Odd question about checking piston to wall clearance

#1

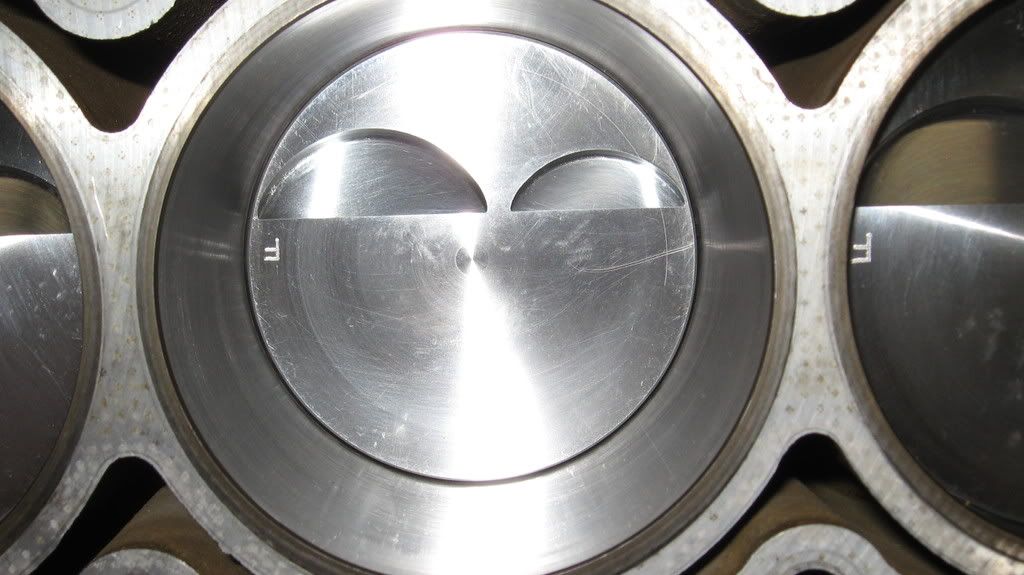

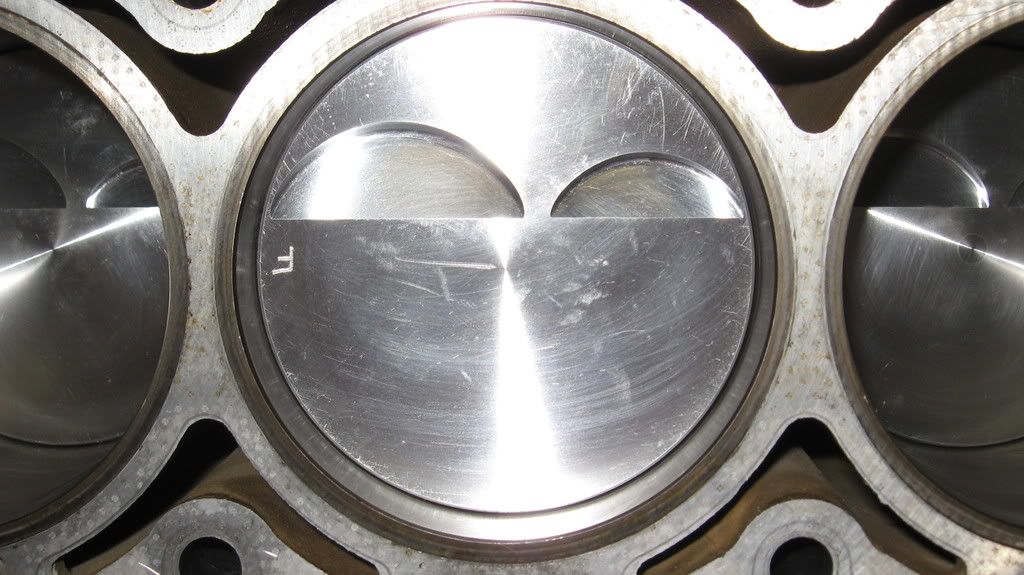

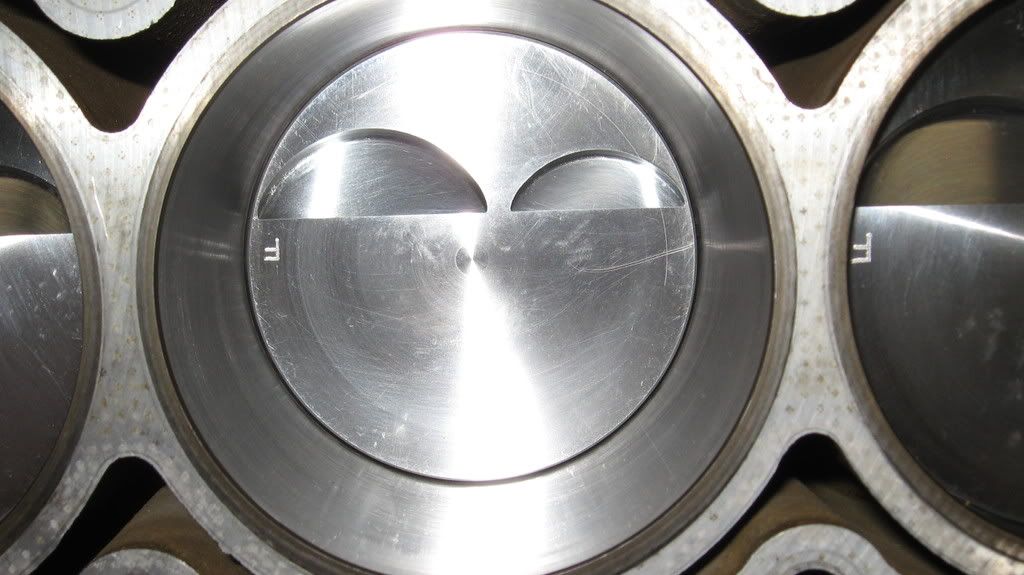

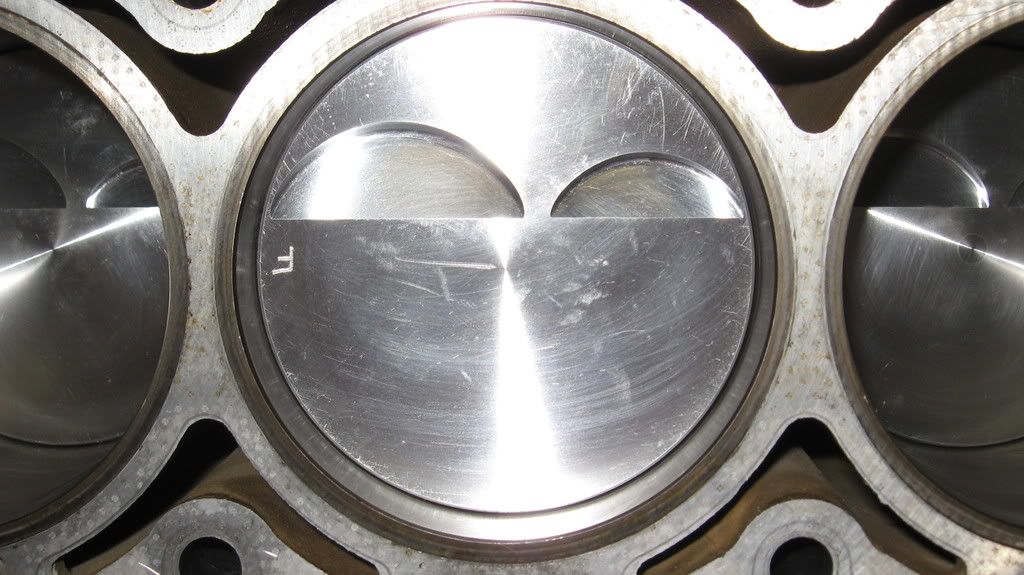

I had the bores bored/honed to 3.905 recently to fit the Diamond pistons that I bought. I am planning on spraying on it later probably around 250 or 300 so I know the clearances are suppose to be a little looser between the piston and outer wall. I installed the pistons last week and everything looks pretty good but to me some of the clearances "look" a little tight. I know it sounds crazy for me to say that it simply "looks" a little tight but I'm just trying to make sure everything is taken care of and checked and double checked before I start this thing up and beat on it. I don't want any mistakes. I was wonding if I could check the clearances with a feeler gauge to get an accurate measurement. Or should I just stop being so particular about everything and just put it back together? Here's some pictures of the bores. What do you guys think?

#2

TECH Addict

iTrader: (9)

Join Date: Jun 2004

Location: Brunswick, Ga

Posts: 2,939

Likes: 0

Received 0 Likes

on

0 Posts

All the cylinders should be the same. You said , "some" . I'd check it. You can check it with a feeler gauge, but you'll need to take it back apart. Did you check the ring gap? I had my block honed and mine barely fit a .002 feeler gauge on the pistons. My speed pro rings gap checked at .020 in every cylinder. I was pretty happy everything was that tight. When engine building... measure 3 times, Torque once.

#4

All the cylinders should be the same. You said , "some" . I'd check it. You can check it with a feeler gauge, but you'll need to take it back apart. Did you check the ring gap? I had my block honed and mine barely fit a .002 feeler gauge on the pistons. My speed pro rings gap checked at .020 in every cylinder. I was pretty happy everything was that tight. When engine building... measure 3 times, Torque once.