Comp trunion upgrade

#1

TECH Resident

Thread Starter

Join Date: Feb 2002

Location: Roseville, Ca.

Posts: 843

Likes: 0

Received 0 Likes

on

0 Posts

So I was going to do this tonight, but can't find my snap ring pliers...

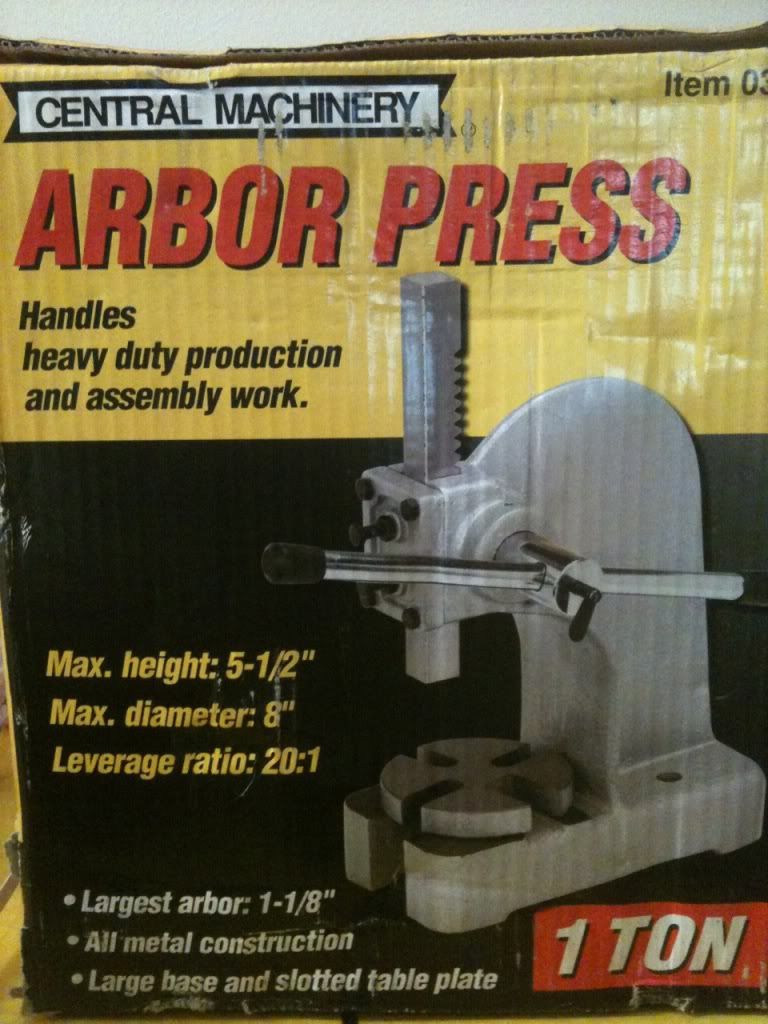

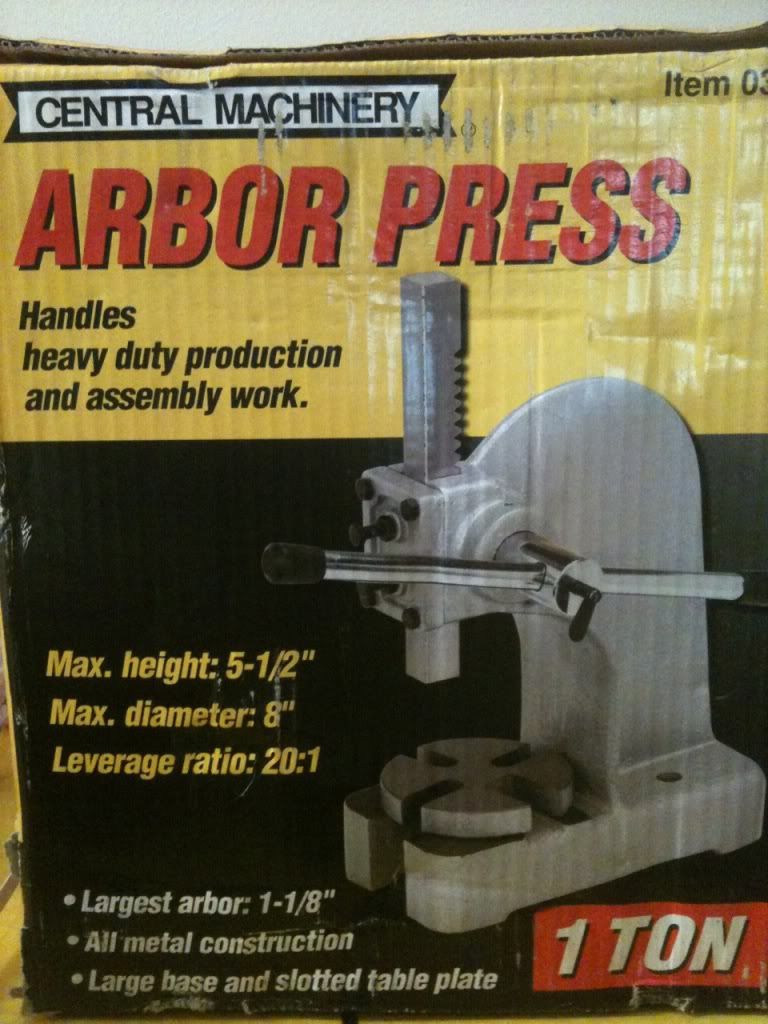

anyway, I bought an Arbor press at Harbor freight for $44.00.

This first pic shows a Harland rebuilt rocker on the left, stock on the right and the new comp trunions below.

The Harlands got oil starved in my last motor and the bearings are wasted.

Anyone have any tips or tricks to share?

anyway, I bought an Arbor press at Harbor freight for $44.00.

This first pic shows a Harland rebuilt rocker on the left, stock on the right and the new comp trunions below.

The Harlands got oil starved in my last motor and the bearings are wasted.

Anyone have any tips or tricks to share?

#2

Launching!

iTrader: (2)

Join Date: Feb 2009

Location: Morrison, Colorado

Posts: 225

Likes: 0

Received 0 Likes

on

0 Posts

I just got done installing them in my motor, have had a chance to start it yet still waiting on a couple small parts... What kind of advice are you looking for??? install advice???

#3

TECH Resident

Thread Starter

Join Date: Feb 2002

Location: Roseville, Ca.

Posts: 843

Likes: 0

Received 0 Likes

on

0 Posts

Yes. Does it take a lot of force to press the bearings? Should I soak them in oil before I put them in the car? I'm a newb to this... What should I NOT do?

#4

Teching In

iTrader: (28)

Join Date: Dec 2008

Location: SE Minnesota

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

I just put a set together, but haven't installed them in the car. With a press they go together fairly easy. The only thing I was concerned with was there is enough space between the snap rings, bearings, and trunion that if you don't press them on far enough, the rocker can slide side to side, if you press them on too far, it will drag when it pivots. Or it's possible to press it all the way against one snap ring and the rocker will be off center. I assume Harland puts the small washers under the snap rings to take up the slack, the comp kit doesn't come with them. I called Comp's tech line and they said they had never heard of a problem of the rockers moving around on the trunion, and I searched on here and didn't find anyone having problems. So, I just centered the rocker and pushed each bearing in far enough so it didn't move side to side and didn't bind. You'll get a feel for them after you put a few together. Oh, and I think they tell you to put the lettering on the bearings to the outside.

#6

Teching In

iTrader: (28)

Join Date: Dec 2008

Location: SE Minnesota

Posts: 39

Likes: 0

Received 0 Likes

on

0 Posts

I checked out Fastenal, McMaster-Carr and a few others to see about getting washers, but decided maybe I was being a little too picky if no one was having trouble with out them. But, I don't think there would be a problem using the Harland washers if you have them, as long as they don't restrict oil getting to the bearings.

Trending Topics

#8

Launching!

iTrader: (2)

Join Date: Feb 2009

Location: Morrison, Colorado

Posts: 225

Likes: 0

Received 0 Likes

on

0 Posts

What i did was press the bearings in so that they were flush with the outside of the rocker that way the turnion will be centered and not alot of play in them, if you go too far you can always back the off a little with a tap of a hammer... Make sure the lettering on the bearings is facing out but i am sure you read that in the instructions, I put mine together with a couple of sockets and a hammer lol not the right way but it worked.

#9

On The Tree

iTrader: (22)

Join Date: Dec 2008

Location: Ferndale, Mi

Posts: 120

Likes: 0

Received 0 Likes

on

0 Posts

sbsrkh hit the nail on the head with the only concern that I had while assembling mine. You can wing it just by looking at how far you push the bearing into the rocker. I did mine with my humongous vice and didn't have any problems. I used a bunch of sockets to do the pushing out of the old trunions and the installation of the new ones. Here's a couple pics:

#11

TECH Resident

Thread Starter

Join Date: Feb 2002

Location: Roseville, Ca.

Posts: 843

Likes: 0

Received 0 Likes

on

0 Posts

In MY mind, the only way to settle the issue if washers are needed and if there is indeed too much play would be to look at the wipe pattern on the tip. Irregular or any contact on or over the edges might be the smoking gun if it IS a problem?

Here's the contact area of a Harlan... anyone care to post up a pic of their Comps WITHOUT the washers?

Here's the contact area of a Harlan... anyone care to post up a pic of their Comps WITHOUT the washers?

#12

TECH Regular

iTrader: (1)

seems like there was a thread a while back about a problem with using the stock bolts with this kit. anyone else remember this?

found it

https://ls1tech.com/forums/generatio...-question.html

found it

https://ls1tech.com/forums/generatio...-question.html

#14

TECH Resident

Thread Starter

Join Date: Feb 2002

Location: Roseville, Ca.

Posts: 843

Likes: 0

Received 0 Likes

on

0 Posts

seems like there was a thread a while back about a problem with using the stock bolts with this kit. anyone else remember this?

found it

https://ls1tech.com/forums/generatio...-question.html

found it

https://ls1tech.com/forums/generatio...-question.html

Last edited by Steve Gunn; 07-28-2010 at 07:50 AM.

#15

TECH Resident

iTrader: (10)

The thread listed above seems to be mostly concerned about the non-threaded portion of the bolt being too long and that extending the threads on stock bolts is a solution. The non-threaded portion of the stock bolts does extend past the bottom of the pedestal, but not much. Of bigger concern is the extra .300 length of the stock bolt causes it to stick out a lot further into the intake port and seems that it could be an even bigger problem on the exhaust side.

Stock on intake

Comp bolt

Stock bolt and pedestal

Stock on intake

Comp bolt

Stock bolt and pedestal

#16

TECH Resident

Thread Starter

Join Date: Feb 2002

Location: Roseville, Ca.

Posts: 843

Likes: 0

Received 0 Likes

on

0 Posts

That's some badass portwork.

I don't think with or without the washers would matter now that I have them out and see how thin they are. But I'll install them anyway.

I don't think with or without the washers would matter now that I have them out and see how thin they are. But I'll install them anyway.