installed motor/trans, now clutch is slipping... HELP!

#1

Launching!

Thread Starter

iTrader: (7)

Join Date: Oct 2008

Location: Cocoa, FL

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

LS1 dropped bearing, so I put in a 5.3 with my t56. new pilot bearing, mobile 1 synthetic, new clutch fluid.

slave was never removed from the transmission, and was bled using factory bleeder, then rebled with a mighty-vac to ensure it wasnt a bleeding issue.

clutch is a Spec stage 3 clutch/pressure plate, it was reused during the swap. i ensured it was clean before going back together.

pedal is strong, and has no problem going into gears.

seems like the clutch is slipping between 35-45%. Car isnt drivable.

help! lol

slave was never removed from the transmission, and was bled using factory bleeder, then rebled with a mighty-vac to ensure it wasnt a bleeding issue.

clutch is a Spec stage 3 clutch/pressure plate, it was reused during the swap. i ensured it was clean before going back together.

pedal is strong, and has no problem going into gears.

seems like the clutch is slipping between 35-45%. Car isnt drivable.

help! lol

Last edited by SpecV44; 04-12-2010 at 01:38 PM.

#2

On The Tree

iTrader: (2)

A little more info:

The clutch engages all the way at the top of the pedal. I mean ALL THE WAY. It never fully grabs before it runs out of pedal. The car drives, but you can tell it is not fully engaging the clutch. It goes into all gears fine with the car running and not moving, but will slip if you give it more than 1/4 throttle. I didn't check to see if the previous installer had used the shim when we had the transmission out, but even if they HAD used the shim, it drove fine before, so it shouldn't be a shim issue. However, the reading I've done indicates that removing the shim (if there is one) would help.

The clutch engages all the way at the top of the pedal. I mean ALL THE WAY. It never fully grabs before it runs out of pedal. The car drives, but you can tell it is not fully engaging the clutch. It goes into all gears fine with the car running and not moving, but will slip if you give it more than 1/4 throttle. I didn't check to see if the previous installer had used the shim when we had the transmission out, but even if they HAD used the shim, it drove fine before, so it shouldn't be a shim issue. However, the reading I've done indicates that removing the shim (if there is one) would help.

#4

Is the crank depth different on the 5.3L? If so it could be pushing the clutch back farther, towards the motor, causing the geometry to be different. I have not spent much time around the 5.3L hence my question about this?

You can check the geometry by following the instructions in the link below. Take a look, take some measurements, and let me know what you find. Thanks,

https://ls1tech.com/forums/manual-tr...need-shim.html

You can check the geometry by following the instructions in the link below. Take a look, take some measurements, and let me know what you find. Thanks,

https://ls1tech.com/forums/manual-tr...need-shim.html

#5

On The Tree

iTrader: (2)

Thanks for the input Jeremy. There's not supposed to be a difference in crank depth between the 5.3L and 5.7L. We'll pull the trans, re-torque the flywheel and pressure plate and measure for the shim. I'm almost certain its a geometry problem. I have a spare 5.3L and a 5.7L sitting at home, I'll take some external measurements as well.

#7

Launching!

Thread Starter

iTrader: (7)

Join Date: Oct 2008

Location: Cocoa, FL

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

UPDATE:

Pulled trans Saturday, reinstalled Sunday. When I had the trans out, I pulled slave off, flywheel, clutch, pressure plate off. Resurfaced the pressure plate, cleaned up the clutch disk (grooved kind of deep, so I knocked them down, as they were raised), re-cleaned everything, put everything back together using the correct torque specs, in the correct order on both flywheel and pressure plate. Installed NEW slave, without the shim this time, bled it before installing in the trans, then vacuum bled it for 30 minutes after installation (never broke line between bleeding out and bleeding in).

NO change, ZERO, ZIP, ZILCH, NADA. Still engages at the top of the pedal, and doesnt seem to be engaging far enough, like it is running out of pedal travel, but I cant pull the pedal up anymore. The only difference is that now the clutch chatters, but I think that is because it is technically, like a new clutch now, everything smooth. Perhaps the fingers on the pressure plate tweaked out when it was removed from the LS1? We tore it down out of the car, so the trans never rested on them or anything.

Pulled trans Saturday, reinstalled Sunday. When I had the trans out, I pulled slave off, flywheel, clutch, pressure plate off. Resurfaced the pressure plate, cleaned up the clutch disk (grooved kind of deep, so I knocked them down, as they were raised), re-cleaned everything, put everything back together using the correct torque specs, in the correct order on both flywheel and pressure plate. Installed NEW slave, without the shim this time, bled it before installing in the trans, then vacuum bled it for 30 minutes after installation (never broke line between bleeding out and bleeding in).

NO change, ZERO, ZIP, ZILCH, NADA. Still engages at the top of the pedal, and doesnt seem to be engaging far enough, like it is running out of pedal travel, but I cant pull the pedal up anymore. The only difference is that now the clutch chatters, but I think that is because it is technically, like a new clutch now, everything smooth. Perhaps the fingers on the pressure plate tweaked out when it was removed from the LS1? We tore it down out of the car, so the trans never rested on them or anything.

Trending Topics

#8

Launching!

Thread Starter

iTrader: (7)

Join Date: Oct 2008

Location: Cocoa, FL

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

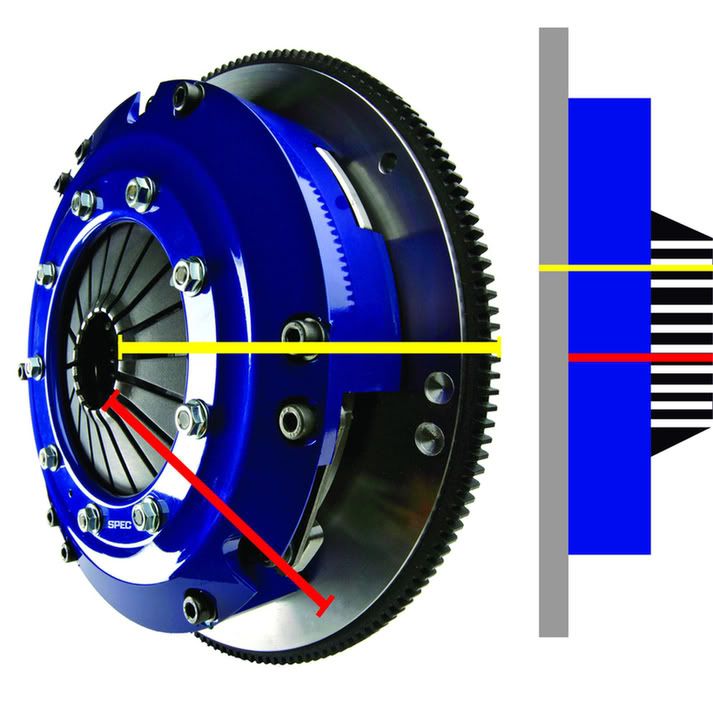

When measuring, the distance from the fingers to the bellhousing (transmission side, not engine side) was almost identical to the distance from the face of the throwout bearing and the bellhousing (trans side). We left the shim out when we reinstalled it this time, and no change. It had a 1/8" shim behind the slave that we took out. But, the shim was in there the first time we installed it, so it doesnt seem to be a geometry issue, it seems to be a pressure plate/clutch issue...

#9

If the measurement A and B are the same then that explains why the pedal is at the top of its travel. I am not looking at the parts but if you took a measurement of the clutches stack height that would be a good point of reference for geometry. Measure from the mounting surface on the back of the flywheel where it seats to the crank to the diaphragm finger peak. Let me know what you find. Of course, you can always give me a call and I will issue an RMA so we can check the parts out here if you like. Thanks,

#10

Launching!

Thread Starter

iTrader: (7)

Join Date: Oct 2008

Location: Cocoa, FL

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

ok, so measure from the back side of the flywheel (not the side with the pressure plate bolted to it) to the front of the finger peak?

I am uploading a picture now to verify which measurement you are looking for.

I am uploading a picture now to verify which measurement you are looking for.

#12

Launching!

Thread Starter

iTrader: (7)

Join Date: Oct 2008

Location: Cocoa, FL

Posts: 202

Likes: 0

Received 0 Likes

on

0 Posts

well, changed the pressure plate/clutch last night, and now everything is good.

I compared the "new" pressure plate against the old pressure plate, and found out what was wrong: The mating surface on the pressure plate (where it meets the clutch disk) was too far away from the clutch. I set the 2 pressure plates on the ground, and the "new" one was 1/8"-3/16" further OUT than the old one. The fingers also pulled in when torqued down, as the old one did NOT do. Still unsure as to WHY this happened, but none the less.

I compared the "new" pressure plate against the old pressure plate, and found out what was wrong: The mating surface on the pressure plate (where it meets the clutch disk) was too far away from the clutch. I set the 2 pressure plates on the ground, and the "new" one was 1/8"-3/16" further OUT than the old one. The fingers also pulled in when torqued down, as the old one did NOT do. Still unsure as to WHY this happened, but none the less.