New motor knocking sound?

#1

11 Second Club

Thread Starter

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

I built a 4" stroker LS2, all good parts, all new, properly clearanced.

I am using the stock cam, and related parts, except for the valve springs. I put in the 918's. Motor is knocking or ticking. I read a ton on the sewing machine sound, I removed and reinstalled all my rockers, twice. I even started the car up with no valve covers on and tried to push on the rockers to see if any were loose. It still is noisy. I'm on the verge of pulling it out and tearing it down to check the bottom end. I had another mechanic take a listen to it and he thinks it's lifter noise. I did seem to have a couple of rockers that only needed just under 1 turn to get to 22ft/pd. The only other valvetrain change would be LS9 head gaskets, but I heard they are the same thickness as the originals anyway.

Any ideas?

I am using the stock cam, and related parts, except for the valve springs. I put in the 918's. Motor is knocking or ticking. I read a ton on the sewing machine sound, I removed and reinstalled all my rockers, twice. I even started the car up with no valve covers on and tried to push on the rockers to see if any were loose. It still is noisy. I'm on the verge of pulling it out and tearing it down to check the bottom end. I had another mechanic take a listen to it and he thinks it's lifter noise. I did seem to have a couple of rockers that only needed just under 1 turn to get to 22ft/pd. The only other valvetrain change would be LS9 head gaskets, but I heard they are the same thickness as the originals anyway.

Any ideas?

#2

Did you let it run for a complete warm up cycle? Did you check pudhrod length? I did this job today and the lifters take a while to pump up. If you checked pushrod length you would know for sure. Is it two or all eight of them?

#3

u should but the lifter in a new oil for 24 over night before u install them

and the rockers angle is fine coz u used the oem one

so my idea is the push rod length ? get push rod tester and major the length to make shore

if u rive it to 2000-2500 rbm still making sound ?

and the rockers angle is fine coz u used the oem one

so my idea is the push rod length ? get push rod tester and major the length to make shore

if u rive it to 2000-2500 rbm still making sound ?

#4

I would guess push rod length

#5

11 Second Club

Thread Starter

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

If these valvetrain parts all worked together (minus the springs) before, why would pushrod length change? Is it possible to collapse a lifter by tightening the rocker out of sequence (valve opened because cam was not on base circle) which results in the lifter staying collapsed?

I have warmed it up completely, and tried revving it up a little, 3000-3500, but the noise is still there.

The noise seems to go away as the rpm increases.

When I ran it with the valve covers off there was oil coming through all the pushrods, just a dribble, but as the rpm increases, by even 500 rpm the dribble increases quickly. Oil pressure is 50psi cold at idle, 45psi hot idle.

I have warmed it up completely, and tried revving it up a little, 3000-3500, but the noise is still there.

The noise seems to go away as the rpm increases.

When I ran it with the valve covers off there was oil coming through all the pushrods, just a dribble, but as the rpm increases, by even 500 rpm the dribble increases quickly. Oil pressure is 50psi cold at idle, 45psi hot idle.

#7

Stock cam? Or the cam you had in before the stroker kit? Has the block deck or heads been milled? I always soaked lifters overnight too, but ***IF*** that was the problem, you'd think they'd quiet down by now. Who actually machind the block/rotating assem? Who assembled it?

Trending Topics

#8

Either way. I'd recheck for proper rockerarm/valve contact. The videos make it sound like a diesel.

Good luck dude.

Good luck dude.

#9

11 Second Club

Thread Starter

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

Stock cam, brand new scat crank and rods, clevite 77 bearings, plastigauged, assembled by me. (I am a mechanic, and have built multiple engines, this is my first LS though)

Block is stock deck, heads are un-milled. I did find 1 or 2 lifters that after zero lash was found I could push the pushrod down into the lifter fairly easily with my thumb, is that normal? This was after 2 heat cycles.

One other note is that the exhaust manifold to turbo pipe is without gaskets right now and is leaking. So there is some noise there, but not that discernable ticking.

Block is stock deck, heads are un-milled. I did find 1 or 2 lifters that after zero lash was found I could push the pushrod down into the lifter fairly easily with my thumb, is that normal? This was after 2 heat cycles.

One other note is that the exhaust manifold to turbo pipe is without gaskets right now and is leaking. So there is some noise there, but not that discernable ticking.

Last edited by Marktainium; 04-24-2011 at 04:55 PM.

#10

I would make sure all exhaust leaks solved prior to trying to find a noise. Fixing the preload should help. But I assume it didn't solve it, huh? Plasicgauge isn't the best. Especially for a TURBO motor.

#14

11 Second Club

Thread Starter

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

All the clearancing was done. Turned over on the engine stand I don't know how many times, done "by the book". Understood that plastigauge isn't the best way, but it's what I had. If the general concensus is rod knock or clearance issue then out it comes. It does become quieter with rpm increase.

I turned the motor over with the oil pan gasket removed. There was no contact. I shimmed the windage tray away from the crank 3 flat washers, I checked the reluctor to piston clearance, and did the necesary grinding on the cylinder wall skirts to clearance the rod bolts. I turned the motor over by hand after the pan was installed and had no issues there.

I turned the motor over with the oil pan gasket removed. There was no contact. I shimmed the windage tray away from the crank 3 flat washers, I checked the reluctor to piston clearance, and did the necesary grinding on the cylinder wall skirts to clearance the rod bolts. I turned the motor over by hand after the pan was installed and had no issues there.

Last edited by Marktainium; 04-24-2011 at 08:36 PM.

#16

"I did find 1 or 2 lifters that after zero lash was found I could push the pushrod down into the lifter fairly easily with my thumb, is that normal? This was after 2 heat cycles.

"

You should not be able to push the lifter plunger down with your thumb after all the air is out of it. It sometimes takes a while.

"

You should not be able to push the lifter plunger down with your thumb after all the air is out of it. It sometimes takes a while.

#17

11 Second Club

Thread Starter

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

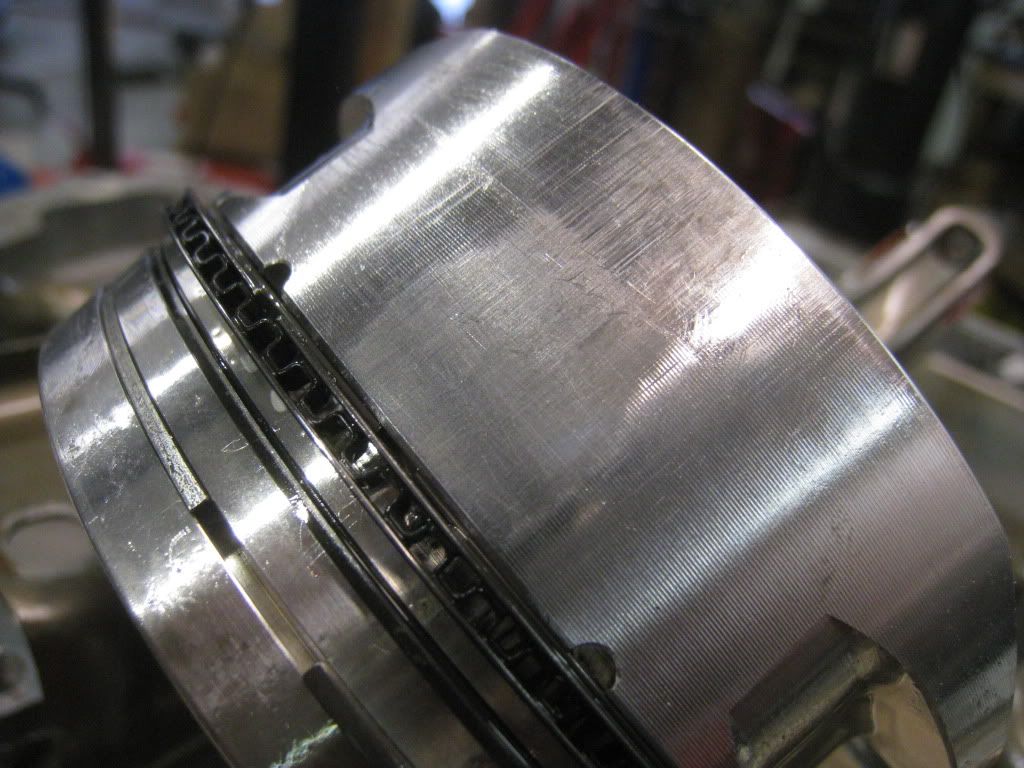

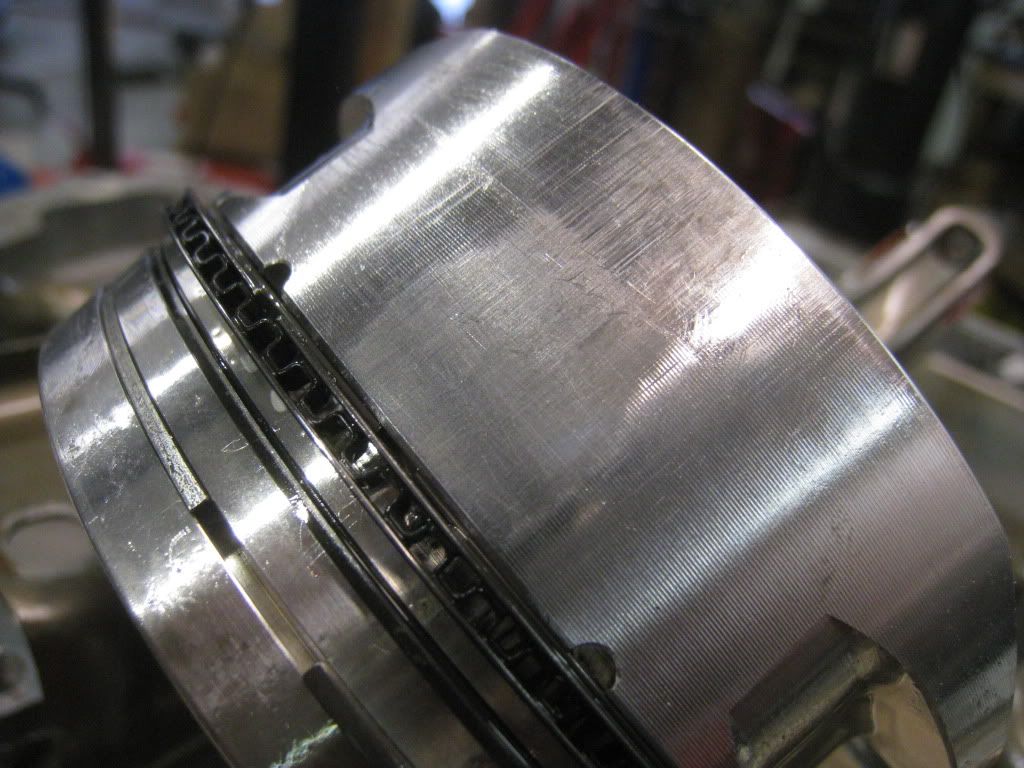

I researched the heck out of this noise and decided better safe than sorry. I pulled the motor over the last few days. I ordered a new set of lifters, and head gaskets. I pulled the rockers and spark plugs and turned it over by hand. No noises, no uneven resistance. I pulled the heads and checked again. Still all good. Pulled the motor completely and checked rod end play, none found. I was turning it over while it was hanging from my hoist, and I heard a soft knock sound. Investigating further, I found the culprit. Piston slap.

This motor has forged pistons that call for .004" clearance. It seems that as the stroke rolls over from up to down that knock sound is the skirt flopping from one side to the other. I think.... I'm going to take the short block to a local pro engine builder to have him inspect it, just to be sure.

I inspected all the lifters and found them all to be full of oil, and resistant to being compressed. There was one that "gave" a little, but not enough to make me feel that that was the culprit. I will replace them anyway.

This motor has forged pistons that call for .004" clearance. It seems that as the stroke rolls over from up to down that knock sound is the skirt flopping from one side to the other. I think.... I'm going to take the short block to a local pro engine builder to have him inspect it, just to be sure.

I inspected all the lifters and found them all to be full of oil, and resistant to being compressed. There was one that "gave" a little, but not enough to make me feel that that was the culprit. I will replace them anyway.

#19

Teching In

Join Date: Jun 2010

Location: Yeppoon, Qld. Australia

Posts: 29

Likes: 0

Received 0 Likes

on

0 Posts

I researched the heck out of this noise and decided better safe than sorry. I pulled the motor over the last few days. I ordered a new set of lifters, and head gaskets. I pulled the rockers and spark plugs and turned it over by hand. No noises, no uneven resistance. I pulled the heads and checked again. Still all good. Pulled the motor completely and checked rod end play, none found. I was turning it over while it was hanging from my hoist, and I heard a soft knock sound. Investigating further, I found the culprit. Piston slap.

This motor has forged pistons that call for .004" clearance. It seems that as the stroke rolls over from up to down that knock sound is the skirt flopping from one side to the other. I think.... I'm going to take the short block to a local pro engine builder to have him inspect it, just to be sure.

I inspected all the lifters and found them all to be full of oil, and resistant to being compressed. There was one that "gave" a little, but not enough to make me feel that that was the culprit. I will replace them anyway.

This motor has forged pistons that call for .004" clearance. It seems that as the stroke rolls over from up to down that knock sound is the skirt flopping from one side to the other. I think.... I'm going to take the short block to a local pro engine builder to have him inspect it, just to be sure.

I inspected all the lifters and found them all to be full of oil, and resistant to being compressed. There was one that "gave" a little, but not enough to make me feel that that was the culprit. I will replace them anyway.

#20

11 Second Club

Thread Starter

Join Date: Mar 2008

Location: New Westminster, B.C., Canada

Posts: 445

Likes: 0

Received 1 Like

on

1 Post

Well, after tearing it down I found excessive scuffing on the piston sides, both major and minor thrust sides. I took a bunch of pics and relayed them to the piston manufacturer. he had me send them back to him for inspection. He sent them out to an independent measuring company, who measures to within a millionth of an inch. Turns out the pistons are ok but the problem was that the oil ring support ring that I received was the wrong size. From what I was told , once it was installed into the oil ring groove, being that it was for a slightly smaller diameter piston, it deformed into a wavy shape which in turn pinched the oil control ring which in turn prevented proper piston skirt / side lubrication. I have since received the pistons back, with new rings, and new support rings.

I'm getting pretty good at filing rings, as this is the third set for this engine, which still hasn't been driven.

I got everything put back together this last weekend and was lowering the car down off of the jackstands to fire it up when a wheel fell off of my jack causing the jack to stop moving and the car moved on the jack which ended up with the jack going through the oil pan. AWESOME!

I pulled the motor back out the next day, and tried to weld up the cracks but as the pan cooled the welds cracked. I ordered another oil pan and am waiting for that now.

My patience is being severely tested, and I'm close to locking up the garage and breaking off the key in the locks. My birthday is a week from today, I hope to have it driving by then.

I'm getting pretty good at filing rings, as this is the third set for this engine, which still hasn't been driven.

I got everything put back together this last weekend and was lowering the car down off of the jackstands to fire it up when a wheel fell off of my jack causing the jack to stop moving and the car moved on the jack which ended up with the jack going through the oil pan. AWESOME!

I pulled the motor back out the next day, and tried to weld up the cracks but as the pan cooled the welds cracked. I ordered another oil pan and am waiting for that now.

My patience is being severely tested, and I'm close to locking up the garage and breaking off the key in the locks. My birthday is a week from today, I hope to have it driving by then.