Want advice/criticism on next project...

#1

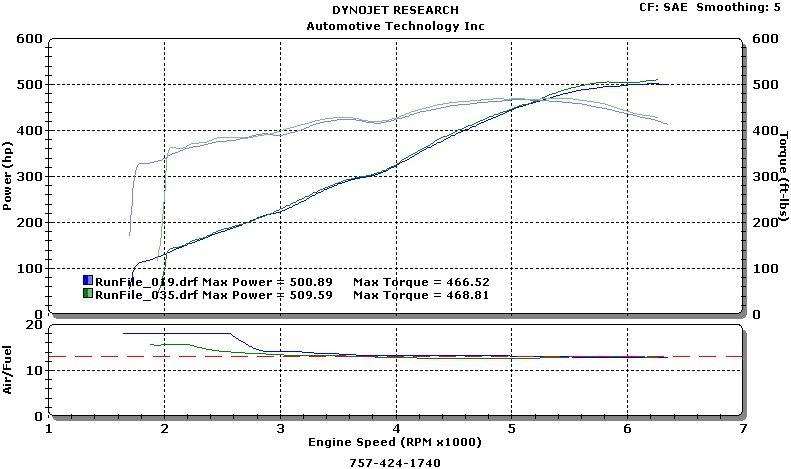

Lookin at my next project motor to end up like this...

370ci iron block

PRC (or other) CNC L92 heads milled to get 11.4:1 or close SCR

L76 intake

235/243 .646/.653 112+4 (LSK lobes)

Forged mahle pistons -4cc, 4.030"

Forged callies compstar rods 6.125"

ARP main studs, head bolts, rod bolts, etc.

All bolt ons, headers, underdrive pulley, etc. except EWP to start out

What do you guys think? What kind of power could I be looking at? I want any opinions, criticism, whatever you guys think about this setup b/c I wanna get it all lined out before I start on it. I picked a camshaft that shouldnt have to be turned much over 6300 or 6400 on this setup b/c I understand the limitations of the L76 intake. Later on, if they ever get it out, I will buy a Fast for L92 setups. Any info and input is welcome here...whether you like my setup or hate it, let me know.

370ci iron block

PRC (or other) CNC L92 heads milled to get 11.4:1 or close SCR

L76 intake

235/243 .646/.653 112+4 (LSK lobes)

Forged mahle pistons -4cc, 4.030"

Forged callies compstar rods 6.125"

ARP main studs, head bolts, rod bolts, etc.

All bolt ons, headers, underdrive pulley, etc. except EWP to start out

What do you guys think? What kind of power could I be looking at? I want any opinions, criticism, whatever you guys think about this setup b/c I wanna get it all lined out before I start on it. I picked a camshaft that shouldnt have to be turned much over 6300 or 6400 on this setup b/c I understand the limitations of the L76 intake. Later on, if they ever get it out, I will buy a Fast for L92 setups. Any info and input is welcome here...whether you like my setup or hate it, let me know.

Last edited by moeZ28; 02-05-2008 at 02:36 PM.

#3

TECH Junkie

iTrader: (4)

who told you that you'd be able to achieve 11.4:1 cr with a-4cc piston and those heads? it is my understanding that they can't be milled much, if any, past 64cc due to intake fitment and potential valve problems. i don't think a 64cc chamber and -4cc dish piston will equate to 11.4:1 cr?

my solution to this problem is the use of diamond forged 10cc dome pistons with L92 valve reliefs. with a 64 cc head i will be somewhere around 13:1 cr - the best i've gathered thus far.

i think the cam is too small for those heads. i assume this engine is going in a 4th gen. fbod? if at all possible, see if you can't fit a gmpp L92 carbed intake on top of that engine. also, are you going to spin over 7,200 rpm? if not, why are you using aftermarket rods? i have a set of stock 6.0 rods i'll sell you cheap

edit: you already have the rods.

my solution to this problem is the use of diamond forged 10cc dome pistons with L92 valve reliefs. with a 64 cc head i will be somewhere around 13:1 cr - the best i've gathered thus far.

i think the cam is too small for those heads. i assume this engine is going in a 4th gen. fbod? if at all possible, see if you can't fit a gmpp L92 carbed intake on top of that engine. also, are you going to spin over 7,200 rpm? if not, why are you using aftermarket rods? i have a set of stock 6.0 rods i'll sell you cheap

edit: you already have the rods.

#4

12 Second Club

iTrader: (2)

Join Date: Mar 2004

Location: Jenison, MI

Posts: 478

Likes: 0

Received 0 Likes

on

0 Posts

If you're going to build an engine don't use stock rods. I'll bet you really want to run 13:1 also. I don't think your cam is too small either. You are just going to get biased opinions posting here. Just talk it over with your engine builder and save youself the grief.

#5

I am the engine builder...I built the motor for the car in my sig. That motor put down 489rwhp corrected on a different dyno. No, I dont want 13:1 compression. This is a street car, and I am not turning the motor that high either. I picked the cam I did b/c it will make good top end power, but still have some ***** down in the midrange. Staying with 370ci so if I screw up or blow the engine up, I can always re-machine and go with a longer stroke later. Oh, and forged rods will be a must...it's gonna get a healthy dose of nitrous oxide...

So with a .040" gasket, -2 or -4cc valve reliefs, and milling those heads like around .030" or .040" wont get me around mid 11's compression? What would it take with -2 or -4cc valve reliefs to get that?

So with a .040" gasket, -2 or -4cc valve reliefs, and milling those heads like around .030" or .040" wont get me around mid 11's compression? What would it take with -2 or -4cc valve reliefs to get that?

#6

TECH Junkie

iTrader: (4)

i am building a 374, making use of as much compression i can get and a much larger cam. i've looked into these L92 heads quite a bit, so far my only concern was getting any kind of compression out of them.

no mention of nitrous in the first post, i was assuming an n/a build of that description - which stock rods would have NO problem handling.

i am building a street car, as well. the use of e-85 will calm down any concerns with the compression. i like your setup, it should idle and drive great while making some good power. that intake is going to basically shut off @ ~6,200 rpm, you might factor that into your cam a little bit more, as i can see the one you've listed pulling considerably higher than that.

no mention of nitrous in the first post, i was assuming an n/a build of that description - which stock rods would have NO problem handling.

i am building a street car, as well. the use of e-85 will calm down any concerns with the compression. i like your setup, it should idle and drive great while making some good power. that intake is going to basically shut off @ ~6,200 rpm, you might factor that into your cam a little bit more, as i can see the one you've listed pulling considerably higher than that.

#7

I have seen that the intake does have trouble over 6200 or so, but usually thats on bigger cubes. I would assume on a 370ci, it would be able to breathe just a little higher than that...at least a couple hundred rpms. I guess we will see. But yeah, on the 400+ cube motors, the L76 does run out of breathe some. I dont want to go any bigger on the cam b/c I have seen much better results from the medium sized cams on L92 heads than with monster cams. I think the cam I chose will be ok, maybe a little too much lift on the exhaust side. I saw a thread where a car made huge numbers on a 427ci with a little lazier exhaust lobe...23? duration at .050", and .5?? lift made over 600rwhp. Thats just sick!! I would love to run higher compression if E85 was available here in Kentucky where I live, but there are no stations carrying it near my home, which sucks royally! So, 93 will have to do. I figure with a -4cc valve relief, I should be able to mill the heads enough, with using a thinner gasket, to get mid 11's on compression. -4cc doesnt sound like much, but its deeper than most people realize. Those heads in my sig were milled .070" (CNC 853's) and I turned the motor 7200 rpms with a TREX V2 cam, with -4cc valve relief pistons.

Trending Topics

#9

What size cam are you running and what kind of power did you make? Looks like I would easily be to mill the heads .040" or .050" and have a -4cc head and be in the low to mid 11's compression. We will see what happens when i actually start this project...I think it will be a nice running car that drives pretty well and has good power under the curve. Maybe not the most power under the curve, but good power.

#10

TECH Junkie

iTrader: (2)

What size cam are you running and what kind of power did you make? Looks like I would easily be to mill the heads .040" or .050" and have a -4cc head and be in the low to mid 11's compression. We will see what happens when i actually start this project...I think it will be a nice running car that drives pretty well and has good power under the curve. Maybe not the most power under the curve, but good power.

#13

TECH Addict

iTrader: (22)

Join Date: Sep 2004

Location: tennessee

Posts: 2,639

Likes: 0

Received 0 Likes

on

0 Posts

for around 11:4 scr with pistons .008 out of hole and an .040 cometic with a 4.030 bore your will need around a 62 cc combustion chamber if i added it up right. going down to a 60 cc makes it around 11:7 scr.

#14

Looks like a .048" mill will get the chamber to 62cc...right? The heads are at 70cc out of the box, .006" = 1cc, so .006" x 8cc = .048" mill to get 11.4:1 with a .040 cometic, and depending on how far out of the hole the pistons are. Is this factoring in the -2 or -4cc valve reliefs or just a flat piston?

#16

Dont worry, got it under control. My next question was gonna be if anyone individual or vender experimented with milling L92/LS3 heads around .050"? I am at work and had to jump off before doing that. Aint no gettin carried away, I dont have any of the parts, or even the car to put it in yet...so I got time brother!