leak......pissed help

#1

12 Second Club

Thread Starter

iTrader: (3)

Join Date: Apr 2004

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

I'm so ******* pissed off right now... It's snowing out and I went to the shop and uploaded a pre-dyno tune into my car cranked her up and it started and idled magnificently.....then from no where I see this reddish liquid coming from down under..........coolant....WTF! all the bolts were torqued accordingly...I put 6 miles on it last night and saw no leakage....wtf is up..... my buddy @ the Pontiac dealership is ordering me new head gaskets tomarrow... here goes another 6 hours of my life ohhh well.....any ideas... no coolant in the oil.....checked..just seeping from the drivers side.......

so I went from cloud 9 to -6 but the car sounds awesome...

(just did a cam and heads install)

so I went from cloud 9 to -6 but the car sounds awesome...

(just did a cam and heads install)

#4

12 Second Club

iTrader: (13)

Join Date: Nov 2001

Location: San Diego, CA

Posts: 1,898

Likes: 0

Received 0 Likes

on

0 Posts

Can you see clearly where the coolant is leaking from ?

It could also be the coolant lines/plugs at the top/back of the heads... Id' check them before pulling the heads again.

Rob (Bad30th)

It could also be the coolant lines/plugs at the top/back of the heads... Id' check them before pulling the heads again.

Rob (Bad30th)

#7

TECH Junkie

Join Date: Dec 2001

Location: Lakeland, FL

Posts: 3,242

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Bad30th

Can you see clearly where the coolant is leaking from ?

It could also be the coolant lines/plugs at the top/back of the heads... Id' check them before pulling the heads again.

Rob (Bad30th)

It could also be the coolant lines/plugs at the top/back of the heads... Id' check them before pulling the heads again.

Rob (Bad30th)

DITTO this happened to me also its like a 2.50 cent part to get direct from the factory, If you over tighten the plugs they will leak. Check this first you can see it if you just lift the car and shine a flashlight up by the rear of the heads from underneath if you see a straight line going down the heads from the top that is real shiny you found your culprit.

If you look in the radiator does it look milky? If it does then i doubt it is the plugs but do yourself a favor and check em cause you can fix it in 15 minutes.

Trending Topics

#9

12 Second Club

iTrader: (6)

Ditto too, didn't realize on passenger rear head you need the coolant plug from your old heads. The driver's side has the coolant connection ( screw in with electrical connection ) so you're fine there. I freaked when I saw it but it was immediately after starting it up and getting to temp that it started flowing like mad.

#10

TECH Addict

iTrader: (2)

Join Date: Oct 2004

Location: Miami, Fl.

Posts: 2,890

Likes: 0

Received 0 Likes

on

0 Posts

old thread but identical problem.

Just got the head (passenger side) on there and at first, i saw nothing. But this morning, i was letting here run for a bit before work and i noticed a small leak or pool coming from the pass head. Its seeping between the head and the block, almost right under the front coolant crossover piece.

So, what should i look for? I torque'd the heads down at 70inch/lbs in the prescribed method. I cleaned out the bolt holes as much as possible and i used a new 6.0l head gasket.

Can a little swab of gasket maker, high temp stuff do the trick or is that just another one of my band-aid fix ideas?

Just got the head (passenger side) on there and at first, i saw nothing. But this morning, i was letting here run for a bit before work and i noticed a small leak or pool coming from the pass head. Its seeping between the head and the block, almost right under the front coolant crossover piece.

So, what should i look for? I torque'd the heads down at 70inch/lbs in the prescribed method. I cleaned out the bolt holes as much as possible and i used a new 6.0l head gasket.

Can a little swab of gasket maker, high temp stuff do the trick or is that just another one of my band-aid fix ideas?

#13

12 Second Club

iTrader: (6)

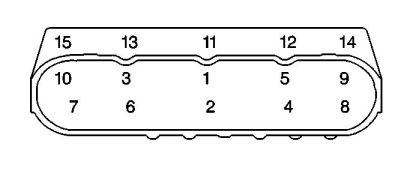

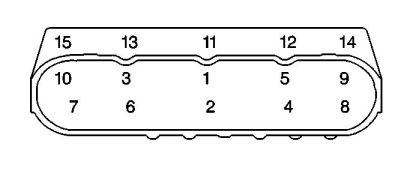

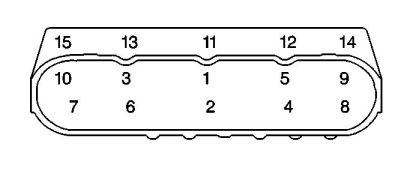

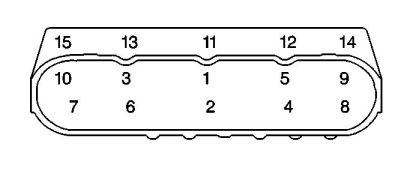

FROM LS1HOWTO.COM:

Now, grab a socket wrench and lightly turn the bolts until they stop. Now for the very precise part. You need to get your torque wrench out now and fit it with a 3" extension and a 15mm socket.

Using the sequence illustrated above, torque all 10 15mm bolts to 22lb-ft.

OPTIONAL: Safety check! One one side of the motor install 2 pushrods (one exhaust, one intake), the rocker pedestal, and two rockers...then turn the motor over by hand two full turns. While this method wont be exact, if the engine didn't stop when you were turning it you most likely installed the cam correctly. If it felt like it stopped at one point and wouldn't go further, chances are a piston is hitting a valve and you need to disassemble things and go back to the dot to dot part, OR, your cam is huge and the piston to valve clearance is ZERO (it'd take a really big cam for this to happen)

Ok, now for a GREAT tip from Scott99Z. Take a felt tip marker and draw a horizontal line on the head of each bolt. This is very important.

Now, using the sequence illustrated above, turn all 10 15mm bolts an additional 90 degrees using a large socket wrench and a lot of muscle. Try to get as close to 90 degrees as possible...you may have to do multiple turns of 30 degrees or 2 turns of 45 degrees. When done all the lines on the bolt heads should be totally vertical.

Next, again using the sequence above, turn bolts 1 through 8 another 90 degrees. This will take an immense amount of effort...if you have a buddy helping both of you should turn the wrench simultaniously. These 8 bolts will now all have horizontal lines on them

Using the sequence above, turn bolts 9 and 10 an additional 50 degrees. Again, this will take a lot of effort. 50 degrees should result in a diagonal line on the bolts

Finally, using the sequence above, torque bolts 11 through 15 to 22 lb-ft.

Now, grab a socket wrench and lightly turn the bolts until they stop. Now for the very precise part. You need to get your torque wrench out now and fit it with a 3" extension and a 15mm socket.

Using the sequence illustrated above, torque all 10 15mm bolts to 22lb-ft.

OPTIONAL: Safety check! One one side of the motor install 2 pushrods (one exhaust, one intake), the rocker pedestal, and two rockers...then turn the motor over by hand two full turns. While this method wont be exact, if the engine didn't stop when you were turning it you most likely installed the cam correctly. If it felt like it stopped at one point and wouldn't go further, chances are a piston is hitting a valve and you need to disassemble things and go back to the dot to dot part, OR, your cam is huge and the piston to valve clearance is ZERO (it'd take a really big cam for this to happen)

Ok, now for a GREAT tip from Scott99Z. Take a felt tip marker and draw a horizontal line on the head of each bolt. This is very important.

Now, using the sequence illustrated above, turn all 10 15mm bolts an additional 90 degrees using a large socket wrench and a lot of muscle. Try to get as close to 90 degrees as possible...you may have to do multiple turns of 30 degrees or 2 turns of 45 degrees. When done all the lines on the bolt heads should be totally vertical.

Next, again using the sequence above, turn bolts 1 through 8 another 90 degrees. This will take an immense amount of effort...if you have a buddy helping both of you should turn the wrench simultaniously. These 8 bolts will now all have horizontal lines on them

Using the sequence above, turn bolts 9 and 10 an additional 50 degrees. Again, this will take a lot of effort. 50 degrees should result in a diagonal line on the bolts

Finally, using the sequence above, torque bolts 11 through 15 to 22 lb-ft.

#14

TECH Addict

iTrader: (2)

Join Date: Oct 2004

Location: Miami, Fl.

Posts: 2,890

Likes: 0

Received 0 Likes

on

0 Posts

If using ARP headbolts:

Apply the moly lube that came with the ARP bolts to the threads, as well as under the head of the bolt and both sides of the washer. Only a light coating is needed. If you don't have the included moly lube, put some motor oil on the threads.

Torque all 15mm bolts to 30lbft in the torque sequence above.

OPTIONAL: Safety check! One one side of the motor install 2 pushrods (one exhaust, one intake), the rocker pedestal, and two rockers...then turn the motor over by hand two full turns. While this method wont be exact, if the engine didn't stop when you were turning it you most likely installed the cam correctly. If it felt like it stopped at one point and wouldn't go further, chances are a piston is hitting a valve and you need to disassemble things and go back to the dot to dot part, OR, your cam is huge and the piston to valve clearance is ZERO (it'd take a really big cam for this to happen)

Do a second pass at 50lbft, and finally a 3rd at 70lbft.

Finally install the 5 smaller ARP bolts and torque them to 22lbft.

Apply the moly lube that came with the ARP bolts to the threads, as well as under the head of the bolt and both sides of the washer. Only a light coating is needed. If you don't have the included moly lube, put some motor oil on the threads.

Torque all 15mm bolts to 30lbft in the torque sequence above.

OPTIONAL: Safety check! One one side of the motor install 2 pushrods (one exhaust, one intake), the rocker pedestal, and two rockers...then turn the motor over by hand two full turns. While this method wont be exact, if the engine didn't stop when you were turning it you most likely installed the cam correctly. If it felt like it stopped at one point and wouldn't go further, chances are a piston is hitting a valve and you need to disassemble things and go back to the dot to dot part, OR, your cam is huge and the piston to valve clearance is ZERO (it'd take a really big cam for this to happen)

Do a second pass at 50lbft, and finally a 3rd at 70lbft.

Finally install the 5 smaller ARP bolts and torque them to 22lbft.

#15

TECH Addict

iTrader: (2)

Join Date: Oct 2004

Location: Miami, Fl.

Posts: 2,890

Likes: 0

Received 0 Likes

on

0 Posts

this is how i did it...

three passes, 25lbs, 50lbs, 70lbs.

I read that someone went 80lbs, should i try this or will it cause an issue?

also, i JUST got this gasket, i know that we should reuse them but in al seriousness, i wont get another for a couple days, can i reuse this gasket? ITs been on for two days and ran no more than 30 minutes.

three passes, 25lbs, 50lbs, 70lbs.

I read that someone went 80lbs, should i try this or will it cause an issue?

also, i JUST got this gasket, i know that we should reuse them but in al seriousness, i wont get another for a couple days, can i reuse this gasket? ITs been on for two days and ran no more than 30 minutes.

#16

TECH Senior Member

iTrader: (4)

What did you use for lube, the 70 lb-ft is based on the ARP moly lube and anything else will change the torque requirement to get the right preload on the bolt. Also, one other thought, there were some problems a while back with ARP bolts bottoming in the hole because the block wasn't tapped deep enough and the head gasket started leaking.

#17

TECH Addict

iTrader: (2)

Join Date: Oct 2004

Location: Miami, Fl.

Posts: 2,890

Likes: 0

Received 0 Likes

on

0 Posts

well, as for the arp bolts "defective", i've had the motor running before this for almost 3k miles and this is the first leak i get.

Hmm, now you got me thinking... i didn't use their moly lube, since i couldn't find any around and my local speed shop was out. (unbelieveable!!) anyways, so i sued some graphite (grey) anti-sieze from prematex and coated the bolts, and subsiquently everything else i touched for a day, heavy.

MAybe this is it. So, should i torque them down a bit more maybe to 90ft/lbs. or 95ft/lbs.? 100ft/lbs even....

as a last resort, a buddy of mine, manager at the auto parts store, recommended this stuff, Permanent Metallic Block Seal. It seals head gaskets, blocks, radiators. However, it is no compatible with anitfreeze so a thorough flush of the radiator is necesary to use this stuff...

any comments on this product?

Hmm, now you got me thinking... i didn't use their moly lube, since i couldn't find any around and my local speed shop was out. (unbelieveable!!) anyways, so i sued some graphite (grey) anti-sieze from prematex and coated the bolts, and subsiquently everything else i touched for a day, heavy.

MAybe this is it. So, should i torque them down a bit more maybe to 90ft/lbs. or 95ft/lbs.? 100ft/lbs even....

as a last resort, a buddy of mine, manager at the auto parts store, recommended this stuff, Permanent Metallic Block Seal. It seals head gaskets, blocks, radiators. However, it is no compatible with anitfreeze so a thorough flush of the radiator is necesary to use this stuff...

any comments on this product?

#18

TECH Senior Member

iTrader: (4)

Don't put in the goop, you will have clogged everything. Call the ARP tech line, they are still there on the west coast. Tell them exactly how you installed them and what you used, get their advice. Make sure you tell them aluminum block and heads.

Also, one other thought, have you re-checked the torque on a cold motor? The outer bolts are pretty accessible, might be worth checking one to see if it is still at 70 lb-ft.

Also, one other thought, have you re-checked the torque on a cold motor? The outer bolts are pretty accessible, might be worth checking one to see if it is still at 70 lb-ft.

#19

TECH Addict

iTrader: (2)

Join Date: Oct 2004

Location: Miami, Fl.

Posts: 2,890

Likes: 0

Received 0 Likes

on

0 Posts

right, just did that. Real friendly ppl actually!!!!

But its a iron block, aluminum heads.... haha just messing with ya!!!!

Anyways, spoke to the tech, robert i think, and he said take all teh nuts off and re torque them down to a suggested 85ft/lbs.

Do you think 90ft/lbs would be ok?

But its a iron block, aluminum heads.... haha just messing with ya!!!!

Anyways, spoke to the tech, robert i think, and he said take all teh nuts off and re torque them down to a suggested 85ft/lbs.

Do you think 90ft/lbs would be ok?