Cam overlap and Boost

#1

TECH Apprentice

Thread Starter

iTrader: (5)

Join Date: Dec 2007

Location: Southern Colorado Front Range

Posts: 347

Likes: 0

Received 0 Likes

on

0 Posts

What EXACTLY can I expect with increased cam overlap in a Centrifugal supercharger application? I realize this is a multi faceted question, which is why I specified "centrifugal" supercharger. Even more specifically; Can I use cam overlap as a "tool" to bleed off overboost with a higher compression engine like an LS3? Will the increased scavenging/blowthrough effect of the overlap, coupled with the boost, cool the combustion chamber enough to reduce tendancy of detonation in this application?

#2

11Second Club

iTrader: (3)

Join Date: Dec 2004

Location: Dallas (Richardson), TX, USA

Posts: 1,294

Likes: 0

Received 0 Likes

on

0 Posts

My understanding is that you will bleed off boost which costs you some efficiency from the blower. However, it does bleed off compression by decreasing your dynamic compression ratio. The overlap probably won't net you any more power (since that's really meant to "draw" in the intake charge on an N/A motor, which isn't necessary when it's force fed). However, the increase duration will probably net you more power. Whether that power outweighs the decrease in efficiency of the blower is beyond me.

I'm using a 230/236 on a 112 LSA with my D1SC on a 10:1 CR motor with a 3.70 blower pulley. We'll see if that's enough to keep detonation under control!

I'm using a 230/236 on a 112 LSA with my D1SC on a 10:1 CR motor with a 3.70 blower pulley. We'll see if that's enough to keep detonation under control!

#3

More overlap will soften the power in the lower rev's, but then again a centrifugal supercharger does not make much power at lower rev's anyway. End result, more power at high rev's, but again that is where the centrifugal supercharger makes the most boost, at max rpm's. So I guess what I am saying is this: you will kill what low rpm power you were getting from the blower, but more than make it up on the top end.

#4

TECH Enthusiast

iTrader: (8)

Join Date: Feb 2006

Location: Denver Colo.

Posts: 524

Likes: 0

Received 0 Likes

on

0 Posts

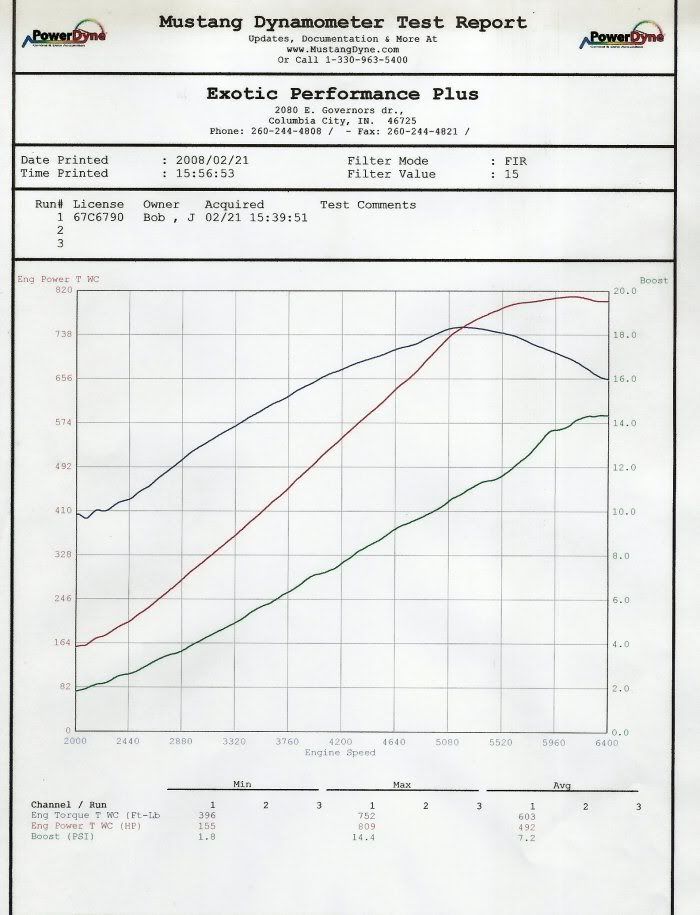

Here is 1 example, 742RWHP 722RWTQ Forged 347ci LS1. Compression 9.5 to 1, CNC ported 241 Heads nearly 300cfm of flow, Polished Weiand Intake to match heads, small cam - GM HotCam (218/227 .525 .525 112lsa) w/other supporting Internal mods.

Procharger D1SC w/ 14 to 15 max psi.

Snow Meth Injection w/1000ml spray added in early 2007.

My car,

751 rwhp 639 rwtq Stock short block 346ci. cnc'd ls6 heads 11.4:1 Fast 90mm intake 220/224 .576/.581 116 lsa

Procharger D1SC @ 12#,s

I make less boost but have more HP. The first car used a 3.4 in. pulley I use a 4.0 pulley. He does have a 12 bolt w/3.73 and my rear is a stock 10 bolt, but that would make only a small difference.

#6

8 Second Club

Join Date: Dec 2007

Location: smyrna del

Posts: 25

Likes: 0

Received 0 Likes

on

0 Posts

What EXACTLY can I expect with increased cam overlap in a Centrifugal supercharger application? I realize this is a multi faceted question, which is why I specified "centrifugal" supercharger. Even more specifically; Can I use cam overlap as a "tool" to bleed off overboost with a higher compression engine like an LS3? Will the increased scavenging/blowthrough effect of the overlap, coupled with the boost, cool the combustion chamber enough to reduce tendancy of detonation in this application?

#7

TECH Apprentice

Thread Starter

iTrader: (5)

Join Date: Dec 2007

Location: Southern Colorado Front Range

Posts: 347

Likes: 0

Received 0 Likes

on

0 Posts

I don't believe this to be correct.

Here is 1 example, 742RWHP 722RWTQ Forged 347ci LS1. Compression 9.5 to 1, CNC ported 241 Heads nearly 300cfm of flow, Polished Weiand Intake to match heads, small cam - GM HotCam (218/227 .525 .525 112lsa) w/other supporting Internal mods.

Procharger D1SC w/ 14 to 15 max psi.

Snow Meth Injection w/1000ml spray added in early 2007.

My car,

751 rwhp 639 rwtq Stock short block 346ci. cnc'd ls6 heads 11.4:1 Fast 90mm intake 220/224 .576/.581 116 lsa

Procharger D1SC @ 12#,s

I make less boost but have more HP. The first car used a 3.4 in. pulley I use a 4.0 pulley. He does have a 12 bolt w/3.73 and my rear is a stock 10 bolt, but that would make only a small difference.

Here is 1 example, 742RWHP 722RWTQ Forged 347ci LS1. Compression 9.5 to 1, CNC ported 241 Heads nearly 300cfm of flow, Polished Weiand Intake to match heads, small cam - GM HotCam (218/227 .525 .525 112lsa) w/other supporting Internal mods.

Procharger D1SC w/ 14 to 15 max psi.

Snow Meth Injection w/1000ml spray added in early 2007.

My car,

751 rwhp 639 rwtq Stock short block 346ci. cnc'd ls6 heads 11.4:1 Fast 90mm intake 220/224 .576/.581 116 lsa

Procharger D1SC @ 12#,s

I make less boost but have more HP. The first car used a 3.4 in. pulley I use a 4.0 pulley. He does have a 12 bolt w/3.73 and my rear is a stock 10 bolt, but that would make only a small difference.

My question would be: Does anyone know what would happen if a substantial amount of boost were added to this engine/cam equation? "Substantial" = I'm running an 8" Innovations West crank pulley, 2.7" Riechard Racing blower pulley, and a 3.54 step up ratio. The Novi2000 is NOT a small unit. I have already spoken to Paxton and they said that the blower is capable of spinning much higher than the 55,000rpm recommended max. 55,000 is simply its max efficiency. It isn't really doing anything more for the engine past that point. The way the pulleys are set up, I'll be seeing max efficiency by 5600rpm or so. The engine probably won't see the high side of 6000.

Its cool to lose some boost to the cam if it is actually helping other factors such as cooling the cylinders, reducing detonation, increasing volumetric efficiency, reducing the amount I have to enrichen the fuel supply, etc.

Let me know what you guys think... or we could just pool bets on how long the engine lasts. hahaha

Trending Topics

#8

Teching In

Join Date: Mar 2006

Location: Andalusia, AL

Posts: 48

Likes: 0

Received 0 Likes

on

0 Posts

Im having an issue like that on my car to. I have stock heads 241 heads 90/90 setup and a forged short block GM head gaskets on a 347. the cam is .588/.601, 228/236, on a 114 lobe sep. it has only 4 degrees of overlap. Also a D1SC with a 3.4 Riechard racing pulley. at bout 5500 in stops building boost at 10 psi. tomorrow im gonna pressure check for boost leaks. Not sure if the race valve is lose letting out all my bost or what. Im stumped folks say different things from the wrong cam, boost leak, MAF problems, or delete the MAF and get a 3-bar MAP sensor and tune it with it. I considered goin with the EPP forced induction cam .595/.608, 232/240, on a 115 lobe sep. but thats just more money to spend.

#9

9 Second Truck Club

iTrader: (17)

I don't believe this to be correct.

Here is 1 example, 742RWHP 722RWTQ Forged 347ci LS1. Compression 9.5 to 1, CNC ported 241 Heads nearly 300cfm of flow, Polished Weiand Intake to match heads, small cam - GM HotCam (218/227 .525 .525 112lsa) w/other supporting Internal mods.

Procharger D1SC w/ 14 to 15 max psi.

Snow Meth Injection w/1000ml spray added in early 2007.

My car,

751 rwhp 639 rwtq Stock short block 346ci. cnc'd ls6 heads 11.4:1 Fast 90mm intake 220/224 .576/.581 116 lsa

Procharger D1SC @ 12#,s

I make less boost but have more HP. The first car used a 3.4 in. pulley I use a 4.0 pulley. He does have a 12 bolt w/3.73 and my rear is a stock 10 bolt, but that would make only a small difference.

Here is 1 example, 742RWHP 722RWTQ Forged 347ci LS1. Compression 9.5 to 1, CNC ported 241 Heads nearly 300cfm of flow, Polished Weiand Intake to match heads, small cam - GM HotCam (218/227 .525 .525 112lsa) w/other supporting Internal mods.

Procharger D1SC w/ 14 to 15 max psi.

Snow Meth Injection w/1000ml spray added in early 2007.

My car,

751 rwhp 639 rwtq Stock short block 346ci. cnc'd ls6 heads 11.4:1 Fast 90mm intake 220/224 .576/.581 116 lsa

Procharger D1SC @ 12#,s

I make less boost but have more HP. The first car used a 3.4 in. pulley I use a 4.0 pulley. He does have a 12 bolt w/3.73 and my rear is a stock 10 bolt, but that would make only a small difference.

#10

LS1Tech Co-Founder

iTrader: (34)

Kevin's (kp) experience with cam swaps was the best comparo I've seen.

Bigger cam = more power but more duration can mean soggier low end and have to spin the engine/blower higher to make that power.

So would you run a 224/224//114 or run a 236/244//112? It.... depends.

These conversations should always start with... "My goal is to..."

Bigger cam = more power but more duration can mean soggier low end and have to spin the engine/blower higher to make that power.

So would you run a 224/224//114 or run a 236/244//112? It.... depends.

These conversations should always start with... "My goal is to..."

#11

LS1Tech Co-Founder

iTrader: (34)

I made 680rwhp and went 9.40@143mph with my YSi with some belt slippage, 236/246 ish cam. That was 18 psi with a very simple, super low compression 348ci. I shifted it at 7 grand. It made 754rwhp with 21.5 psi. Keep in mind that's thru a T400 so add another 70-100rwhp for an MN6 car. Went 5.9/116 so it could have gone 9.3@147 without belt slippage IMO.

#12

TECH Apprentice

Thread Starter

iTrader: (5)

Join Date: Dec 2007

Location: Southern Colorado Front Range

Posts: 347

Likes: 0

Received 0 Likes

on

0 Posts

Kevin's (kp) experience with cam swaps was the best comparo I've seen.

Bigger cam = more power but more duration can mean soggier low end and have to spin the engine/blower higher to make that power.

So would you run a 224/224//114 or run a 236/244//112? It.... depends.

These conversations should always start with... "My goal is to..."

Bigger cam = more power but more duration can mean soggier low end and have to spin the engine/blower higher to make that power.

So would you run a 224/224//114 or run a 236/244//112? It.... depends.

These conversations should always start with... "My goal is to..."

#13

TECH Enthusiast

iTrader: (8)

Join Date: Feb 2006

Location: Denver Colo.

Posts: 524

Likes: 0

Received 0 Likes

on

0 Posts

Also, the dyno was a Dynojet, so the #'s are inflatted, and they are corrected to sea level @ 20%, because he couldn't get the uncorrected #'s.

#14

TECH Enthusiast

iTrader: (8)

Join Date: Feb 2006

Location: Denver Colo.

Posts: 524

Likes: 0

Received 0 Likes

on

0 Posts

ok. My goal is to break into 800+ streetable RWHP with the setup I'm intending to use here. My questions still remain: Can I use the cam overlap to my benefit? I'm hoping the increased cubic inches will offset the loss of low end power loss of my chosen cam. I'm hoping the overlap will increase the volumetric efficiency of the engine even with the blower. I'm actually hoping to get the results Ricky Bobby did.

A bigger cam makes more power n/a, but boosted you would have to use a smaller pulley to push more air to get the same amount of air/fuel to stay in the cylinder as a cam with less overlap. This is why people believe less overlap is more efficient.

On the other hand, If my understanding of overlap is correct, the added overlap is for volocity. I would think that even if the air is pressurised, if it can move faster, than you would see the same effect of the higher volocity forcing in just that little bit more. Thus increasing volumetric efficency. The draw back to doing this is, you creat more parasitic loss to spin the blower faster.

The only way to truely know what overlap is best, is too try several cams until you find the one that makes the most power.

I know there are others that know way more than me, but since they are not here, I gave you what I know.

Sorry if it's not alot of help but, either way, you should easily make you goal of 800 hp. A 427 is a big motor and your cam doesn't appear to be so big that it would hinder the potential of your motor.

For myself, having to deal with emissions had alot to do with my selection. I passed last year, so I got what I needed.

Good Luck, John

#15

TECH Apprentice

Thread Starter

iTrader: (5)

Join Date: Dec 2007

Location: Southern Colorado Front Range

Posts: 347

Likes: 0

Received 0 Likes

on

0 Posts

From what I have seen on the board, it went from little overlap is best, a few years ago, too a fair amount is better.

A bigger cam makes more power n/a, but boosted you would have to use a smaller pulley to push more air to get the same amount of air/fuel to stay in the cylinder as a cam with less overlap. This is why people believe less overlap is more efficient.

On the other hand, If my understanding of overlap is correct, the added overlap is for volocity. I would think that even if the air is pressurised, if it can move faster, than you would see the same effect of the higher volocity forcing in just that little bit more. Thus increasing volumetric efficency. The draw back to doing this is, you creat more parasitic loss to spin the blower faster.

The only way to truely know what overlap is best, is too try several cams until you find the one that makes the most power.

I know there are others that know way more than me, but since they are not here, I gave you what I know.

Sorry if it's not alot of help but, either way, you should easily make you goal of 800 hp. A 427 is a big motor and your cam doesn't appear to be so big that it would hinder the potential of your motor.

For myself, having to deal with emissions had alot to do with my selection. I passed last year, so I got what I needed.

Good Luck, John

A bigger cam makes more power n/a, but boosted you would have to use a smaller pulley to push more air to get the same amount of air/fuel to stay in the cylinder as a cam with less overlap. This is why people believe less overlap is more efficient.

On the other hand, If my understanding of overlap is correct, the added overlap is for volocity. I would think that even if the air is pressurised, if it can move faster, than you would see the same effect of the higher volocity forcing in just that little bit more. Thus increasing volumetric efficency. The draw back to doing this is, you creat more parasitic loss to spin the blower faster.

The only way to truely know what overlap is best, is too try several cams until you find the one that makes the most power.

I know there are others that know way more than me, but since they are not here, I gave you what I know.

Sorry if it's not alot of help but, either way, you should easily make you goal of 800 hp. A 427 is a big motor and your cam doesn't appear to be so big that it would hinder the potential of your motor.

For myself, having to deal with emissions had alot to do with my selection. I passed last year, so I got what I needed.

Good Luck, John

My car is pig heavy too.. I love my stereo gear.

But I really appreciate the feedback. You are dealing with the same altitude issues Stock48 and I are (if not higher in Denver). So that makes your experience even more valuable in my situation. This altitude thing does change up the rules a bit.

This is where I agree with Lemons12 and his point of view; In this instance at least, my tuning is going to make or break me. Fuel mapping and timing are going to be critical issues and no "cookie cutter" flash pack is going to cut it here.

I have also read the back issue threads here on the overlap issue. The veteran LS1Tech guys all make valid points and know thier ****. I was just a little taken by the fact that noone seems to agree on what to expect with the overlap issue, especially as it pertains to forced induction applications. So I started this thread to see if anyone has tried or experimented with it already.

#16

TECH Fanatic

iTrader: (6)

I was thinking about trying to use the cam in my sig for FI, but everyone says I'm crazy. I'm probably going to restall to 5000 whenever I go FI, so I don't really care about loss of down low power. Currently it's right at 23 degrees of overlap. My other thought was going to Trickflows 550hp package(since I want heads also) which comes with a 238/242 .595/.595 on a 112 cam, which is at 16 degrees of overlap.

#19

LS1Tech Co-Founder

iTrader: (34)

TurboAV...

242/248 .621/.615 on a 111

The question really is if you had less overlap would the car make more power and be quicker at the track?

I think that this 242/248 .621/.615 on a 111 cam would be big in a stock cube engine, but would perform decent with a blower.

I ran a 240/244 cam in a 348 cid and it wanted to be shifted over 7100, if I had added a blower it would have moved my shift points even higher I think.

242/248 .621/.615 on a 111

The question really is if you had less overlap would the car make more power and be quicker at the track?

I think that this 242/248 .621/.615 on a 111 cam would be big in a stock cube engine, but would perform decent with a blower.

I ran a 240/244 cam in a 348 cid and it wanted to be shifted over 7100, if I had added a blower it would have moved my shift points even higher I think.