Ouch... (Jesel rocker arm failure)

#1

I was coming home from the local hang out last weekend and the car started running funny. I figured I fouled a plug or something (although I never have before) because the car wasn't making any weird noises at all.

The next day I cranked it and sprayed some water on the header primaries. All were smoking hot except for the #7 cylinder. I pull the plug out and it looks a little dark but not too bad. I throw a new one in the wire and test it, definitely getting spark. Put it back in (new plug), crank it back up, still nothing. I let it sit until today, and decided to swap an injector. As I got ready to do that I figured I'd pull the valve cover just in case (4 bolts, I have relocated coils).

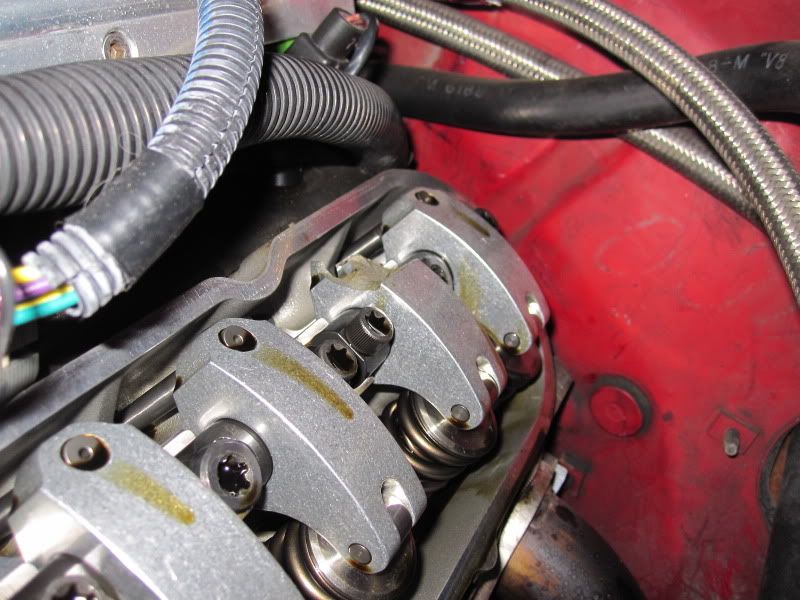

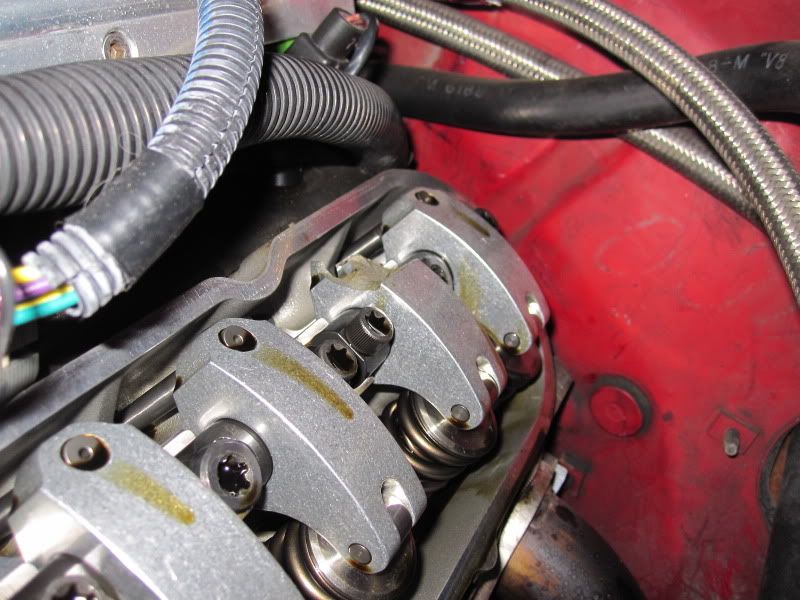

Here is what I find......

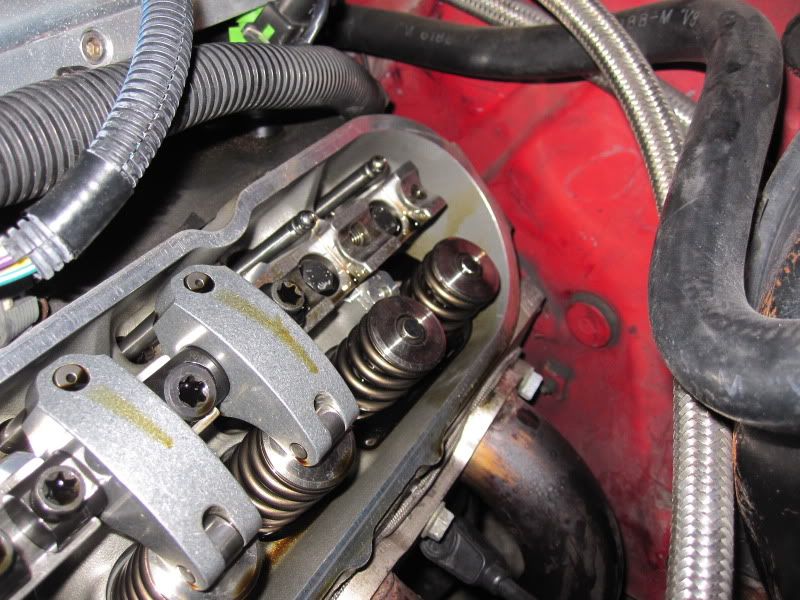

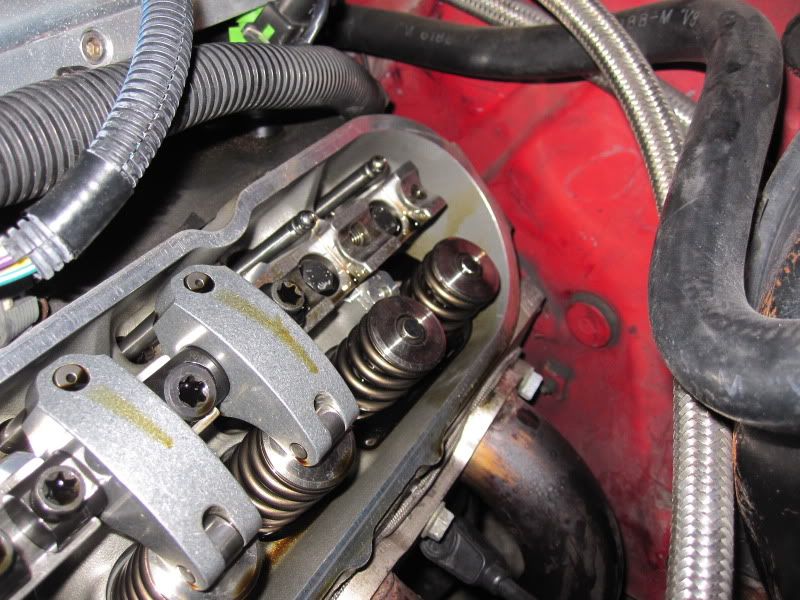

Does not look to be any other damage. When it broke, it shoved the lifter up and it stayed away from the cam. There isn't even a pushrod dent in the valve cover lol. The car did not make the SLIGHTEST noise from the valvetrain lol. I am calling Jesel tomorrow to see what they think. This is from my LME 408, Trickflow heads, Smith Brothers pushrods, etc. I'm super relieved that nothing else is wrong. These are the Jesel SS shaft mounted rockers ($900ish).

There's only around 6k on the whole motor. Those are nice valve springs/retainers, and I have a fairly small cam (242/246 .620). I also only turn it around 6800-7000. My pistons are relieved for the valves (Wiseco 8cc), so I highly doubt that I had a valve hit.

I'm not mad about it, as I know **** happens, but these are some really expensive rockers lol. It looks to me like there may have just been something wrong with the casting. Depending on how Jesel handles this, I will decide if I'm going to be pissed or not.

UPDATE!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! 11/3/09

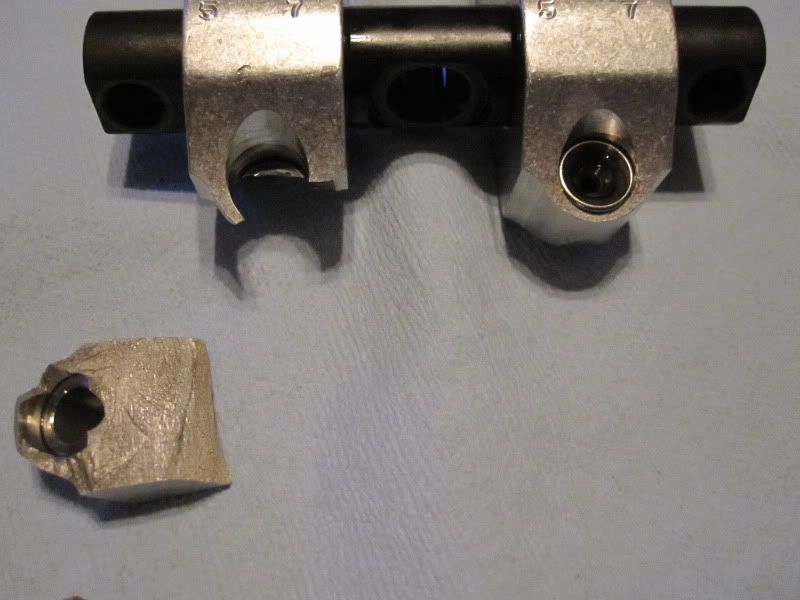

So it looks like the bottom of my rockers had been in contact with the rocker stand rails. This must have happened back when I had the huge cam. I figure the rocker arms clearanced themselves and then most likely didn't hit after I put the new (smaller) cam in. You can see the marks where they were rubbing. The marks between the 5 and 7 are from the top of the bolts that sit directly below the rockers.

I drug my feet for a while then got in touch with Jesel. Rob Remesi from Jesel returned my emails and was very nice. I told them about the interference issues and the problems that others have experienced. I also expressed the fact that I understood that this failure could have very well happened due to a general installation error. He swiftly reccomended that I send the rocker arms in for inspection and he would replace the rocker bodies free of charge. I am very pleased with the service I received from Jesel and would recommend them to anyone. These showed up around 7 business days after I shipped them out.

The next day I cranked it and sprayed some water on the header primaries. All were smoking hot except for the #7 cylinder. I pull the plug out and it looks a little dark but not too bad. I throw a new one in the wire and test it, definitely getting spark. Put it back in (new plug), crank it back up, still nothing. I let it sit until today, and decided to swap an injector. As I got ready to do that I figured I'd pull the valve cover just in case (4 bolts, I have relocated coils).

Here is what I find......

Does not look to be any other damage. When it broke, it shoved the lifter up and it stayed away from the cam. There isn't even a pushrod dent in the valve cover lol. The car did not make the SLIGHTEST noise from the valvetrain lol. I am calling Jesel tomorrow to see what they think. This is from my LME 408, Trickflow heads, Smith Brothers pushrods, etc. I'm super relieved that nothing else is wrong. These are the Jesel SS shaft mounted rockers ($900ish).

There's only around 6k on the whole motor. Those are nice valve springs/retainers, and I have a fairly small cam (242/246 .620). I also only turn it around 6800-7000. My pistons are relieved for the valves (Wiseco 8cc), so I highly doubt that I had a valve hit.

I'm not mad about it, as I know **** happens, but these are some really expensive rockers lol. It looks to me like there may have just been something wrong with the casting. Depending on how Jesel handles this, I will decide if I'm going to be pissed or not.

UPDATE!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! 11/3/09

So it looks like the bottom of my rockers had been in contact with the rocker stand rails. This must have happened back when I had the huge cam. I figure the rocker arms clearanced themselves and then most likely didn't hit after I put the new (smaller) cam in. You can see the marks where they were rubbing. The marks between the 5 and 7 are from the top of the bolts that sit directly below the rockers.

I drug my feet for a while then got in touch with Jesel. Rob Remesi from Jesel returned my emails and was very nice. I told them about the interference issues and the problems that others have experienced. I also expressed the fact that I understood that this failure could have very well happened due to a general installation error. He swiftly reccomended that I send the rocker arms in for inspection and he would replace the rocker bodies free of charge. I am very pleased with the service I received from Jesel and would recommend them to anyone. These showed up around 7 business days after I shipped them out.

Last edited by TheBlurLS1; 11-03-2009 at 09:50 PM.

#4

9 Second Club

iTrader: (23)

Join Date: Oct 2002

Location: Mastic Long Island N.Y.

Posts: 1,150

Likes: 0

Received 0 Likes

on

0 Posts

The good news is it appears you have all the parts/pieces from the rocker arm. This is the one thing that scares me about my linkbar Morels. The lifter will not stay up and the pushrod has a path to get by the lifter below it and down into the crankcase no trays to seal that area up.

#7

TECH Addict

iTrader: (75)

Join Date: Apr 2005

Location: Rock Hill, South Carolina

Posts: 2,578

Likes: 0

Received 0 Likes

on

0 Posts

sounds to me like casting error. at least i hope so cause like you said those are high dollar rockers. btw i like your engine bay well organized and clean. hope jesel gives you a break. what coil relo kit do you have?

Trending Topics

#9

I built my own relocation kit with some all thread, some aluminum plate, some washers, and some nuts. The wires are the Taylor universal kit with the LT-1 boot kit (from Thunder Racing).

#10

Jesel rocker fact. Non adjustable rockers are weaker than adjustable rockers in that area. I have used countless Jesel rockers on my engines and the only failure I had was with a set of non adjustable rockers. There is a lot more meat around the rush-rod cup on the adjustable rockers... I had a J2K series rocker break in the same place. (Non adjustable style) But with that said, Jesel is still be best rocker you can buy. (JMHO)

#11

TECH Senior Member

iTrader: (127)

Jesel rocker fact. Non adjustable rockers are weaker than adjustable rockers in that area. I have used countless Jesel rockers on my engines and the only failure I had was with a set of non adjustable rockers. There is a lot more meat around the rush-rod cup on the adjustable rockers... I had a J2K series rocker break in the same place. (Non adjustable style) But with that said, Jesel is still be best rocker you can buy. (JMHO)

i will use either jesel or stock in my engines. nothing else. imo

#12

On The Tree

iTrader: (21)

Join Date: Jul 2005

Location: Alex. Louisiana

Posts: 126

Likes: 0

Received 0 Likes

on

0 Posts

Jesell ss rockers should be only used as stock replacement rockers only! I had set I bought for my 408 build, and read a thread that stated he was not getting full lift out of his Jesell ss rockers. Long story short I talked with Jesel they said that the SS Rockers were for Stock Replacment only and their Web States that, Rep said needed to get the J2k rockers for anything over stock!! When I say Stock Replacement I mean Stock Lift Cam "ONLY"

#13

TECH Addict

iTrader: (22)

Jesell ss rockers should be only used as stock replacement rockers only! I had set I bought for my 408 build, and read a thread that stated he was not getting full lift out of his Jesell ss rockers. Long story short I talked with Jesel they said that the SS Rockers were for Stock Replacment only and their Web States that, Rep said needed to get the J2k rockers for anything over stock!! When I say Stock Replacement I mean Stock Lift Cam "ONLY"

Last edited by Stang's Bane; 09-21-2009 at 01:31 PM.

#14

TECH Fanatic

Aluminum rocker arms like these are almost never castings. They are extrusions which are cut of the extruded bar like slicing bread. They are then machined in the area of the roller tip, the pushrod cup or adjuster, valve spring clearance and of course the bearing bore. Notice the lack of machining marks on the rest of the body.

2024 is a strong sluminum and there is some grain flow during the extruding process. Unfortunately the grain flow is along the bar (loaf in the bread example) rather than from the roller tip end to the pushrod end.

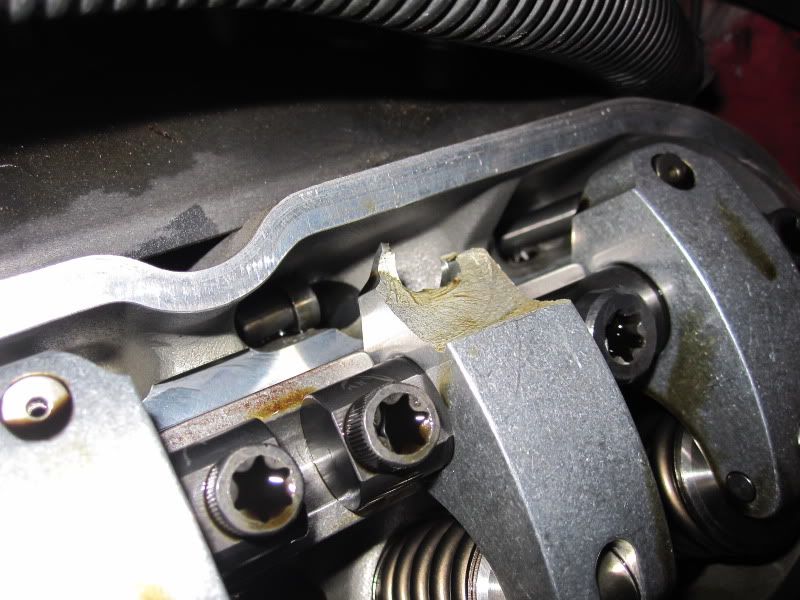

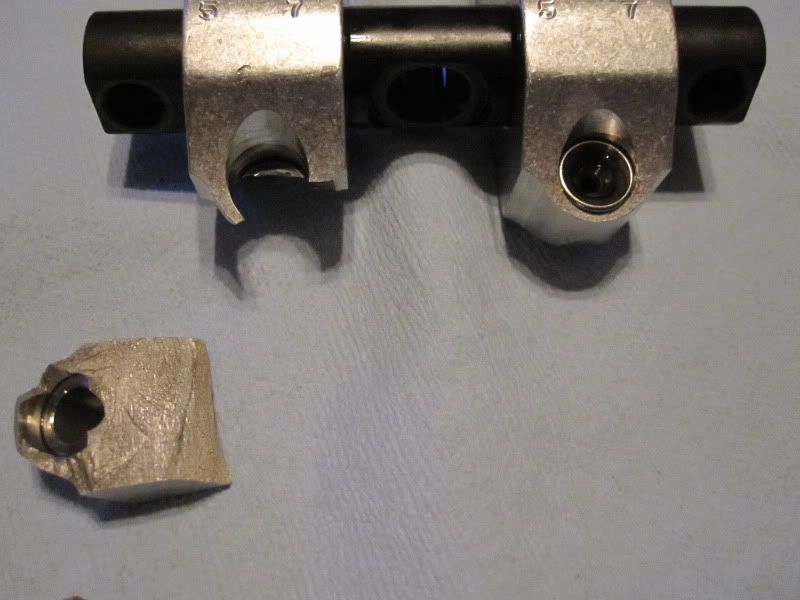

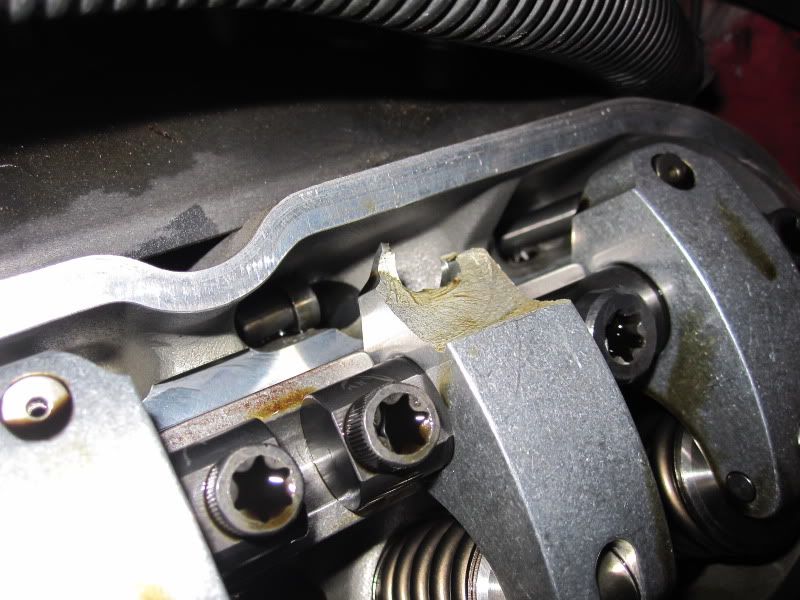

The fracture in this rocker looks like it started in the thin area of the pushrod cup where the little piece broke out. That is a very highly loaded area. The major cleavage (yeah, that's what it's called ) looks like it is along the side-to-side grain flow of an extrusion. This does not look to be the start of the failure but the result when the small piece cracked out and the subsequent pushrod loads continued to open the crack.

) looks like it is along the side-to-side grain flow of an extrusion. This does not look to be the start of the failure but the result when the small piece cracked out and the subsequent pushrod loads continued to open the crack.

It would be conjecture to say what caused the crack to start without examining the parts first hand, but a sharp nick or a tool mark in the fillet radius where the crack is could be the weak spot. It could also be something in the parent metal like a small void that happened to be in just the wrong place.

IMO, this failure probably took a while to develop and proceeded from a small crack at the little broken piece due to repeated loading (fatigue) until it broke catastrophically. You are fortunate that everything went well after the failure. Your pictures and replacing the broken parts for the one picture are very helpful.

Unfortunately stuff like this can happen in areas that are highly stressed (high loads on small cross-sections as in "pounds per square inch"). Obviously Jesel doesn't ask for my advice but I would add material (atually machine less away) in the area of the small piece to increase the wall thickness. The long steel pushrod cup helps transfer the pushrod loads to the aluminum without sharp interruptions like a knurl which some use.

but I would add material (atually machine less away) in the area of the small piece to increase the wall thickness. The long steel pushrod cup helps transfer the pushrod loads to the aluminum without sharp interruptions like a knurl which some use.

Let us know what happens. Again, you were darn lucky to not have collateral damage.

My $.02

Jon

2024 is a strong sluminum and there is some grain flow during the extruding process. Unfortunately the grain flow is along the bar (loaf in the bread example) rather than from the roller tip end to the pushrod end.

The fracture in this rocker looks like it started in the thin area of the pushrod cup where the little piece broke out. That is a very highly loaded area. The major cleavage (yeah, that's what it's called

) looks like it is along the side-to-side grain flow of an extrusion. This does not look to be the start of the failure but the result when the small piece cracked out and the subsequent pushrod loads continued to open the crack.

) looks like it is along the side-to-side grain flow of an extrusion. This does not look to be the start of the failure but the result when the small piece cracked out and the subsequent pushrod loads continued to open the crack. It would be conjecture to say what caused the crack to start without examining the parts first hand, but a sharp nick or a tool mark in the fillet radius where the crack is could be the weak spot. It could also be something in the parent metal like a small void that happened to be in just the wrong place.

IMO, this failure probably took a while to develop and proceeded from a small crack at the little broken piece due to repeated loading (fatigue) until it broke catastrophically. You are fortunate that everything went well after the failure. Your pictures and replacing the broken parts for the one picture are very helpful.

Unfortunately stuff like this can happen in areas that are highly stressed (high loads on small cross-sections as in "pounds per square inch"). Obviously Jesel doesn't ask for my advice

but I would add material (atually machine less away) in the area of the small piece to increase the wall thickness. The long steel pushrod cup helps transfer the pushrod loads to the aluminum without sharp interruptions like a knurl which some use.

but I would add material (atually machine less away) in the area of the small piece to increase the wall thickness. The long steel pushrod cup helps transfer the pushrod loads to the aluminum without sharp interruptions like a knurl which some use. Let us know what happens. Again, you were darn lucky to not have collateral damage.

My $.02

Jon

#15

Jesell ss rockers should be only used as stock replacement rockers only! I had set I bought for my 408 build, and read a thread that stated he was not getting full lift out of his Jesell ss rockers. Long story short I talked with Jesel they said that the SS Rockers were for Stock Replacment only and their Web States that, Rep said needed to get the J2k rockers for anything over stock!! When I say Stock Replacement I mean Stock Lift Cam "ONLY"

OldSStroker - The only reason why I figured these rockers are cast is because the surface finish is the same all the way around. If they were extruded, it seems like there would be cut marks on the ends (where they were sliced), unless they went through some sort of surface finisher (tumbler) afterwards.

I'm with you though. I think if the pushrod end was one smooth radius with a little more meat all the way around, it probably wouldn't have happened, but there's no way to tell for sure. There may have just been something wrong with this one rocker (material, manufacturing defect, machining error, etc. )

It also looks like (as you said) the aluminum around the cup deformed until the shard broke out, then left the rest of the arm weak and ready to bend/break off.

#16

TECH Fanatic

OldSStroker - The only reason why I figured these rockers are cast is because the surface finish is the same all the way around. If they were extruded, it seems like there would be cut marks on the ends (where they were sliced), unless they went through some sort of surface finisher (tumbler) afterwards.

1) Contour mill the pushrod end of a long section of the entrusion.

2) Slice off blanks from the extrusion. An automated circular cold saw can make a very smooth finish.

3) Heavily mass finish (tumble or vibro) to radiius sharp edges and provide mottled surface finish. How about high-g tumbling and/or compressive stress inducing shot peening?

4) Machine blank for roller, pushrod cup, spring clearance and shaft/bearings and roller pin bores.

Something like that anyway. It really doesn't matter, but it's fun to reverse engineer the manufacturing process.

Maybe some Jesel engineer will read this and let us know. Yeah, right!

Jon

#18

I've noticed they can be really highly priced parts, sorry to hear that this happened. My buddies always tell me that you have to pay to play, but that's BS- once you get to a level of expenditure you shouldn't have to worry about some things when you're not running a car to extremes- I would figure that the higher costs items should hold up to moderate use and even some extreme use, which is what you pay for. Just MHO.

#20

On The Tree

wow wtf man. the jesels breaking would have been the last on my diagnosis list as well. i have a magnetic base and dial indicator if you decide you really want to measure at the valve.. should be long enough to stick it to the shock tower or something. i also have some tester springs so your lifters wont fail. just holler if you need anything..

it certainly looks like a material failure to me from the pics..

looks like those smith bros. are still mint lol.. those things are the cat's meow

it certainly looks like a material failure to me from the pics..

looks like those smith bros. are still mint lol.. those things are the cat's meow