ARP 12pt head stud torque specs?

#1

On The Tree

Thread Starter

iTrader: (1)

Join Date: Oct 2004

Posts: 178

Likes: 0

Received 0 Likes

on

0 Posts

anyone know what the torque specs are for the big nuts and the little nuts? i got the sequence just not the specs. also what size sockets will i need? thanks

#5

TECH Senior Member

iTrader: (4)

I spoke with ARP on this:

Small bolts: 23 lb-ft

Large nuts: 70 lb-ft

All values are measured with their Assembly Lube. Something different may result in different torque values. Use a three step tightening sequence.

I have looked at the Blackcamaro procedure, it doesn't make sense to me why you "pre-stretch" studs. They are elastic, no need to do this.

Small bolts: 23 lb-ft

Large nuts: 70 lb-ft

All values are measured with their Assembly Lube. Something different may result in different torque values. Use a three step tightening sequence.

I have looked at the Blackcamaro procedure, it doesn't make sense to me why you "pre-stretch" studs. They are elastic, no need to do this.

#6

SSU's Drunk Typing Whore

iTrader: (47)

Join Date: Jan 2004

Posts: 4,609

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Paulz2820

that website doesn't work...memory got yah down?

It should work - I ll post a direct link for ya.

http://www.blackcamaro.com/headstud.htm

#7

SSU's Drunk Typing Whore

iTrader: (47)

Join Date: Jan 2004

Posts: 4,609

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by vettenuts

I spoke with ARP on this:

Small bolts: 23 lb-ft

Large nuts: 70 lb-ft

All values are measured with their Assembly Lube. Something different may result in different torque values. Use a three step tightening sequence.

I have looked at the Blackcamaro procedure, it doesn't make sense to me why you "pre-stretch" studs. They are elastic, no need to do this.

Small bolts: 23 lb-ft

Large nuts: 70 lb-ft

All values are measured with their Assembly Lube. Something different may result in different torque values. Use a three step tightening sequence.

I have looked at the Blackcamaro procedure, it doesn't make sense to me why you "pre-stretch" studs. They are elastic, no need to do this.

Trending Topics

#8

Staging Lane

iTrader: (5)

Join Date: Dec 2003

Location: Beaumont, TX

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

It isn't "prestretching" that you are doing when you torque these nuts several times. The torque READING will be affected by friction from microscopic imperfections on the surface of the threads that are smoothed down by the process of torquing the fasteners several times.

Torquing them, then loosening, several times, seasons the mating surfaces of the threads, and eliminates that friction as a factor that affects torque readings.

Torquing them, then loosening, several times, seasons the mating surfaces of the threads, and eliminates that friction as a factor that affects torque readings.

#11

Staging Lane

iTrader: (5)

Join Date: Dec 2003

Location: Beaumont, TX

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

From the ARP tech pages:

So...ARP sez even with the approved lube, you should tighten and loosen several times.

(in best Forrest Gump voice) "...and that's all I got to say about that."

"Friction is an extremely challenging problem because it is so variable and difficult to control. The best way to avoid the pitfalls of friction is by using the stretch method. This way preload is controlled and independent of friction. Each time the bolt is torqued and loosened, the friction factor gets smaller. Eventually the friction levels out and becomes constant for all following repetitions. Therefore, when installing a new bolt where the stretch method cannot be used, the bolt should be tightened and loosened several times before final torque. The number of cycles depends on the lubricant. For ARP recommended lubes, five loosening and tightening cycles is sufficient." (Bold in original)

That and more can be found at http://www.arp-bolts.com/Tech/TechInstall.htmlSo...ARP sez even with the approved lube, you should tighten and loosen several times.

(in best Forrest Gump voice) "...and that's all I got to say about that."

#13

11 Second Club

iTrader: (9)

I tend to think they mean "all fasteners", bolts or studs.

Using a Torque Wrench

If the stretch method cannot be used in a particular installation, and the fasteners must be installed by torque alone, there are certain factors that should be taken into account. ARP research has verified the following “rules” pertaining to use of a torque wrench:

1. The friction factor changes from one application to the next. That is, the friction is at its highest value when the fastener is first tightened. Each additional time the fastener is torqued and loosened, this value gets smaller. Eventually the friction levels out and becomes constant for all following repetitions. Therefore, new fasteners should be tightened and loosened through several cycles before applying final torque. The number of times depends on the lubricant. For all situations where ARP lubricants are used, five cycles are required before final torquing.

2. The lubricant used is the main factor in determining friction, and therefore, the torque for a particular installation. Motor oil is a commonly used lubricant because of it’s ready availability. If less friction is desired in order to install the fasteners with less torque, special low friction lubricants are available. With special lubes, the required torque can be reduced as much as 20 to 30 percent. It is important to keep in mind that the reverse is also true. If the torque value has been specified for a particular fastener on the basis of low friction lube, installing the fastener with motor oil will result in insufficient preload; the torque has to be increased to compensate for the extra friction caused by the motor oil.

3. Surface finish is also important. For example, black oxide behaves differently than a polished fastener. It is therefore important to observe the torque recommendations supplied with each fastener.

NOTE: It is possible for even the most expensive of torque wrenches to lose accuracy. We have seen fluctuations of as much as ten (10) foot pounds of torque from wrench to wrench. Please have your torque wrench checked periodically for accuracy

Using a Torque Wrench

If the stretch method cannot be used in a particular installation, and the fasteners must be installed by torque alone, there are certain factors that should be taken into account. ARP research has verified the following “rules” pertaining to use of a torque wrench:

1. The friction factor changes from one application to the next. That is, the friction is at its highest value when the fastener is first tightened. Each additional time the fastener is torqued and loosened, this value gets smaller. Eventually the friction levels out and becomes constant for all following repetitions. Therefore, new fasteners should be tightened and loosened through several cycles before applying final torque. The number of times depends on the lubricant. For all situations where ARP lubricants are used, five cycles are required before final torquing.

2. The lubricant used is the main factor in determining friction, and therefore, the torque for a particular installation. Motor oil is a commonly used lubricant because of it’s ready availability. If less friction is desired in order to install the fasteners with less torque, special low friction lubricants are available. With special lubes, the required torque can be reduced as much as 20 to 30 percent. It is important to keep in mind that the reverse is also true. If the torque value has been specified for a particular fastener on the basis of low friction lube, installing the fastener with motor oil will result in insufficient preload; the torque has to be increased to compensate for the extra friction caused by the motor oil.

3. Surface finish is also important. For example, black oxide behaves differently than a polished fastener. It is therefore important to observe the torque recommendations supplied with each fastener.

NOTE: It is possible for even the most expensive of torque wrenches to lose accuracy. We have seen fluctuations of as much as ten (10) foot pounds of torque from wrench to wrench. Please have your torque wrench checked periodically for accuracy

#14

Originally Posted by Paulz2820

that website doesn't work...memory got yah down?

BTW for those skipping the pre-stretching (what ARP referred to it as, whether it is stretching or just working the threads, whatever), I also cut a couple corners the first time, 2 weeks later the heads were loose enough that coolant was dripping out the corners and I could turn a few of the nuts by HAND!

The second time around after fully removing and cleaning the heads again, I did the full procedure including 3 passes at the final torque, and they held for good. Well worth the extra 30 mins instead of 8 hours later doing it all over again.....

-Dave

#15

TECH Senior Member

iTrader: (4)

OK, because none of this makes sense to me I contacted ARP. The reason it doesn't make sense to me is that there is a head gasket that would be getting loaded five times prior to final tightening.

The ARP tech told me the web site is referring to rod bolts, not head bolts/studs. For head bolts/studs, they recommend around 20 lb-ft increments to maximum torque. For the LS1 kit 234-4316, which I have, the final numbers are 70 lb-ft and 23 lb-ft.

The ARP tech told me the web site is referring to rod bolts, not head bolts/studs. For head bolts/studs, they recommend around 20 lb-ft increments to maximum torque. For the LS1 kit 234-4316, which I have, the final numbers are 70 lb-ft and 23 lb-ft.

#16

Originally Posted by vettenuts

OK, because none of this makes sense to me I contacted ARP. The reason it doesn't make sense to me is that there is a head gasket that would be getting loaded five times prior to final tightening.

The ARP tech told me the web site is referring to rod bolts, not head bolts/studs. For head bolts/studs, they recommend around 20 lb-ft increments to maximum torque. For the LS1 kit 234-4316, which I have, the final numbers are 70 lb-ft and 23 lb-ft.

The ARP tech told me the web site is referring to rod bolts, not head bolts/studs. For head bolts/studs, they recommend around 20 lb-ft increments to maximum torque. For the LS1 kit 234-4316, which I have, the final numbers are 70 lb-ft and 23 lb-ft.

Whatever, after my ordeal, I was happy to follow their procedure and it worked out perfectly.

-Dave

#17

TECH Senior Member

iTrader: (4)

My instruction sheet makes not mention of it. Now the person who answered the phone was not technically savvy, but I had him consult the lead tech so I hopefully got good answers. This is my second call on this and the answers are the same for both calls.

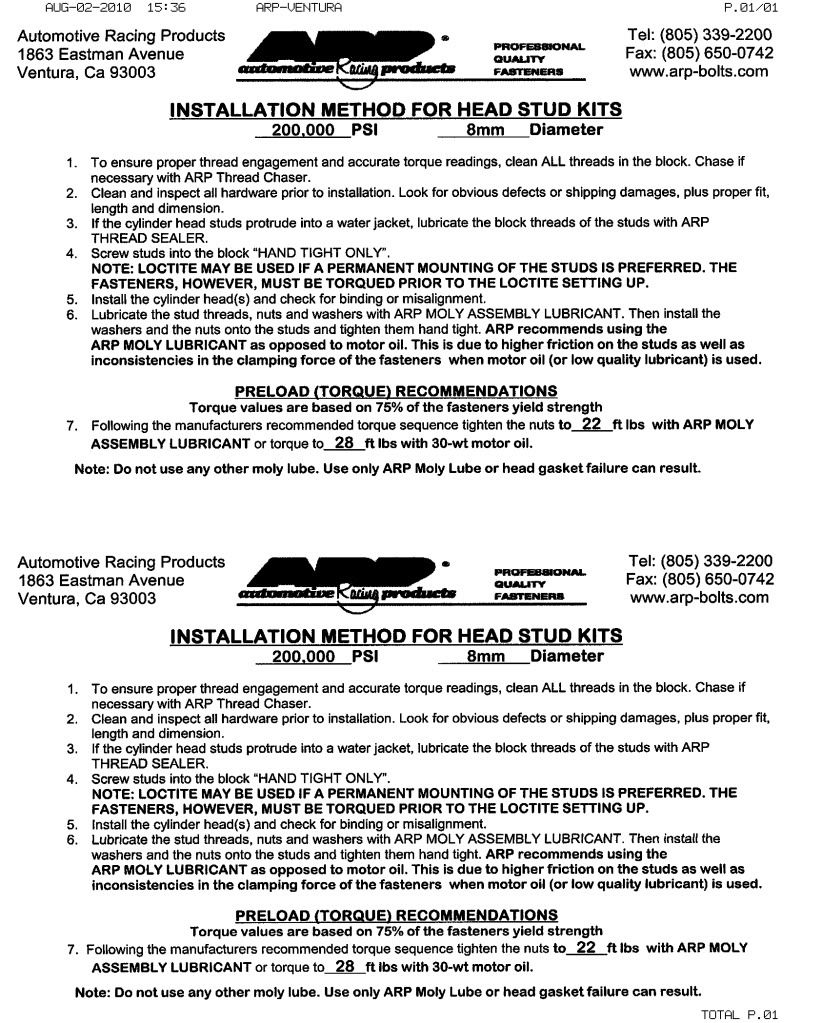

My instructions state "Torque values are based on 75% of the fasteners yield strength. Use the manufacturers torque sequence but ndo not use the engine manufacturers torque specs."

My instructions state "Torque values are based on 75% of the fasteners yield strength. Use the manufacturers torque sequence but ndo not use the engine manufacturers torque specs."

#19

TECH Regular

iTrader: (17)

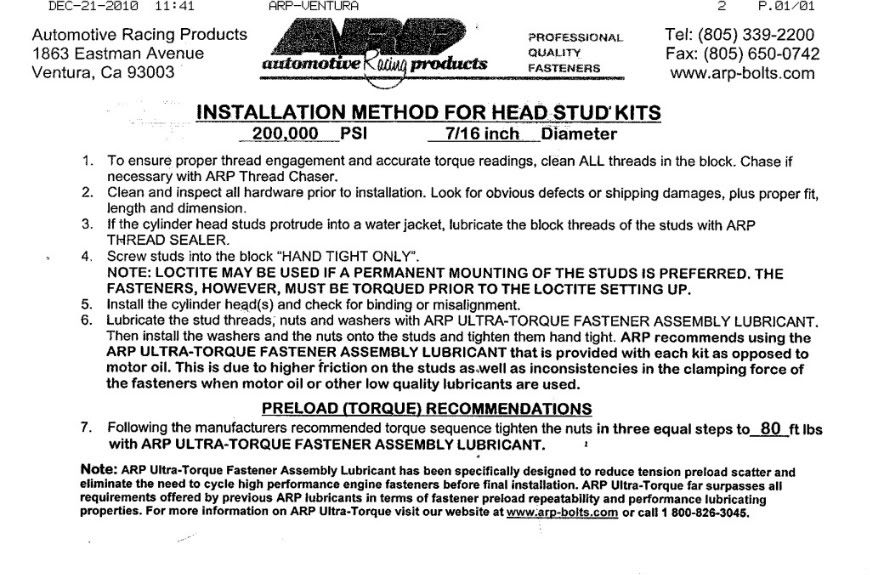

Since I misplaced my paperwork, I pulled the search up in Google and this came up. Things have changed since these specs were posted. In case anyone else happens to pull this thread up from the dead, I wanted to take the opportunity to post the proper specs as of today. Use of their Ultra Torque lubricant is highly recommended because it's the best guarantee you'll get that you'll get the proper yield on the first full torque pass and each successive pass.

Here's a great video on the results of using various lubricants.

The spec for ARP 2000's on the LS motor is three equal steps to 80 ft lbs on the 7/16" studs and three equal steps to 25 on the 5/16" studs.

Here's a link to the instructions. http://arpinstructions.com/instructions/234-4316.pdf

Here's a great video on the results of using various lubricants.

The spec for ARP 2000's on the LS motor is three equal steps to 80 ft lbs on the 7/16" studs and three equal steps to 25 on the 5/16" studs.

Here's a link to the instructions. http://arpinstructions.com/instructions/234-4316.pdf