No compression any cylinders, push rods?

#1

Hi, potentially dumb question but search keeps telling me there are no matches for the word "compression". I'll try again later I guess.

That aside, my question is thigs: I bought a motor and did a cam swap, using the push rods that came with the cam (an eps cam with 7.425 push rods). My car will not start and I have been trying to figure out why. I did a compression test on a few cylinders, and none have any compression at all. When turning over, the motor spins almost freely and the starter doesn't sound like it's fighting any resistance.

I'm wondering if the push rods being too long could cause this, and if this might explain the backfires that I'm getting out of both ends of the car.

As a test, I just swapped in some stock length push rods and there was no change in compression, but it's possible they are too long as well.

I tried with two different compression testers. Before I buy a push rod checker I thought I'd solicit feedback about whether or not improper push rods could be causing these problems. Thanks in advance

That aside, my question is thigs: I bought a motor and did a cam swap, using the push rods that came with the cam (an eps cam with 7.425 push rods). My car will not start and I have been trying to figure out why. I did a compression test on a few cylinders, and none have any compression at all. When turning over, the motor spins almost freely and the starter doesn't sound like it's fighting any resistance.

I'm wondering if the push rods being too long could cause this, and if this might explain the backfires that I'm getting out of both ends of the car.

As a test, I just swapped in some stock length push rods and there was no change in compression, but it's possible they are too long as well.

I tried with two different compression testers. Before I buy a push rod checker I thought I'd solicit feedback about whether or not improper push rods could be causing these problems. Thanks in advance

#2

TECH Resident

iTrader: (25)

Join Date: Jul 2005

Location: Houston

Posts: 818

Likes: 0

Received 0 Likes

on

0 Posts

Yes they are open if it pops while cranking it

there should be play in the rocker arms if you push on the back side or lift on the front of the rocker when the llifter rides on the base cirqle,that is the lifter travel

When you tighen the rocker down with the lifter on B.C. you should only have to turn the rocker bolt 1 to 1 1/4 turn after zero lash

there should be play in the rocker arms if you push on the back side or lift on the front of the rocker when the llifter rides on the base cirqle,that is the lifter travel

When you tighen the rocker down with the lifter on B.C. you should only have to turn the rocker bolt 1 to 1 1/4 turn after zero lash

#3

Thanks. Just checked and there is a bit of play on the rockers of valves that are presumably closed. Checked compression on a cylinder with play and still got zero compression. This is a crappy auto store rental, though I've tried with two different ones.

#5

I had considered that, so I pulled the motor and took the front off to double check. Cam and crank were dot to dot. I can't seem to get youtube videos to embed but I made these yesterday, using the stock 7.4 push rods (instead of the longer 7.425) . There are no plugs in cylinders 1 or 3. I'm no expert, but should there be flash showing up like that? I'm guessing not.

https://www.youtube.com/watch?v=ErvP...ature=youtu.be

https://www.youtube.com/watch?v=zjey...ature=youtu.be

https://www.youtube.com/watch?v=ErvP...ature=youtu.be

https://www.youtube.com/watch?v=zjey...ature=youtu.be

Last edited by chuckd71; 08-10-2014 at 09:16 AM.

#6

Turn it over by hand until #1 intake closes, see if the piston is near bottom dead center.

In addition, it should be near TDC just after the exhaust closes & before the intake opens. You can insert a small dowel or straw in the spark plug hole to check piston position

Perhaps your camshaft was ground incorrectly and the cam gear is out of position since the dots align.

In addition, it should be near TDC just after the exhaust closes & before the intake opens. You can insert a small dowel or straw in the spark plug hole to check piston position

Perhaps your camshaft was ground incorrectly and the cam gear is out of position since the dots align.

Trending Topics

#8

As I cycle it, standing at the front facing toward the rear of the car turning it clockwise, the straw drops down into the plug hole as the exhaust (the non-offest rocker arm?) is opening. As I continue, the straw is pushed out and the exhaust closes. At this point the straw is almost horizontal and, at least in my mind, it feels almost pinched between the heads and the piston. More turning of the crank and the intake (offset) valve opens as the straw drops. More tuning, the straw stops and valve closes, more turning and the straw is again pushed up and sticking out almost horizontally. Hope that makes sense.

#11

If you can do a leak down test with the valves closed that would rule out bent valves/blown pistons. You could do it with the rockers off to eliminate the pushrod length issue also.

#16

That's certainly true, though that's always the case unless you build the motor yourself or buy a crate. At this point I can either worry about that or ask questions, learn some stuff and try to solve my current problem, and I think the second approach is the way to go.

No place seems to rent a leak down tool so I just ran to buy one, hopefully this will shed some light on things.

No place seems to rent a leak down tool so I just ran to buy one, hopefully this will shed some light on things.

#17

TECH Resident

iTrader: (25)

Join Date: Jul 2005

Location: Houston

Posts: 818

Likes: 0

Received 0 Likes

on

0 Posts

Did you turn it over without checking p to v after the cam swap?If its a large cam on a stock motor w/o valve reliefs that is a must do step

You most likely bent your valves turning it over

You most likely bent your valves turning it over

#18

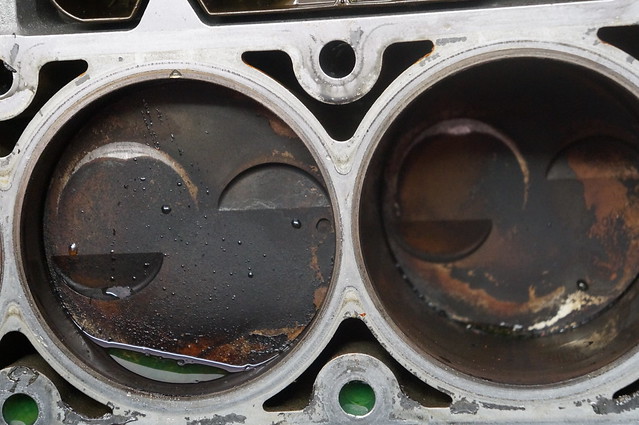

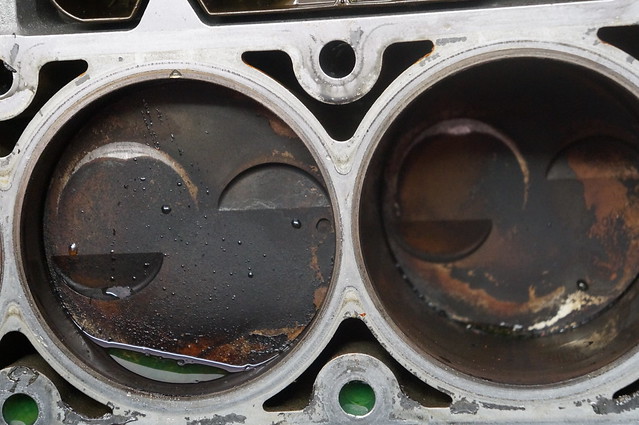

Well, this is not encouraging. 80-100% leakage, plus when I hook up the compressor directly to the spark plug socket I hear air coming out the throttle body. Rocker arms have been loosened to the point that they might as well be off.

DSC03046

DSC03046

Really wish I would've bought one of these things last summer.

I've kind of decided that no matter what, I am going to sell this motor and use the funds to buy a cheaper one (that'll I'll turbo later) plus a T56. Either way though, I get the impression the motor needs to come out and the heads need to come off. Does that seem like a fair assessment? Shitty situation, but if that is what needs to happen I guess I'm prepared to do it. I don't want to sell someone a motor if there is something wrong with it. Thanks for all the suggestions so far.

DSC03046

DSC03046Really wish I would've bought one of these things last summer.

I've kind of decided that no matter what, I am going to sell this motor and use the funds to buy a cheaper one (that'll I'll turbo later) plus a T56. Either way though, I get the impression the motor needs to come out and the heads need to come off. Does that seem like a fair assessment? Shitty situation, but if that is what needs to happen I guess I'm prepared to do it. I don't want to sell someone a motor if there is something wrong with it. Thanks for all the suggestions so far.

#20

Pulled the heads, broke a socket extension then switched to the breaker bar, these arp bolts are tough.

Popped the heads off and everything looked good, valves and piston tops are super clean.

Just kidding. Their fucked. Actually I think the pistons will be fine but yeah, intake valves are garbage. What a rookie mistake. At least I know what the problem is now and can start making progress, so that feels good.

Found some intake valves pretty cheap, now the question is this - do I part this out or fix these (what I assume are) simple things and drive it. If I keep it can either throw the ls7 cam back in and sell this cam or haul the motor to Shacklett's to get the pistons cut.

I'm thinking I might just sell this EPS cam and put the money toward a new cam. A turbo is a long-term plan and I think the LS7 cam might be better for that. Guess it depends on what flycutting costs and how long it take.

DSC03048

DSC03048

DSC03049

DSC03049

DSC03050

DSC03050

DSC03051

DSC03051

Thanks to everyone for their help, I would've pulled the heads eventually but doing it today got me a head start on moving forward.

Popped the heads off and everything looked good, valves and piston tops are super clean.

Just kidding. Their fucked. Actually I think the pistons will be fine but yeah, intake valves are garbage. What a rookie mistake. At least I know what the problem is now and can start making progress, so that feels good.

Found some intake valves pretty cheap, now the question is this - do I part this out or fix these (what I assume are) simple things and drive it. If I keep it can either throw the ls7 cam back in and sell this cam or haul the motor to Shacklett's to get the pistons cut.

I'm thinking I might just sell this EPS cam and put the money toward a new cam. A turbo is a long-term plan and I think the LS7 cam might be better for that. Guess it depends on what flycutting costs and how long it take.

DSC03048

DSC03048 DSC03049

DSC03049 DSC03050

DSC03050  DSC03051

DSC03051 Thanks to everyone for their help, I would've pulled the heads eventually but doing it today got me a head start on moving forward.