Next Project - Built LQ4, 0.030 over

#1

TECH Fanatic

Thread Starter

Due to cost reasons I decided to build another LS motor rather than a Gen 3 6.1 hemi. That will have to wait.

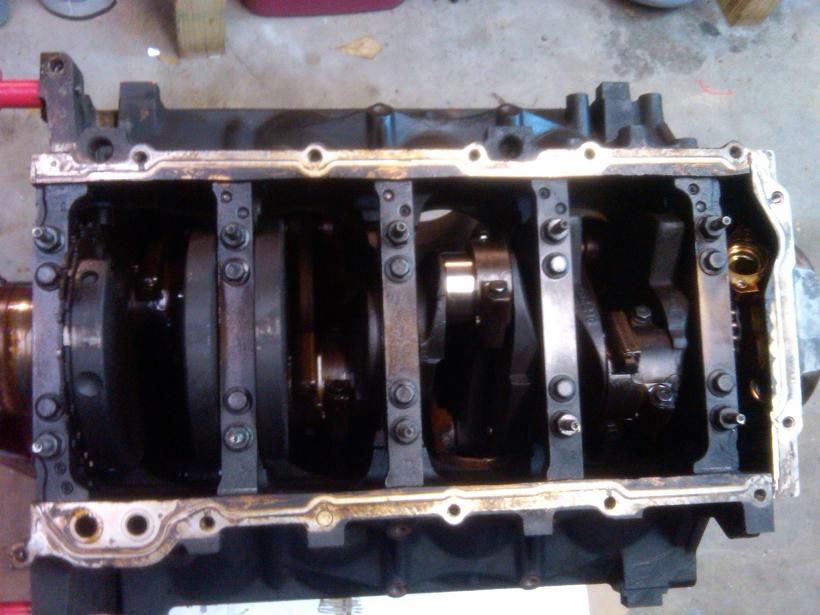

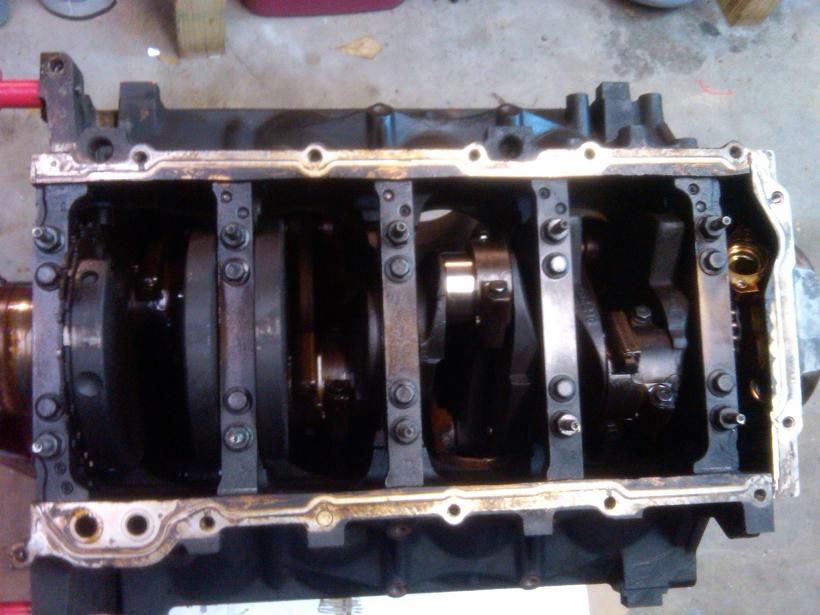

I picked up an '03 LQ4 short block for cheap. The previous owner had blown a head gasket and 2 cylinders filled up with coolant. He let it sit for 2 months and of course resulted in light surface corrosion inside the cylinders and seized rings.

This is great for me because the block is in otherwise excellent condition with no issues at all. A 0.030" bore will completely eliminate the corrosion.

Here is the current plan:

Host Vehicle: TBD

370 cu inch shrot block

Stock crank, clevite P bearings, new OEM main bolts

Scat forged I-beams with ARP bolts

4.030" forged pistons -4cc, Mahle

rotating assembly balance

All machining by H squared racing engines

cam: TBD

heads: TBD

As with my previous build, all clearances will be painstakingly measured and recorded.

Here are some pics;

measuring deck height of OEM pistons. The readings are slightly off due to some tough carbon buildup on the deck surface, but the readings are +/- 0.003" from each other.

measuring depth of dish in piston = 0.048"

Deck heights as measured. This tells me that the deck is most likely square and does not require deck machining, however I will measure again when the deck is cleaned and the new rotating assembly is installed, just to be sure.

1: 0.009"

2: 0.009"

3: 0.011"

4: n/a

5: 0.012"

6: 0.012"

7: 0.013"

8: 0.009"

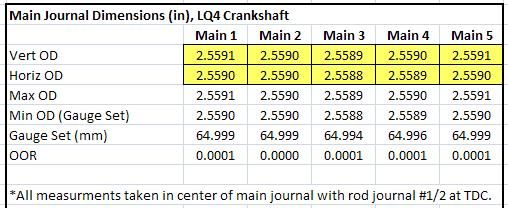

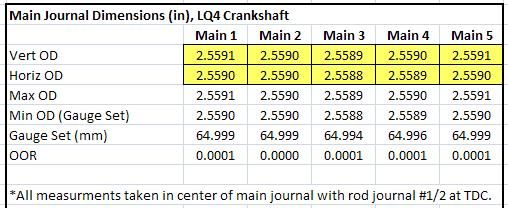

I also measured the OEM crankshaft main/rod journal dimensions. Everything checked out within spec:

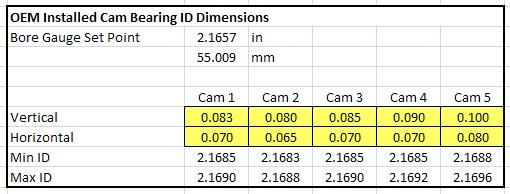

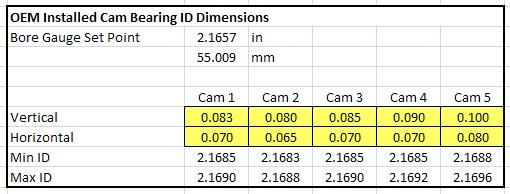

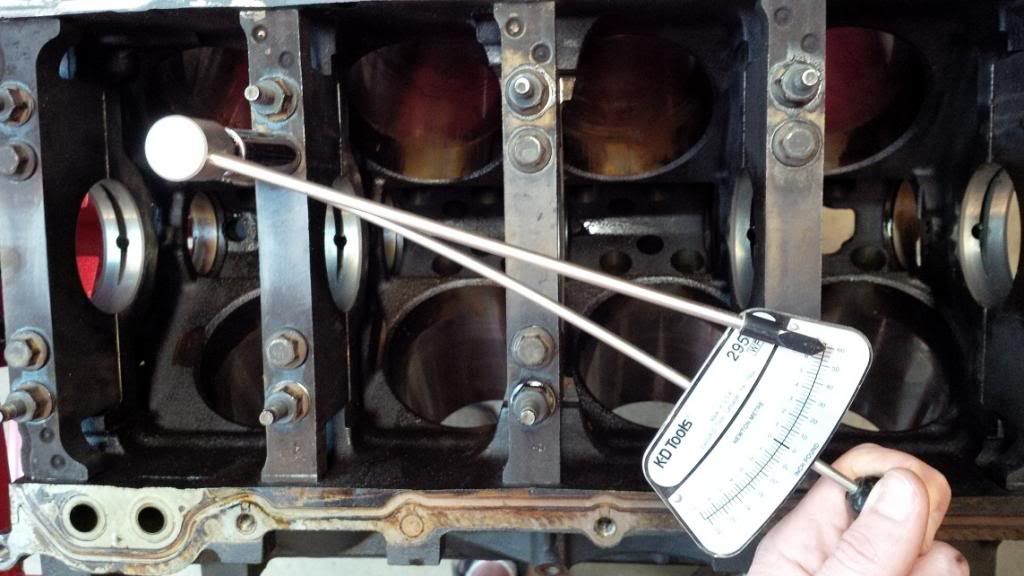

cam bearings look good as well. I measured all the inside diameters with the bore gauge. Readings are right on spec, so I do not plan to replace these bearings. Cam bearing clearance will likely be in the range of 0.0025" - 0.0035". But won't know for sure until new cam journal OD measurements are taken.

removing the PITA metal ring from the knock sensor seal. This little puller worked perfectly.

I picked up an '03 LQ4 short block for cheap. The previous owner had blown a head gasket and 2 cylinders filled up with coolant. He let it sit for 2 months and of course resulted in light surface corrosion inside the cylinders and seized rings.

This is great for me because the block is in otherwise excellent condition with no issues at all. A 0.030" bore will completely eliminate the corrosion.

Here is the current plan:

Host Vehicle: TBD

370 cu inch shrot block

Stock crank, clevite P bearings, new OEM main bolts

Scat forged I-beams with ARP bolts

4.030" forged pistons -4cc, Mahle

rotating assembly balance

All machining by H squared racing engines

cam: TBD

heads: TBD

As with my previous build, all clearances will be painstakingly measured and recorded.

Here are some pics;

measuring deck height of OEM pistons. The readings are slightly off due to some tough carbon buildup on the deck surface, but the readings are +/- 0.003" from each other.

measuring depth of dish in piston = 0.048"

Deck heights as measured. This tells me that the deck is most likely square and does not require deck machining, however I will measure again when the deck is cleaned and the new rotating assembly is installed, just to be sure.

1: 0.009"

2: 0.009"

3: 0.011"

4: n/a

5: 0.012"

6: 0.012"

7: 0.013"

8: 0.009"

I also measured the OEM crankshaft main/rod journal dimensions. Everything checked out within spec:

cam bearings look good as well. I measured all the inside diameters with the bore gauge. Readings are right on spec, so I do not plan to replace these bearings. Cam bearing clearance will likely be in the range of 0.0025" - 0.0035". But won't know for sure until new cam journal OD measurements are taken.

removing the PITA metal ring from the knock sensor seal. This little puller worked perfectly.

Last edited by RezinTexas; 07-28-2014 at 06:45 AM.

#2

TECH Fanatic

Thread Starter

Here's a couple pics of the Gen 4 rods from my last build, '04 LM7.

These rods were setup with a 0.945" pin, press fit.

Will typical aftermarket pistons work with that, or is it a special size?

These rods were setup with a 0.945" pin, press fit.

Will typical aftermarket pistons work with that, or is it a special size?

#3

I personally wouldn't bother reinstalling OEM PM rods. Budget (Scat/Eagle/Procomp) would be better than PM rods. JMO

#6

Super Hulk Smash

iTrader: (7)

Diamond makes them with the .945 - but they're like $650 a set without rings. Probably the best street/strip piston out there tho. PN is 11510

Wiseco "junkyard dog" pistons w/rings run about that. But I don't see a .945 option with at .030" over. Just .020" in their catalog.

Wiseco "junkyard dog" pistons w/rings run about that. But I don't see a .945 option with at .030" over. Just .020" in their catalog.

#7

I might be misinformed but I thought 408's had to have a new crank, like a stroker, to accommodate the new length of the connection rods.

The new stroker crank + cylinder bore 0.30 over + shorter connection rods = 408 ci.

Am I wrong, please explain.

The new stroker crank + cylinder bore 0.30 over + shorter connection rods = 408 ci.

Am I wrong, please explain.

Trending Topics

#9

#10

TECH Fanatic

Thread Starter

yeah, sticking with the stock crankshaft for this one. I would like to do another stroker, but I have 2 excellent condition truck cranks on the shelf ready to go. All journals are perfect and within spec.

#11

TECH Fanatic

Thread Starter

Diamond makes them with the .945 - but they're like $650 a set without rings. Probably the best street/strip piston out there tho. PN is 11510

Wiseco "junkyard dog" pistons w/rings run about that. But I don't see a .945 option with at .030" over. Just .020" in their catalog.

Wiseco "junkyard dog" pistons w/rings run about that. But I don't see a .945 option with at .030" over. Just .020" in their catalog.

#13

Moderator

iTrader: (20)

Scat I Beams are great, and with a .927" pin it will open up your piston choices. I have used the H Beams several times in 700whp engines with great success and the machining is pretty well done.

As far as Diamond, they're nice but Wiseco usually has more features for the same price which is why I'd go with them. Coated skirts, multi fit valve pockets, etc are all standard features that you don't typically get with the Diamond pistons.

Probes are pretty decent for a budget piston that won't see high rpm or big big power. They're a little thinner in key areas making them a little weaker, but very light. The Probe 3.905" pistons I have are about 390g where Wiseco's are more like 420g.

As far as Diamond, they're nice but Wiseco usually has more features for the same price which is why I'd go with them. Coated skirts, multi fit valve pockets, etc are all standard features that you don't typically get with the Diamond pistons.

Probes are pretty decent for a budget piston that won't see high rpm or big big power. They're a little thinner in key areas making them a little weaker, but very light. The Probe 3.905" pistons I have are about 390g where Wiseco's are more like 420g.

#14

Registered User

Join Date: Mar 2013

Location: Rhode Island

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

What final compression ratio are you looking to achieve? I myself am doing an lq4 bored .030 over and am just looking to see what you will be around, also what heads are you going to run?

#15

TECH Fanatic

Thread Starter

Scat I Beams are great, and with a .927" pin it will open up your piston choices. I have used the H Beams several times in 700whp engines with great success and the machining is pretty well done.

As far as Diamond, they're nice but Wiseco usually has more features for the same price which is why I'd go with them. Coated skirts, multi fit valve pockets, etc are all standard features that you don't typically get with the Diamond pistons.

Probes are pretty decent for a budget piston that won't see high rpm or big big power. They're a little thinner in key areas making them a little weaker, but very light. The Probe 3.905" pistons I have are about 390g where Wiseco's are more like 420g.

As far as Diamond, they're nice but Wiseco usually has more features for the same price which is why I'd go with them. Coated skirts, multi fit valve pockets, etc are all standard features that you don't typically get with the Diamond pistons.

Probes are pretty decent for a budget piston that won't see high rpm or big big power. They're a little thinner in key areas making them a little weaker, but very light. The Probe 3.905" pistons I have are about 390g where Wiseco's are more like 420g.

probably 11.3 SCR and 8.5 DCR - same as my last build. Don't know about heads yet, will decide that later.

#16

TECH Fanatic

Thread Starter

I'm reviving this build finally  Other stuff got in the way, but its back on track now.

Other stuff got in the way, but its back on track now.

Here is the updated plan:

370 in^3

Mahle pistons (Probe no longer available when I checked on 24-Jan-14)

Scat 6.125" Rods

New GM main bolts

Clevite P Bearings

Block machine work (bore/hone, decking, cleaning) by H squared racing engines in Houston.

I just ordered the Bearings, bolts, and a new Mitutoyo 4-5" micrometer (for the pistons), and a 50mm sub-anvil for the bore gauge. Planning to order the pistons/rods next week.

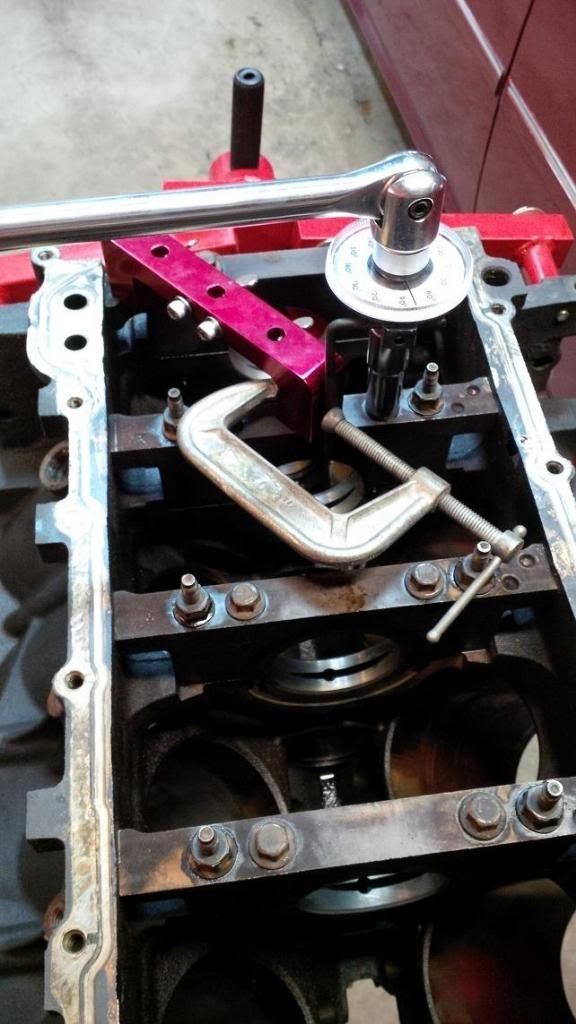

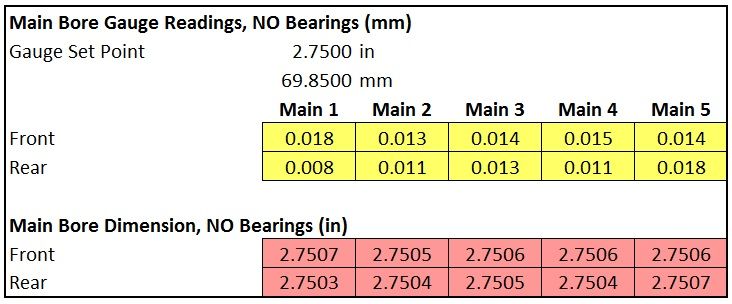

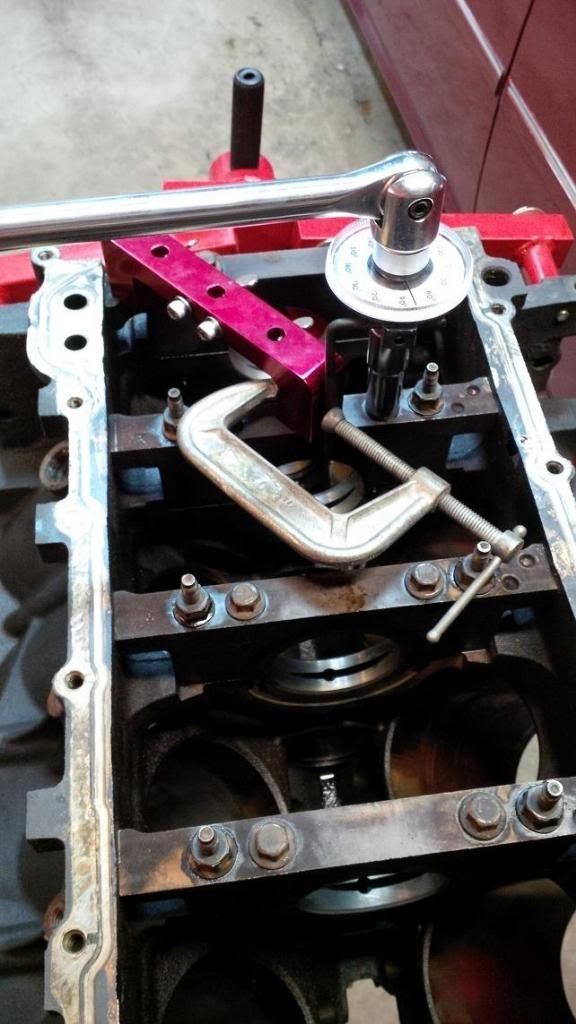

I installed and torqued the main caps with the old bolts to check the bore dimensions. Here is the initial low-torque pass per the Potak book:

This was my first experience with an angle gauge. As you can see I had to jerry-rig the gauge to keep it from moving heh heh

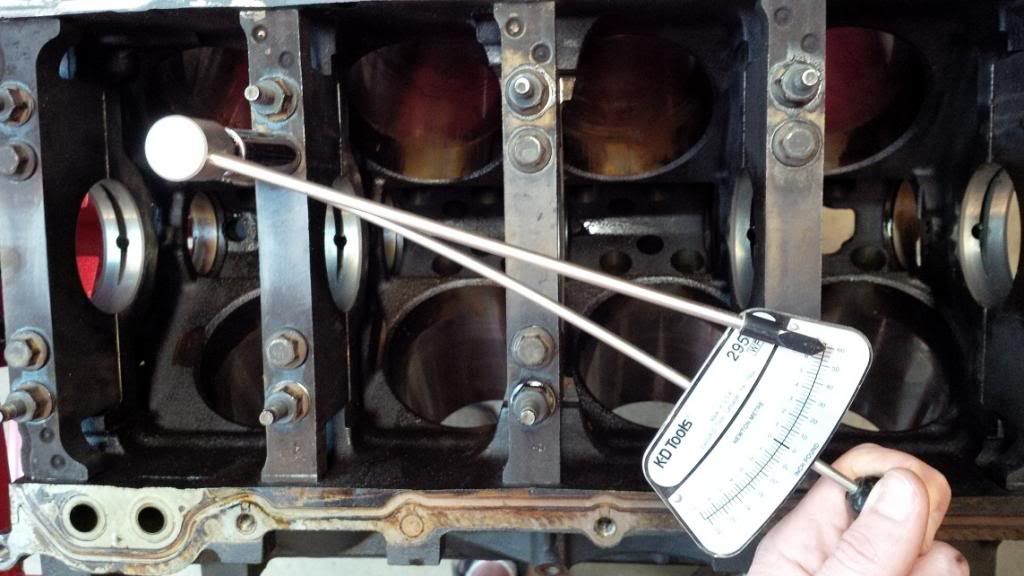

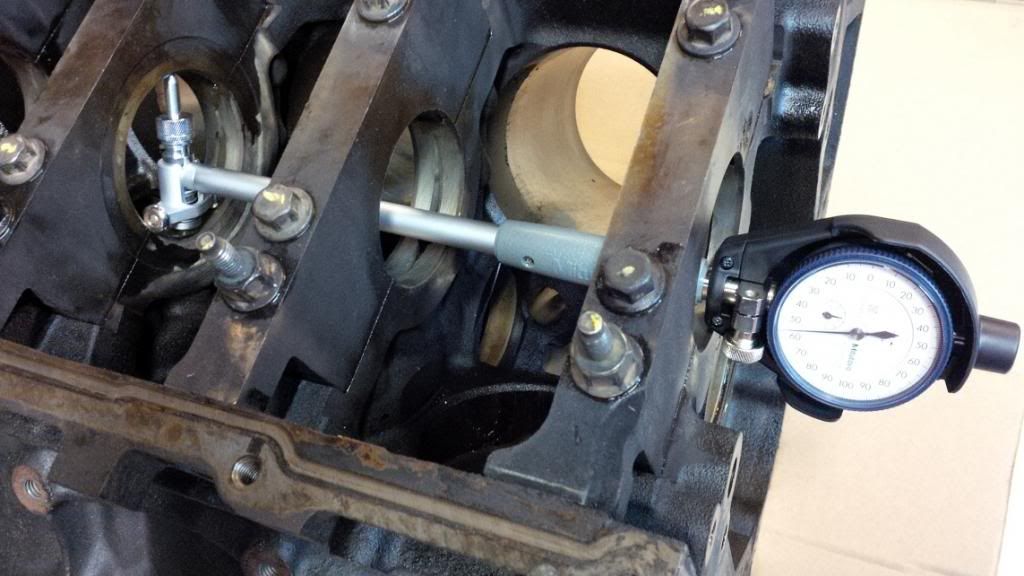

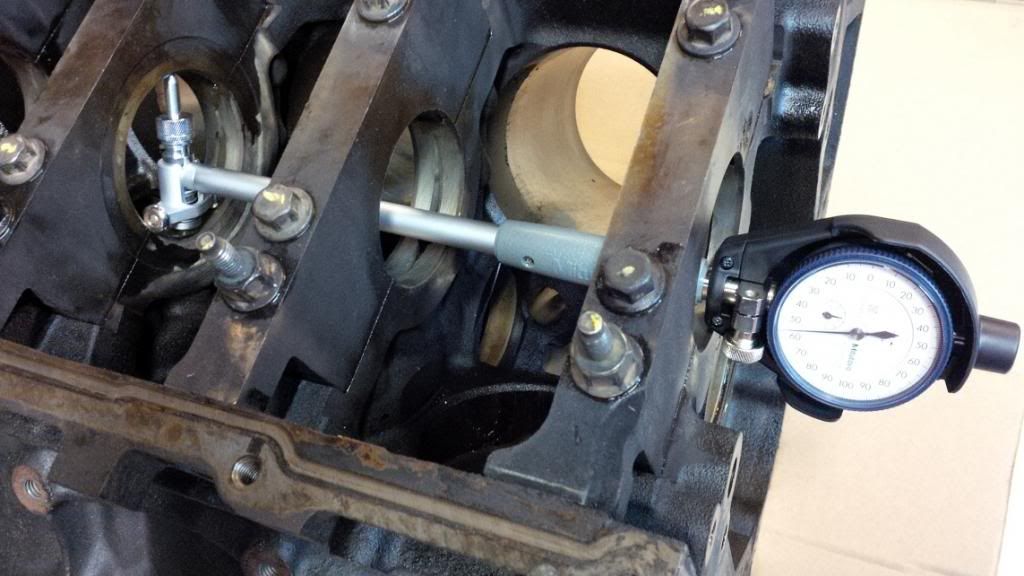

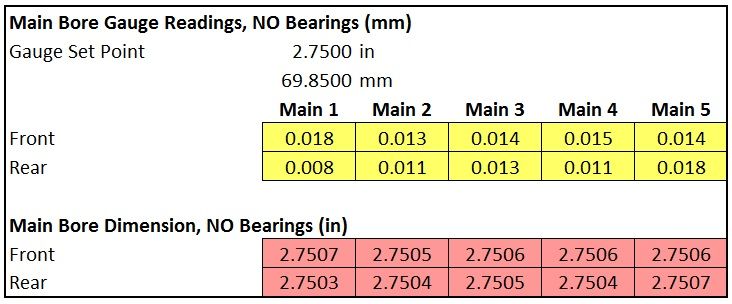

Measuring the bare bores (no bearings) with the bore gauge:

All the main bore dimensions were spot-on, so I don't think it needs any main bore honing.

Thanks for looking! I'm planning to have the shortblock done in about 6 weeks.

Other stuff got in the way, but its back on track now.

Other stuff got in the way, but its back on track now.Here is the updated plan:

370 in^3

Mahle pistons (Probe no longer available when I checked on 24-Jan-14)

Scat 6.125" Rods

New GM main bolts

Clevite P Bearings

Block machine work (bore/hone, decking, cleaning) by H squared racing engines in Houston.

I just ordered the Bearings, bolts, and a new Mitutoyo 4-5" micrometer (for the pistons), and a 50mm sub-anvil for the bore gauge. Planning to order the pistons/rods next week.

I installed and torqued the main caps with the old bolts to check the bore dimensions. Here is the initial low-torque pass per the Potak book:

This was my first experience with an angle gauge. As you can see I had to jerry-rig the gauge to keep it from moving heh heh

Measuring the bare bores (no bearings) with the bore gauge:

All the main bore dimensions were spot-on, so I don't think it needs any main bore honing.

Thanks for looking! I'm planning to have the shortblock done in about 6 weeks.

Last edited by RezinTexas; 01-24-2014 at 01:32 PM.

#17

TECH Fanatic

Thread Starter

A few questions:

1. Apparently this LQ4 engine is from 99-00 as the crankshaft is the long one. I'm planning to use an '04 LM7 crank instead and have it properly balanced. Any issues with doing this? The LM7 crank is in pretty much perfect condition, all dimensions well within sepc, and no grooves or lines.

2. I got the new Clevite P main bearings and installed the #1 main bearing set and measured the clearance. Clearance to the LM7 crank (2.5590" journal) is 0.0012" - 0.0018", so this is too tight for an iron block. Is there any way I can remove 0.001" of material from the crank journal? Am I better off getting different bearings? Which bearings would I need?

3. I've already ordered new GM main bolts/studs, but how many people re-use these with success? How many torque-cycles have you done on them? The Potak book recommends to replace after just a few cycles.

1. Apparently this LQ4 engine is from 99-00 as the crankshaft is the long one. I'm planning to use an '04 LM7 crank instead and have it properly balanced. Any issues with doing this? The LM7 crank is in pretty much perfect condition, all dimensions well within sepc, and no grooves or lines.

2. I got the new Clevite P main bearings and installed the #1 main bearing set and measured the clearance. Clearance to the LM7 crank (2.5590" journal) is 0.0012" - 0.0018", so this is too tight for an iron block. Is there any way I can remove 0.001" of material from the crank journal? Am I better off getting different bearings? Which bearings would I need?

3. I've already ordered new GM main bolts/studs, but how many people re-use these with success? How many torque-cycles have you done on them? The Potak book recommends to replace after just a few cycles.

Last edited by RezinTexas; 01-24-2014 at 11:58 AM.

#18

Moderator

iTrader: (20)

1) I don't see any problems with interchanging the cranks, it may need a little more heavy metal to balance.

2) You can grind the crank. There's a guy here that everyone uses right off of 1960 and Jones. His name is Pete. You'll need to give home the exact size you want each journal to be ground to. He's kind of...finicky.

3) I've used the stock bolts/studs in several applications. You shouldn't have to torque them too many times, maybe two or three more times which would be fine.

2) You can grind the crank. There's a guy here that everyone uses right off of 1960 and Jones. His name is Pete. You'll need to give home the exact size you want each journal to be ground to. He's kind of...finicky.

3) I've used the stock bolts/studs in several applications. You shouldn't have to torque them too many times, maybe two or three more times which would be fine.

#19

TECH Fanatic

Thread Starter

Parts just ordered from WS6store.com:

1. Scat rods (26125716)

2. Mahle pistons (LS1314030F04)

A big thanks to Mike, always a pleasure to deal with.

Great, Pete sounds like a good reference

1. Scat rods (26125716)

2. Mahle pistons (LS1314030F04)

A big thanks to Mike, always a pleasure to deal with.

1) I don't see any problems with interchanging the cranks, it may need a little more heavy metal to balance.

2) You can grind the crank. There's a guy here that everyone uses right off of 1960 and Jones. His name is Pete. You'll need to give home the exact size you want each journal to be ground to. He's kind of...finicky.

3) I've used the stock bolts/studs in several applications. You shouldn't have to torque them too many times, maybe two or three more times which would be fine.

2) You can grind the crank. There's a guy here that everyone uses right off of 1960 and Jones. His name is Pete. You'll need to give home the exact size you want each journal to be ground to. He's kind of...finicky.

3) I've used the stock bolts/studs in several applications. You shouldn't have to torque them too many times, maybe two or three more times which would be fine.