Ls1 oil pan bolt hole stripped questions

#1

So I'm torquing down my oil pan and 2 bolts holes in the block are stripped, I know they are supposed to be torqued down to 18 ft lbs....

Well one bolt holds till about 5-10 lb's and the other bolt barely holds but it will thread a few rotations and then its loose again..

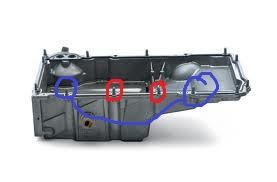

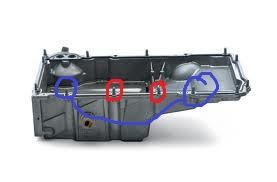

circled in red is the 2 bolts that are stripped, I was told by somebody that since the bolts circled in blue are sandwiching the stripped bolts that it should be ok and to just put some red loctite on the stripped bolts and tighten them as much as they can go...

what are some of your guy's thoughts on this, I know there's "helicoil" kits... but are they easy to use and what size kit would I need?

I know I should helicoil it but if people on here have went through a similar experience then I should be fine.. I mean all the other bolts torqued down perfectly..

Well one bolt holds till about 5-10 lb's and the other bolt barely holds but it will thread a few rotations and then its loose again..

circled in red is the 2 bolts that are stripped, I was told by somebody that since the bolts circled in blue are sandwiching the stripped bolts that it should be ok and to just put some red loctite on the stripped bolts and tighten them as much as they can go...

what are some of your guy's thoughts on this, I know there's "helicoil" kits... but are they easy to use and what size kit would I need?

I know I should helicoil it but if people on here have went through a similar experience then I should be fine.. I mean all the other bolts torqued down perfectly..

#2

The LS pans are structural, I wouldn't rely on loctite to hold stripped bolts in properly.

Heli-coils work well, if you don't want to figure it out i'd suggest finding someone locally with some experience doing them and just repairing them, will be much better in the end.

You will have to remove the pan to do the repair properly though. Good luck.

Heli-coils work well, if you don't want to figure it out i'd suggest finding someone locally with some experience doing them and just repairing them, will be much better in the end.

You will have to remove the pan to do the repair properly though. Good luck.

#3

The LS pans are structural, I wouldn't rely on loctite to hold stripped bolts in properly.

Heli-coils work well, if you don't want to figure it out i'd suggest finding someone locally with some experience doing them and just repairing them, will be much better in the end.

You will have to remove the pan to do the repair properly though. Good luck.

Heli-coils work well, if you don't want to figure it out i'd suggest finding someone locally with some experience doing them and just repairing them, will be much better in the end.

You will have to remove the pan to do the repair properly though. Good luck.

Im researching helicoil kits and will buy one tommorow and get it done...

Time to drill into my block

#4

TECH Junkie

iTrader: (1)

I used this M8 X 1.25 Helicoil kit to repair the stripped oilpan bolt hole.

You need only 18lbs of holding power.

They might be found elsewhere for cheaper, or possibly free shipping.

Before installing the helicoil, you'll want to verify the correct depth to sink it, since it is shorter than the depth of the hole.

Simple to do, & they hold perfectly!

http://www.ebay.com/itm/Helicoil-554...27b0e4&vxp=mtr

Post #20 confirms oilpan to block bolt size.

https://ls1tech.com/forums/conversio...-buy-them.html

You need only 18lbs of holding power.

They might be found elsewhere for cheaper, or possibly free shipping.

Before installing the helicoil, you'll want to verify the correct depth to sink it, since it is shorter than the depth of the hole.

Simple to do, & they hold perfectly!

http://www.ebay.com/itm/Helicoil-554...27b0e4&vxp=mtr

Post #20 confirms oilpan to block bolt size.

https://ls1tech.com/forums/conversio...-buy-them.html

Last edited by gMAG; 02-20-2013 at 12:46 AM.

#5

I used this M8X 1.25 Helicoil kit to repair the stripped oilpan bolt hole.

You need only 18lbs of holding power.

They might be found elsewhere for cheaper, or possibly free shipping.

You'll want to verify the correct depth to sink the helicoil, since the helicoil is not exactly the same length as the depth of the hole.

Simple to do, & they hold perfectly!

http://www.ebay.com/itm/Helicoil-554...27b0e4&vxp=mtr

Post #20 confirms oilpan to block bolt size.

https://ls1tech.com/forums/conversio...-buy-them.html

You need only 18lbs of holding power.

They might be found elsewhere for cheaper, or possibly free shipping.

You'll want to verify the correct depth to sink the helicoil, since the helicoil is not exactly the same length as the depth of the hole.

Simple to do, & they hold perfectly!

http://www.ebay.com/itm/Helicoil-554...27b0e4&vxp=mtr

Post #20 confirms oilpan to block bolt size.

https://ls1tech.com/forums/conversio...-buy-them.html