Locked up Solid, LONG READ!!!

#1

Yes, it's a long read but I figure the devil is in the details so here's everything I can think of that's relevant...

Well, here's the story and I'll post details as I find them. I'm not sure if it was just bad luck or if my massive brain fart led to this failure. Time may tell but wanted to open a discussion on my current situation even though I'm literally sick to my stomach.

LQ9 is the victim. History on this motor, verified, not hearsay... Brand spanking new GM direct crate motor. Been sitting in a project vehicle for 6+ years that a friend had and I picked up off him to finish up. Awesome right???

8 months of finishing up this project working off "to do" lists... One line item was fill oil. I drained whatever had been in it for ages and put in a name brand racing oil line of break in oil. I'm not going to get into an oil debate, just assume it's a quality break in style oil. I did this about 2 months ago.

About 3 weeks ago, I built myself a nice priming system based off a garden sprayer and knocked that out. It took quite a bit being that I have an engine cooler plumbed to the back of the truck. Here's where I made my one major mistake. Dumbass me didn't even think about the fact that I essentially had now drastically overfilled the engine with oil! Good intention, stupid mistake! Arm chair quarterback it all you want. I Effed it up and it may have cost me the engine, personally, I've been wanting to puke since yesterday afternoon but if you feel the need to talk crap, whatever, boost your moral, mine already is in the dumps.

So... WIth that known... Get my hands on a stand alone harness from PSI and have a local shop do a PCM tune for me. BTW, this is my first exposure to the LS based platform so I leaned on a local shop for help/advice, etc... Got the harness and PCM in hand this past Friday afternoon.

By mid day Sat I was ready to turn the key. Mistake #2, didn't double check the oil, I knew it was full! LOL, understatement... Turn the key and it fires right up instantly! I'm running an autometer oil pressure gauge plumbed into the top of the engine right at the firewall. Took about 5-10 seconds for pressure to build on the gauge. All good. I let it run for maybe 60 seconds at most and then had an amazing mental celebration!!! I had a couple temporary wiring situations though so I made those correct, buttoned everything up and tied it all up nice and neat. Later that afternoon I decided to go for my first long start up and get her up to running temp.

Fired it right up, all good. Slowly watching gauges, water temps climbing with the sender in the head. Oil temp lagged but the sending unit is at the back of the truck with the cooler so that was understandable. Smoke starts rising off various areas of the exhaust manifold, block, etc... It's an old NEW engine that's been sitting around for ages though, understandable. While monitoring gauges, visual checks, etc I'm also grabbing fans to air out my garage that's slowly filling with smoke. Soon the smoke at the engine end is getting pretty mellow but now it's more from the back. I figure it's coming off the cooler, no worries, slap a fan back there. Keep watching... Gets to about 215 degrees and I'm waiting for the fan to kick on for the radiator not knowing what it's set at in the pcm but the smoke from the rear is just getting worse and worse.

BTW, no exhaust on this thing yet. just about 10" of pipe right off the manifold. For giggles I dive under the truck and realize the smoke isn't rising off the cooler but is coming off the drivers side exhaust bank!!! CRAP!!! Jump up and kill her. At this same moment I realize instantly that I hadn't rechecked the oil level since prime and that it was likely WAY overfilled!!! Another obvious sign, the nice coating of oil all over the bottom and across the ground from the oil spraying thru the exhaust system. At this point though all still sounded fine and seemed fine.

That was all on Sat...

Sunday morning I head out, drain the oil to the appropriate full level which was probably about 3 quarts worth and then move on to some other items. I fire it up at some point in the day and it "clunks"... Not dead battery click but like engine wont turn over clunks. random! Hit the starter again and it fires up. Won't idle though and kinda kicks back a little almost it seems and then stalls. HUH??? WTF??? Hit the starter again and it fires up, throttle is needed to keep it running. Interesting... Later in the afternoon I pull my trailer out to load it up with intention of having the exhaust done on it yesterday afternoon. I fire it up, still no idle but sounds fine. I pull it out of my garage, drive it down about 6 houses to the end of my street, U-turn and back to park it in front of my neighbors house to line it up for the trailer. Get trailer situated, hop back in and Clunks again!!! WTF??? 2nd start try and it fires up with throttle, still no idle. Pull it on the trailer. At this point I'm thinking maybe the O2 sensors are trashed from the oil coating and not too worried about it. Maybe the oil coated O2's are keeping it from idle and giving goofy signal causing the clunk too? Seemed feasible in my uneducated mind.

Yesterday... Here's where it goes bad... Haul it to the exhaust shop. Unstrap it. Go to fire it. CLUNK again. WTF??? It lights up on the 2nd attempt but this time for the first time, it sounds different. This is about 5 seconds total of time here in this description. Over the LOUD straight piped exhaust, its sounding almost like a metallic clanking but the exhaust is so loud I can't 100% tell. It's sputtering a bit and just seems wrong. I go to kill it but it dies first. 5 seconds at most. WTF was that? Now I kill the fuel pump which is wired separate. Hit the starter, nothing but a clunk. Interesting. Next I pull the two plugs to the coil banks. Fuel pump off, CLUNK. Crap!!! This is getting ugly. Borrow a spark plug socket. Pull all the drivers side plugs and the front two on the pass. I can't get the rear two cause of access with the tools I was borrowing from the exhaust shop. I then borrow a ratchet/socket for the crank and well DAMN IT!!!!!

I can rotate the crank back and forth about one ratchet click's worth of rotation. I'm talking just a tiny bit. It's not completely 100% locked up but definitely isn't spinning.

Put the straps back on, drive home resisting the urge to puke and holding back the pansy urge to have the eyes tear up! So much effort, so much cash, so much work with everything in motion to test run her next week, GONE!!! It's not even so much the money, while that sucks... It's just the frustration of an end seriously in grasp ripped away! I back the trailer into my sideyard, put a cover over it and try to forget for a bit. Granted, that's impossible...

Game plan right now is to take a break before I come back to it. I just need to wrench on something else right now cause I'm so frustrated...

But, say late sept, early Oct when the time comes to see WTF happened and if it was my oil overfilling insanely stupid mistake or just a bad luck deal of a brand new crate motor that's been sitting... Where do I even start? I figured easy/dumbest and work my way up.

Step 1, pull spark plugs and starter, see if it turns by hand. assuming nope, drop the pan. Inspect for fun stuff in the bottom of the pan and the whole bottom of the engine for obvious signs of failure. Assuming nothing, pull valve covers. Not expecting to see anything there but pull them... Assuming nothing, pull the heads next. If still nothing, pull the whole motor.

Is that what you guys would do?

Advice? Guesses? Bets on what it is? Like I said, I'm already absolutely sickened and furious with myself and the situation I'm in now. Trust me, I get it!!!! IDIOT!!! I know!!!! But it's what it is and here I am with a mess to fix up.

Thoughts? Ideas?

For reference, this is the ride the motor resides in and was hoping to tear around in next weekend!

First 2 pics taken yesterday morning...

Back when it was innocent still... LOL

I'm not even sure what to do... Try to find out what happened first I guess. I feel like cause it's a BRAND SPANKING NEW CRATE MOTOR I'm best off trying to work with what I have rather then buying a used motor I don't know the history of or picking up a used long block. I'm thinking if it's something on the bottom have my short block rebuilt. If something up top have those rebuilt. What direction would you head in my shoes?

Well, here's the story and I'll post details as I find them. I'm not sure if it was just bad luck or if my massive brain fart led to this failure. Time may tell but wanted to open a discussion on my current situation even though I'm literally sick to my stomach.

LQ9 is the victim. History on this motor, verified, not hearsay... Brand spanking new GM direct crate motor. Been sitting in a project vehicle for 6+ years that a friend had and I picked up off him to finish up. Awesome right???

8 months of finishing up this project working off "to do" lists... One line item was fill oil. I drained whatever had been in it for ages and put in a name brand racing oil line of break in oil. I'm not going to get into an oil debate, just assume it's a quality break in style oil. I did this about 2 months ago.

About 3 weeks ago, I built myself a nice priming system based off a garden sprayer and knocked that out. It took quite a bit being that I have an engine cooler plumbed to the back of the truck. Here's where I made my one major mistake. Dumbass me didn't even think about the fact that I essentially had now drastically overfilled the engine with oil! Good intention, stupid mistake! Arm chair quarterback it all you want. I Effed it up and it may have cost me the engine, personally, I've been wanting to puke since yesterday afternoon but if you feel the need to talk crap, whatever, boost your moral, mine already is in the dumps.

So... WIth that known... Get my hands on a stand alone harness from PSI and have a local shop do a PCM tune for me. BTW, this is my first exposure to the LS based platform so I leaned on a local shop for help/advice, etc... Got the harness and PCM in hand this past Friday afternoon.

By mid day Sat I was ready to turn the key. Mistake #2, didn't double check the oil, I knew it was full! LOL, understatement... Turn the key and it fires right up instantly! I'm running an autometer oil pressure gauge plumbed into the top of the engine right at the firewall. Took about 5-10 seconds for pressure to build on the gauge. All good. I let it run for maybe 60 seconds at most and then had an amazing mental celebration!!! I had a couple temporary wiring situations though so I made those correct, buttoned everything up and tied it all up nice and neat. Later that afternoon I decided to go for my first long start up and get her up to running temp.

Fired it right up, all good. Slowly watching gauges, water temps climbing with the sender in the head. Oil temp lagged but the sending unit is at the back of the truck with the cooler so that was understandable. Smoke starts rising off various areas of the exhaust manifold, block, etc... It's an old NEW engine that's been sitting around for ages though, understandable. While monitoring gauges, visual checks, etc I'm also grabbing fans to air out my garage that's slowly filling with smoke. Soon the smoke at the engine end is getting pretty mellow but now it's more from the back. I figure it's coming off the cooler, no worries, slap a fan back there. Keep watching... Gets to about 215 degrees and I'm waiting for the fan to kick on for the radiator not knowing what it's set at in the pcm but the smoke from the rear is just getting worse and worse.

BTW, no exhaust on this thing yet. just about 10" of pipe right off the manifold. For giggles I dive under the truck and realize the smoke isn't rising off the cooler but is coming off the drivers side exhaust bank!!! CRAP!!! Jump up and kill her. At this same moment I realize instantly that I hadn't rechecked the oil level since prime and that it was likely WAY overfilled!!! Another obvious sign, the nice coating of oil all over the bottom and across the ground from the oil spraying thru the exhaust system. At this point though all still sounded fine and seemed fine.

That was all on Sat...

Sunday morning I head out, drain the oil to the appropriate full level which was probably about 3 quarts worth and then move on to some other items. I fire it up at some point in the day and it "clunks"... Not dead battery click but like engine wont turn over clunks. random! Hit the starter again and it fires up. Won't idle though and kinda kicks back a little almost it seems and then stalls. HUH??? WTF??? Hit the starter again and it fires up, throttle is needed to keep it running. Interesting... Later in the afternoon I pull my trailer out to load it up with intention of having the exhaust done on it yesterday afternoon. I fire it up, still no idle but sounds fine. I pull it out of my garage, drive it down about 6 houses to the end of my street, U-turn and back to park it in front of my neighbors house to line it up for the trailer. Get trailer situated, hop back in and Clunks again!!! WTF??? 2nd start try and it fires up with throttle, still no idle. Pull it on the trailer. At this point I'm thinking maybe the O2 sensors are trashed from the oil coating and not too worried about it. Maybe the oil coated O2's are keeping it from idle and giving goofy signal causing the clunk too? Seemed feasible in my uneducated mind.

Yesterday... Here's where it goes bad... Haul it to the exhaust shop. Unstrap it. Go to fire it. CLUNK again. WTF??? It lights up on the 2nd attempt but this time for the first time, it sounds different. This is about 5 seconds total of time here in this description. Over the LOUD straight piped exhaust, its sounding almost like a metallic clanking but the exhaust is so loud I can't 100% tell. It's sputtering a bit and just seems wrong. I go to kill it but it dies first. 5 seconds at most. WTF was that? Now I kill the fuel pump which is wired separate. Hit the starter, nothing but a clunk. Interesting. Next I pull the two plugs to the coil banks. Fuel pump off, CLUNK. Crap!!! This is getting ugly. Borrow a spark plug socket. Pull all the drivers side plugs and the front two on the pass. I can't get the rear two cause of access with the tools I was borrowing from the exhaust shop. I then borrow a ratchet/socket for the crank and well DAMN IT!!!!!

I can rotate the crank back and forth about one ratchet click's worth of rotation. I'm talking just a tiny bit. It's not completely 100% locked up but definitely isn't spinning.

Put the straps back on, drive home resisting the urge to puke and holding back the pansy urge to have the eyes tear up! So much effort, so much cash, so much work with everything in motion to test run her next week, GONE!!! It's not even so much the money, while that sucks... It's just the frustration of an end seriously in grasp ripped away! I back the trailer into my sideyard, put a cover over it and try to forget for a bit. Granted, that's impossible...

Game plan right now is to take a break before I come back to it. I just need to wrench on something else right now cause I'm so frustrated...

But, say late sept, early Oct when the time comes to see WTF happened and if it was my oil overfilling insanely stupid mistake or just a bad luck deal of a brand new crate motor that's been sitting... Where do I even start? I figured easy/dumbest and work my way up.

Step 1, pull spark plugs and starter, see if it turns by hand. assuming nope, drop the pan. Inspect for fun stuff in the bottom of the pan and the whole bottom of the engine for obvious signs of failure. Assuming nothing, pull valve covers. Not expecting to see anything there but pull them... Assuming nothing, pull the heads next. If still nothing, pull the whole motor.

Is that what you guys would do?

Advice? Guesses? Bets on what it is? Like I said, I'm already absolutely sickened and furious with myself and the situation I'm in now. Trust me, I get it!!!! IDIOT!!! I know!!!! But it's what it is and here I am with a mess to fix up.

Thoughts? Ideas?

For reference, this is the ride the motor resides in and was hoping to tear around in next weekend!

First 2 pics taken yesterday morning...

Back when it was innocent still... LOL

I'm not even sure what to do... Try to find out what happened first I guess. I feel like cause it's a BRAND SPANKING NEW CRATE MOTOR I'm best off trying to work with what I have rather then buying a used motor I don't know the history of or picking up a used long block. I'm thinking if it's something on the bottom have my short block rebuilt. If something up top have those rebuilt. What direction would you head in my shoes?

Last edited by sirhk100; 08-26-2014 at 02:15 PM.

#4

No on the remote filter housing but it did have a setup that allowed for an external cooler to be plumbed directly in above the filter in the stock position. It had oil pressure on the gauge and the cooler at the rear got up to about 160 degrees when I did that full heat cycle sat night. It was flowing for sure.

If you look closely here you can see the filter in the stock location but the cooler lines plumbed in directly above it.

Pulled this out though a little earlier this evening...

And then ran a bore camera down thru that cylinder. The piston is physically gone. Like not a hole... GONE... Dropped it thru 4 times in a row till we saw the crank. Put the mirror attachment on the camera and rotated it as we lowered it. It's gone...

Cylinder next to this one. top of the piston with the bore camera looks 100% perfectly brand new.

If you look closely here you can see the filter in the stock location but the cooler lines plumbed in directly above it.

Pulled this out though a little earlier this evening...

And then ran a bore camera down thru that cylinder. The piston is physically gone. Like not a hole... GONE... Dropped it thru 4 times in a row till we saw the crank. Put the mirror attachment on the camera and rotated it as we lowered it. It's gone...

Cylinder next to this one. top of the piston with the bore camera looks 100% perfectly brand new.

#6

LOL, time to pull the engine... Pretty sure with the entire piston missing from the cylinder it's more then drop the pan at this stage. I'm already on the hunt for a whole new motor. I'll slap this one on the stand and tear it apart just to satisfy morbid curiosity but I'm pretty darn sure it's already written off. With the bore camera down the cylinder, even the rod was no place to be found...

#7

TECH Regular

iTrader: (9)

Join Date: Mar 2013

Location: Rockwall, TX

Posts: 406

Likes: 0

Received 0 Likes

on

0 Posts

Man OP sorry to hear about your engine. If it were me I think I'd take the motor apart and see what all is damaged before buying another one.

Since you do your own wrenching it could probably be put back together "cheaply", or if you ever intended to go bigger/better with the motor (forged/stroker/compression,etc) just look at this event as a gentle push in that direction

Since you do your own wrenching it could probably be put back together "cheaply", or if you ever intended to go bigger/better with the motor (forged/stroker/compression,etc) just look at this event as a gentle push in that direction

Last edited by 74u; 08-27-2014 at 06:58 PM.

Trending Topics

#8

Yeah, huge bummer. I'm definitely going to tear into it to see what exactly is left of it for sure and see if I can see what caused it at the very least.

I actually just wanted a nice solid stock reliable engine. LOL, guess you just gotta get past that first 10-15 minutes! Definitely a bummer but life goes on and it'll be running soon one way or another. Will likely have it torn fully down by late Sept.

With it locked up solid, piston/rod literally missing, I'm guessing that head is pretty hammered... I'm not exactly holding my breath for much to be salvageable.

I was literally sick to my stomach Monday evening, like borderline puking almost from it but now... All I could do was laugh when we were running the camera thru the cylinder last night. Checking options and see what I can do.

I actually just wanted a nice solid stock reliable engine. LOL, guess you just gotta get past that first 10-15 minutes! Definitely a bummer but life goes on and it'll be running soon one way or another. Will likely have it torn fully down by late Sept.

With it locked up solid, piston/rod literally missing, I'm guessing that head is pretty hammered... I'm not exactly holding my breath for much to be salvageable.

I was literally sick to my stomach Monday evening, like borderline puking almost from it but now... All I could do was laugh when we were running the camera thru the cylinder last night. Checking options and see what I can do.

#9

BTW, I mentioned that I accidentally overfilled it on that initial fire and that first warm up cycle. I measured exactly what I drained out of it last night and it was exactly 2 quarts over full. I know that can lead to damage but gut feeling, this was something different. Who knows though... What's done is done...

#12

Definitely sucks. Gonna push it in the garage tonight and maybe even start tinkering with it some. If not tonight probably tomorrow night for sure with hopes of pulling it on Sat. I'm assuming I'll have to drop the pan and figure out how to free it up to get it to spin so I can rotate it around and access the flexplate/torque convertor bolts to get it free from the transmission. Once that's loose, it should come out pretty quick and easy. Yank the harness free from it, couple lines. Couple bolts, out it comes...

#13

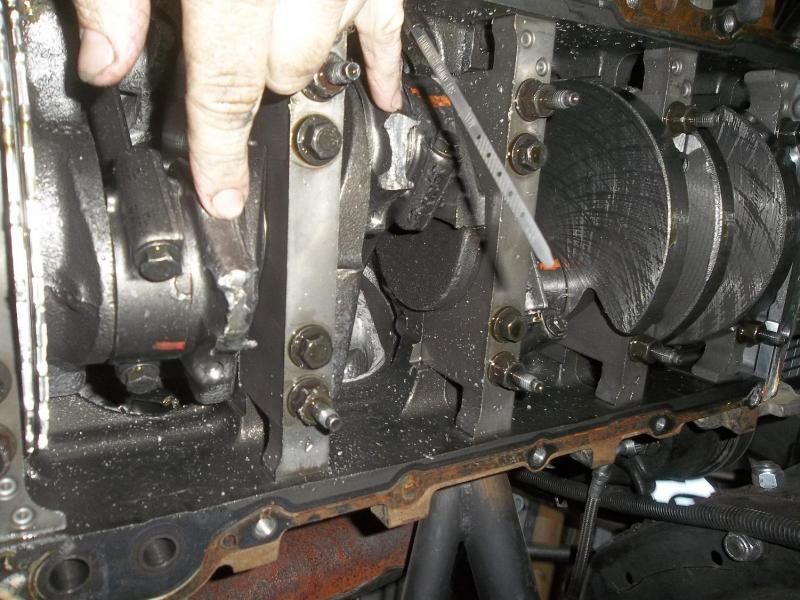

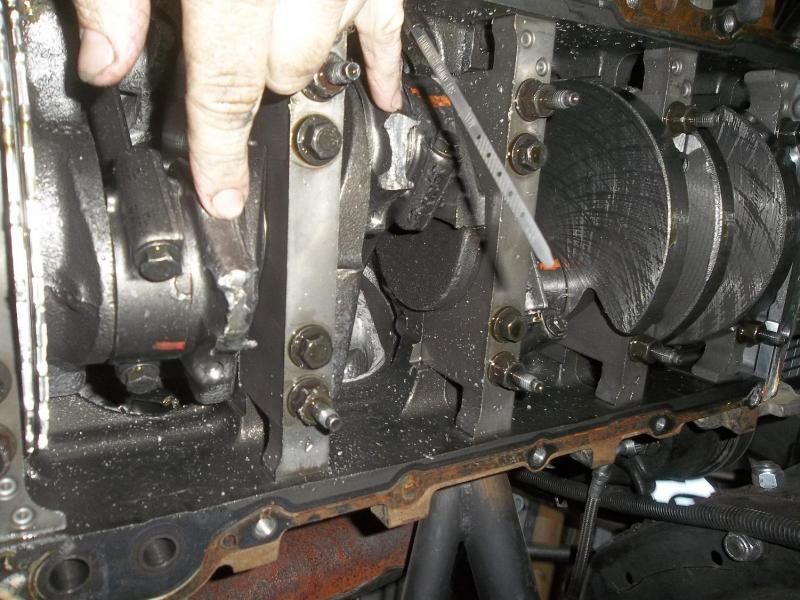

Well, should have it pulled tomorrow. I can get to the torque convertor bolts now though...

Don't worry, I see what you see too! LOL

The catch is, I know something you don't from those pictures!!! There's two of them suckers not attached to the spinny parts! LOL

But boy oh boy, look how clean that thing is!!!! Almost like new! LOL

Don't worry, I see what you see too! LOL

The catch is, I know something you don't from those pictures!!! There's two of them suckers not attached to the spinny parts! LOL

But boy oh boy, look how clean that thing is!!!! Almost like new! LOL

#14

soooooooooooo, not holding my breath still but... Let's say this thing is rebuild-able. Head is likely gone on the cylinder that the piston disintegrated in. I know easy power is heads/cam combo. This is an offroad truck. Reliability is 100% key!!!! Power is nice but getting home from the middle of absolutely nowhere wins the demands. Say you had like a $5K budget to rebuild with. Torque is my friend, HP is cool but torque when the sand gets soft and hills get steep is key... What would you slap it back together with? Stroker? Cam and heads with quality rod/piston combo, stock bore/stroke? Am I dreaming with a budget like that?

BTW, I won't complain one bit staying under $5K so just cause that number is there, doesn't necessarily mean I want to spend it. I built the truck initially being 100% happy with what I had being 100% stock but if it's able to be saved and since it's apart and since guys can't leave things alone....

BTW, I won't complain one bit staying under $5K so just cause that number is there, doesn't necessarily mean I want to spend it. I built the truck initially being 100% happy with what I had being 100% stock but if it's able to be saved and since it's apart and since guys can't leave things alone....

#15

TECH Regular

iTrader: (9)

Join Date: Mar 2013

Location: Rockwall, TX

Posts: 406

Likes: 0

Received 0 Likes

on

0 Posts

Are you willing to run premium pump gas? Stroke & compression will definitely make lots more torque from idle on up. Do you have headers, or manifolds?

Your budget is doable assuming your block survived and doesn't require much machining.

Balanced stroker assy w/rings & bearings - $2200

cam bearings (if needed) - $40

Block machining - $300 - $800 depending on what's needed

Cam (custom grind) - $400

Upgraded valve springs (if needed) - $200

New timing set (if needed) - $125

Head Gaskets - $75 - $125 depending on needs

Head bolts - $60

317 Heads/pair (if needed) - $300

Pushrods (if different length is needed) - $100

Oil pump upgrade - $125

New oil pan baffle - $???

MISC (coolant/oil/filter/2 cases of brake clean/assy lubes/sealers/thread locker/spark plugs/balancer bolt/tool rental/etc) - $300

$5k assuming you can assemble and there are no major surprises. First step is get the block to a reputable machinist and have it checked. Until you know where you are at on the block, until you have a total plan from intake to pan and until you know all components are available and in stock - don't buy anything.

Also, I forgot...plan on $500 for tuning on a dyno.

Your budget is doable assuming your block survived and doesn't require much machining.

Balanced stroker assy w/rings & bearings - $2200

cam bearings (if needed) - $40

Block machining - $300 - $800 depending on what's needed

Cam (custom grind) - $400

Upgraded valve springs (if needed) - $200

New timing set (if needed) - $125

Head Gaskets - $75 - $125 depending on needs

Head bolts - $60

317 Heads/pair (if needed) - $300

Pushrods (if different length is needed) - $100

Oil pump upgrade - $125

New oil pan baffle - $???

MISC (coolant/oil/filter/2 cases of brake clean/assy lubes/sealers/thread locker/spark plugs/balancer bolt/tool rental/etc) - $300

$5k assuming you can assemble and there are no major surprises. First step is get the block to a reputable machinist and have it checked. Until you know where you are at on the block, until you have a total plan from intake to pan and until you know all components are available and in stock - don't buy anything.

Also, I forgot...plan on $500 for tuning on a dyno.

Last edited by 74u; 09-06-2014 at 10:00 AM.

#16

TECH Regular

iTrader: (9)

Join Date: Mar 2013

Location: Rockwall, TX

Posts: 406

Likes: 0

Received 0 Likes

on

0 Posts

This could get you a good head start if the piston used can give you the CR you need...

https://ls1tech.com/forums/parts-cla...ort-block.html

https://ls1tech.com/forums/parts-cla...ort-block.html

#17

Yes, premium gas is not a concern. This isn't a daily driver, it's something that's trailered out on weekends to have fun with.

Thanks for the tips! Definitely not moving forward till I see what i'm really left with and will plan from there. I'm the type that won't pull the trigger till I've got 100% of my options and choices made and then dive in all at once. Patience is something I've been blessed with and it seems like it helps me in the long run get to where I want to be more times then not. I feel like this blown motor is simply a case of bad luck and it needs fixed so I want to address all my options, lay them on the table and then see which will suit me best.

and 74U, interesting on that link!!!

Well, I was lazy yesterday... Heading out now to see if I can get this thing pulled out.

Thanks for the tips! Definitely not moving forward till I see what i'm really left with and will plan from there. I'm the type that won't pull the trigger till I've got 100% of my options and choices made and then dive in all at once. Patience is something I've been blessed with and it seems like it helps me in the long run get to where I want to be more times then not. I feel like this blown motor is simply a case of bad luck and it needs fixed so I want to address all my options, lay them on the table and then see which will suit me best.

and 74U, interesting on that link!!!

Well, I was lazy yesterday... Heading out now to see if I can get this thing pulled out.

#18

I would also take a look at your fuel injectors if one sticks it will hyro-lock a cylinder hopefully the 2nd time around goes better for you. I don't think 2-3 quarts of extra oil caused that failure, you might just have had a defective connecting rod....I would put some Manley rods/forged pistons in the motor on a re-build, getting stuck in the desert isnt a fun thing to have happen.

#19

TECH Junkie

iTrader: (11)

There's not a whole lot of free space volume in an LS crankcase, consider why GM ended putting "breather" windows in the walls between the journals. Oil is pretty much non-compressible and a piston coming down on an actual oil level could easily hydrolock. I'd tend to believe the overfill was the cause...

#20

Well, motor is out and on a stand. Been procrastinating it a bit. I'm going to pull the heads and see how bad the one cylinder where the piston completely let go is looking. At this point, I'm leaning towards just picking up a used runner to get it in the truck and up and going. So far, initially, the block doesn't "look" bad, I'd obviously have it inspected. If the heads don't look too bad my current game plan is oil this whole thing up and set it in the shed for the time being. Get a used runner in the truck and get it in the dirt and start having fun with it. I've got another vehicle project in line that I'd like to get done the first half of 2015 so I'll likely knock that out. Give myself a year or so of playing with the truck and learning about it and then when the want for more power creeps up like it always done, I can pull out this headache and start building something out of it...

That's the thought pattern as of now at least...

That's the thought pattern as of now at least...