Why LSA doesn't matter

#121

Moderator

I would modify that to say that pretty much all cams have at least some overlap at just 0.005" of opening, which is just a crack. However, we are mostly talking here about overlap at .050" which is much more than a crack. As far as I know, no stock cam has any overlap at that opening.

As speedtiger explained, as the exhaust valve closes, the intake valve starts to open so that you have a "ram" effect of the exhaust pulling in air/mixture from the intake manifold. So, when the exhaust valve is almost closed at .005" (a crack), overlap is the number of crankshaft degrees from the position where the intake valve started to open. That .005" opening is enough to give a ram effect, but not a whole lot.

We mostly talk about overlap at .050". So, when the exhaust valve is closing but still moderately open at .050", we ask if the intake valve has already started to open. If the answer is Yes, we have positive overlap, if not, we have zero or Negative overlap.

If Yes, the Positive overlap is again the number of crankshaft degrees from the position where the intake valve started to open.

If No, the Negative overlap is the the number of degrees the crankshaft has to turn before the intake valve starts to open.

Note: I might have it reversed - that overlap references when the intake valve is open by .005" or .050", but the result would be the same. I will edit this post if true, or other correction needed.

The nice ram effect of high positive overlap works mostly at higher RPM; at lower RPM, it allows unburned fuel mixture to go right out the exhaust pipe, hurting low end torque. Most significantly high positive overlap always allows some unburned fuel to go out the exhaust, causing sky high emissions and fuel consumption; therefore all stock cams calculate as negative overlap at .050 and very modest overlap at .005".

I hope this gives a "simple" explanation, at the expense of some technical inaccuracies.

As speedtiger explained, as the exhaust valve closes, the intake valve starts to open so that you have a "ram" effect of the exhaust pulling in air/mixture from the intake manifold. So, when the exhaust valve is almost closed at .005" (a crack), overlap is the number of crankshaft degrees from the position where the intake valve started to open. That .005" opening is enough to give a ram effect, but not a whole lot.

We mostly talk about overlap at .050". So, when the exhaust valve is closing but still moderately open at .050", we ask if the intake valve has already started to open. If the answer is Yes, we have positive overlap, if not, we have zero or Negative overlap.

If Yes, the Positive overlap is again the number of crankshaft degrees from the position where the intake valve started to open.

If No, the Negative overlap is the the number of degrees the crankshaft has to turn before the intake valve starts to open.

Note: I might have it reversed - that overlap references when the intake valve is open by .005" or .050", but the result would be the same. I will edit this post if true, or other correction needed.

The nice ram effect of high positive overlap works mostly at higher RPM; at lower RPM, it allows unburned fuel mixture to go right out the exhaust pipe, hurting low end torque. Most significantly high positive overlap always allows some unburned fuel to go out the exhaust, causing sky high emissions and fuel consumption; therefore all stock cams calculate as negative overlap at .050 and very modest overlap at .005".

I hope this gives a "simple" explanation, at the expense of some technical inaccuracies.

The following users liked this post:

Abs (11-08-2023)

#122

TECH Junkie

iTrader: (9)

We mostly talk about overlap at .050". So, when the exhaust valve is closing but still moderately open at .050", we ask if the intake valve has already started to open. If the answer is Yes, we have positive overlap, if not, we have zero or Negative overlap.

If Yes, the Positive overlap is again the number of crankshaft degrees from the position where the intake valve started to open.

If No, the Negative overlap is the the number of degrees the crankshaft has to turn before the intake valve starts to open.

Note: I might have it reversed - that overlap references when the intake valve is open by .005" or .050", but the result would be the same. I will edit this post if true, or other correction needed.

If Yes, the Positive overlap is again the number of crankshaft degrees from the position where the intake valve started to open.

If No, the Negative overlap is the the number of degrees the crankshaft has to turn before the intake valve starts to open.

Note: I might have it reversed - that overlap references when the intake valve is open by .005" or .050", but the result would be the same. I will edit this post if true, or other correction needed.

Last edited by JimMueller; 01-06-2015 at 08:55 AM.

#123

Old School Heavy

iTrader: (16)

Which is exactly what can mislead people to draw the wrong conclusions and create the fallacy of negative overlap. There is really no such thing as "negative overlap" in modern 4 cycle car or motorcycle engines.

That is not to say that looking at overlap at .050" of cam lift does not have some value in designing or predicting a camshafts influence over engine behavior. But, looking at overlap at .050" alone leads to nonsensical terms like negative overlap that can mislead people when they are trying to determine how the overlap of a given camshaft will affect their engine's driving characteristics.

As I mentioned before the positive effects that overlap can create will be observed and upper midrange and high RPMs. The detriments will be lower idle vacuum, decreased idle and low speed efficiency and driving manners. It is at this low speed where you will gain insight by looking at seat timing overlap. Seat timing overlap will disrupt the engines ability to generate vacuum and decrease cylinder pressures at idle and low speeds. So, it is essential that this is understood to truly predict how a given cam will behave.

That is not to say that looking at overlap at .050" of cam lift does not have some value in designing or predicting a camshafts influence over engine behavior. But, looking at overlap at .050" alone leads to nonsensical terms like negative overlap that can mislead people when they are trying to determine how the overlap of a given camshaft will affect their engine's driving characteristics.

As I mentioned before the positive effects that overlap can create will be observed and upper midrange and high RPMs. The detriments will be lower idle vacuum, decreased idle and low speed efficiency and driving manners. It is at this low speed where you will gain insight by looking at seat timing overlap. Seat timing overlap will disrupt the engines ability to generate vacuum and decrease cylinder pressures at idle and low speeds. So, it is essential that this is understood to truly predict how a given cam will behave.

#124

TECH Regular

iTrader: (3)

Also Martin did you happen to know UDHarold at all? Cam designer that changed many things in the industry passed away recently. I feel like it's up to guys like you to continue pushing the REAL science behind cam design theory, and not what you can pull off a shelf.

Seat timing overlap will disrupt the engines ability to generate vacuum and decrease cylinder pressures at idle and low speeds

#126

TECH Junkie

iTrader: (9)

The detriments will be lower idle vacuum, decreased idle and low speed efficiency and driving manners. It is at this low speed where you will gain insight by looking at seat timing overlap. Seat timing overlap will disrupt the engines ability to generate vacuum and decrease cylinder pressures at idle and low speeds.

Last edited by JimMueller; 01-06-2015 at 11:56 AM. Reason: spelling

#127

I base my valve events off the IC event as that is the first valve event I choose because it directly determines how much mixture is trapped at the end of the compression stroke.

So if we close the intake valve earlier, the exhaust valve needs to open later than it would if we had a 4" stroke.

Also, since we have less cylinder displacement due to a shorter stroke, the overlap requirement changes as well. Since the cylinder displaces less volume a reduction in overlap would be called for versus a 4" stroke.

That is the quick and easy differences between the timing requirements for a 4" stroke and a 3.622" stroke.

With your combination I would likely choose the following events for a 4" stroke:

5.5 IO

47.5 IC

59.5 EO

5.5 EC

For a 3.622" stroke

2 IO

43 IC

55 EO

2 EC

First cam would be 233/245 114+3

Second cam would be 225/237 113.5+3

I will add that in a turbo application where back pressure is commonly up to 2 times higher than manifold pressure (or even higher than that) lower amounts of overlap and even negative amounts of overlap are favorable.

Another application where negative overlap would be favorable would be in a smog application that has to pass a tail pipe sniffer test.

If we had an abundance of valve overlap in a smog application there is a good chance that it will not pass due to excessive emissions. At low engine speeds the cylinder doesn't have the assistance of wave tuning to help with gas exchange during overlap. As a result you wind up with a cylinder full of unburnt gasses which wouldn't occur at higher engine speeds. These unburnt gasses create much higher NOX emissions which means that your chances of passing that sniffer test are slim to none.

Pretty much all cams including stockers have overlap. So, negative overlap is really a misnomer. The thing that gives people the wrong impression is that it is popular these days to look at cam specs at .050" lift at the cam.

With that put aside, how much overlap and the function of overlap is one of the main things this thread is all about. There is a ton of information out there about the function overlap going way back to when Ed "The Godfather" Iskenderian introduced his "5 cycle" cam marketing campaign.

There is an intricate relationship between the exhaust system, header design, valve layout, intake configuration and camshaft valve event overlap. In short, the scenario is that the exhaust rushing out past the exhaust valve will leave a vacuum in its wake which will pull on the intake tract during the time when both valves are open at TDC (overlap).

The benefit is that it can increase cylinder filling and volumetric efficiency in the midrange and upper RPM. The detriment is that it reduces engine idle vacuum while diminishing low speed response and efficiency.

What is ideal for any given engine application depends on that intricate relationship between the exhaust system, header design, valve layout, intake configuration and camshaft valve event overlap. It also should including the desired engine characteristics of the end user.

With that put aside, how much overlap and the function of overlap is one of the main things this thread is all about. There is a ton of information out there about the function overlap going way back to when Ed "The Godfather" Iskenderian introduced his "5 cycle" cam marketing campaign.

There is an intricate relationship between the exhaust system, header design, valve layout, intake configuration and camshaft valve event overlap. In short, the scenario is that the exhaust rushing out past the exhaust valve will leave a vacuum in its wake which will pull on the intake tract during the time when both valves are open at TDC (overlap).

The benefit is that it can increase cylinder filling and volumetric efficiency in the midrange and upper RPM. The detriment is that it reduces engine idle vacuum while diminishing low speed response and efficiency.

What is ideal for any given engine application depends on that intricate relationship between the exhaust system, header design, valve layout, intake configuration and camshaft valve event overlap. It also should including the desired engine characteristics of the end user.

Changes in cylinder displacement due to a change in crankshaft stroke should also be duly noted in reference to how large this third port ends up needing to be.

As bore diameter and cylinder displacement grow, and valve diameter remains relatively unchanged, the length that the overlap event needs to occur grows dramatically.

So any "overlap" or "positive overlap" is if the intake valve is open for any number of degrees while the exhaust valve is open, so IVO + EVC. And "negative overlap" is the delay in degrees between EVC and IVO, so ... EVC-IVO? Is "positive overlap" another way of saying the overlap bias favors the intake?

So the number of crank degrees that the intake valve is open for while the exhaust valve is open equals overlap. This can occur well into the intake stroke in a high RPM race oriented engine.

For instance:

IO event of 6 crank degrees BTDC @.050" and an EC event of 6 crank degrees ATDC @.050" equals 12 degrees of positive valve overlap. This means that when the intake valve is open .085"(.050 lobe lift x 1.7 rocker ratio) on the exhaust stroke the piston is located 6 crank degrees BTDC and that when the exhaust valve is open .085" on the intake stroke the piston is 6 crank degrees ATDC.

IO event of 6 crank degrees ATDC @.050" and an EC event of 6 crank degrees BTDC @.050" equals 12 degrees of negative overlap. This means that when the intake valve is open .085" on the intake stroke the piston is located 6 crank degrees ATDC and when the exhaust valve is open .085" on the exhaust stroke the piston is located 6 crank degrees BTDC.

Which is exactly what can mislead people to draw the wrong conclusions and create the fallacy of negative overlap. There is really no such thing as "negative overlap" in modern 4 cycle car or motorcycle engines.

That is not to say that looking at overlap at .050" of cam lift does not have some value in designing or predicting a camshafts influence over engine behavior. But, looking at overlap at .050" alone leads to nonsensical terms like negative overlap that can mislead people when they are trying to determine how the overlap of a given camshaft will affect their engine's driving characteristics.

As I mentioned before the positive effects that overlap can create will be observed and upper midrange and high RPMs. The detriments will be lower idle vacuum, decreased idle and low speed efficiency and driving manners. It is at this low speed where you will gain insight by looking at seat timing overlap. Seat timing overlap will disrupt the engines ability to generate vacuum and decrease cylinder pressures at idle and low speeds. So, it is essential that this is understood to truly predict how a given cam will behave.

That is not to say that looking at overlap at .050" of cam lift does not have some value in designing or predicting a camshafts influence over engine behavior. But, looking at overlap at .050" alone leads to nonsensical terms like negative overlap that can mislead people when they are trying to determine how the overlap of a given camshaft will affect their engine's driving characteristics.

As I mentioned before the positive effects that overlap can create will be observed and upper midrange and high RPMs. The detriments will be lower idle vacuum, decreased idle and low speed efficiency and driving manners. It is at this low speed where you will gain insight by looking at seat timing overlap. Seat timing overlap will disrupt the engines ability to generate vacuum and decrease cylinder pressures at idle and low speeds. So, it is essential that this is understood to truly predict how a given cam will behave.

Would that be Harold Brookshire ? The man behind the Ultradyne asymmetric lobe and Lunati Voodoo lobe ?

Martins Street heat stage 1 for LS1 has 2.5 degrees of overlap and the SNS stage 2 for LS1 has 11 degrees of overlap. Is the sweet spot somewhere between these two numbers ? With "sweet spot" meaning increase in power above 2K rpm with very little hit in MPG and "somewhere" changing because of displacement and exhaust tuning ?

Martins Street heat stage 1 for LS1 has 2.5 degrees of overlap and the SNS stage 2 for LS1 has 11 degrees of overlap. Is the sweet spot somewhere between these two numbers ? With "sweet spot" meaning increase in power above 2K rpm with very little hit in MPG and "somewhere" changing because of displacement and exhaust tuning ?

I would say yes to your second question, at least in a 346-364" engine that operates under 6500-6800rpm with a long runner EFI intake manifold and a 1.75-1.875" primary with a 3.0" collector.

2.5 degrees of valve overlap @.050" lobe lift will still cause some power loss off idle up to roughly 1800-2000rpm in a 346" engine. Not quite as pronounced in a 364" engine, but still very close.

#128

Moderator

Martins Street heat stage 1 for LS1 has 2.5 degrees of overlap and the SNS stage 2 for LS1 has 11 degrees of overlap. Is the sweet spot somewhere between these two numbers ? With "sweet spot" meaning increase in power above 2K rpm with very little hit in MPG and "somewhere" changing because of displacement and exhaust tuning ?

In another thread I started, I mentioned that I am now building a stroker LS3. I was stunned when Martin first suggested a cam with 23 degrees of overlap, knowing that I found 11 degrees a bit much on my LS2. However, he explained that since a stroker needs to pull in significantly more mixture through the same sized valves, it needs more duration, which will result in more overlap. He estimated that a stroker with 16 degrees of overlap will "feel" similar to a non-stroker with 10 degrees of overlap. We finally settled on 19 degrees of overlap; this would be crazy high for an LS1, but not an LS3 419ci stroker.

Furthermore, different intake manifolds have different characteristics and resonance frequencies. As I understand it, the previous cylinder's intake valve closing will create a pulse in the intake manifold and ideally you want the next intake valve open to take advantage of the pressure wave.

I'm sure Martin could add additional parameters, but the "sweet spot" will depend upon an engine's bore and stroke, valve size, intake porting details, exhaust system, intake manifold, stall speed, vehicle weight and of course your personal preferences.

Considering all the complexities, we should consider ourselves fortunate that we can order a custom cam through Martin for the same price as a non-optimal self cam. Its great that he is sharing so much information in this thread, but lets face it, few of us will ever fully understand it. I certainly won't.

#129

Old School Heavy

iTrader: (16)

What ranges of seat overlap tend to exacerbate idle or low speed driving problems? My PatG cam is a 271/279 @ .006", 222/230 @ .050", 146/153 @ .200", 110 ICL, 114 ECL. If I've calculated that correctly, the seat overlap is 51*, where does that fall into the seat overlap range which could cause drivability problems?

You take one guy with an old school LS retrofit like mine and I might tell you 10 degrees of overlap at .050" or 60 degrees at .006" has great drivability. Then conversely you take another guy with a Caddy CTSV who might tell you his cam with "0" overlap at .050" or 50 degrees of overlap at .006" is just not as smooth as his stock cam. Furthermore, an owner with an automatic equipped car may not gripe about low speed bucking like an owner with a manual transmission equipped car might.

With good tuning, I bet a lot of performance oriented guys will suffer 10 degrees of overlap @ .050" with no complaints, hell they may even like it. Your grandma, maybe not so much. LOL

Ha! No chance. I prefer to just jump in when the mood strikes.

#130

The reason I tend to stick to generalities instead of exact amounts in this conversation is that there is no line in the sand. It is a continuous variable from very low overlap to very high overlap. To cloud this up a bit more, you have to take into consideration the endless possible engine combinations that it may be applied to along with, and more importantly, the vehicle owners perception.

You take one guy with an old school LS retrofit like mine and I might tell you 10 degrees of overlap at .050" or 60 degrees at .006" has great drivability. Then conversely you take another guy with a Caddy CTSV who might tell you his cam with "0" overlap at .050" or 50 degrees of overlap at .006" is just not as smooth as his stock cam. Furthermore, an owner with an automatic equipped car may not gripe about low speed bucking like an owner with a manual transmission equipped car might.

With good tuning, I bet a lot of performance oriented guys will suffer 10 degrees of overlap @ .050" with no complaints, hell they may even like it. Your grandma, maybe not so much. LOL

Ha! No chance. I prefer to just jump in when the mood strikes.

You take one guy with an old school LS retrofit like mine and I might tell you 10 degrees of overlap at .050" or 60 degrees at .006" has great drivability. Then conversely you take another guy with a Caddy CTSV who might tell you his cam with "0" overlap at .050" or 50 degrees of overlap at .006" is just not as smooth as his stock cam. Furthermore, an owner with an automatic equipped car may not gripe about low speed bucking like an owner with a manual transmission equipped car might.

With good tuning, I bet a lot of performance oriented guys will suffer 10 degrees of overlap @ .050" with no complaints, hell they may even like it. Your grandma, maybe not so much. LOL

Ha! No chance. I prefer to just jump in when the mood strikes.

#131

Thanks again martin. I took the specs gave me and loaded them into a Dyno Sim. All thing being equal with the combos, the big bore short stroke was equal with power and 1ft lb ahead in torque. Not what I expected at all.thanks for the info.

#134

TECH Apprentice

What are your guys thoughts on rocker ratio and how they alter overlap/duration? Obviously not measuring from the seat at 0. More like @0.05 for example and so on.

#135

As rocker ratio increases, so does duration at the valve. Although the amount of cam degrees in terms of duration has not changed nor has the LSA, the amount of flow area that the engine sees during valve overlap has been dramatically altered.

This would necessitate a reduction in duration and valve overlap for things to return to equilibrium once again.

Although I don't agree with the way David Vizard chooses his camshafts, his thoughts on valve overlap requirements versus rocker arm ratio and valve diameter are spot on. His thoughts and literature in regards to this matter are great for those that are wanting to learn the answer to the question, "how much overlap does my engine need for max performance?"

Valve diameter has the largest impact on how much flow is created at low valve lifts. Much more so than port cross section. Because of this, cylinder displacement, rocker ratio and valve diameter have the largest impact on how much overlap is needed for max performance.

This would necessitate a reduction in duration and valve overlap for things to return to equilibrium once again.

Although I don't agree with the way David Vizard chooses his camshafts, his thoughts on valve overlap requirements versus rocker arm ratio and valve diameter are spot on. His thoughts and literature in regards to this matter are great for those that are wanting to learn the answer to the question, "how much overlap does my engine need for max performance?"

Valve diameter has the largest impact on how much flow is created at low valve lifts. Much more so than port cross section. Because of this, cylinder displacement, rocker ratio and valve diameter have the largest impact on how much overlap is needed for max performance.

#136

Moderator

Hopefully I'm not making it more confusing.

Last edited by mrvedit; 01-23-2015 at 10:28 PM.

#137

TECH Regular

iTrader: (3)

As rocker ratio increases, so does duration at the valve. Although the amount of cam degrees in terms of duration has not changed nor has the LSA, the amount of flow area that the engine sees during valve overlap has been dramatically altered.

This would necessitate a reduction in duration and valve overlap for things to return to equilibrium once again.

Although I don't agree with the way David Vizard chooses his camshafts, his thoughts on valve overlap requirements versus rocker arm ratio and valve diameter are spot on. His thoughts and literature in regards to this matter are great for those that are wanting to learn the answer to the question, "how much overlap does my engine need for max performance?"

Valve diameter has the largest impact on how much flow is created at low valve lifts. Much more so than port cross section. Because of this, cylinder displacement, rocker ratio and valve diameter have the largest impact on how much overlap is needed for max performance.

This would necessitate a reduction in duration and valve overlap for things to return to equilibrium once again.

Although I don't agree with the way David Vizard chooses his camshafts, his thoughts on valve overlap requirements versus rocker arm ratio and valve diameter are spot on. His thoughts and literature in regards to this matter are great for those that are wanting to learn the answer to the question, "how much overlap does my engine need for max performance?"

Valve diameter has the largest impact on how much flow is created at low valve lifts. Much more so than port cross section. Because of this, cylinder displacement, rocker ratio and valve diameter have the largest impact on how much overlap is needed for max performance.

The durations remind me of your Street Heat 1 v2 for LS2 but the events and overlap are way off. No shelf cam looks like this. Is this example one of the reasons you tell us LSA does not matter ?

#138

TECH Apprentice

The 0.05" is cam lift, e.g. as measured on the lifters. Therefore lifter ratio does not change the measured/advertised duration. The higher rocker ratio would increase the effective duration. At .050 cam lift, 1.7 rockers give you a .085 valve opening. Therefore a higher rocker ratio will give you more duration at a .085 valve opening.

Hopefully I'm not making it more confusing.

Hopefully I'm not making it more confusing.

#139

Like what is talked about in this post ? So my stock 243 heads have 21.625 cubic inches per inch of valve diameter and the chart says 108 LSA would work the best. If I follow the OP's choice a 228/232 duration on a 108 with no advance, I get the valve events of IVO 6 - IVC 42 - EVO 48 - EVC 8 with 14° of overlap.

The durations remind me of your Street Heat 1 v2 for LS2 but the events and overlap are way off. No shelf cam looks like this. Is this example one of the reasons you tell us LSA does not matter ?

The durations remind me of your Street Heat 1 v2 for LS2 but the events and overlap are way off. No shelf cam looks like this. Is this example one of the reasons you tell us LSA does not matter ?

I do agree with his thoughts on how much overlap is needed when cylinder volume, valve diameter, rocker ratio and low lift cylinder head flow are known.

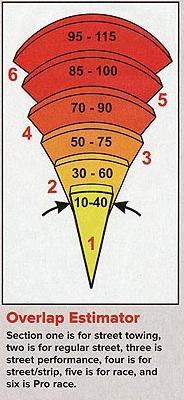

Here is his chart:

I have actually used this chart as reference before with high RPM N/A engines. Keep in mind, this is seat to seat valve overlap which is calculated at .006" lobe lift for a hydraulic or .020" lobe lift for a solid.

What I have done is calculate cylinder displacement versus valve diameter first. If I end up with a large amount of cylinder displacement versus valve diameter I err towards the high end of the scale. If I end up with a small amount of cylinder displacement versus valve diameter I err towards the lower end of the scale.

Then once I know how much overlap in total is needed, I work on where that overlap period needs to start, and where it needs to finish. This would include choosing where the intake valve opens and where the exhaust valve closes. As I've mentioned earlier in this thread, where the intake valve opens and where the exhaust valve closes are based on pressures created in the intake port, cylinder and exhaust port/system.

There is also a benefit in opening the intake valve early that doesn't relate to pressure in cylinder or in the exhaust port/system during the overlap event. The sooner the intake valve is opened while the piston is on the exhaust stroke, the more lift you are able to achieve by the time the piston starts the intake stroke. Since the intake valve will have been opened much earlier, by the time the piston reaches top dead center you could quite possibly have .100"-.200" valve lift @TDC.

Since the cylinder head flows more air at higher lifts, if we can get the valve open further at the beginning of the intake stroke, we have more flow available to meet the demand for airflow in the cylinder which is created by the downwards motion of the piston and the speed it creates.

Of course in a perfect world we wouldn't have to open the intake valve so early and expose the intake tract to potential reversion issues as we'd just snap the intake valve open instantly to max lift. Since we live in a world that has rules based on physics, that would be an impossible feat to obtain. Even though having the valve open further when the piston starts the intake stroke is a benefit in terms of meeting piston CFM demands more efficiently, it can potentially lead to exposing the intake port to higher pressure spent exhaust gasses since the engine is still on the exhaust stroke when the intake valve opens. This would negate any potential gains in VE due to the reversion it would cause.

Balancing the intake opening event with pressure in the cylinder and trying to obtain the most amount of lift @TDC is the goal. Finding the sweet spot that is located somewhere in the middle is what you're after ultimately.

Last edited by Sales@Tick; 01-30-2015 at 04:47 PM.

#140

Old School Heavy

iTrader: (16)

Then once I know how much overlap in total is needed, I work on where that overlap period needs to start, and where it needs to finish. This would include choosing where the intake valve opens and where the exhaust valve closes. As I've mentioned earlier in this thread, where the intake valve opens and where the exhaust valve closes are based on pressures created in the intake port, cylinder and exhaust port/system.

There is also a benefit in opening the intake valve early that doesn't relate to pressure in cylinder or in the exhaust port/system during the overlap event. The sooner the intake valve is opened while the piston is on the exhaust stroke, the more lift you are able to achieve by the time the piston starts the intake stroke. Since the intake valve will have been opened much earlier, by the time the piston reaches top dead center you could quite possibly have .100"-.200" valve lift @TDC.

Since the cylinder head flows more air at higher lifts, if we can get the valve open further at the beginning of the intake stroke, we have more flow available to meet the demand for airflow in the cylinder which is created by the downwards motion of the piston and the speed it creates.

Of course in a perfect world we wouldn't have to open the intake valve so early and expose the intake tract to potential reversion issues as we'd just snap the intake valve open instantly to max lift. Since we live in a world that has rules based on physics, that would be an impossible feat to obtain. Even though having the valve open further when the piston starts the intake stroke is a benefit in terms of meeting piston CFM demands more efficiently, it can potentially lead to exposing the intake port to higher pressure spent exhaust gasses since the engine is still on the exhaust stroke when the intake valve opens. This would negate any potential gains in VE due to the reversion it would cause.

Balancing the intake opening event with pressure in the cylinder and trying to obtain the most amount of lift @TDC is the goal. Finding the sweet spot that is located somewhere in the middle is what you're after ultimately.

There is also a benefit in opening the intake valve early that doesn't relate to pressure in cylinder or in the exhaust port/system during the overlap event. The sooner the intake valve is opened while the piston is on the exhaust stroke, the more lift you are able to achieve by the time the piston starts the intake stroke. Since the intake valve will have been opened much earlier, by the time the piston reaches top dead center you could quite possibly have .100"-.200" valve lift @TDC.

Since the cylinder head flows more air at higher lifts, if we can get the valve open further at the beginning of the intake stroke, we have more flow available to meet the demand for airflow in the cylinder which is created by the downwards motion of the piston and the speed it creates.

Of course in a perfect world we wouldn't have to open the intake valve so early and expose the intake tract to potential reversion issues as we'd just snap the intake valve open instantly to max lift. Since we live in a world that has rules based on physics, that would be an impossible feat to obtain. Even though having the valve open further when the piston starts the intake stroke is a benefit in terms of meeting piston CFM demands more efficiently, it can potentially lead to exposing the intake port to higher pressure spent exhaust gasses since the engine is still on the exhaust stroke when the intake valve opens. This would negate any potential gains in VE due to the reversion it would cause.

Balancing the intake opening event with pressure in the cylinder and trying to obtain the most amount of lift @TDC is the goal. Finding the sweet spot that is located somewhere in the middle is what you're after ultimately.

The early IVO is a perfect example of that. On the topic of the IVO, I would also add, which you have mentioned before, that peak piston speed and hence peak demand for flow happens in the 70s degrees After Top Dead Center depending on the rod ratio. So, getting that valve open early can be very beneficial for getting the most out of the headflow.

On this topic, I really liked what Geoff Skinner said. He said he chooses the EVC last. He uses that to get the desired amount of overlap because his IVO has already been chosen for the reasons we talk about above. I really saw examples of this thought process on some of the cams that Brett Bauer created for some max effort 6 liter stuff. The exhaust valve close was much more ATDC than the IVO was BTDC. Because of this the cam had a 26 degree duration split too. It looked unorthodox at first glance, but that camshaft made stupid big HP for a 6 liter deal and are still some of the most powerful 6 liter combos I have in my data.