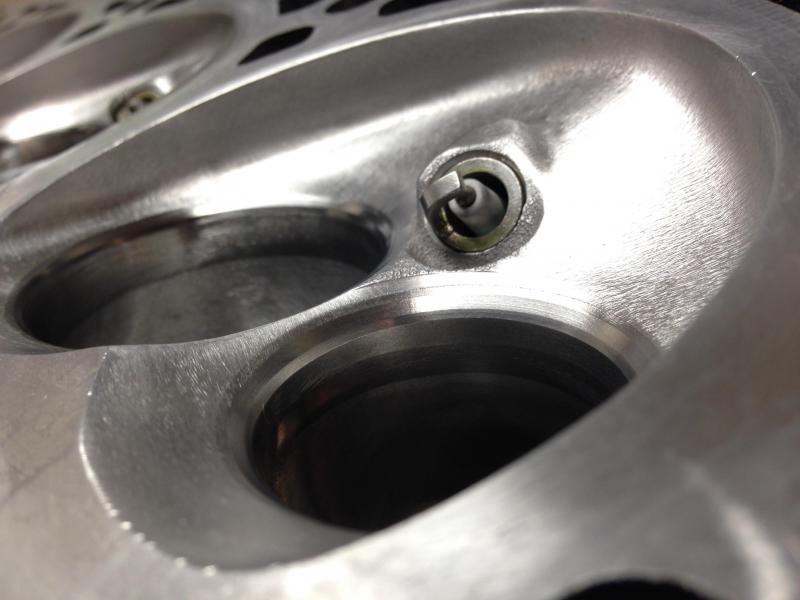

home ported and polished 243/799 heads

#1

just got done polishing and cleaning up the heads and the finaly step is getting them milled. most likely milling them to 0.030" or around 59cc. that with a ls9 HG of 0.051" that'll be around a SCR of 11.5:1. ensuring PTV of course. i got one of the heads flow tested on cyl 2 and 6. i should had done a before comparison on the same bench but didnt occur to me at the time. both cyl flowed nearly identical. the shop used a "freddy flow" and apparently it flows 2% of the super flow machines. i dunno how accurate it was but it was the only one in the area. anyways only way to tell if these work is to run them and take it to the track lol

avg ls6 cfm:

lift int/exh

.1 57/45

.2 122/101

.3 183/134

.4 225/159

.5 250/172

.6 247/180

home ported ls6 cfm

.1 xx/xx

.2 168/115

.3 221/142

.4 250/163

.5 266/177

.6 278/189

seeing how the exhaust was just a hair hgiher than stock i went back and opened up the inner walls and a bit of the ceiling w/o touching the hump. i just polished the exhaust ports a bit more to smooth the walls out. all in all it prolly took 11-13 total hours over the course. im actually pleased that im at least consistant.

now im just curious if i ought to get the valves done with a valve job, but the intake plate is very thin. is it worth a valve job on the intake valves? theres plenty of meat on the exhaust and may do a 3 angle valve job. if i do the intake, i heard ppl says they had to backcut the chambers or something?

anyways here are the pics:

[URL=http://s99.photobucket.com/user/fst100/media/2013-11-09_09-44-42_516_zps0ccef76a.jpg.html][IMG]http:

avg ls6 cfm:

lift int/exh

.1 57/45

.2 122/101

.3 183/134

.4 225/159

.5 250/172

.6 247/180

home ported ls6 cfm

.1 xx/xx

.2 168/115

.3 221/142

.4 250/163

.5 266/177

.6 278/189

seeing how the exhaust was just a hair hgiher than stock i went back and opened up the inner walls and a bit of the ceiling w/o touching the hump. i just polished the exhaust ports a bit more to smooth the walls out. all in all it prolly took 11-13 total hours over the course. im actually pleased that im at least consistant.

now im just curious if i ought to get the valves done with a valve job, but the intake plate is very thin. is it worth a valve job on the intake valves? theres plenty of meat on the exhaust and may do a 3 angle valve job. if i do the intake, i heard ppl says they had to backcut the chambers or something?

anyways here are the pics:

[URL=http://s99.photobucket.com/user/fst100/media/2013-11-09_09-44-42_516_zps0ccef76a.jpg.html][IMG]http:

#3

TECH Junkie

iTrader: (5)

most likely milling them to 0.030" or around 59cc. that with a ls9 HG of 0.051" that'll be around a SCR of 11.5:1

You will get the same SCR, but with better quench and the heads will flow slightly better the less they are milled.

#5

Super Hulk Smash

iTrader: (7)

Cometics seal fine. You just have to get the block clean. If you mill the heads, they'll be fine to seal. Then you just have to focus on the block deck surface. Grab you some of the non-marring plastic scrapers, some B-12 chemtool, and goto work. You might need some Permatex gasket remover, but I've only found it online. No store around here carries it for some reason. But usually the B-12 and plastic scrapers get the deck nice and shiny.

#6

hmm i may look further into that. if i mill the heads .018 or 61cc using the 0.040 HG that puts the SCR at 11.6:1(DCR 8.8:1)im having diablo formula racing(DFR) do the head swap-(dont have time to do it over the winter). with the 243/799 is it every 0.006=1cc?

edit-valve job on both intake and exhaust?

edit-valve job on both intake and exhaust?

#7

11 Second Club

iTrader: (2)

When I DIY'd my 241s I like you flowed them with the GM valvejob as the

heads only had 15,700 miles on them so the seats were in better shape than

yours. I know I left some flow on the table as I only gained 12-14 IN. and 20

on the EX with about 4.5 hours total time invested.

A 3 angle on your intakes will probably be worth 6-9 cfm and your exhausts

look pretty wide...so I'm guessing a radius seat cut might net you double

digits improvement from your flow chart.

heads only had 15,700 miles on them so the seats were in better shape than

yours. I know I left some flow on the table as I only gained 12-14 IN. and 20

on the EX with about 4.5 hours total time invested.

A 3 angle on your intakes will probably be worth 6-9 cfm and your exhausts

look pretty wide...so I'm guessing a radius seat cut might net you double

digits improvement from your flow chart.

Trending Topics

#10

8 Second Club

iTrader: (3)

Either you guys grind fast, or I am sloooow!

I even paused an bought the Wastwood long burr kit. I easily spent 30 hours.

My machinist liked my work, had me do just a bit more after he did the VJ.

4 angles on the intake and 3 on the exh. He used a radius cutter on the exh. Not cheap work when done right.

I did not flow them. Nice to see that pretty basic work nets good results.

Ron

I even paused an bought the Wastwood long burr kit. I easily spent 30 hours.

My machinist liked my work, had me do just a bit more after he did the VJ.

4 angles on the intake and 3 on the exh. He used a radius cutter on the exh. Not cheap work when done right.

I did not flow them. Nice to see that pretty basic work nets good results.

Ron

#12

looks great ronssnova. i still see a bit of the casting on the intake side. are you going to remove and smooth that out more? i bought a few long 6" 1/2" think burr sets as well as the 6" 1/2" thick mandrel for the tapered sandpaper (tootsie rolls). that made reaching in the hard to see/reach areas much easier.

for the intake i read to not smooth it too much cause you dont want to have the fuel puddle so i left the chamber 80grit.

for the intake i read to not smooth it too much cause you dont want to have the fuel puddle so i left the chamber 80grit.

#16

Im putting together the materials Iíll need when supplying the parts to the shop Iíll be getting the heads swapped. Iím currently running an LS6 intake manifold but after watching a DIY ls6 heads video, I noticed the person was using a cathedral style intake manifold gasket for the intake opening on the heads-basically port matching. My question is in regards to the intake manifold cathedral style gasket(fel-pro FEL-13125). I am certain im not using that type on my current build(317 heads and ls6 intake manifold) but rather the square gaskets that fit onto the intake manifold itself, fel-pro 375-MS92438. Does it matter which style gasket to use or is one better than the other?

cathedral style

square style

cathedral style

square style

#17

TECH Senior Member

iTrader: (42)

PS The rubber intake gaskets are the ones to use.

Last edited by slt200mph; 11-11-2013 at 02:39 PM.