ARP 1/2? && 3/8" head stud torque specs

#1

ARP says:

factory 8mm studs go to 22ft/lbs

11mm: 70ft/lbs

The chart look like:

1/2" x 20 = 107ft/lbs

3/8" x 24 = 44ft/lbs

If memory serves me correctly main studs are 60 inside/50 outside for aluminum block, iron the same?

factory 8mm studs go to 22ft/lbs

11mm: 70ft/lbs

The chart look like:

1/2" x 20 = 107ft/lbs

3/8" x 24 = 44ft/lbs

If memory serves me correctly main studs are 60 inside/50 outside for aluminum block, iron the same?

#4

TECH Fanatic

iTrader: (1)

Join Date: Aug 2005

Location: Galveston, TX

Posts: 1,202

Likes: 0

Received 0 Likes

on

0 Posts

Quoted from ls1howto.com

Apply the moly lube that came with the ARP bolts to the threads, as well as under the head of the bolt and both sides of the washer. Only a light coating is needed. If you don't have the included moly lube, put some motor oil on the threads.

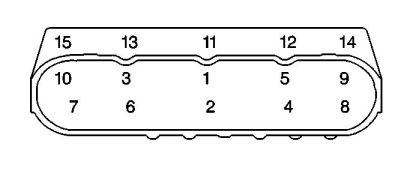

Torque all 15mm bolts to 30lbft in the torque sequence above.

Do a second pass at 50lbft, and finally a 3rd at 70lbft.

Finally install the 5 smaller ARP bolts and torque them to 22lbft.

Torque all 15mm bolts to 30lbft in the torque sequence above.

Do a second pass at 50lbft, and finally a 3rd at 70lbft.

Finally install the 5 smaller ARP bolts and torque them to 22lbft.

#7

TECH Junkie

iTrader: (3)

Join Date: May 2003

Location: Clayton, North Carolina

Posts: 3,898

Likes: 0

Received 6 Likes

on

6 Posts

You should use the same numbers as when it was honed. We use a few different ways, but the 1/2 stuff is 100-110 with a torque wrench. The 3/8 stuff we have been using 40. The under bolts can't be done directly with a torque wrench. We use a offset 12 point box wrench on the end of a 3/8 torque wrench. With this set up we torque a lower bolt to 40, then mark the nut exacly at the stop point. Then break it loose and use the box wrench/torque wrench combo with lower settings until you find the number that stops the nut in the same place. Use that number to tighten the upper row.

Kurt

Kurt