LS1 Noob...Couple questions doing a rebuild

#1

Launching!

Thread Starter

iTrader: (1)

Join Date: Mar 2009

Posts: 259

Likes: 0

Received 0 Likes

on

0 Posts

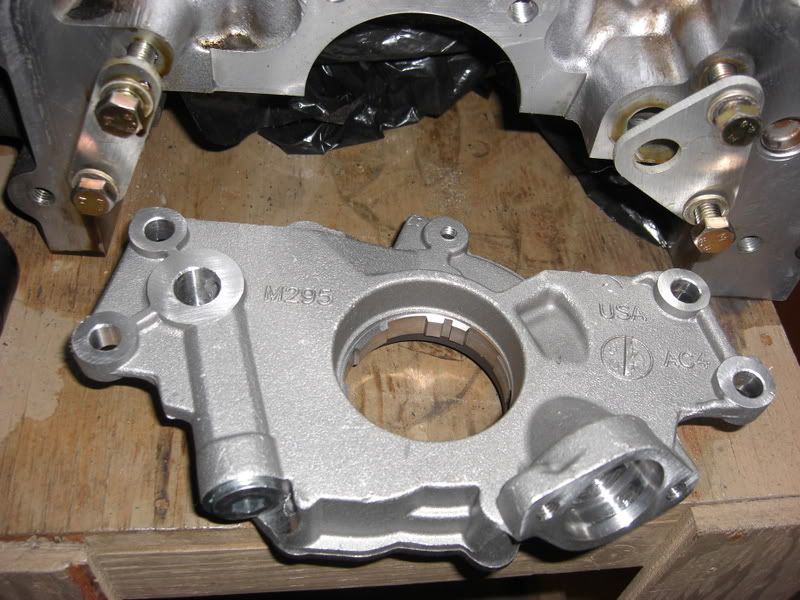

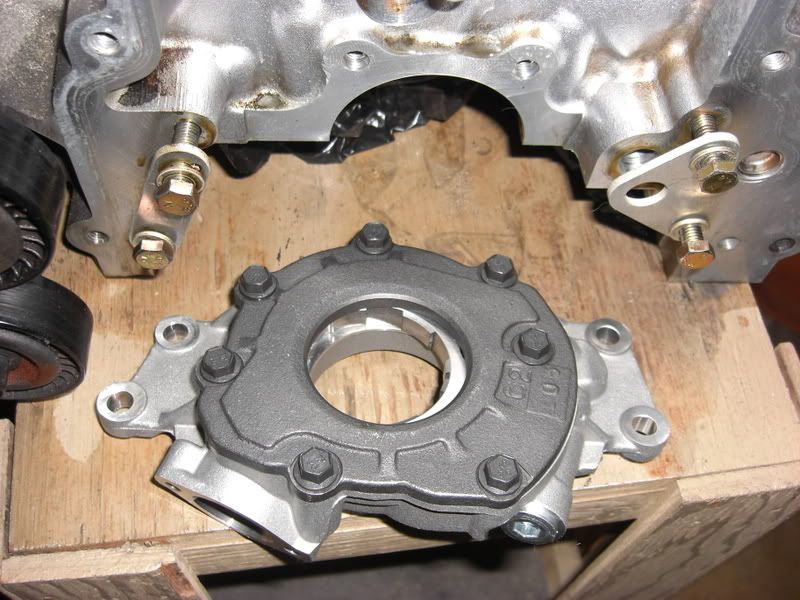

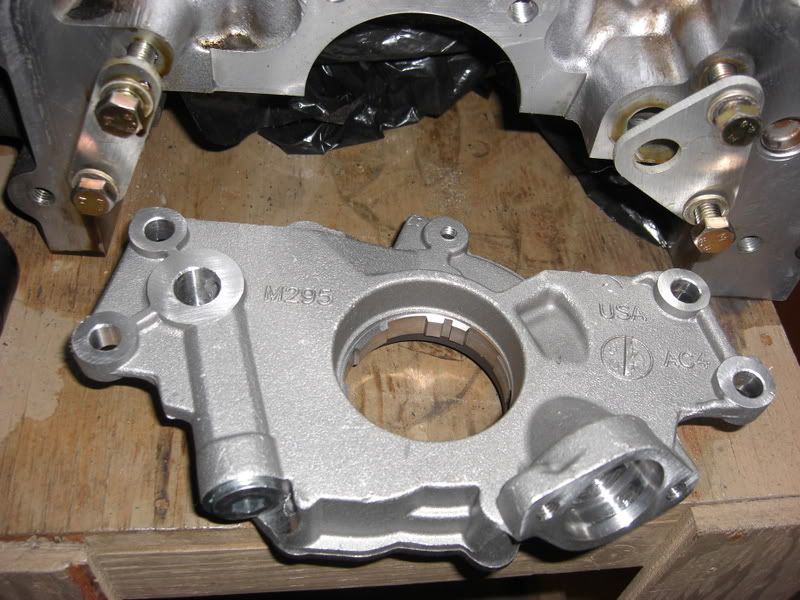

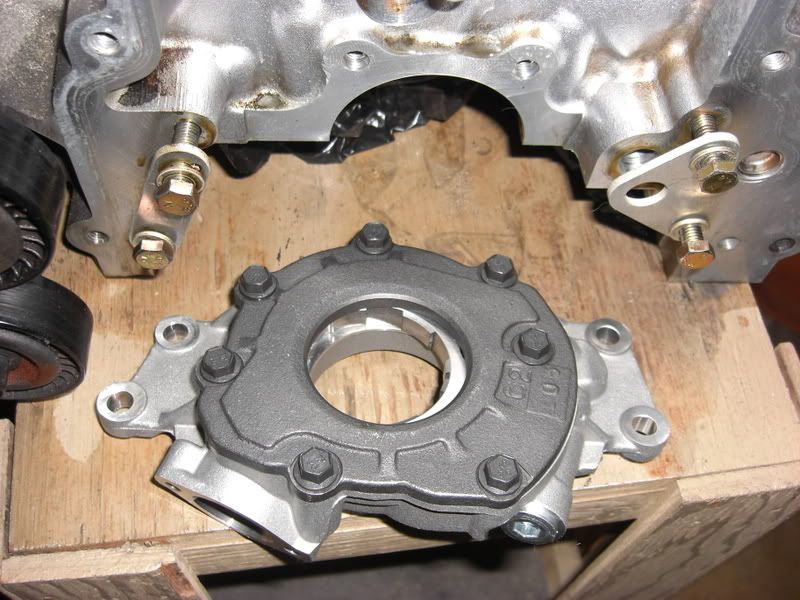

This is my first LS1 teardown and rebuild....I like to check in with the experienced about certain things...So here it is...The motor had a ECS cam in it and a double roller chain..are the thin metal (one with the hole in it) plates with the oil pump bolts through them the oil pump shims to space it out for the double roller??

I've searched and found MANY mixed answers on this, are the cam bearings normally copper? I'm going to replace these anyway but it's bugging me if I don't know...

What can I use to clean the head bolt holes? My tap is too short...I read about cutting up an old bolt? how? any pics?

The cam pin broke off in the cam....can I just knock the rest into the cam and put in a new pin? Not sure if there's a step stopping the pin from going in a certain amount or something...?

Thanks for all help....

I've searched and found MANY mixed answers on this, are the cam bearings normally copper? I'm going to replace these anyway but it's bugging me if I don't know...

What can I use to clean the head bolt holes? My tap is too short...I read about cutting up an old bolt? how? any pics?

The cam pin broke off in the cam....can I just knock the rest into the cam and put in a new pin? Not sure if there's a step stopping the pin from going in a certain amount or something...?

Thanks for all help....

#2

TECH Fanatic

iTrader: (71)

Yes those plates space the pump to clear the thicker gear and chain.

I dont know what they are made of but I know they are not magnetic, so if you find metal bearing material in your filter if it is magnetic its either rod or main bearing material.

You should be able to get the pin out, maybe try a left hand drill bit, obviously smaller than the pin and carefully and slowly drill it, as soon as it catches it should pull right out.

Use an old bolt and a cut off wheel to cut a small V groove into one side then another 180* around.You dont have to go too deep. So you have two gaps that run parallel with the bolt, if you can use a dye before your use it thats a good idea, that way you dont mess up the threads.

When I pulled my heads I used that method, then blew the holes out with air, and still had alot of coolant in the holes. I twisted paper towels and screwed them down the holes over, and over, and over until every one came out dry. You need to do this...if you dont when you torque the head it can and probably will crack the block.

I dont know what they are made of but I know they are not magnetic, so if you find metal bearing material in your filter if it is magnetic its either rod or main bearing material.

You should be able to get the pin out, maybe try a left hand drill bit, obviously smaller than the pin and carefully and slowly drill it, as soon as it catches it should pull right out.

Use an old bolt and a cut off wheel to cut a small V groove into one side then another 180* around.You dont have to go too deep. So you have two gaps that run parallel with the bolt, if you can use a dye before your use it thats a good idea, that way you dont mess up the threads.

When I pulled my heads I used that method, then blew the holes out with air, and still had alot of coolant in the holes. I twisted paper towels and screwed them down the holes over, and over, and over until every one came out dry. You need to do this...if you dont when you torque the head it can and probably will crack the block.

#3

Launching!

Thread Starter

iTrader: (1)

Join Date: Mar 2009

Posts: 259

Likes: 0

Received 0 Likes

on

0 Posts

Yes those plates space the pump to clear the thicker gear and chain.

I dont know what they are made of but I know they are not magnetic, so if you find metal bearing material in your filter if it is magnetic its either rod or main bearing material.

You should be able to get the pin out, maybe try a left hand drill bit, obviously smaller than the pin and carefully and slowly drill it, as soon as it catches it should pull right out.

Use an old bolt and a cut off wheel to cut a small V groove into one side then another 180* around.You dont have to go too deep. So you have two gaps that run parallel with the bolt, if you can use a dye before your use it thats a good idea, that way you dont mess up the threads.

When I pulled my heads I used that method, then blew the holes out with air, and still had alot of coolant in the holes. I twisted paper towels and screwed them down the holes over, and over, and over until every one came out dry. You need to do this...if you dont when you torque the head it can and probably will crack the block.

I dont know what they are made of but I know they are not magnetic, so if you find metal bearing material in your filter if it is magnetic its either rod or main bearing material.

You should be able to get the pin out, maybe try a left hand drill bit, obviously smaller than the pin and carefully and slowly drill it, as soon as it catches it should pull right out.

Use an old bolt and a cut off wheel to cut a small V groove into one side then another 180* around.You dont have to go too deep. So you have two gaps that run parallel with the bolt, if you can use a dye before your use it thats a good idea, that way you dont mess up the threads.

When I pulled my heads I used that method, then blew the holes out with air, and still had alot of coolant in the holes. I twisted paper towels and screwed them down the holes over, and over, and over until every one came out dry. You need to do this...if you dont when you torque the head it can and probably will crack the block.

Obviously I have the motor out and all cleaned out, prob going to take it to work and steam clean it and blow out everything with air actually. I'll try and find an old head bolt to sacrifice as a tap....that cam pin is in there pretty damn tight....I tried using a centerpunch and drilling it and it didn't make a dent....it's hard stuff...I also had a skinny hardened skinny punch in the hole behind it and it didnt budge even with some GOOD whacks.....I'm not going to pay for a shop to do it if I can just knock the pin in some and put in a new pin...so anybody know if I can hit it in more?? is there a step in there that will stop it from going all the way back?? Someone has to have a ls1 cam laying around at least.....