rocker questions

#4

10 Second Club

iTrader: (8)

Join Date: Feb 2004

Location: Milwaukee, WI

Posts: 2,846

Likes: 0

Received 0 Likes

on

0 Posts

I agree don't get the 1.8's if you ever plan on doing a cam swap. Get the cam now and the rockers after. You won't see much if any gain from a rocker swap. Stock rockers work on many cams.

#6

10 Second Club

iTrader: (3)

Join Date: Mar 2004

Location: orlando, fl

Posts: 4,266

Likes: 0

Received 0 Likes

on

0 Posts

you can use the 1.8 and do a cam swap later if you so desire. you just have to choose a cam that'll best benefit with the rockers.

here's my dyno of the vinci/crane 1.8 accelerated lift rockers on the wife's 99 formula with stock cam

dyno 9 before

dyno 11 500 miles later

dyno 14 10 months later

here's my dyno of the vinci/crane 1.8 accelerated lift rockers on the wife's 99 formula with stock cam

dyno 9 before

dyno 11 500 miles later

dyno 14 10 months later

#7

10 Second Club

iTrader: (3)

Join Date: Mar 2004

Location: orlando, fl

Posts: 4,266

Likes: 0

Received 0 Likes

on

0 Posts

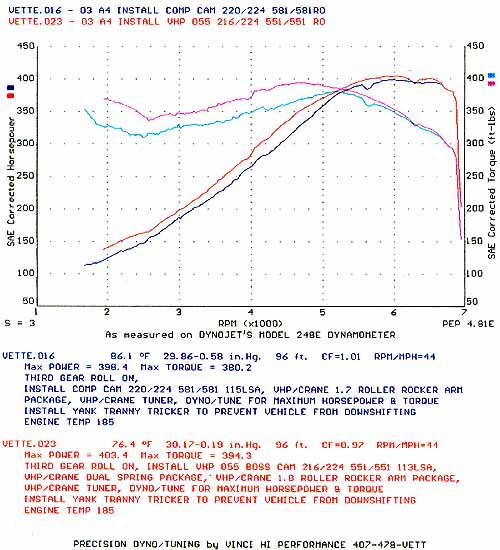

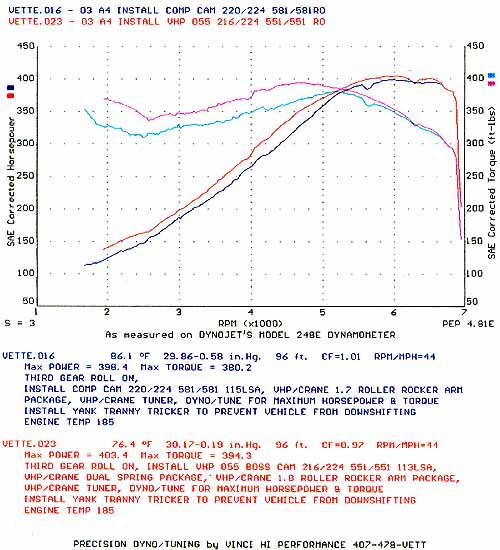

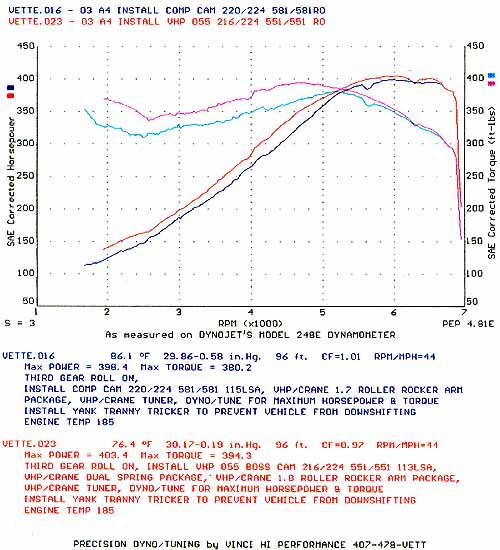

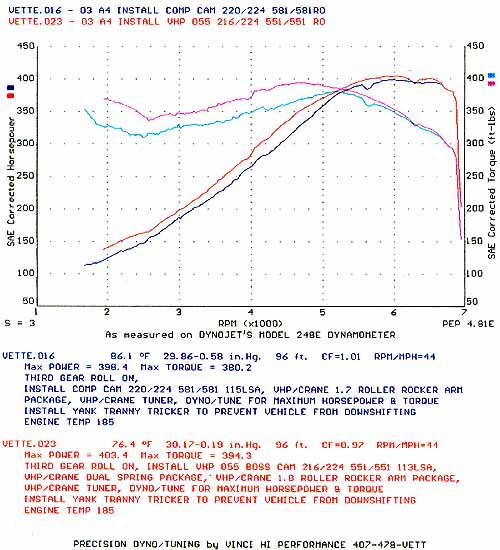

now case in point of using 1.8 rockers with after market cams. this is a dyno of the PROJECT AFR 03 corvette vinci is doing. it compares a comp cam 224/224 .581/.581 LSA 115 with 1.7 accelerated lift rockers VS vinci 055 216/224 .551/.551 (1.7) LSA 113 with 1.8 accelerated lift rockers. this brings the total lift to .583/.583. less cam, more rocker ratio (brings total lift to the same on both cams) did better overall.

Trending Topics

#10

On The Tree

Join Date: Apr 2004

Location: Quiet Place in the Country, FL

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by mrr23

now case in point of using 1.8 rockers with after market cams. this is a dyno of the PROJECT AFR 03 corvette vinci is doing. it compares a comp cam 224/224 .581/.581 LSA 115 with 1.7 accelerated lift rockers VS vinci 055 216/224 .551/.551 (1.7) LSA 113 with 1.8 accelerated lift rockers. this brings the total lift to .583/.583. less cam, more rocker ratio (brings total lift to the same on both cams) did better overall.

#11

TECH Senior Member

iTrader: (4)

If you are referring to my post above, I am simply quoting the guidance given by several vendors on cam selection. One quick look at Thunder Racing and you can see they don't advise the use of 1.8's on many of their cams. This is taken directly from their site: "Due to the fast ramp rate of this camshaft, the use of 1.8 rockers is not recommended."

#12

10 Second Club

iTrader: (3)

Join Date: Mar 2004

Location: orlando, fl

Posts: 4,266

Likes: 0

Received 0 Likes

on

0 Posts

might want to call them and ask why. is it because the valve springs they use not capable of controlling the valve? i don't think anyone has ever explained why other than fast ramp rates. i do not know why. maybe someone from TR will chime in and answer.

#13

On The Tree

Join Date: Apr 2004

Location: Quiet Place in the Country, FL

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by vettenuts

If you are referring to my post above, I am simply quoting the guidance given by several vendors on cam selection. One quick look at Thunder Racing and you can see they don't advise the use of 1.8's on many of their cams. This is taken directly from their site: "Due to the fast ramp rate of this camshaft, the use of 1.8 rockers is not recommended."

#15

11 Second Club

Join Date: Nov 2001

Location: NE PA

Posts: 1,320

Likes: 0

Received 0 Likes

on

0 Posts

I'm using the Crane 1.80 Quick-Lift rockers in my motor. I had a custom grind cam specifically made to use with them. It's a Cam Motion cam that I supplied the specs for and obtained through Futral. As most know, the Futral/Cam Motion cams may not be the most aggressive available, but their ramp rates are definitely on the aggressive side.

This cam and the Crane 1.80 rockers work just fine together and this combination is yielding good power for me so I think the idea of fast ramp rates and higher ratio rockers not working together is based on opinion and not fact. Also, keep in mind that the new 500 hp, 7000 rpm redline, LS7 motor has a pretty stout cam and it comes with 1.80 rockers from the factory.

Here's a dyno graph from the last tune with the mods in my sig.

This cam and the Crane 1.80 rockers work just fine together and this combination is yielding good power for me so I think the idea of fast ramp rates and higher ratio rockers not working together is based on opinion and not fact. Also, keep in mind that the new 500 hp, 7000 rpm redline, LS7 motor has a pretty stout cam and it comes with 1.80 rockers from the factory.

Here's a dyno graph from the last tune with the mods in my sig.

#16

TECH Senior Member

The only problem with the stock ones are the bearing issues.

Most if not all aftermarkets have had clearance issues or floating issues.

One of the solutions is to send your rockers to Nasty's and get them fitted with new trunions and c-clip kit from Harland. ~200 bucks.

It is much better to try to keep yor stock 1.7 ratio as much as possible.

The CRANE 1.7's are nice but mucho $$$ for the swap IMO. ~ $600+ That money could get a cam kit.

Most if not all aftermarkets have had clearance issues or floating issues.

One of the solutions is to send your rockers to Nasty's and get them fitted with new trunions and c-clip kit from Harland. ~200 bucks.

It is much better to try to keep yor stock 1.7 ratio as much as possible.

The CRANE 1.7's are nice but mucho $$$ for the swap IMO. ~ $600+ That money could get a cam kit.

#17

On The Tree

Join Date: Apr 2004

Location: Quiet Place in the Country, FL

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 01TA

I believe the issue would be with possible valveguide wear from the extra stress of the 1.8 ratio on top of the TR or XER cams already very fast ramps.

#18

On The Tree

Join Date: Apr 2004

Location: Quiet Place in the Country, FL

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by PREDATOR-Z

The only problem with the stock ones are the bearing issues.

Most if not all aftermarkets have had clearance issues or floating issues.

One of the solutions is to send your rockers to Nasty's and get them fitted with new trunions and c-clip kit from Harland. ~200 bucks.

It is much better to try to keep yor stock 1.7 ratio as much as possible.

The CRANE 1.7's are nice but mucho $$$ for the swap IMO. ~ $600+ That money could get a cam kit.

Most if not all aftermarkets have had clearance issues or floating issues.

One of the solutions is to send your rockers to Nasty's and get them fitted with new trunions and c-clip kit from Harland. ~200 bucks.

It is much better to try to keep yor stock 1.7 ratio as much as possible.

The CRANE 1.7's are nice but mucho $$$ for the swap IMO. ~ $600+ That money could get a cam kit.

#19

TECH Senior Member

I mispunctuated I meant that:

"Most if not all aftermarkets have had clearance issues. Or some floating issues."

you are absolutely right on with regards to "no concrete proof of rockers causing float", but I've seen a few people switch to aftermarkets, have float, then switch back to stockers and float dissapears.

One thing that baffles me is that if aftermarkets were so necessary why can't anyone just make one roller tiped rocker, that just fits under the covers.

Most sponsors here just reuse the stockers on their motor build ups.

"Most if not all aftermarkets have had clearance issues. Or some floating issues."

you are absolutely right on with regards to "no concrete proof of rockers causing float", but I've seen a few people switch to aftermarkets, have float, then switch back to stockers and float dissapears.

One thing that baffles me is that if aftermarkets were so necessary why can't anyone just make one roller tiped rocker, that just fits under the covers.

Most sponsors here just reuse the stockers on their motor build ups.

#20

11 Second Club

Join Date: Nov 2001

Location: NE PA

Posts: 1,320

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by PREDATOR-Z

One thing that baffles me is that if aftermarkets were so necessary why can't anyone just make one roller tiped rocker, that just fits under the covers.

Most sponsors here just reuse the stockers on their motor build ups.

Most sponsors here just reuse the stockers on their motor build ups.

As far as "most" reusing the stockers on their motor buildups, that is changing more and more everyday and all the motors I've seen built this year so far had one brand or another roller tip rockers on their heads. Even if you're going to stick with the stock ratio, it only makes sense to use roller tip rockers if you want to get the most out of your motor. I don't think anyone at this last date is going to argue that roller tip rockers don't make more power.