ARP 234-5608 Main Studs - Am I missing something

#1

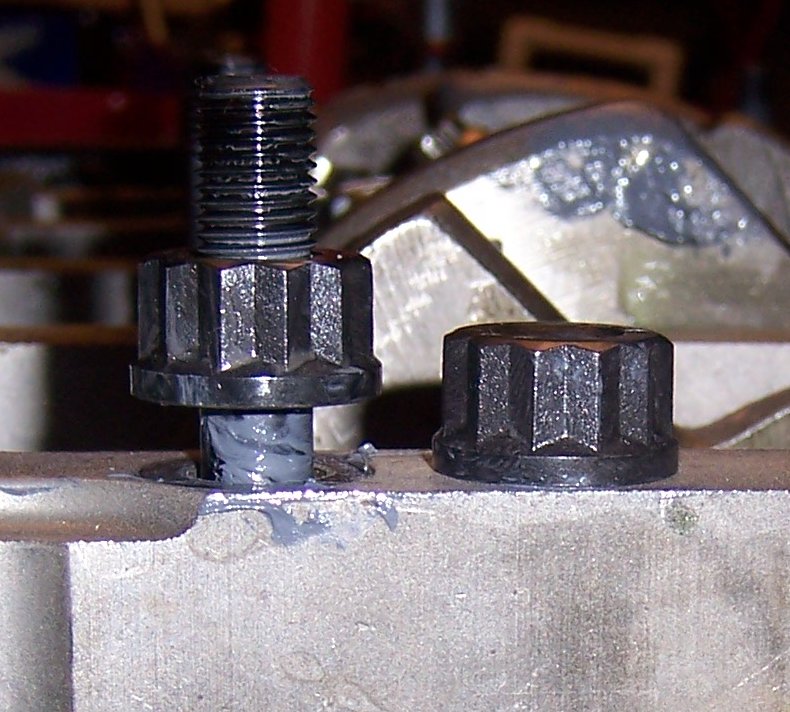

For those who have used those studs, look at the following pic. I've used ARP studs before for heads, this is the first time I've used them for my caps. It says to hand-tighten the studs in place, as always. Then put the nuts on top, torque to spec.

I hand tighten them, and the windage-tray studs end up sticking up so far the nut can't reach the cap. I ordered them from summit. What came in the sealed box was the windage studs, the cap studs, the side bolts, 20 nuts for the caps, 10 nuts for the studs and moly grease. Were there supposed to be any washers?

Am I supposed to tighten the windage tray studs tighter? The threads have all been cleaned and chased, they're in with about 10lb-ft of torque so far, I mean it's beyond hand tight at this point and they still won't reach. Let me know if I'm just doing something wrong..

I hand tighten them, and the windage-tray studs end up sticking up so far the nut can't reach the cap. I ordered them from summit. What came in the sealed box was the windage studs, the cap studs, the side bolts, 20 nuts for the caps, 10 nuts for the studs and moly grease. Were there supposed to be any washers?

Am I supposed to tighten the windage tray studs tighter? The threads have all been cleaned and chased, they're in with about 10lb-ft of torque so far, I mean it's beyond hand tight at this point and they still won't reach. Let me know if I'm just doing something wrong..

#2

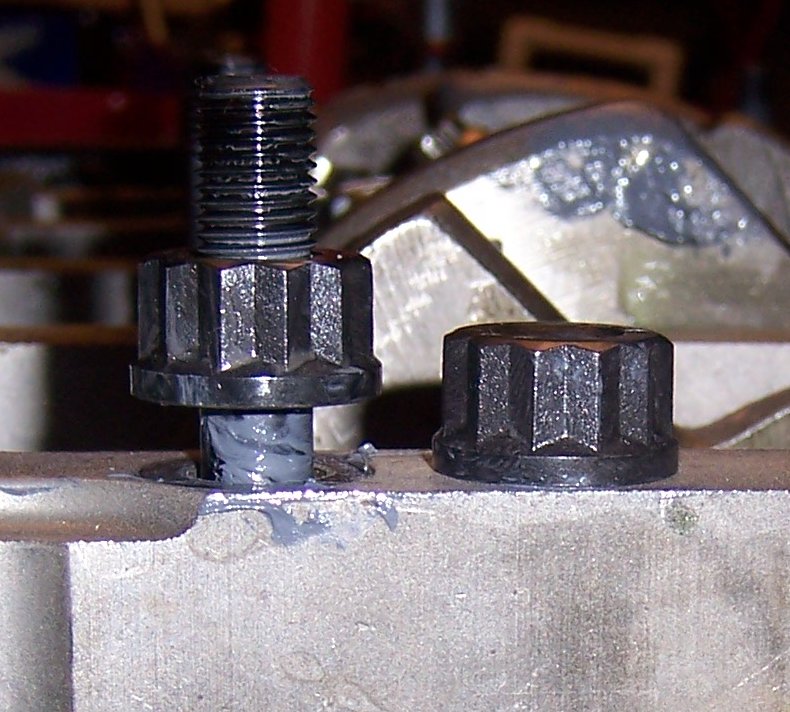

For those who have used those studs, look at the following pic. I've used ARP studs before for heads, this is the first time I've used them for my caps. It says to hand-tighten the studs in place, as always. Then put the nuts on top, torque to spec.

I hand tighten them, and the windage-tray studs end up sticking up so far the nut can't reach the cap. I ordered them from summit. What came in the sealed box was the windage studs, the cap studs, the side bolts, 20 nuts for the caps, 10 nuts for the studs and moly grease. Were there supposed to be any washers?

Am I supposed to tighten the windage tray studs tighter? The threads have all been cleaned and chased, they're in with about 10lb-ft of torque so far, I mean it's beyond hand tight at this point and they still won't reach. Let me know if I'm just doing something wrong..

I hand tighten them, and the windage-tray studs end up sticking up so far the nut can't reach the cap. I ordered them from summit. What came in the sealed box was the windage studs, the cap studs, the side bolts, 20 nuts for the caps, 10 nuts for the studs and moly grease. Were there supposed to be any washers?

Am I supposed to tighten the windage tray studs tighter? The threads have all been cleaned and chased, they're in with about 10lb-ft of torque so far, I mean it's beyond hand tight at this point and they still won't reach. Let me know if I'm just doing something wrong..

Trending Topics

#8

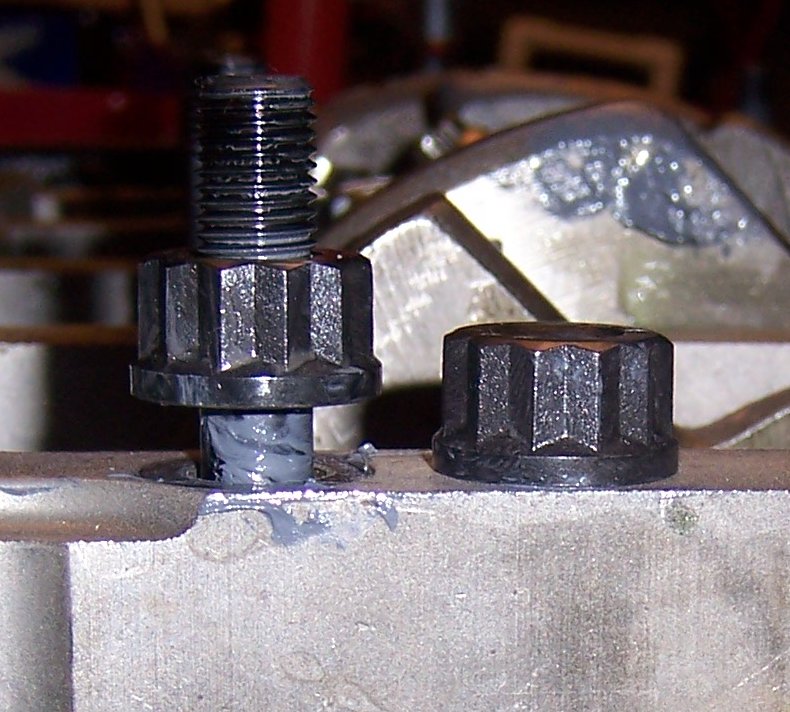

Just an update, as the thread shows I had the studs backwards. The studs with the "longer" threads goes on the outside. Then just ream out 3 holes in your windage tray to allow for the larger studs to stick through.

That'll teach me to try and build a rotating assembly in the wee hours of the morning.

That'll teach me to try and build a rotating assembly in the wee hours of the morning.

#9

TECH Fanatic

iTrader: (10)

Join Date: Dec 2003

Location: omaha, NE

Posts: 1,004

Likes: 0

Received 0 Likes

on

0 Posts

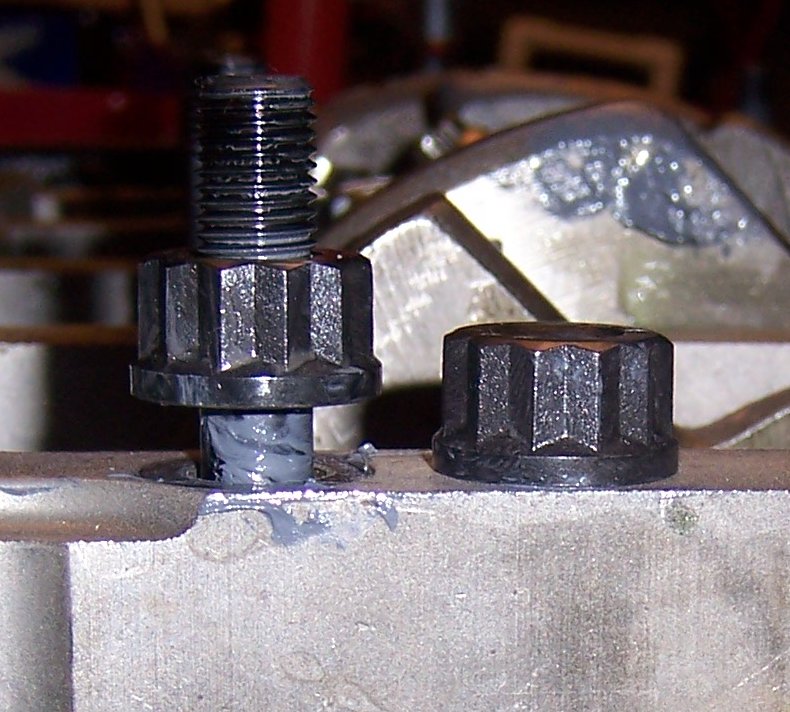

Just an update, as the thread shows I had the studs backwards. The studs with the "longer" threads goes on the outside. Then just ream out 3 holes in your windage tray to allow for the larger studs to stick through.

That'll teach me to try and build a rotating assembly in the wee hours of the morning.

That'll teach me to try and build a rotating assembly in the wee hours of the morning.