Looking for low profile LS1 crank pulley...

#1

Staging Lane

Thread Starter

Greetings! I'm new here.

Does anyone know of a LS1-compatible crank pulley that will protrude no farther forward than the pulley bolt head on the front of the crank? The goal is to minimize the length, of the engine front to back. I have found LS2 and L76 pulleys to have less offset, but I am looking for as low profile as possible, since there is NO ROOM in the bumper. Accessories will be mounted further back to match, on custom brackets.

Background build:

I'm making hard plans to swap a LS1 into my 2005 Subaru Legacy GT, retaining stock 5AT with adapters, motor plate, etc. However, the stock engine is not long front to back (about half the length of the LS1 with water pump), and the LS1 front cylinders will be sitting on the plane of the radiator. So I need to make the front pulleys as far back and close to the motor front as possible. Goal is to get the shortest possible engine. Plan is to run a remote electric or side-mounted water pump, and to use or machine the lowest profile crank pulley offset available. Front motor plates will be used to custom mount all belt-driven accessories.

Attached photo shows 27" forward from trans bellhousing. That's the little 2.5 liter boxer engine, which is almost ready to make 395whp on E85, but with mediocre driveability, full boost by 3500rpm. You can't safely make more than 450whp on a stock EJ25 (that's with E85), and by then driveability is terrible with peak boost at 4000rpm (or later). It's also very expensive to build the motor, with little return on investment. It needs to go bye bye.

Thanks in advance!!!

Does anyone know of a LS1-compatible crank pulley that will protrude no farther forward than the pulley bolt head on the front of the crank? The goal is to minimize the length, of the engine front to back. I have found LS2 and L76 pulleys to have less offset, but I am looking for as low profile as possible, since there is NO ROOM in the bumper. Accessories will be mounted further back to match, on custom brackets.

Background build:

I'm making hard plans to swap a LS1 into my 2005 Subaru Legacy GT, retaining stock 5AT with adapters, motor plate, etc. However, the stock engine is not long front to back (about half the length of the LS1 with water pump), and the LS1 front cylinders will be sitting on the plane of the radiator. So I need to make the front pulleys as far back and close to the motor front as possible. Goal is to get the shortest possible engine. Plan is to run a remote electric or side-mounted water pump, and to use or machine the lowest profile crank pulley offset available. Front motor plates will be used to custom mount all belt-driven accessories.

Attached photo shows 27" forward from trans bellhousing. That's the little 2.5 liter boxer engine, which is almost ready to make 395whp on E85, but with mediocre driveability, full boost by 3500rpm. You can't safely make more than 450whp on a stock EJ25 (that's with E85), and by then driveability is terrible with peak boost at 4000rpm (or later). It's also very expensive to build the motor, with little return on investment. It needs to go bye bye.

Thanks in advance!!!

#3

Staging Lane

Thread Starter

Thanks miker2!

Problem is that's too thick for my crammed application.

Will likely need to swap to a single-belt pulley, not the stock double-belt pulley.

Anyone know of a one-belt crank pulley w/ integrated balancer that slides onto LS1 crank? Perhaps a later LS or older LT? I spent the last several years learning every possible thing about high perf Subi engines, and now I'm back to square one Spent the last couple hours looking at pics of GM pulleys, and it's a waste of time without any wrench time on these motors. Subi boxer-4cylinder doesn't even have a harmonic balancer!

Spent the last couple hours looking at pics of GM pulleys, and it's a waste of time without any wrench time on these motors. Subi boxer-4cylinder doesn't even have a harmonic balancer!

The one inch is a big deal, will be a game changer with where I locate a new corvette radiator, whether I can keep my bumper beam, etc.

Having a 23" long LS1 instead of 24" would be incredible! Would be a slap in the face to all the LS1 fans with a LegacyGT who swear it can never fit in that car! With a flipped intake manifold, it will fit!

Problem is that's too thick for my crammed application.

Will likely need to swap to a single-belt pulley, not the stock double-belt pulley.

Anyone know of a one-belt crank pulley w/ integrated balancer that slides onto LS1 crank? Perhaps a later LS or older LT? I spent the last several years learning every possible thing about high perf Subi engines, and now I'm back to square one

Spent the last couple hours looking at pics of GM pulleys, and it's a waste of time without any wrench time on these motors. Subi boxer-4cylinder doesn't even have a harmonic balancer!

Spent the last couple hours looking at pics of GM pulleys, and it's a waste of time without any wrench time on these motors. Subi boxer-4cylinder doesn't even have a harmonic balancer!The one inch is a big deal, will be a game changer with where I locate a new corvette radiator, whether I can keep my bumper beam, etc.

Having a 23" long LS1 instead of 24" would be incredible! Would be a slap in the face to all the LS1 fans with a LegacyGT who swear it can never fit in that car! With a flipped intake manifold, it will fit!

Last edited by ClimberD; 08-27-2011 at 12:11 AM.

#4

12 Second Club

Join Date: Feb 2006

Location: Catlettsburg, Ky

Posts: 876

Likes: 0

Received 0 Likes

on

0 Posts

Ever thought about looking in to the LS4 accessory brackets? Any FWD car, whether 4,6 or 8cyl NEVER seem to have much room between the accessories and the fenderwell.

#5

Staging Lane

Thread Starter

Thanks for the tip! I googled it but did not see anything. One problem is I don't really know how to search efficiently for GM parts yet. Don't know all the tricks.

Something a little more like this profile is what I'm after, but I imagine a 4 cylinder balance would be no good for a 5.7l V8 http://www.drivewire.com/vehicle/che...onic-balancer/

A single serpentine crank pulley with no other material protruding, and flush to the timing cover, would be perfect.

Would it be possible to flip a hollow pulley around, overlapping a harmonic balancer? I'm happy to do anything to get that extra inch.

Something a little more like this profile is what I'm after, but I imagine a 4 cylinder balance would be no good for a 5.7l V8 http://www.drivewire.com/vehicle/che...onic-balancer/

A single serpentine crank pulley with no other material protruding, and flush to the timing cover, would be perfect.

Would it be possible to flip a hollow pulley around, overlapping a harmonic balancer? I'm happy to do anything to get that extra inch.

#6

Staging Lane

Thread Starter

Mighty Whitey FTW! LS4 accessories/pulleys are the ticket! Now just need to figure out how to swap over everything, whether to go for a LS4 crank or what. Might just make sense to buy the whole LS4...

#7

Staging Lane

Thread Starter

So far it's an LS1 engine with LS4 crank pulley, water pump, possibly LS4 A/C or stock Subaru A/C depending on which is easier.

LS4 alternator and power steering are no good. Too high up, hood will not close. Will make a custom adapter for that little stuff.

LS4 alternator and power steering are no good. Too high up, hood will not close. Will make a custom adapter for that little stuff.

Trending Topics

#8

TECH Resident

iTrader: (1)

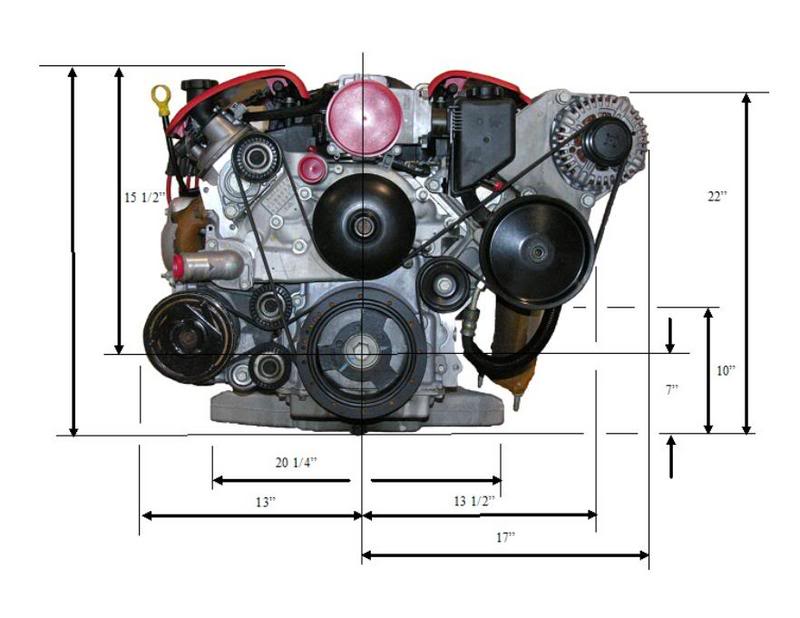

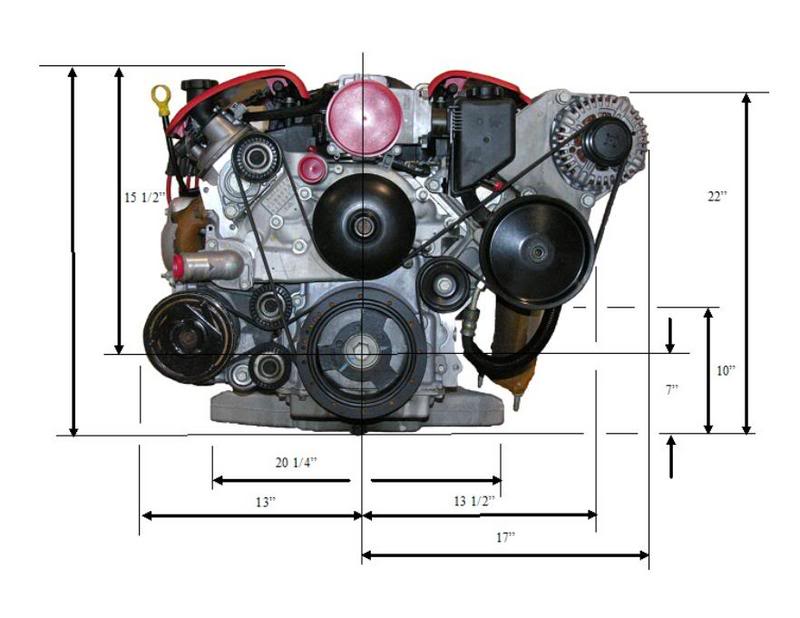

Here are a couple of pics to show how short the LS4 pulley is on an LS4 (10 mm shorter crank snout vs. the RWD setup):

Here is a truck water pump vs LS4 pulley (notice the slight gap at the rear where the pump was pushing against the LS4 cam sensor):

The LS4 water pump while very thin is very wide. Factory LS4 belt routing and water pump:

Here is a truck water pump vs LS4 pulley (notice the slight gap at the rear where the pump was pushing against the LS4 cam sensor):

The LS4 water pump while very thin is very wide. Factory LS4 belt routing and water pump:

#9

Staging Lane

Thread Starter

Can you confirm I just take a LS1 crankshaft to my machine shop and get it lathed down 10mm? Still enough threading for the pulley bolt? Alternatively, I can get a LS4 crank shaft, but have read conflicting things about whether that would swap into an LS1... LS2 will swap into LS1... I may do a custom pressure plate anyways, since starter teeth for a Subaru are on the torque converter. Goal is to have the thinnest motor plate possible. Any thoughts on what to do?

Those same pics from your the other thread are what made the decision so easy As they said, great pictures! Also love the final measurement of a 25 3/8" long engine! It will be a little shorter up top, because power steering and alternator will be mounted as low as possible. Flipped intake manifold here too! Will need the room for intercooling, one day.

As they said, great pictures! Also love the final measurement of a 25 3/8" long engine! It will be a little shorter up top, because power steering and alternator will be mounted as low as possible. Flipped intake manifold here too! Will need the room for intercooling, one day.

Since this pic is 27", and engine will be at most 26.4" with adapter plate, it will fit!!! It's hard to see here, but this engine bay is insanely wide to accommodate a flat engine with overhead cams, that an LS4 water pump will fit no problem. I might even be able to mount an accessory to the side of it...

Those same pics from your the other thread are what made the decision so easy

As they said, great pictures! Also love the final measurement of a 25 3/8" long engine! It will be a little shorter up top, because power steering and alternator will be mounted as low as possible. Flipped intake manifold here too! Will need the room for intercooling, one day.

As they said, great pictures! Also love the final measurement of a 25 3/8" long engine! It will be a little shorter up top, because power steering and alternator will be mounted as low as possible. Flipped intake manifold here too! Will need the room for intercooling, one day.Since this pic is 27", and engine will be at most 26.4" with adapter plate, it will fit!!! It's hard to see here, but this engine bay is insanely wide to accommodate a flat engine with overhead cams, that an LS4 water pump will fit no problem. I might even be able to mount an accessory to the side of it...

Last edited by ClimberD; 08-28-2011 at 12:37 PM.

#10

Staging Lane

Thread Starter

It would appear that no one has actually bolted a LS4 crank into an LS1 block/rods yet, but it appears to be an interchangeable part. Can probably confirm by comparing rod and main bearing part numbers

This person also asked about it in https://ls1tech.com/forums/ls4-perfo...ew-ls4-qs.html

This mentions that the LS4 timing cover isn't anything crazy different, and as such there probably won't be any interference with the LS1 timing cover and LS4 pulley accessories. https://ls1tech.com/forums/conversio...rp-anyone.html

Thanks again fieroguru for your excellent posts all over this site!

So far the shopping list is:

LS1 engine w/o accessories

LS4 crankshaft, new bearings

LS4 crank pulley, bolt

LS4 water pump and idler pulleys

Down the road, will need some headers that exit to the rear at a much higher plane than stock and all these long tube aftermarket. There's an old engine mounting crossmember in the way.

Thus far planning to use Subaru power steering pump and alternator, since LSx versions aren't going to work any better with custom mounting. The exception to that would be if LSx powersteering pump will make the steering wheel easier to turn, or will mount any easier, which I know nothing about (yet). Subaru alternator is 140amp, don't know what GM is yet. Just making a list.

Might also try to retain stock A/C pump since integrated climate control is already in the Subi. Don't know whether it would make any difference what A/C is used. Maybe not. All things to look into.

Making this list for anyone who wants to lend some knowledge, or anyone from LegacyGT.com who wants to follow and get over the stupid notion that this swap cannot be done. Search tags: LS1 LS2 STi WRX EJ25 EJ255 EJ257 swap Chevy V8 Legacy GT.

This person also asked about it in https://ls1tech.com/forums/ls4-perfo...ew-ls4-qs.html

This mentions that the LS4 timing cover isn't anything crazy different, and as such there probably won't be any interference with the LS1 timing cover and LS4 pulley accessories. https://ls1tech.com/forums/conversio...rp-anyone.html

Thanks again fieroguru for your excellent posts all over this site!

So far the shopping list is:

LS1 engine w/o accessories

LS4 crankshaft, new bearings

LS4 crank pulley, bolt

LS4 water pump and idler pulleys

Down the road, will need some headers that exit to the rear at a much higher plane than stock and all these long tube aftermarket. There's an old engine mounting crossmember in the way.

Thus far planning to use Subaru power steering pump and alternator, since LSx versions aren't going to work any better with custom mounting. The exception to that would be if LSx powersteering pump will make the steering wheel easier to turn, or will mount any easier, which I know nothing about (yet). Subaru alternator is 140amp, don't know what GM is yet. Just making a list.

Might also try to retain stock A/C pump since integrated climate control is already in the Subi. Don't know whether it would make any difference what A/C is used. Maybe not. All things to look into.

Making this list for anyone who wants to lend some knowledge, or anyone from LegacyGT.com who wants to follow and get over the stupid notion that this swap cannot be done. Search tags: LS1 LS2 STi WRX EJ25 EJ255 EJ257 swap Chevy V8 Legacy GT.

Last edited by ClimberD; 08-28-2011 at 09:28 PM.

#11

TECH Resident

iTrader: (1)

Glad I could be of some help.

The only 2 concerns I would have about using the LS4 crank in a LS1 block would be the overall balance and the LS4 crankshaft being 3mm shorter on the flywheel side as well. This will pull the flywheel in closer to the block and possibly cause a starter engagement/clearance issue.

Since you are swapping to another transmission, you might want to confirm the overall diameter of the current flywheel in your car. The diameter of the flywheel is a decent indicator of how closely the bellhousing bolt patterns are spaced. The LS flywheels are all 168 tooth (about 14" in diameter) and might be large enough to run right through the bellhousing bolt pattern (this is the case when trying to use a 168 tooth flywheel with a GM Metric Pattern transmission). To get around this issue, you will either need a thick (about 1 1/2") adapter plate to encase the 168 tooth flywheel and then bring in sufficient material to engage the transmission bell housing bolts, or convert to a smaller diameter flwheel (like the 142 used on the LS4, which is about 12" in diameter), but then you have to figure out a starter setup.

On my swap, I went the 142 tooth route and ended up making a bolt on starter mount for the transmission and reused the stock LS4 starter. However, in a RWD application the starter on the transmission could be a potential firewall clearance issue.

An alternative is to mount the starter directly under/inside the oil pan like the LS4 prototype location. Starting with a GTO oil pan would be benefitical from a starter clearance standpoint, but may have other interferance issues.

There is a LS4 water pump setup on ebay right now. They are quite proud of it, but it is available.

The only 2 concerns I would have about using the LS4 crank in a LS1 block would be the overall balance and the LS4 crankshaft being 3mm shorter on the flywheel side as well. This will pull the flywheel in closer to the block and possibly cause a starter engagement/clearance issue.

Since you are swapping to another transmission, you might want to confirm the overall diameter of the current flywheel in your car. The diameter of the flywheel is a decent indicator of how closely the bellhousing bolt patterns are spaced. The LS flywheels are all 168 tooth (about 14" in diameter) and might be large enough to run right through the bellhousing bolt pattern (this is the case when trying to use a 168 tooth flywheel with a GM Metric Pattern transmission). To get around this issue, you will either need a thick (about 1 1/2") adapter plate to encase the 168 tooth flywheel and then bring in sufficient material to engage the transmission bell housing bolts, or convert to a smaller diameter flwheel (like the 142 used on the LS4, which is about 12" in diameter), but then you have to figure out a starter setup.

On my swap, I went the 142 tooth route and ended up making a bolt on starter mount for the transmission and reused the stock LS4 starter. However, in a RWD application the starter on the transmission could be a potential firewall clearance issue.

An alternative is to mount the starter directly under/inside the oil pan like the LS4 prototype location. Starting with a GTO oil pan would be benefitical from a starter clearance standpoint, but may have other interferance issues.

There is a LS4 water pump setup on ebay right now. They are quite proud of it, but it is available.

#12

Staging Lane

Thread Starter

Glad I don't need to deal with all that trouble. Subaru starter sits in the transmission, and runs teeth on the torque converter (which is "3500 stall" stock). So the only challenges are making the motor mid plate as thin as possible, which will still be near an inch thick aluminum, and to get a flywheel to play nice with the converter. I know some converter-side compatibility tricks, and will learn about the GM flywheel options. Would love to lathe off flywheel teeth if a GM flywheel ends up being the budget winner.

The balance is a concern. I now need to look into that as well! (Don't know anything yet)

Thank you!

The balance is a concern. I now need to look into that as well! (Don't know anything yet)

Thank you!

#13

Staging Lane

Thread Starter

Here's the one and only big problem with this swap that I have not figured out how to solve yet...

Cutaway of my all wheel drive transmission. You can see how the torque converter sits in a separate enclosure directly above and in front of the front differential, both in front of the actual transmission interworkings. It does not sit in the car flat like that, but actually tilts back.

So to get the LSx to fit without sitting up through the roof, I'm going to have to lower the front of the trans, and possibly even raise the back of the trans. This could be hell on the u-joints in the driveshaft... Not really sure how wise it will turn out to be to do this, but there's one way to find out.

Cutaway of my all wheel drive transmission. You can see how the torque converter sits in a separate enclosure directly above and in front of the front differential, both in front of the actual transmission interworkings. It does not sit in the car flat like that, but actually tilts back.

So to get the LSx to fit without sitting up through the roof, I'm going to have to lower the front of the trans, and possibly even raise the back of the trans. This could be hell on the u-joints in the driveshaft... Not really sure how wise it will turn out to be to do this, but there's one way to find out.

#14

TECH Fanatic

iTrader: (2)

If you are going to use LS4 accessories and turn the intake around anyway (the LS4 intake is backwards BTW) You might want to look into just using the LS4 in its entirety. Since you will be using an adapter anyway the bellhousing pattern is much smaller as well and would be easier to make a plate for.

#15

Staging Lane

Thread Starter

If you are going to use LS4 accessories and turn the intake around anyway (the LS4 intake is backwards BTW) You might want to look into just using the LS4 in its entirety. Since you will be using an adapter anyway the bellhousing pattern is much smaller as well and would be easier to make a plate for.

If I were to buy a LS4, I would basically be buying it for:

-Crankshaft length (pre-balanced)

-Crank pulley

-Water pump

-Water pump idlers

-Timing cover

-A/C compressor fitment

-Gen IV injectors/rails appear to be a little shorter (hood clearance)

All of the above would obviously not need to be sourced, saving time and possible money.

Down sides:

-LS4 has DOD, which may complicate ECU setup

-LS4 intake manifold would need to be replaced

LS1/LS6 manifold can be flipped easy.

Neutral sides:

-Likely going to swap out headers either way

That's a lot of upsides. It will all come down to price.

Separately, this is another hugely important measurement for this swap: Crank pulley bolt to top of intake manifold, Height. Going to go measure the car again and see how much engine/trans maneuvering will be required, roughly.

Last edited by ClimberD; 08-29-2011 at 10:36 PM.

#16

Staging Lane

Thread Starter

Separately, this is another hugely important measurement for this swap: Crank pulley bolt to top of intake manifold, Height: call it 15.0". Going to go measure the car again and see how much engine/trans maneuvering will be required, roughly.

EDIT: If one was to bolt the engine to the transmission as it sits now, the engine would stick up ~6" too high. That's a LOT of combined tilting down/forward the front of the transmission, and overall lowering of the assembly. Drivetrain geometry might get ugly... Engine crossmember is going to get hacked up and re-welded with a giant valley in it. I can probably cut off the bottom of the front differential housing, machine it relatively flat, and weld in a sheet of 1/4" aluminum to buy an extra 1" of ground clearance under that lowest point.

Time for some trigonometry... if I lower the whole assembly vertically (including the transmission) tail of the transmission 1" and make it a hinge from which the front of the 60" long assembly will swing down lower, then an additional 5" lowering up front would be a 4.76* angle change... well would actually be a little less relative to the rear pumpkin because also dropped the rear of the trans 1". I will calculate all this at the end since people on the Subi forums will want to know.

So if ~5* of off angle is not bad for a drive shaft U-joint (or split across both u-joints, then this should be no problem! That said, the front axle shafts are all over the place with the extra lowering of the vehicle (raising of the hubs) and hard acceleration out of corners is never any problem, so realistically we are in business!!!

Will read this later, has good info: http://www.fiero.nl/cgi-bin/fiero/sh...tyle=printable

EDIT: If one was to bolt the engine to the transmission as it sits now, the engine would stick up ~6" too high. That's a LOT of combined tilting down/forward the front of the transmission, and overall lowering of the assembly. Drivetrain geometry might get ugly... Engine crossmember is going to get hacked up and re-welded with a giant valley in it. I can probably cut off the bottom of the front differential housing, machine it relatively flat, and weld in a sheet of 1/4" aluminum to buy an extra 1" of ground clearance under that lowest point.

Time for some trigonometry... if I lower the whole assembly vertically (including the transmission) tail of the transmission 1" and make it a hinge from which the front of the 60" long assembly will swing down lower, then an additional 5" lowering up front would be a 4.76* angle change... well would actually be a little less relative to the rear pumpkin because also dropped the rear of the trans 1". I will calculate all this at the end since people on the Subi forums will want to know.

So if ~5* of off angle is not bad for a drive shaft U-joint (or split across both u-joints, then this should be no problem! That said, the front axle shafts are all over the place with the extra lowering of the vehicle (raising of the hubs) and hard acceleration out of corners is never any problem, so realistically we are in business!!!

Will read this later, has good info: http://www.fiero.nl/cgi-bin/fiero/sh...tyle=printable

Last edited by ClimberD; 08-29-2011 at 10:32 PM.

#17

Staging Lane

Thread Starter

Some more measurements: The front diff housing only hangs 4" below the bottom of the torque converter, and I can lower than to 3" if needed via cutting off the excess volume and welding in an aluminum plate, as previously stated. Would also be nice to weld a short skid plate into the engine crossmember to protect it. Speaking of which, great thread showing the crossmember.

http://bbs.legacycentral.org/viewtopic.php?f=11&t=35739

I will notch out the middle under the transmission as deep as the power steering will allow, then weld in support around the new valley shape. Problem with Subaru is everything already fits like a glove. No wasted space...

http://bbs.legacycentral.org/viewtopic.php?f=11&t=35739

I will notch out the middle under the transmission as deep as the power steering will allow, then weld in support around the new valley shape. Problem with Subaru is everything already fits like a glove. No wasted space...

Last edited by ClimberD; 08-31-2011 at 02:48 AM.

#18

Hi,

I just registered for the forum so I could post this reply.

Great thread and great information. I am in the process of doing something similar to an Audi and have the same problem. I had already come to the conclusion that the LS4 accessories were likely the best bet so now I need to find a set (If anyone has a set to sell please PM me)

One thing to consider that may help your packaging that I am looking at is to use an electric water pump. You will still need adapter plates and AN fittings on the block that will be about as thick as the LS4 pump, but you can mount the pump away from the motor where you have more space.

Another plus side is that you can have the pump run whenever the fan is on but ignition off so the block actually gets cooled after shutting the motor off.

Something like this $400 pump would work fine. 55gpm, 10K hour lifetime, 8amps

http://www.summitracing.com/parts/EMP-E558AR/

Or this $300 pump. 35-37gpm, http://www.summitracing.com/parts/CSI-925C/

My project: 2003 RS6 + LS1 (For now, later to be LS3TT)

I just registered for the forum so I could post this reply.

Great thread and great information. I am in the process of doing something similar to an Audi and have the same problem. I had already come to the conclusion that the LS4 accessories were likely the best bet so now I need to find a set (If anyone has a set to sell please PM me)

One thing to consider that may help your packaging that I am looking at is to use an electric water pump. You will still need adapter plates and AN fittings on the block that will be about as thick as the LS4 pump, but you can mount the pump away from the motor where you have more space.

Another plus side is that you can have the pump run whenever the fan is on but ignition off so the block actually gets cooled after shutting the motor off.

Something like this $400 pump would work fine. 55gpm, 10K hour lifetime, 8amps

http://www.summitracing.com/parts/EMP-E558AR/

Or this $300 pump. 35-37gpm, http://www.summitracing.com/parts/CSI-925C/

My project: 2003 RS6 + LS1 (For now, later to be LS3TT)

#19

Staging Lane

Thread Starter

Nice project! With proper RS6 AWD you're going to have the time of your life. Is that a bent power steering pulley?

Either way, it sure does look like you've run out of room up front with those super thick GTO accessories. I'm sure you've read they stick out more than Corvette accessories.

If you get the LS4 crank pulley, it will stick out 10mm more than it was designed for, so it won't line up with the other LS4 accessories. At least this is what I read, but have not confirmed in person. So that means a couple options:

1) Swap in LS4 crank shaft.

2) Swap in LS4 crank pulley and shim or fab up modified accessory brackets to run other LS4 accessories.

3) Swap in LS4 crank pulley and keep the accessories you already have and shim their brackets or make new ones.

4) Find other creative way to make LS4 crank pulley on LS1 crank shaft line up with LS4. accessories.

Consider just buying an entire LS4 long block, as some are so cheap that you might be able to justify stripping all the accessory drive parts off (and timing cover and cam position sensor, etc.) and then sell the block and heads.

Thank you for posting, I hope we can compare notes going forward, as we are basically in the same boat, you with a longer engine bay than mine (lucky).

Either way, it sure does look like you've run out of room up front with those super thick GTO accessories. I'm sure you've read they stick out more than Corvette accessories.

If you get the LS4 crank pulley, it will stick out 10mm more than it was designed for, so it won't line up with the other LS4 accessories. At least this is what I read, but have not confirmed in person. So that means a couple options:

1) Swap in LS4 crank shaft.

2) Swap in LS4 crank pulley and shim or fab up modified accessory brackets to run other LS4 accessories.

3) Swap in LS4 crank pulley and keep the accessories you already have and shim their brackets or make new ones.

4) Find other creative way to make LS4 crank pulley on LS1 crank shaft line up with LS4. accessories.

Consider just buying an entire LS4 long block, as some are so cheap that you might be able to justify stripping all the accessory drive parts off (and timing cover and cam position sensor, etc.) and then sell the block and heads.

Thank you for posting, I hope we can compare notes going forward, as we are basically in the same boat, you with a longer engine bay than mine (lucky).

#20

Hi,

Glad to help and I thought this was the closest to your problem that I have found so far.

You are correct on all your points, I recently found a complete LS4 for $600! However I think I am going to go a slightly different route if possible. Yes that is a bent PS pump, I suspect it took a ding in the wreck that killed the 04 GTO.

I run a motorsport shop so am familiar with having to build all sorts of odd stuff. I am going to order parts of the LS4 accessory system direct form GM as its not too $$ brand new. I am hoping to not have to open this motor, as if I do I will doubtless get into trouble kitting it out with stroker kits etc LOL.

My plan right now is to try to use the LS4 crank pulley and buld my own mounts for the Audi 190A water cooled alternator, and the audi AC pump,and the Gm PS pump. I will run electric water pump.

I also plan to swap in an LS3 intake if possible and flip it to put the stock 90mm LS3 throttle body DBW at the back.

I am super new to all this LSx stuff so if anyone sees any problems with my plan please LMK.

I will keep you updated for sure on my progress which I hope will be fast as I need this thing finished in 5 weeks.

Cheers

Timmy

Glad to help and I thought this was the closest to your problem that I have found so far.

You are correct on all your points, I recently found a complete LS4 for $600! However I think I am going to go a slightly different route if possible. Yes that is a bent PS pump, I suspect it took a ding in the wreck that killed the 04 GTO.

I run a motorsport shop so am familiar with having to build all sorts of odd stuff. I am going to order parts of the LS4 accessory system direct form GM as its not too $$ brand new. I am hoping to not have to open this motor, as if I do I will doubtless get into trouble kitting it out with stroker kits etc LOL.

My plan right now is to try to use the LS4 crank pulley and buld my own mounts for the Audi 190A water cooled alternator, and the audi AC pump,and the Gm PS pump. I will run electric water pump.

I also plan to swap in an LS3 intake if possible and flip it to put the stock 90mm LS3 throttle body DBW at the back.

I am super new to all this LSx stuff so if anyone sees any problems with my plan please LMK.

I will keep you updated for sure on my progress which I hope will be fast as I need this thing finished in 5 weeks.

Cheers

Timmy