: Nashville, TN

Posts: 879

Likes: 0

Received 0 Likes

on

0 Posts

Great back-to-back comparisons and a chance to find out how far big cathedrals with a FAST can really go.

Great back-to-back comparisons and a chance to find out how far big cathedrals with a FAST can really go.Jason

#87

Tony, since you have it open, why not put a tight lash solid roller in it? You can have the same #s @.050, you can get a faster intake ramp lobe and a slower exhaust ramp. With all of the different cam lobes, you can build your own cam specs. I would use a Lobe center 106 because it produces a peaker torque curve. If this was a daily driver only, then it might be a bit hard to sit in traffic. Let face it, there is no performance to be gained below 2500 RPM, when your driving around on the street, the motor make more than enough torque.

#89

Tony, since you have it open, why not put a tight lash solid roller in it? You can have the same #s @.050, you can get a faster intake ramp lobe and a slower exhaust ramp. With all of the different cam lobes, you can build your own cam specs. I would use a Lobe center 106 because it produces a peaker torque curve. If this was a daily driver only, then it might be a bit hard to sit in traffic. Let face it, there is no performance to be gained below 2500 RPM, when your driving around on the street, the motor make more than enough torque.

Keep in mind I have paid attention to all the details maximizing the valve control with this aggressive hydraulic grind (which was a custom I spec'ed and had Comp grind for me) by selecting the right valvetrain components such as limited travel lifters, beefy 3/8 .095 wall pushrods, hollow stem lightweight intake and exhaust valves, the right valvespring paying attention to seat and open pressure, lightweight rockers, etc., etc.

In fact my intake valve at 2.160 diameter only weighs 90 grams.....to put that in perspective, a standard issue 2.02 valve commonly found in our AFR 205/210 series LS heads weighs 107 grams.....our 2.08 valve in the larger 230 head closer to 120 grams (thats a huge difference and the weight savings goes up exponentially in available valve control). Im even using a hollow stem exhaust valve which was probably overkill because a solid stem 1.600 valve weighs 97 grams or so but I felt going lighter would also help spring life and why not run the 78 gram version seeing I left no stones unturned in many other areas of the build.

The other thing to consider is a modern hydraulic lobe has a lot faster ramp off the seat....the solid isn't as quick even in a tightlash grind because they have to somewhat gently lift and drop the lifter to take up the lash with no provision of hydraulic assistance. Most of the benefits of a solid over an aggressive modern day hydraulic profile (with the use of a Spintron and other trick equipment now used in all the development work) is the fact that most average enthusiasts don't set up the valvetrain as thoroughly and ultimately get valve control issues that effect power a great deal....then at the end of the day a solid naturally looks alot better at the higher end of the curve because the hydraulic was experiencing valve control issues causing the power curve to flatten, get erratic, or drop like a stone if its a really poorly designed set-up. The other situation a solid naturally shines is in a really high RPM combination (8K plus).....if your building a combo that can effectively use that type of RPM then a solid is the only way to fly IMO.

Back in the day the hydraulic roller lobes were lazy....had crappy valve control, and really compromised your power results. Not so anymore as proven here on a daily basis and when you really pay attention to all the details (such as this build), the results and subsequent power curve look just like a solid roller was installed. Lifter design has come along way as well....and that's arguably as important or even more so than the design of the cam lobes themselves. Without a quality lifter you couldn't take advantage of the modern day aggressive lobe profiles. IMO. if you select all your components properly (and you cant miss or overlook any of them), it seems to me the only thing the solid roller set-up still offers you (in a 7K ish type application) is a peek under your valve covers a few times a year when you adjust lash

Also, I would venture to say that especially concerning the "modern engine designs" (the new Hemi, the LS of course, etc.) more time is spent at the cam companies pushing the envelope on new hydraulic lobe designs than adding new solid lobes to their master lobe list.

Anyway....sorry for the long winded response. Im going to save discussing your narrow 106 LSA suggestion for another post. IMO it misses the mark on this build for numerous reasons and I will share why when I have a little more time later or tomorrow.

Regards,

Tony

Last edited by Tony Mamo @ AFR; 08-21-2011 at 04:34 AM.

#90

TECH Resident

iTrader: (6)

Join Date: Jul 2004

Location: West Palm Beach fl usa

Posts: 934

Received 0 Likes

on

0 Posts

So after literally years in the making I finally had a chance to see the "Vader 454" unleash some of its fury at the Westech dyno facility in Mira Loma, CA (using the same dyno and test cell I use to do all my LS testing for directly comparable results).

It was one of those unforgettable days filled with anticipation and excitement and unfortunately as the day progressed some slight disappointment as well.

Im going to quote myself taking a paragraph from the first post I made to start this thread....

It's like I subconsciously knew what might transpire on the dyno....LOL

To make a long story short I didn't get a chance to complete all my testing (I had a short list of changes to make in an effort to extract more power from the combination). About a dozen or so pulls into the day we noticed the engine starting to smoke out of the breather at WOT when we loaded it for the pull. After inspecting leak down, cranking compression, spark plugs, and cutting open the oil filter (everything looking like a clean bill of health) I decided to run it a little more....power was exactly the same but it was venting crankcase fumes during the run. I decided better be safe than sorry and halted any further testing till I find out what was going on.....something had obviously changed. My suspicions were a ring had stuck in one of the grooves or I pushed the limit on my piston to head clearance (quench distance) just a bit too much. After taking the engine home yesterday and not wasting a minute to find out it turns out the latter was exactly what transpired. There was some very light piston to head contact on one side of the piston, enough to close up the critical top ring gap not allowing it to conform to the cylinder wall (hence the blowby we started seeing). In fact I was sooooo close to my target (which was to get the piston so close to the head the carbon is almost cleaned off), it took a dozen or so runs to get the rods hot enough to stretch to the point of light contact. And thats how it goes.....sometimes a couple of thousandths is the difference of winning and losing when it comes to high performance engine assembly.

Lets get to the good stuff.....this engine surpassed my highest expectations and did so with the wrong header (still had the baseline 1.75 tube headers) and without the benefit of the vacuum pump or any of the items I planned on testing to hopefully find a few more ponies (rocker ratio swap, moving the cam position around, etc., etc.).

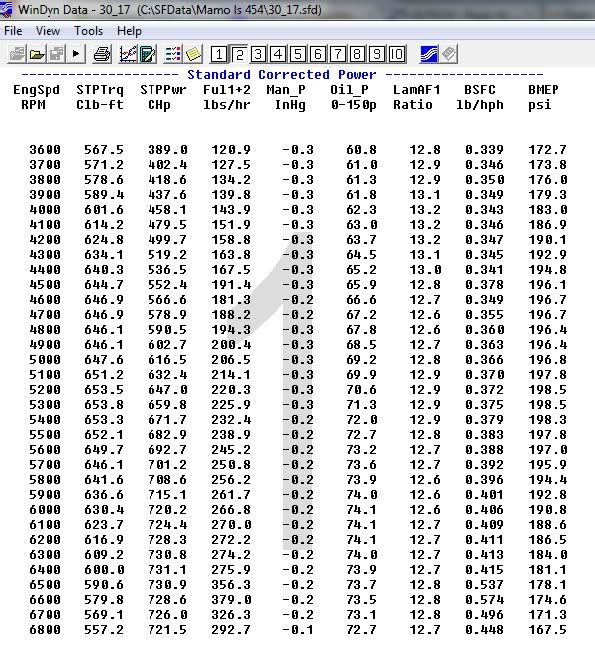

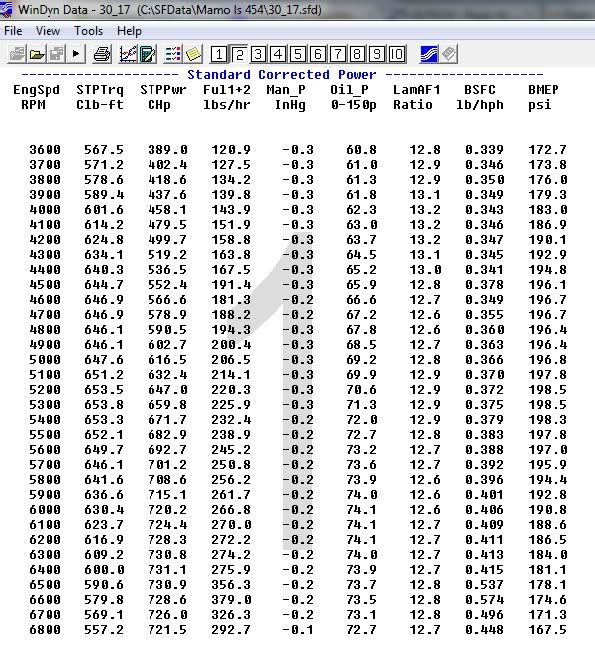

The engine sounded incredible on the dyno and twisted the strain gauge on the SF902 SuperFlow to the tune of 652 ft/lbs of torque and a best of 731 HP!! It was making north of 700 as early as 5700 RPM's and over 640 ft/lbs by 4400 (carrying over 640 all the way to 5800). When we loaded it and started the sweep at 3500 it was already producing 45 more ft/lbs of torque than my 383 made at its peak (about 570) and based on all the previous testing I have done that lead in torque figure will be at least 10-15 ft/lbs higher when I swap to the larger header (1.875 tube)....in fact the larger header will fatten the power and torque curve everywhere in an application like this.

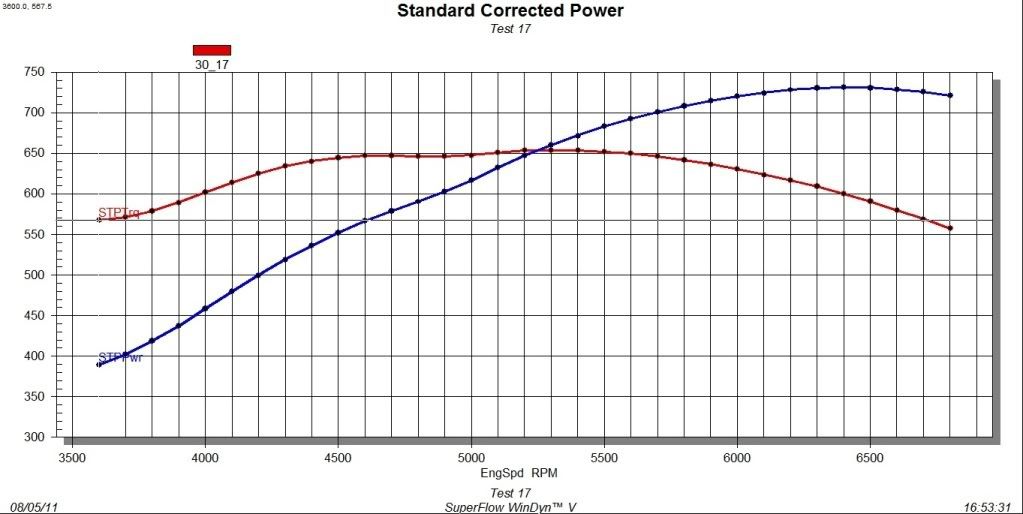

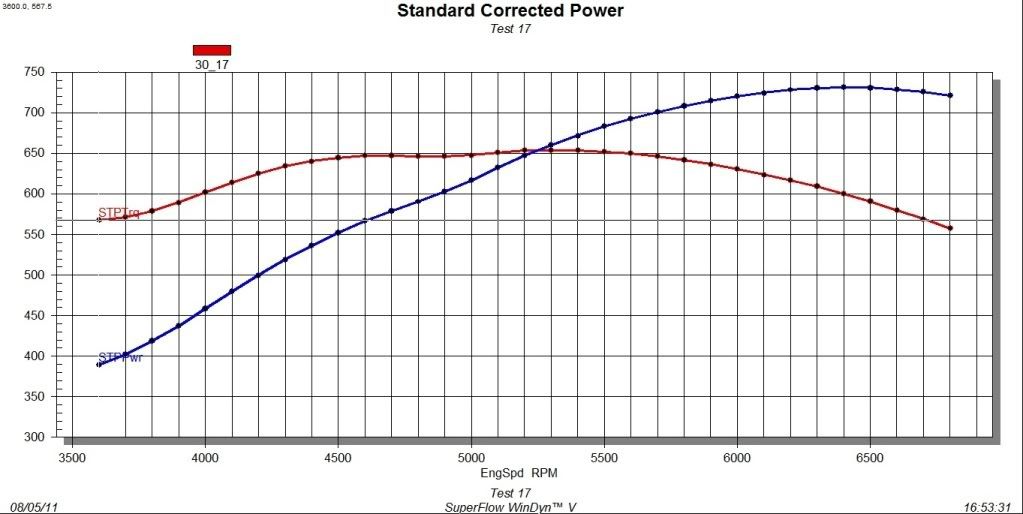

Check out the dyno curve.....it looks like a boosted engine in some respects

And here is the hard data from that run....

Needless to say I'm thrilled with the results and look forward to returning to the dyno (likely next month) to complete the testing and see what this combination still has in it....the larger header is a no brainer and some of the other moves I would like to make may be worth a few as well.

Cheers,

Tony

PS....I will post the results of the second round of testing in the dyno results section of this board when I have all the data.....at this point this is more of a technical related story with some numbers and a pitstop along the way!

It was one of those unforgettable days filled with anticipation and excitement and unfortunately as the day progressed some slight disappointment as well.

Im going to quote myself taking a paragraph from the first post I made to start this thread....

It's like I subconsciously knew what might transpire on the dyno....LOL

To make a long story short I didn't get a chance to complete all my testing (I had a short list of changes to make in an effort to extract more power from the combination). About a dozen or so pulls into the day we noticed the engine starting to smoke out of the breather at WOT when we loaded it for the pull. After inspecting leak down, cranking compression, spark plugs, and cutting open the oil filter (everything looking like a clean bill of health) I decided to run it a little more....power was exactly the same but it was venting crankcase fumes during the run. I decided better be safe than sorry and halted any further testing till I find out what was going on.....something had obviously changed. My suspicions were a ring had stuck in one of the grooves or I pushed the limit on my piston to head clearance (quench distance) just a bit too much. After taking the engine home yesterday and not wasting a minute to find out it turns out the latter was exactly what transpired. There was some very light piston to head contact on one side of the piston, enough to close up the critical top ring gap not allowing it to conform to the cylinder wall (hence the blowby we started seeing). In fact I was sooooo close to my target (which was to get the piston so close to the head the carbon is almost cleaned off), it took a dozen or so runs to get the rods hot enough to stretch to the point of light contact. And thats how it goes.....sometimes a couple of thousandths is the difference of winning and losing when it comes to high performance engine assembly.

Lets get to the good stuff.....this engine surpassed my highest expectations and did so with the wrong header (still had the baseline 1.75 tube headers) and without the benefit of the vacuum pump or any of the items I planned on testing to hopefully find a few more ponies (rocker ratio swap, moving the cam position around, etc., etc.).

The engine sounded incredible on the dyno and twisted the strain gauge on the SF902 SuperFlow to the tune of 652 ft/lbs of torque and a best of 731 HP!! It was making north of 700 as early as 5700 RPM's and over 640 ft/lbs by 4400 (carrying over 640 all the way to 5800). When we loaded it and started the sweep at 3500 it was already producing 45 more ft/lbs of torque than my 383 made at its peak (about 570) and based on all the previous testing I have done that lead in torque figure will be at least 10-15 ft/lbs higher when I swap to the larger header (1.875 tube)....in fact the larger header will fatten the power and torque curve everywhere in an application like this.

Check out the dyno curve.....it looks like a boosted engine in some respects

And here is the hard data from that run....

Needless to say I'm thrilled with the results and look forward to returning to the dyno (likely next month) to complete the testing and see what this combination still has in it....the larger header is a no brainer and some of the other moves I would like to make may be worth a few as well.

Cheers,

Tony

PS....I will post the results of the second round of testing in the dyno results section of this board when I have all the data.....at this point this is more of a technical related story with some numbers and a pitstop along the way!

Christian

#91

Hey Christian....good to hear from you!

Yep....I was pretty excited about the first round of testing for sure. Its not often the high side of my expectations heading into a dyno test are exceeded but very welcome I assure you.

Whats crazier is I have a few things cooking now that could potentially boost the current baseline very significantly (my "mad hatter" plan I joked about in previous posts). Basically a major rework of my already ported FAST 102 intake....this version however requires lots of epoxy....and not to mention alot of R&D/flowbench time.

When I hit the dyno again the end of next month Im going to rerun/baseline the engine in the exact same configuration I did last time to try and get a better idea of what the recent manifold mods Im working on might be worth.....then move forward with the larger header and a few other moves I didn't get a chance to test previously.

At the end of the day Im hoping for at least 750 when the smoke clears....and honestly even that figure is heavily discounting the gains in airflow I am seeing with the manifold rework. I normally like to temper my expectations heading into any sort of dyno testing however....there is no such thing as a sure thing but Im feeling pretty good about my recent find concerning the rework of this manifold. I also found a few CFM's in the head having a chance to spend a bunch of time flowing the manifold/head as a unit and examining both but the lions share of any gains I see will clearly be from the manifold.

While Im here let me touch on the 106 LSA suggested a few posts up....

First off Im not a fan of narrow LSA cams on any street application as they destroy idle quality and drivability, not to mention fuel economy. And I'm even less of a fan with long runner intakes as they tend to over-scavenge badly with lots of overlap....now your dealing with all the negative aspects of the tight lobe sep cam and not even making the right power due to sucking some of the fresh intake/fuel charge right out the exhaust pipe on the overlap cycle. The better the heads and the longer the runner the less you want to run a narrow LSA cam.

Traditional engines with 4BBL carbs and short single plane manifolds respond alot better to tighter LSA's because they need the help in signal to get things moving and wont over scavenge nearly as easily.

Also, even if you were to look at this purely in "theory" (and what's typically seen in an X-plane carb set-up), going tighter LSA will usually improve low/midrange torque and the expense of peak and especially past peak HP (and hurt the drivability as previously mentioned).

Its all the things I'm not after....I want reasonably good idle quality (light to moderate chop) and perfect drivability so I can cruise in 6th gear at 1500 RPM's with zero surging or protesting from the engine. This clearly requires a wider LSA (less overlap). Also, I would be willing to throw away 20 ft/lbs at 4000 RPM in a minute to pick up 10 - 15 HP peak and 20 past peak (with a slower roll off).....another perk of the wider LSA scenario. In fact I built this engine with enough displacement that I could purposely select a cam (and ultimately it's installed position) that favor the top end and still leave me with more than enough torque to fry the tires at will.

In short I care about the street manners of this combination and making the most power I can from 5000 - 7000 RPM.....nothing in the middle of the two is of importance to me because I'm either cruising down the road usually loafing the motor under 2000 RPM's, or I am selecting the right gear to start hammering it at WOT trying to keep the engine in its sweet spot (5000 - 7000 RPM's) to tap into the highest average power it has to offer.

Yedister, everyone has their opinions on what works and doesn't work (and we are obviously all entitled).....Im only trying to share with you some things about why I feel the opposite (a wider LSA) is better suited to this build and truthfully most builds with AFR heads and FAST (long runner) intake manifolds. I see that you don't post often and I didn't want you to feel like I was coming down on you and trying to belittle what you had to add. I think it made for a good tech discussion honestly and allowed me the opportunity to share why I feel differently and I hope you can appreciate that.....perhaps I gave you a little food for thought as well. BTW, we could certainly argue the point on the solid roller deal as I am still a big fan (of a solid), but I'm more a fan of exploiting the current advancements in valve control and the power potential these modern (aggressive) hyd. lobes are capable of. Until extremely recently the type of power curve displayed by this motor (and others similar set up properly) would have been impossible with for the most part off the shelf components and a hydraulic roller cam requiring zero maintenance.

Good stuff....

Cheers,

Tony

Yep....I was pretty excited about the first round of testing for sure. Its not often the high side of my expectations heading into a dyno test are exceeded but very welcome I assure you.

Whats crazier is I have a few things cooking now that could potentially boost the current baseline very significantly (my "mad hatter" plan I joked about in previous posts). Basically a major rework of my already ported FAST 102 intake....this version however requires lots of epoxy....and not to mention alot of R&D/flowbench time.

When I hit the dyno again the end of next month Im going to rerun/baseline the engine in the exact same configuration I did last time to try and get a better idea of what the recent manifold mods Im working on might be worth.....then move forward with the larger header and a few other moves I didn't get a chance to test previously.

At the end of the day Im hoping for at least 750 when the smoke clears....and honestly even that figure is heavily discounting the gains in airflow I am seeing with the manifold rework. I normally like to temper my expectations heading into any sort of dyno testing however....there is no such thing as a sure thing but Im feeling pretty good about my recent find concerning the rework of this manifold. I also found a few CFM's in the head having a chance to spend a bunch of time flowing the manifold/head as a unit and examining both but the lions share of any gains I see will clearly be from the manifold.

While Im here let me touch on the 106 LSA suggested a few posts up....

First off Im not a fan of narrow LSA cams on any street application as they destroy idle quality and drivability, not to mention fuel economy. And I'm even less of a fan with long runner intakes as they tend to over-scavenge badly with lots of overlap....now your dealing with all the negative aspects of the tight lobe sep cam and not even making the right power due to sucking some of the fresh intake/fuel charge right out the exhaust pipe on the overlap cycle. The better the heads and the longer the runner the less you want to run a narrow LSA cam.

Traditional engines with 4BBL carbs and short single plane manifolds respond alot better to tighter LSA's because they need the help in signal to get things moving and wont over scavenge nearly as easily.

Also, even if you were to look at this purely in "theory" (and what's typically seen in an X-plane carb set-up), going tighter LSA will usually improve low/midrange torque and the expense of peak and especially past peak HP (and hurt the drivability as previously mentioned).

Its all the things I'm not after....I want reasonably good idle quality (light to moderate chop) and perfect drivability so I can cruise in 6th gear at 1500 RPM's with zero surging or protesting from the engine. This clearly requires a wider LSA (less overlap). Also, I would be willing to throw away 20 ft/lbs at 4000 RPM in a minute to pick up 10 - 15 HP peak and 20 past peak (with a slower roll off).....another perk of the wider LSA scenario. In fact I built this engine with enough displacement that I could purposely select a cam (and ultimately it's installed position) that favor the top end and still leave me with more than enough torque to fry the tires at will.

In short I care about the street manners of this combination and making the most power I can from 5000 - 7000 RPM.....nothing in the middle of the two is of importance to me because I'm either cruising down the road usually loafing the motor under 2000 RPM's, or I am selecting the right gear to start hammering it at WOT trying to keep the engine in its sweet spot (5000 - 7000 RPM's) to tap into the highest average power it has to offer.

Yedister, everyone has their opinions on what works and doesn't work (and we are obviously all entitled).....Im only trying to share with you some things about why I feel the opposite (a wider LSA) is better suited to this build and truthfully most builds with AFR heads and FAST (long runner) intake manifolds. I see that you don't post often and I didn't want you to feel like I was coming down on you and trying to belittle what you had to add. I think it made for a good tech discussion honestly and allowed me the opportunity to share why I feel differently and I hope you can appreciate that.....perhaps I gave you a little food for thought as well. BTW, we could certainly argue the point on the solid roller deal as I am still a big fan (of a solid), but I'm more a fan of exploiting the current advancements in valve control and the power potential these modern (aggressive) hyd. lobes are capable of. Until extremely recently the type of power curve displayed by this motor (and others similar set up properly) would have been impossible with for the most part off the shelf components and a hydraulic roller cam requiring zero maintenance.

Good stuff....

Cheers,

Tony

Last edited by Tony Mamo @ AFR; 08-22-2011 at 01:42 PM.

#96

Alot of the square port curves take awhile to build close to peak torque and then slowly roll over (that's what enables the big HP numbers) but they don't ramp up quickly like an optimized cathedral combination.

Look around....you will see what I'm talking about if you want to take the time to do some digging. Pay attention to the shape of the torque curves (especially how quick they build up to peak torque)....that's where your likely to see the difference.

When I get the right size header on this engine it should ramp up even faster IMO with stronger "lead in" torque figures.

Smaller, very optimized high flow ports have been doing this for years....its just alot more challenging to get the big flow necessary to punch a big number upstairs (and not just look good at 4500 RPM and below). And once again I need to mention the cathedral FAST has longer runners than any of the square port stuff and that aids the quick ramp up to peak torque as well (although once again makes punching the big number more challenging as they tend to want to peak and roll over early).

Its hard to argue that a very optimized cathedral set-up (with the right choice of components obviously) is not the ideal street/strip weapon....it gives you a much more responsive package. Assuming your car has good weight transfer and sticky tires (and can harness/utilize the brutal midrange torque) it's really an ideal situation. The car would simply leap from a 4000 RPM roll. Also, a well optimized cathedral set-up will always provide much better part throttle and tip in response (or "roll on" if your a motorcycle aficionado), and that's something I personally put a very high value on.....others could give a hoot, but for a car that spends the bulk of its time on the street its a very welcomed perk IMO....makes the car much more fun to drive.

Of course at some point AFR will dip its toe in the square port stuff and I have a host of different ideas that should make that a very interesting project (but its a loooong way off so don't even ask!....LOL).

In the meantime it looks like the current engine I'm working on will easily satisfy my need for speed....for a little while at least!

Cheers,

Tony

Last edited by Tony Mamo @ AFR; 08-24-2011 at 04:42 PM.

#97

TECH Senior Member

...

I haven't had time to disassemble the entire engine yet but it looks like all the pistons on the passenger side are fine and literally just cleaned the carbon from them during operating conditions (signs of very light contact). Truthfully this was what I was shooting for. The drivers side hit slightly harder....enough to close up the critical .001 ish clearance the top ring groove has cut in it allowing the top ring to spin freely.

...

I haven't had time to disassemble the entire engine yet but it looks like all the pistons on the passenger side are fine and literally just cleaned the carbon from them during operating conditions (signs of very light contact). Truthfully this was what I was shooting for. The drivers side hit slightly harder....enough to close up the critical .001 ish clearance the top ring groove has cut in it allowing the top ring to spin freely.

...

...

Turns out I only had ONE piston make enough contact to pinch about a one inch length of the top ring land.

Obviously that piston/rod combo was slightly longer than the other seven for one reason or another....perhaps a slightly longer rod, a slightly taller wrist pin height, or a slightly longer crank rod throw (a 2.127 instead of a 2.125)....you get the idea. Bottom line it was just enough to push my goal of scraping the carbon off all the piston tops to enough mechanical interference in one hole to close the ring gap a touch. I removed the ring and cleaned the groove up with a feeler gauge wrapped in 400 grit paper in the area it was tight to get the proper thou and some change clearance back and all is good in the world again (the ring spins perfectly in the ring groove now and has perfect lateral clearance again)

(the ring spins perfectly in the ring groove now and has perfect lateral clearance again)

...

Turns out I only had ONE piston make enough contact to pinch about a one inch length of the top ring land.

Obviously that piston/rod combo was slightly longer than the other seven for one reason or another....perhaps a slightly longer rod, a slightly taller wrist pin height, or a slightly longer crank rod throw (a 2.127 instead of a 2.125)....you get the idea. Bottom line it was just enough to push my goal of scraping the carbon off all the piston tops to enough mechanical interference in one hole to close the ring gap a touch. I removed the ring and cleaned the groove up with a feeler gauge wrapped in 400 grit paper in the area it was tight to get the proper thou and some change clearance back and all is good in the world again

...

Thx.

#99

I'm trying to understand and learn from what you're describing... are you saying that when the piston made contact with the head that the ring groove got squashed narrower (the ring/groove clearance got narrower than .001" and the ring got caught in the groove)...? Did I understand this right...?

Thx.

Thx.

Its called "pinching a ring" out in the field....LOL (not an altogether uncommon experience....aluminum rod guys experience this here and there if they dont set the quench conservatively enough to account for the rod stretch which is alot greater than a steel rod and requires a good bit more quench distance on the initial set-up).

We are using a FAST system for tuning but have used a Holley system as well with god results (which is a little more "tidy" in terms of all the wiring harnesses etc.).

Obviously once in the car we will be using the factory PCM to tune it....

CARB approved?.....Not quite

-Tony

#100

Tony thanks for your response. I looked up in Comp. Cams catalog (2007) it was the only one that I found online. I could not find any modern hydraulic lobe with a faster ramp than a solid roller with the same duration @0.50. I always run a dirt track profile cam on the street, I am always after torque and let the horsepower fall it falls. The non LS 434 that is in my Vette has 250/256@0.50 on a 106 with a.682 lift, according to Comp Cams cam guru, not the tech guys , it would pull to 6500 RPM and then start to fall off. Well at 7000 RPM it made 763 HP still going up, max torque was 661 at 5500 5600 RPM, I can’t remember it been 10 years since I built this motor. I don’t like to go above 7000 RPM, just a personnel thing.

I understand about the light weight valve and off the seat acceleration, the dyno curve shows that your selection of components and attention to detail produced a excellent combination. What is the lobe number of the cam? I have been using Engine Analyzer Pro to run different simulation for my 454 / 461 NON LS Build comparing mechanical and hydraulic lobes on the same engines.

(Don’t Hate the First Gen engine, Respect your elders, Who Your Daddy)

Regarding the tighter lobe, with a carb they might be a bit** to drive on the street but, with the advancement in Fuel Injection it not a problem. For my street car, with the cam above with a 11.5 compression and 15 degree heads which flow around 340 with the Mini Ram intake, which has 3” runners it idles at 850 cold, 800 when warmed up. You can tell it not stock, there is no lope to the engine, it RPMs extremely quick. It drives almost like the stock 86 Vette except I have to be light on the gas or I will be having a conversation with a person in uniform and he/she will not asking for autograph because their a fan. This is my weekend car, used for the pleasure of driving, I don’t care about fuel economy, I get around 26 MPG when I keep my foot out of it.

I don’t have a LS engine, so I don’t post much. I come to keep a eye on the competition.

Tony, there is no way I felt that your bashing me!! You’re expressing how and why you built your engine the way you did. I have seen several of your post on other forums, some of those guy were bashing you like disrespected their mothers for no visible reasons. I appreciate your sharing of information and insight about your build. I will be contacting you about the NON LS 461 small block build, I would like to get 700 ft.lbs. of torque from it, might not make it but, there is no failure with good effort .

You’re expressing how and why you built your engine the way you did. I have seen several of your post on other forums, some of those guy were bashing you like disrespected their mothers for no visible reasons. I appreciate your sharing of information and insight about your build. I will be contacting you about the NON LS 461 small block build, I would like to get 700 ft.lbs. of torque from it, might not make it but, there is no failure with good effort .

P.S. When you go back to the dyno next month, how about doing a cam swap after you get your final # with the hydraulic cam, try a mechanical cam with the same duration @0.50 on a tighter lobe? There is nothing like a real world comparison.

I understand about the light weight valve and off the seat acceleration, the dyno curve shows that your selection of components and attention to detail produced a excellent combination. What is the lobe number of the cam? I have been using Engine Analyzer Pro to run different simulation for my 454 / 461 NON LS Build comparing mechanical and hydraulic lobes on the same engines.

(Don’t Hate the First Gen engine, Respect your elders, Who Your Daddy)

Regarding the tighter lobe, with a carb they might be a bit** to drive on the street but, with the advancement in Fuel Injection it not a problem. For my street car, with the cam above with a 11.5 compression and 15 degree heads which flow around 340 with the Mini Ram intake, which has 3” runners it idles at 850 cold, 800 when warmed up. You can tell it not stock, there is no lope to the engine, it RPMs extremely quick. It drives almost like the stock 86 Vette except I have to be light on the gas or I will be having a conversation with a person in uniform and he/she will not asking for autograph because their a fan. This is my weekend car, used for the pleasure of driving, I don’t care about fuel economy, I get around 26 MPG when I keep my foot out of it.

I don’t have a LS engine, so I don’t post much. I come to keep a eye on the competition.

Tony, there is no way I felt that your bashing me!!

You’re expressing how and why you built your engine the way you did. I have seen several of your post on other forums, some of those guy were bashing you like disrespected their mothers for no visible reasons. I appreciate your sharing of information and insight about your build. I will be contacting you about the NON LS 461 small block build, I would like to get 700 ft.lbs. of torque from it, might not make it but, there is no failure with good effort .

You’re expressing how and why you built your engine the way you did. I have seen several of your post on other forums, some of those guy were bashing you like disrespected their mothers for no visible reasons. I appreciate your sharing of information and insight about your build. I will be contacting you about the NON LS 461 small block build, I would like to get 700 ft.lbs. of torque from it, might not make it but, there is no failure with good effort . P.S. When you go back to the dyno next month, how about doing a cam swap after you get your final # with the hydraulic cam, try a mechanical cam with the same duration @0.50 on a tighter lobe? There is nothing like a real world comparison.