Damn stock lower A Arm + bmr k member

#1

While the engine is out of my car (yeah, still) one of the last mods I've been meaning to do is a BMR tubular k member. I followed the instructions, unbolted the rack & pinion, lower a arms, stock k member, etc. Then when I bolted the bmr k member in and the driver's side lower a arm went back on the new k member easily.

I get to the passenger side and with all the pry bars, jacks, etc in the world and I can get the front (closest to the radiator) one in, but then I can't get the effing back one in. It's off by less than a quarter of an inch.

I figure it would be easy, engine out of the car and all that.. meh.

Anyone have this problem before?

I get to the passenger side and with all the pry bars, jacks, etc in the world and I can get the front (closest to the radiator) one in, but then I can't get the effing back one in. It's off by less than a quarter of an inch.

I figure it would be easy, engine out of the car and all that.. meh.

Anyone have this problem before?

#2

TECH Fanatic

I have a UMI k-member and I'm trying to visualize what your saying.. mine had no issues. Ummm... is your a-arm possibly bent? I dont understand how the lower a-arm wont fit into a new k-member unless its bent or the new k-member may be off.. have any photos of what your talking about?

#4

I have a UMI k-member and I'm trying to visualize what your saying.. mine had no issues. Ummm... is your a-arm possibly bent? I dont understand how the lower a-arm wont fit into a new k-member unless its bent or the new k-member may be off.. have any photos of what your talking about?

Trending Topics

#10

12 Second Club

iTrader: (30)

Join Date: Nov 2006

Location: Cloverdale, BC

Posts: 1,348

Likes: 0

Received 0 Likes

on

0 Posts

Is the K member powdercoated? If so try anding down the poweder coat in that area sometimes it's very thick. If thats not the case, or doesnt work File down the top and bottom of the a arm piece slightly where the bolt goes through. (Steel tube in the middle of the bushing).

#11

TECH Resident

iTrader: (12)

Join Date: Apr 2006

Location: Lantana, TX

Posts: 956

Likes: 0

Received 0 Likes

on

0 Posts

Is the k-member too wide or too narrow? Can you get one end in and not the other, or is it only the front that you are having problems with? I read that you got the back in and couldn't get the front and then you did something and the back doesn't go in now either? You have to put both in at the same time and you can't work one side in first or it will get whoppy jaw'd and won't work. Use lots of WD-40 too.

#13

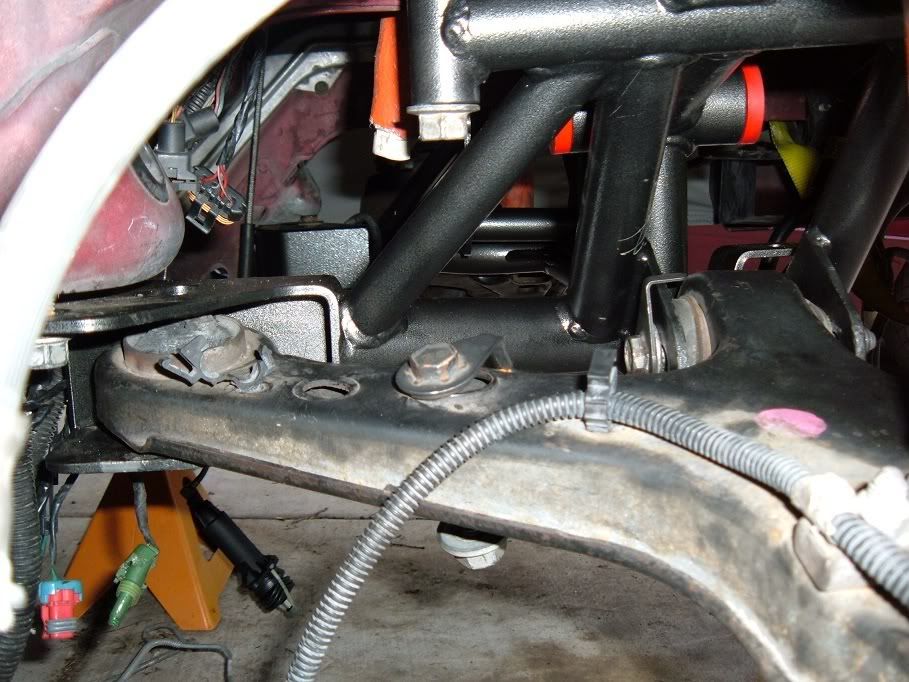

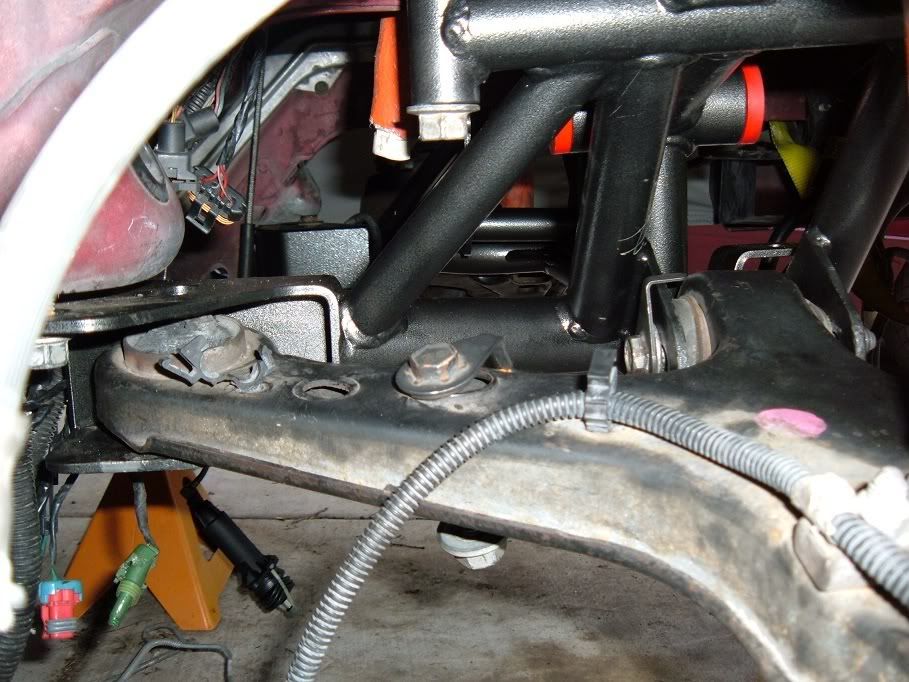

Ok, here is what it looks like (underneath):

Right now the front bolt is bolted in - but that's mainly because I just want to roll it onto a tow truck to take it to my friend's shop - access to a lift to put the engine back in and a lot more room than my driveway.

It does the same thing whether the front bolt is in or not. Whether the kmember is unbolted or bolted. Whether the A arm is jacked up or not. :

:

ALSO NOTE THAT "COCKED" bolt is put there just so I won't lose it. It's not in the right hole (OBVIOUSLY).

Right now the front bolt is bolted in - but that's mainly because I just want to roll it onto a tow truck to take it to my friend's shop - access to a lift to put the engine back in and a lot more room than my driveway.

It does the same thing whether the front bolt is in or not. Whether the kmember is unbolted or bolted. Whether the A arm is jacked up or not.

:

:ALSO NOTE THAT "COCKED" bolt is put there just so I won't lose it. It's not in the right hole (OBVIOUSLY).

Last edited by Z28Roxy; 06-28-2010 at 06:52 PM.

#17

TECH Fanatic

Of the two bolts, you have the front one installed in the photo. Is THAT bolt hole slotted too or just a hole big enough for the bolt? My UMI setup has slots for both bolts. You say that its the same even with that front bolt out though so, that probably wouldn't help anyway. Your a-arm in the photo looks to be in good shape so, wouldn't think its that. My SS that I wrecked took a good blow to the driverside front wheel and bent that sides spindle & uppler and lower a-arms a bit. Your car hasn't been in a small wreck possibly has it?

If the other side went in perfect, take a tape measure and check some distances and angles from both sides. Maybe you can easily prove to yourself that its just a defect. Definitely ask BMR... For the cost of these things and their rep, they will most likely stand behind their part and replace it if there's a problem.

If the other side went in perfect, take a tape measure and check some distances and angles from both sides. Maybe you can easily prove to yourself that its just a defect. Definitely ask BMR... For the cost of these things and their rep, they will most likely stand behind their part and replace it if there's a problem.