Darth Vader....Your LSx Stroker is ready!!

#61

Also....think again about it being a good street engine....LOL

The cam is 10 degrees bigger than a T-Rex being installed in an engine 100+ CID larger than stock (big motors eat up camshafts btw). A 251/254 hyd roller in a 454 is the equivalent of a 230/232 in a 346.....while it wont have a stock sounding idle it will still be extremely streetable with the right tune and complimenting components.

Would I put it in a daily driver? Maybe....depends on the owner.....for a weekend street toy though its perfect and arguably too tame for some. I will post idle clips and video of it driving down the road when I have the opportunity (months away unfortunately because the body of the car is under construction as well right now) but I can tell you without hesitation that besides the moderate performance lope at an idle, its going to drive perfectly around town. No surging or other annoyances associated with an over cammed street car.

I think I posted some of the bits and details in the first post I made but the quick rundown is:

-Bore and stroke 4.186 / 4.125 (exactly 453.9 CID) 11.75 CR

-LS2 aluminum block with Darton dry sleeve liners

-"V2" AFR 245's (with lightweight hollow stem intake valves and some Mamo romance work).

-One of my ported 102 FAST intakes of course

-Comp 251/254....114 LSA....661/624 lift (1.8 intake rocker)

-Callies rotating assy (Dragonslayer crank/Compstar rod)

-Wiseco custom pistons / Total seal rings (non gapless)

-ATI dampener

-Cloyes single roller hex adjust timing set

-A ported OEM pump (I start with a better GM casting and port the internals for more flow)

-Comp limited travel hydraulic lifters (note you have to be a little more fussy with pushrod length and preload).

-Manton 3/8 pushrods (.095 wall tube) and note the 245's were designed to accept the larger pushrods right from the factory.

-New design Yella Terra 10mm Ultralite rockers (a beefier version of their current successful line of rockers but you must drill and tap your rocker stud holes larger to 10mm (versus 8mm stock).

-Lots of attention to clearances and detail during the assembly process

Thanks for all the interest in the build guys....like I said its been a long time coming and appears was well worth the wait.

Cheers,

Tony

Last edited by Tony Mamo @ AFR; 08-06-2011 at 03:13 PM.

#63

what was the vacumme readings on the vac pump?I feel to properly break in rings on a hi-out put motor you you need to do it with out a vac pump for the first few dyno pulls.what do you valve guild and seals look like?doing a ring leak down test?I like the moreso vac pumps.there is a hi-end market for this engine ,can vette rends handle this much power?

#67

Check the title of this post.....its the reason you can never be too careful when it comes to engine assembly.

I haven't had time to disassemble the entire engine yet but it looks like all the pistons on the passenger side are fine and literally just cleaned the carbon from them during operating conditions (signs of very light contact). Truthfully this was what I was shooting for. The drivers side hit slightly harder....enough to close up the critical .001 ish clearance the top ring groove has cut in it allowing the top ring to spin freely.

Turns out the slight difference in deck height (the drivers side pistons stuck out of the hole .001 - .0015 more), and the fact the Cometic .040 gasket only measured .0385 on that side (and .0395 on the passenger side) was the critical few thou I needed to avoid this situation. Im going to replace whatever drivers side pistons had the gap closed up (haven't pulled them all out yet) and get this engine back on the dyno in a couple of months to complete the testing I had planned. Im going to run a head gasket thats .005 thicker and I should be golden and mill the heads slightly more so I don't lose any compression. I may even cut them a few thou additional to raise the CR another tenth or so. Based on the fact I got to check the cranking compression on the dyno, and have a hunch I will back the cam up some which will reduce the DCR (in hopes of trading some low end torque for high RPM power), I think it would tolerate a "skoosh" more static. Will bump it to 11.85 or so....don't forget Im working with 91 octane so I have to be a little more careful. If I find Im getting some knock retard in the car I will just install an N/A meth kit from Snow Performance and call it good.

The biggest delays in getting her back to Westech will be the custom pistons I will need to order but I speculate I should have it reassembled in a couple of months.

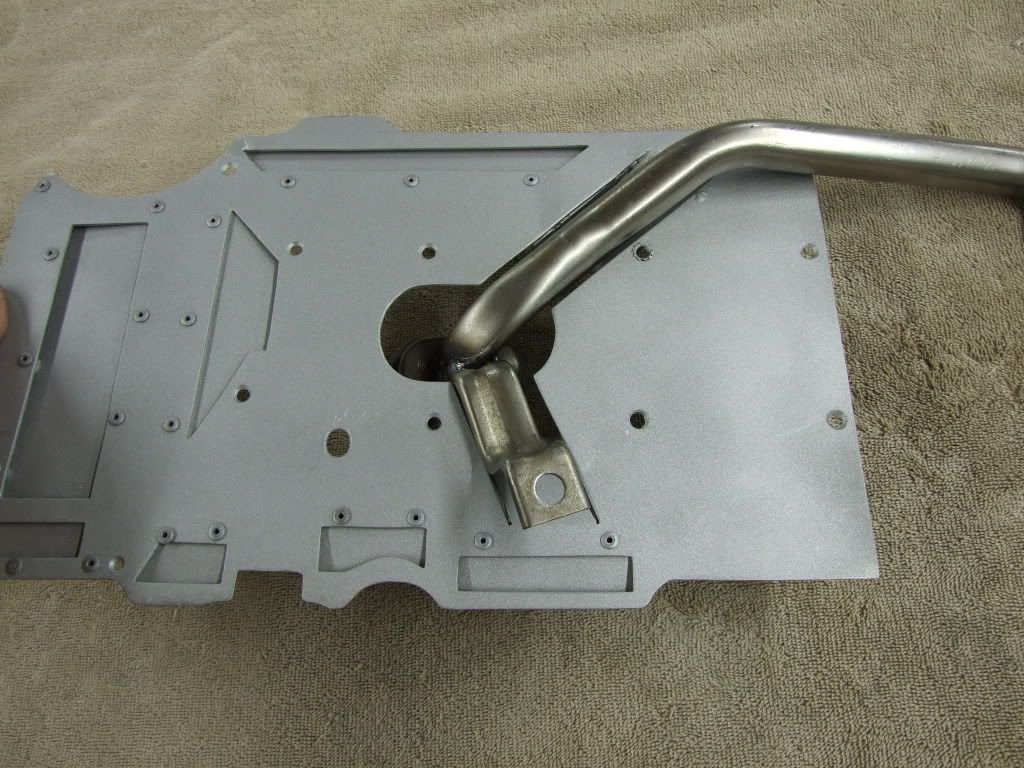

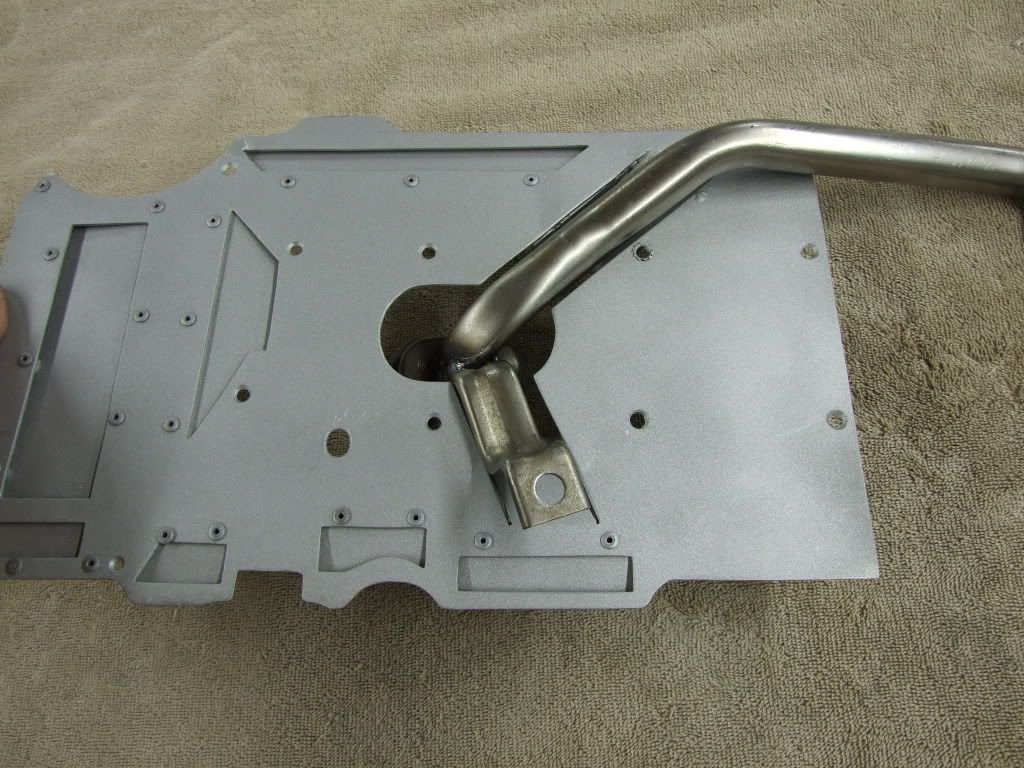

Here are a couple of neat tidbits included with this build.....a picture of an oil pan baffle I built which lets oil down into the sump but provides alot of resistance to it trying to escape and climb up the rotating assembly under high G loads (both laterally and in a straight line). This is an LS2 Corvette pan btw which is normally always "open" just like the picture shows. One hard launch and you have many quarts of power robbing oil climbing up your rear cylinders and rotating assembly and also making it easier to potentially uncover your oil pump pick up allowing a temporary starvation of oil pressure (not good at WOT high RPM operation).

Took some time to fabricate but it was worth it IMO.....I started with a thin piece of cardboard to make the template (using a scissor and an exacto knife) than transferred the final shape to a piece of .075 thick aluminum. Then I had to figure out where and what shape I would cut the slanted baffles/oil returns and cut and install/rivet them as well. Actually it was very time consuming from start to finish....LOL, but worthy of the powerplant it protects (and the added power from keeping the oil in the sump, and not all over the rotating assy and cylinder walls is bonus).

Here was another little trick I also incorporated into this build....I never liked the fact the oil filter diverter (the plastic "barbell") didn't fit more "snuggy" into the main galley. Seemed to me a slight amount of unfiltered oil and any small metal debris could bypass the filter this way....it just wasn't a positive enough solution IMO so I modified the barbell to accept an O-Ring that has about a .010 press around the perimeter. You have to make sure you deburr the oil galleys that intersect this area however or you can damage/cut the O-ring when you install it. I lubed the O-ring(s) when I installed it and it required a light push as you inserted it in the oil galley obviously completely sealing any unfiltered oil from bypassing the filter at this location (where you have the highest oil pressure in the large main feed line directly leaving the pump).

Will keep you guys posted....

Yep....I have had my fair share of C5 differential issues (grenaded one of them when the case cracked, broke an axle on another, etc.) so I decided recently to take the plunge on a C6Z06 rear conversion. The ring and pinion is huge compared to the C5 set-up and the fact I will only have 3.42 gears now is a non event with the torque output this engine is producing.

Cheers,

Tony

I haven't had time to disassemble the entire engine yet but it looks like all the pistons on the passenger side are fine and literally just cleaned the carbon from them during operating conditions (signs of very light contact). Truthfully this was what I was shooting for. The drivers side hit slightly harder....enough to close up the critical .001 ish clearance the top ring groove has cut in it allowing the top ring to spin freely.

Turns out the slight difference in deck height (the drivers side pistons stuck out of the hole .001 - .0015 more), and the fact the Cometic .040 gasket only measured .0385 on that side (and .0395 on the passenger side) was the critical few thou I needed to avoid this situation. Im going to replace whatever drivers side pistons had the gap closed up (haven't pulled them all out yet) and get this engine back on the dyno in a couple of months to complete the testing I had planned. Im going to run a head gasket thats .005 thicker and I should be golden and mill the heads slightly more so I don't lose any compression. I may even cut them a few thou additional to raise the CR another tenth or so. Based on the fact I got to check the cranking compression on the dyno, and have a hunch I will back the cam up some which will reduce the DCR (in hopes of trading some low end torque for high RPM power), I think it would tolerate a "skoosh" more static. Will bump it to 11.85 or so....don't forget Im working with 91 octane so I have to be a little more careful. If I find Im getting some knock retard in the car I will just install an N/A meth kit from Snow Performance and call it good.

The biggest delays in getting her back to Westech will be the custom pistons I will need to order but I speculate I should have it reassembled in a couple of months.

Here are a couple of neat tidbits included with this build.....a picture of an oil pan baffle I built which lets oil down into the sump but provides alot of resistance to it trying to escape and climb up the rotating assembly under high G loads (both laterally and in a straight line). This is an LS2 Corvette pan btw which is normally always "open" just like the picture shows. One hard launch and you have many quarts of power robbing oil climbing up your rear cylinders and rotating assembly and also making it easier to potentially uncover your oil pump pick up allowing a temporary starvation of oil pressure (not good at WOT high RPM operation).

Took some time to fabricate but it was worth it IMO.....I started with a thin piece of cardboard to make the template (using a scissor and an exacto knife) than transferred the final shape to a piece of .075 thick aluminum. Then I had to figure out where and what shape I would cut the slanted baffles/oil returns and cut and install/rivet them as well. Actually it was very time consuming from start to finish....LOL, but worthy of the powerplant it protects (and the added power from keeping the oil in the sump, and not all over the rotating assy and cylinder walls is bonus).

Here was another little trick I also incorporated into this build....I never liked the fact the oil filter diverter (the plastic "barbell") didn't fit more "snuggy" into the main galley. Seemed to me a slight amount of unfiltered oil and any small metal debris could bypass the filter this way....it just wasn't a positive enough solution IMO so I modified the barbell to accept an O-Ring that has about a .010 press around the perimeter. You have to make sure you deburr the oil galleys that intersect this area however or you can damage/cut the O-ring when you install it. I lubed the O-ring(s) when I installed it and it required a light push as you inserted it in the oil galley obviously completely sealing any unfiltered oil from bypassing the filter at this location (where you have the highest oil pressure in the large main feed line directly leaving the pump).

Will keep you guys posted....

Cheers,

Tony

Last edited by Tony Mamo @ AFR; 08-09-2011 at 05:38 PM.

#71

Well....as most of you know who have followed this thread, last week I shared the good and the bad news from my round of dyno testing over at Westech. Looks like I get to share some more good news concerning this project (bonus!)

Last night I finally had some time to take apart the entire shortblock (well....pull ALL the pistons out at least).

Turns out I only had ONE piston make enough contact to pinch about a one inch length of the top ring land.

Obviously that piston/rod combo was slightly longer than the other seven for one reason or another....perhaps a slightly longer rod, a slightly taller wrist pin height, or a slightly longer crank rod throw (a 2.127 instead of a 2.125)....you get the idea. Bottom line it was just enough to push my goal of scraping the carbon off all the piston tops to enough mechanical interference in one hole to close the ring gap a touch. I removed the ring and cleaned the groove up with a feeler gauge wrapped in 400 grit paper in the area it was tight to get the proper thou and some change clearance back and all is good in the world again (the ring spins perfectly in the ring groove now and has perfect lateral clearance again)

(the ring spins perfectly in the ring groove now and has perfect lateral clearance again)

I don't even have to buy a single piston....but to be safe I will order a new top ring as I suspect I may have tweaked it a little getting it out of the piston but besides that and a .005 thicker set of head gaskets, this engine can go back together sooner than anticipated. BUT....now that it's apart again the wheels have been spinning and I may experiment with something else....another mad hatter idea Ive had for awhile but I'm almost afraid to mess with this recipe. We'll see....

This is the thread I posted almost six years ago with lots of 383 test data (cam swaps etc.) but the graphs are no longer visible (a friend was hosting them at the time and I have no access to them at this point). I think there is enough good text to read that you can pick up a few things....barring that feel free to PM me....just allow some time for a response as I am WOT right now in various projects....my personal build featured here only one of them.

A 383 can run hard with the right combination....I would look into an AFR 215 or an AFR 230 if its fairly aggressive....ported FAST.....mid 230's to low 240's cam....etc. etc.

Cheers,

Tony

Last night I finally had some time to take apart the entire shortblock (well....pull ALL the pistons out at least).

Turns out I only had ONE piston make enough contact to pinch about a one inch length of the top ring land.

Obviously that piston/rod combo was slightly longer than the other seven for one reason or another....perhaps a slightly longer rod, a slightly taller wrist pin height, or a slightly longer crank rod throw (a 2.127 instead of a 2.125)....you get the idea. Bottom line it was just enough to push my goal of scraping the carbon off all the piston tops to enough mechanical interference in one hole to close the ring gap a touch. I removed the ring and cleaned the groove up with a feeler gauge wrapped in 400 grit paper in the area it was tight to get the proper thou and some change clearance back and all is good in the world again

I don't even have to buy a single piston....but to be safe I will order a new top ring as I suspect I may have tweaked it a little getting it out of the piston but besides that and a .005 thicker set of head gaskets, this engine can go back together sooner than anticipated. BUT....now that it's apart again the wheels have been spinning and I may experiment with something else....another mad hatter idea Ive had for awhile but I'm almost afraid to mess with this recipe. We'll see....

A 383 can run hard with the right combination....I would look into an AFR 215 or an AFR 230 if its fairly aggressive....ported FAST.....mid 230's to low 240's cam....etc. etc.

Cheers,

Tony

#76

Teching In

iTrader: (2)

Join Date: Jun 2006

Location: Tracy, CA

Posts: 18

Likes: 0

Received 0 Likes

on

0 Posts

https://ls1tech.com/forums/generatio...-job-done.html

-Rick

#78

Guys,

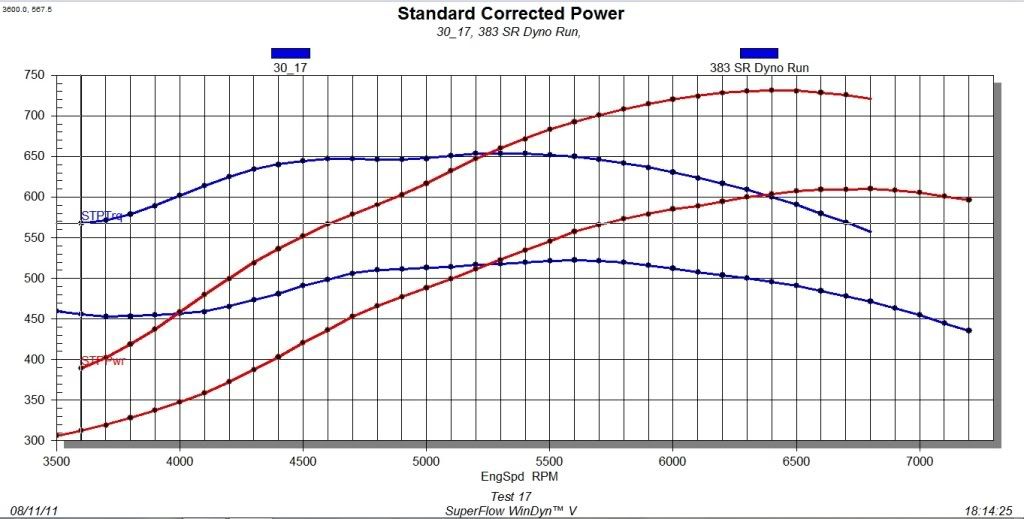

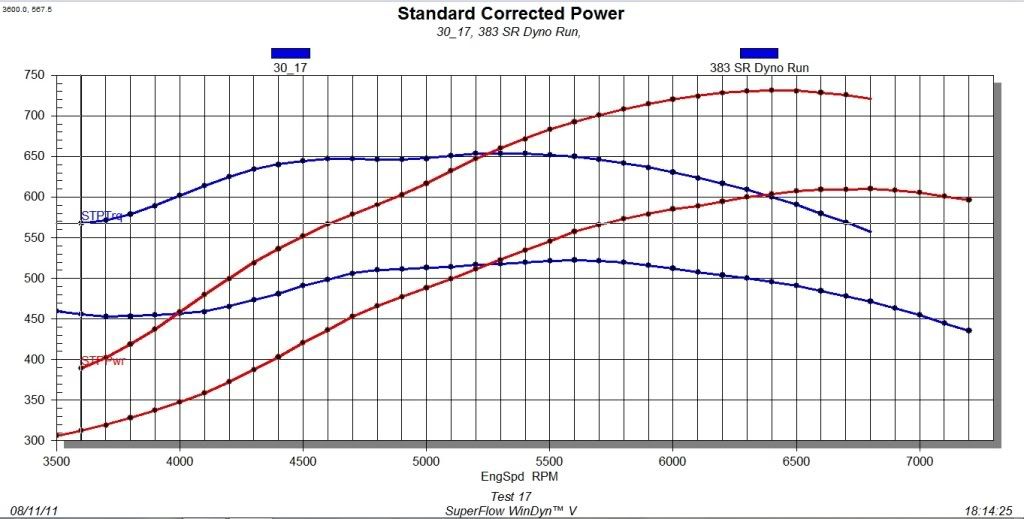

To get a better appreciation of the retarded grunt this new engine is capable off producing, look at how it compares to the really strong 383 I had in my Vette from 05' - mid 08' (keep in mind that engine ran high 10's at 130 traps!). This engine ran as hard as some of the best 402's and even held its own in the company of some of the better 427's as well (though the strong 427's made a little more torque).

The 83' clearly was an over achiever (still is in Rick's C5 as well) producing 545 to the ground with 225 heads and a street friendly solid roller and a very respectable 535 to the ground in it's current configuration with a smallish hydraulic (234/238 on a 114 LSA) and a "Mamofied" set of 205's (very responsive with the optimized 205's in it's current configuration).

This was the best run of the day on Westech's dyno (same dyno, same cell I just tested the 54' on) with the solid roller/225 headed combination back in 2005 although the 545 chassis numbers I mentioned earlier does include a larger 1.875 header which was worth another 10 HP. Actually, both engines in this dyno comparison actually have the smaller 1.75 header but I suspect its hurting the larger 54' a great deal more than the 83'. When I get back to the dyno it will be interesting to see what the larger tube is worth....that's the no brainer gain of the few items I plan on testing when the engine is back together.

While the power gains below are stout, the torque gains are even more retarded. This car will not be very usable in any of the lower two gears (in street trim at least).....probably touch and go even in third depending on the traction available. The right foot is going to have to be very respectful of the go pedal, but that's why we are here right!

Cheers,

Tony

To get a better appreciation of the retarded grunt this new engine is capable off producing, look at how it compares to the really strong 383 I had in my Vette from 05' - mid 08' (keep in mind that engine ran high 10's at 130 traps!). This engine ran as hard as some of the best 402's and even held its own in the company of some of the better 427's as well (though the strong 427's made a little more torque).

The 83' clearly was an over achiever (still is in Rick's C5 as well) producing 545 to the ground with 225 heads and a street friendly solid roller and a very respectable 535 to the ground in it's current configuration with a smallish hydraulic (234/238 on a 114 LSA) and a "Mamofied" set of 205's (very responsive with the optimized 205's in it's current configuration).

This was the best run of the day on Westech's dyno (same dyno, same cell I just tested the 54' on) with the solid roller/225 headed combination back in 2005 although the 545 chassis numbers I mentioned earlier does include a larger 1.875 header which was worth another 10 HP. Actually, both engines in this dyno comparison actually have the smaller 1.75 header but I suspect its hurting the larger 54' a great deal more than the 83'. When I get back to the dyno it will be interesting to see what the larger tube is worth....that's the no brainer gain of the few items I plan on testing when the engine is back together.

While the power gains below are stout, the torque gains are even more retarded. This car will not be very usable in any of the lower two gears (in street trim at least).....probably touch and go even in third depending on the traction available. The right foot is going to have to be very respectful of the go pedal, but that's why we are here right!

Cheers,

Tony

#80

TECH Resident

iTrader: (4)

Join Date: Nov 2004

Location: Nashville, TN

Posts: 879

Likes: 0

Received 0 Likes

on

0 Posts

Nice work Tony! I"m curious how this setup will perform with no issues. For even a big inch street motor, it's hard to argue with a good cathedral head. Even if a similar setup with ported rectangle ports makes similar power, it likely won't have as good of part throttle & under-the-curve power. For a street motor, it seems many still don't take this into enough consideration.

Good luck with traction...

Jason

Good luck with traction...

Jason