Can't get SLP UD Pulley seated all the way

#1

On The Tree

Thread Starter

iTrader: (16)

Join Date: May 2010

Location: Stillwater, OK

Posts: 174

Likes: 0

Received 0 Likes

on

0 Posts

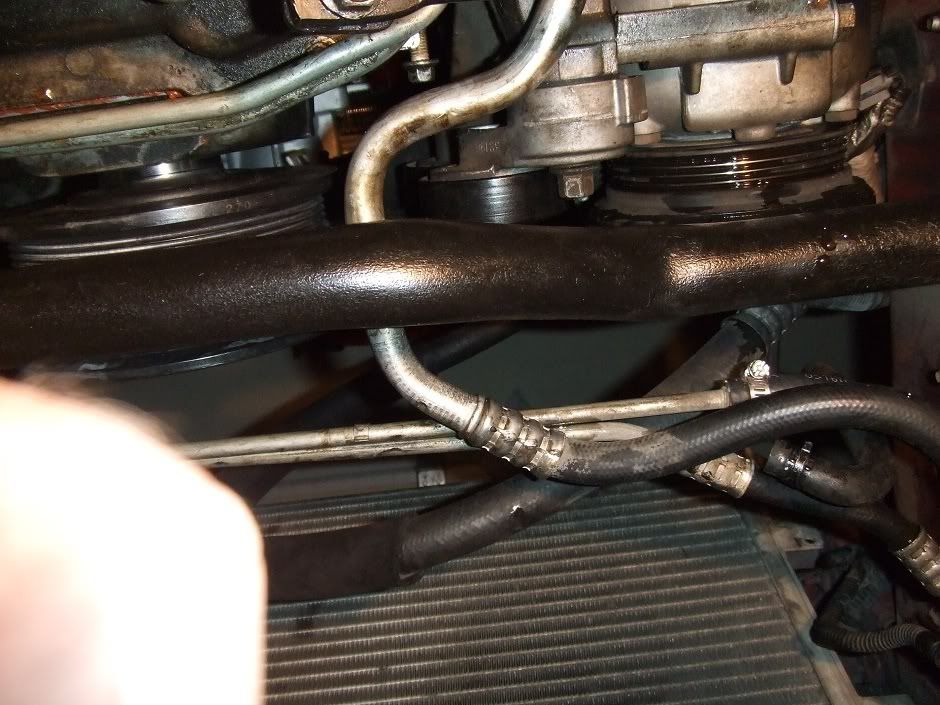

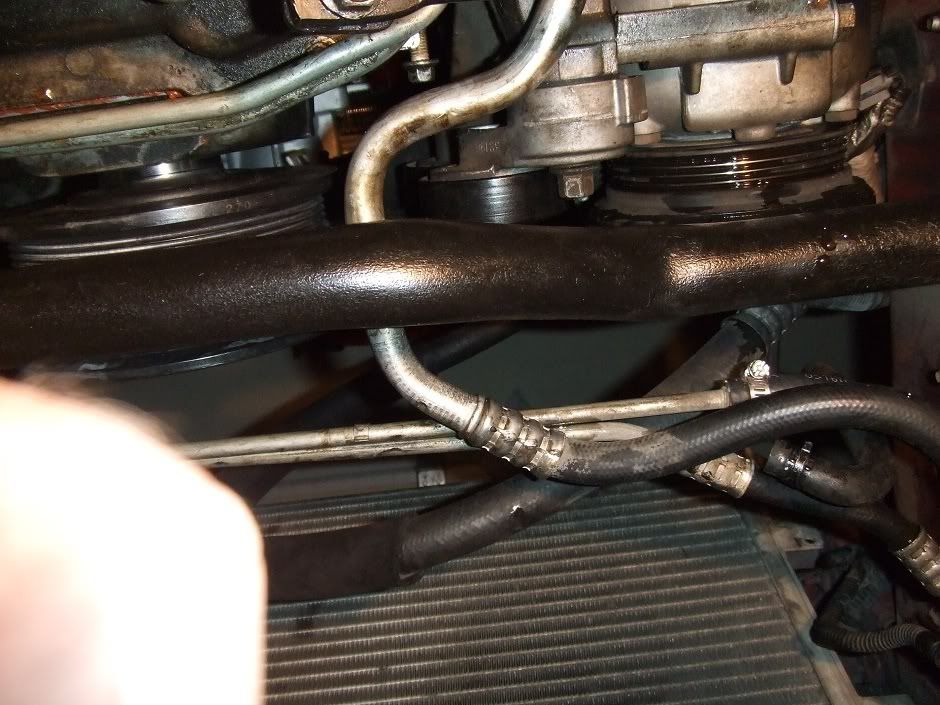

I'm so close to finishing up my cam swap, but I'm stuck! I cannot get the SLP underdrive pulley I bought to seat! How much further does it need to go?

I used the threaded rod, washers, & bolt that I bought from a member here to get to this point, as well as a 3' breakover bar. All it does from this point is bend the washers in & it will not budge any further.

Any ideas or suggestions?

I used the threaded rod, washers, & bolt that I bought from a member here to get to this point, as well as a 3' breakover bar. All it does from this point is bend the washers in & it will not budge any further.

Any ideas or suggestions?

Last edited by osuhog; 09-28-2010 at 07:23 AM.

#4

On The Tree

Thread Starter

iTrader: (16)

Join Date: May 2010

Location: Stillwater, OK

Posts: 174

Likes: 0

Received 0 Likes

on

0 Posts

Man, I almost did the same thing last night, but I just didn't want to take a chance without asking around first. How long ago did you do that, & have you had any problems with the belt slipping off or anything? It looks like it lines right up with everything, but I don't know.

I'm thinking about going back & renting the pulley puller again & pulling it off to slap it in the oven & trying again. I wasn't planning on doing that originally, but I don't know what else to do.

I'm getting ready to search around for this answer, but does the same Chrysler pulley puller from Autozone work with the SLP pulley?

I'm thinking about going back & renting the pulley puller again & pulling it off to slap it in the oven & trying again. I wasn't planning on doing that originally, but I don't know what else to do.

I'm getting ready to search around for this answer, but does the same Chrysler pulley puller from Autozone work with the SLP pulley?

Last edited by osuhog; 09-28-2010 at 10:54 AM.

#7

On The Tree

Thread Starter

iTrader: (16)

Join Date: May 2010

Location: Stillwater, OK

Posts: 174

Likes: 0

Received 0 Likes

on

0 Posts

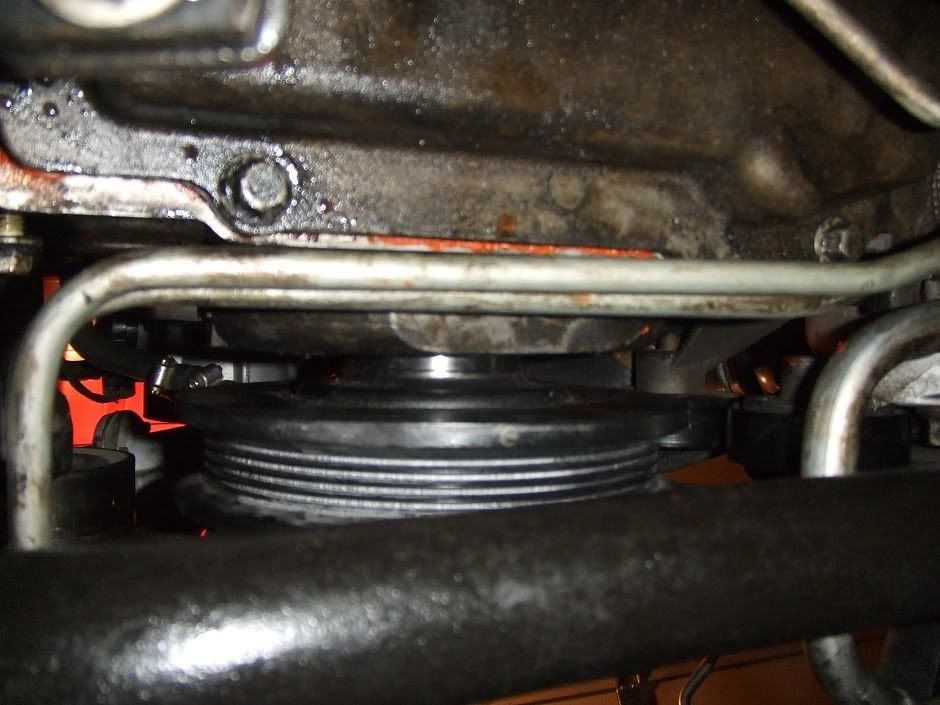

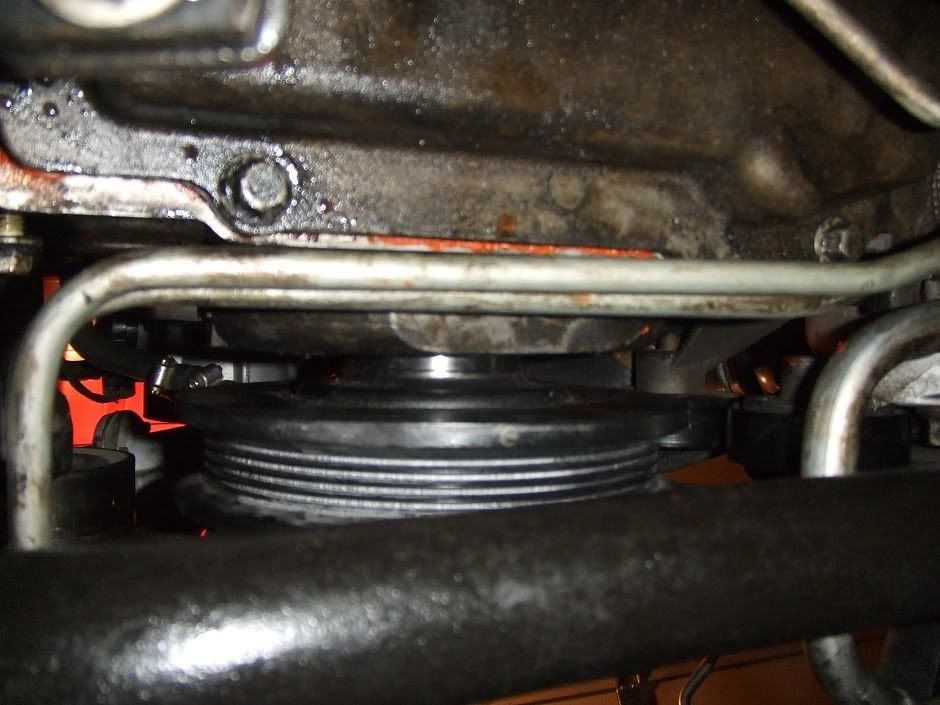

Awesome, thanks for the pics guys, that really helps. I went ahead & pulled it back off at lunch today. I'm gonna heat it in the oven & try again tonight. If it goes to exactly the same point, it's gotta be good.

Trending Topics

#9

On The Tree

Thread Starter

iTrader: (16)

Join Date: May 2010

Location: Stillwater, OK

Posts: 174

Likes: 0

Received 0 Likes

on

0 Posts

Just an update. I popped it in the oven for 20 minutes at 250 last night & slid it back on. Torqued it down with a regular ratchet & no breakover bar & it went right on. Probably could have saved myself 3 hours or more & a bunch of frustration if I would have done this in the first place.

That said, it went to the exact same point, so I actually had it seated before. It was just much easier to tell that it had bottomed out this time.

Again, thanks for the help guys.

That said, it went to the exact same point, so I actually had it seated before. It was just much easier to tell that it had bottomed out this time.

Again, thanks for the help guys.

#11

On The Tree

Thread Starter

iTrader: (16)

Join Date: May 2010

Location: Stillwater, OK

Posts: 174

Likes: 0

Received 0 Likes

on

0 Posts

Interesting. It sure felt like there was an exact point where it was sliding on fairly easily (torquing about as hard as I could without a breakover, so still not actually easy), & then it just stopped sliding on any more. At that point, I torqued it to 200 with the old bolt (high as my torque wrench goes), but it didn't budge any more. I then installed the new bolt, torqued it to 37 ft. lbs., marked it, & went as many degrees as I could, which was probably 100 or so. I couldn't get to the full 160 or whatever it was supposed to be. The LS1howto article said that was fine, so hopefully it is.

Last edited by osuhog; 09-29-2010 at 10:05 AM.