LSx Twinscroll Turbo Design Analysis

#1

Staging Lane

Thread Starter

This is my analysis of setting up a 'single twinscroll turbo' or 'twin twinscroll turbo' system in the most efficient format possible on the LSx V8 engine with firing order 1-8-7-2-6-5-4-3. This firing order does NOT pair well with twinscroll turbo builds, at least not under the most efficient model of twinscroll header design, as will be explained in this post.

Note: Twinscroll aka Twin Scroll aka Divided Turbo

First, background: My car is a 2005 Subaru Legacy GT with 2.5L flat (boxer) 4-cylinder configuration. I can't wait for the day it's replaced with a LSx engine, but that's in a different thread. Anyways, this is another engine configuration (and engine bay design) that makes twinscroll setups very hard to rig up. However, to make greater than 'stock LS1' power on that engine (which many people do) you need a really big turbo, and big turbos are laggy. If a twinscroll SYSTEM, which includes the cam(s), header design and cylinder pairing, turbo wheel dimensions (specifically turbine wheel design), turbine housing area ratio size, exhaust design, wastegate configuration, and a few other lesser things are all working together in harmony, people are able to accomplish some pretty incredible things: Lower EGTs, earlier boost threshold and low-boost ramp-up, faster transient response, wider power curve, relatively higher low-rpm header backpressure, relatively lower high-rpm header backpressure, and all through a bigger turbine housing inlet area ratio that the single scroll turbine housing counterpart. THE CONTENT OF THE ABOVE PARAGRAPH IS A PRIMER, AND IS NOT WITHIN THE SCOPE OF THIS THREAD!!! IT TAKES ENTIRE BOOKS TO LEARN THESE CONCEPTS (OR EQUIVALENT READING ELSEWHERE) SO IF YOU SEEK TO UNDERSTAND THE THINGS I’VE MENTIONED THEN DON’T DO IT BY ASKING WITHOUT FIRST DOING SIGNIFICANT RESEARCH!!! A tip: If you want to learn about turbo science and engineering, the Mitsubishi Evolution guys (found on their top forum) tend to be the most knowledgeable around. Those cars are 100% turbo driven, and are entirely useless off boost, so it grows out of necessity. American car forums tend to be laughably misguided about twinscroll turbo science (no offense) so just skip that.

If you do not understand any or many of these concepts, it will take some outside research to understand HOW these components are working, and A LOT OF ENERGY on top of a good head to understand WHY these components cause these results. This is seriously complex stuff. If you are thinking twice, read the entirely uppercase sentences above.

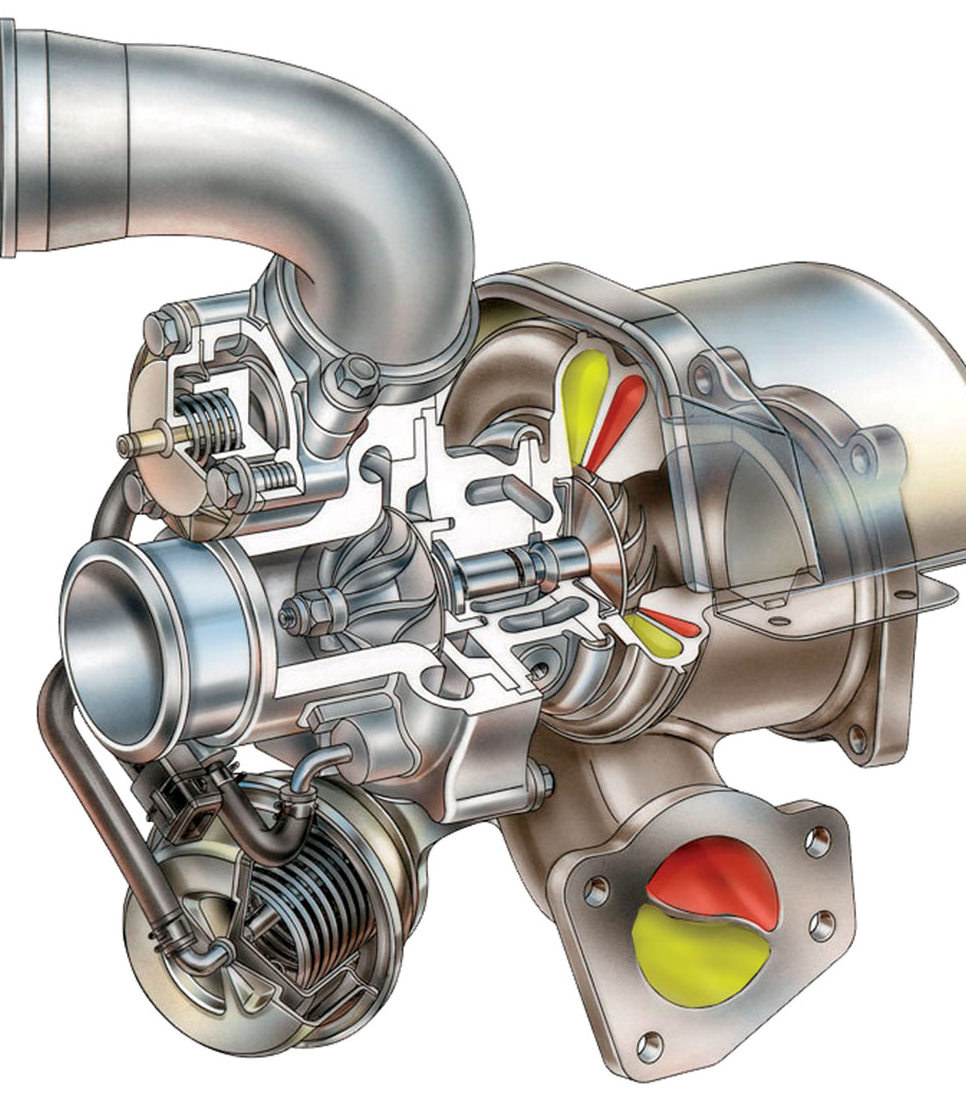

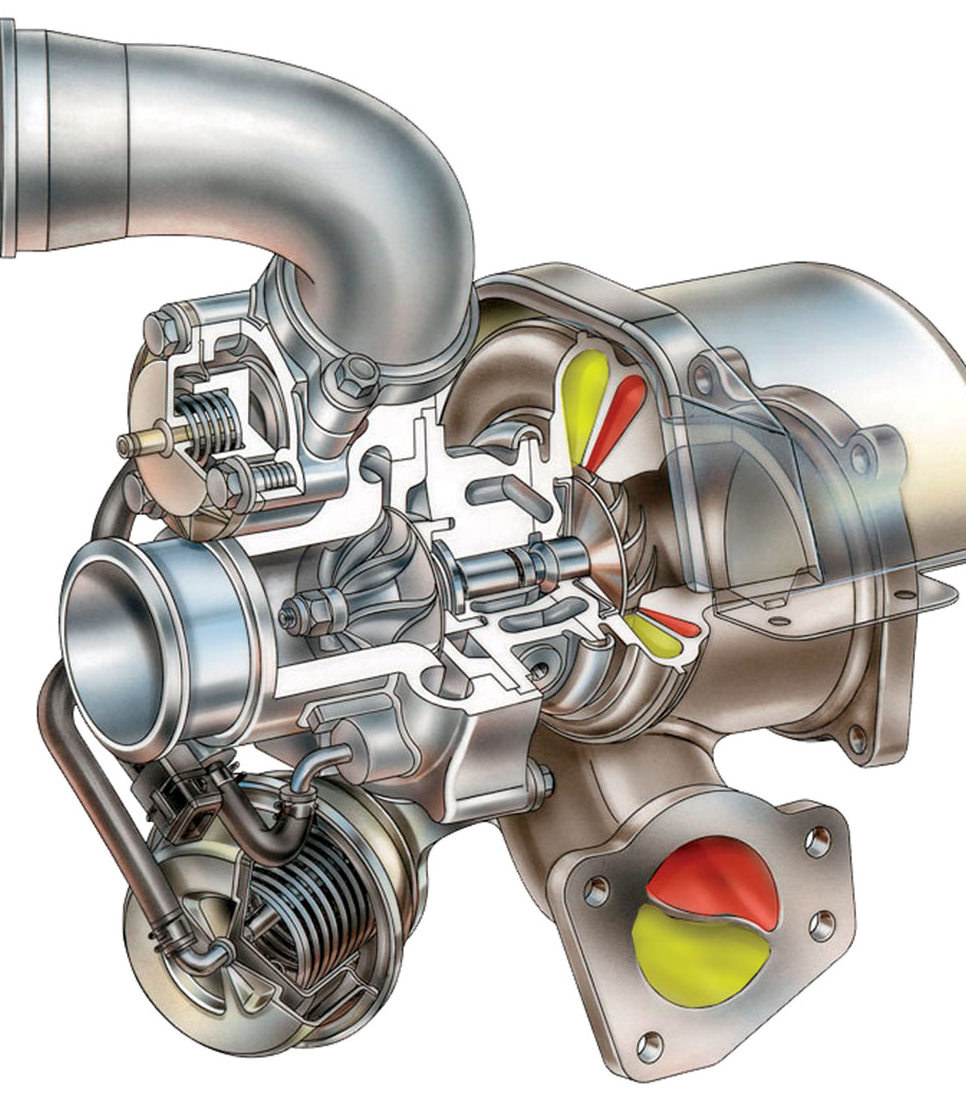

Twinscroll turbo cutaway:

Twinscroll header (left), vs singlescroll header (right) for a 4-cylinder engine. Cylinder pairing for the twinscroll is 1-3 and 2-4. More on this soon.

*These are Full Race Inc. Manifolds (no relation except I have chatted with the owner about this kind of stuff). These are often regarded as the best manifolds in the world, in both design and craftsmanship (and of course price). They don't make anything for the LSx, but then there's no shortage of brilliantly designed LSx headers, at least for N/A.

If you do get the system designed properly, then you can get your turbo to do amazing things. Example: On a Subaru 2.5L engine, the Garrett GT35r turbo is considered laggy and unresponsive. However, in proper twinscroll configuration setup (even with long intercooler piping), it becomes instantly responsive, allowing for excellent gas pedal modulation. If you are a good enough driver, as in the top 1% of professional drivers, then twinscroll helps you modulate throttle this quick.

http://www.youtube.com/watch?v=rs-jAImScms

I have seen this car in person, under the hood, and I know how it is setup.

NOW ONTO THE TOPIC OF THIS THREAD:

A twinscroll turbo is a turbocharger with divided twin header pipe entries. The idea is to keep the exhaust pulses separated, to some degree, in order to improve the exhaust scavenging environment! I did not say “in order to better perform exhaust scavenging” as that is naturally aspirated long-tube equal length header territory. In order to achieve an optimal twinscroll design, you want to pair opposite cylinders PER FIRING ORDER, not location on the engine. This is a huge pain on the LSx engine, and here is why:

Firing order:

1-8-7-2-6-5-4-3

For a single turbo twin scroll, you would pair 4 cylinders joining up and eventually entering one turbo scroll, and the other 4 cylinders doing the same thing, merging up and entering the other scroll. Completely divided until they exit the turbo, at which point it doesn’t really matter. But which cylinders pair together?

1-8-7-2-6-5-4-3

The bold cylinder numbers are for side of the divided turbo flange, and the underlined numbers are for the other scroll of the turbo. Easy as that.

Why is this an epic pain in the butt? Because you’re going to have a mess of header primaries and secondaries throughout the engine bay if you actually do this. Most engine bays do not even have enough room, and are lucky to fit left bank / right bank turbo headers.

HOWEVER, a proper drag car with roomy tube frame and excellent fabricator skill and lots of time could in fact do this setup! The gains would not be staggering over a single scroll counterpart. But for some people who do everything perfect no matter what it takes, and/or are chasing that small increase in volumetric efficiency or decrease in EGT and backpressure, this may be the best possible way to go. Maybe. More on this later.

For twin turbo twinscroll:

We already know our two cylinder groupings: 1-7-6-4 and 8-2-5-3.

So we apply the every-other format: 1-7-6-4 and 8-2-5-3.

So with Turbo A, you would feed it with 1&6 on one side of the divided turbo flange, and 7&4 on the other. On the other turbo, Turbo B, it would be 8&5, then 2&3.

This configuration may prove do-able in a more generous engine bay.

This is also a configuration I am going to try and design, such that one primary from every pair runs under the oil pan, and allows two low-mount turbos to run true twinscroll.

Equal Length: The most optimal design for a twinscroll manifold (or any exhaust) is to have the mating primaries and secondaries be equal length prior to each collector merge. One clear advantage (or disadvantage to the loud folks) is equal length does wonders to smooth out exhaust pulsing and thus smooth out sound. This is simple: your V8 exhaust pulses 67 times a second at just 1000rpms. Your ear (actually brain) cannot pickup that. But you do hear an average of amplitude. If you have unequal length headers (turbo Subarus are famous for this sound) then certain exhaust pulses will be closer to overlapping others, and the result will be higher amplitude and more of a rumble. This would make a Chevy V8 real quiet. However, no one actually does it on a Chevy, as it would require pairing primaries from opposite cylinder banks. It would be a pain to plumb it, and it can be ugly (oh no) to have all that extra pipe.

Short header length: In summary, the Subaru EJ25 (2.5L) spools an identical turbo slower than a Mitsubishi Evo 4G63 (2.0L) largely because the headers on the Subaru are stupid long, and the headers on the EVO are very short. The factors at play here are:

1) Heat retention: 1500*F exhaust energy (heat) wants to move to 120*F engine bay faster than you would think. These small engine turbo guys can make their headers glow on a long WOT pull, which is a visible sign of heat energy NOT getting to the turbo and doing work. Bad.

2) Pulse has further to travel: Obviously an exhaust pulse has to cover more ground, which takes a hair more time and also leads to #1 above. This is not a big deal. The exhaust isn’t exactly crawling, especially when you make your turbo header primaries SMALLER than you think they should be when comparing with the guy who has the bigger *****, oops I mean turbo header primaries in the car next to yours at the local meet or car show.

In summary, take your wealth of N/A long-tube header design knowledge, and don't apply it to turbo header design, unless you want to do things sub-optimally.

So I do not have the correct (proven) answer, but it is entirely likely that if you compare two systems:

A) Short headers merged by cylinder bank and then feeding a singlescroll turbo or twin turbo set, or

B) Longer header primaries required to feed proper twinscroll turbo or twin turbo set,

They might end up being pretty close. I would choose twinscroll for a manual transmission open track car. I would go with the status quo for drag racing. I don’t know what would actually win though, and none of us will probably ever really know for sure. But we do know that it is just so much easier to batch a bank of tubes, that everyone does it that way for that reason and will continue to. Obviously, there is ‘ideal’ and then there is ‘reality’.

Note: Twinscroll aka Twin Scroll aka Divided Turbo

First, background: My car is a 2005 Subaru Legacy GT with 2.5L flat (boxer) 4-cylinder configuration. I can't wait for the day it's replaced with a LSx engine, but that's in a different thread. Anyways, this is another engine configuration (and engine bay design) that makes twinscroll setups very hard to rig up. However, to make greater than 'stock LS1' power on that engine (which many people do) you need a really big turbo, and big turbos are laggy. If a twinscroll SYSTEM, which includes the cam(s), header design and cylinder pairing, turbo wheel dimensions (specifically turbine wheel design), turbine housing area ratio size, exhaust design, wastegate configuration, and a few other lesser things are all working together in harmony, people are able to accomplish some pretty incredible things: Lower EGTs, earlier boost threshold and low-boost ramp-up, faster transient response, wider power curve, relatively higher low-rpm header backpressure, relatively lower high-rpm header backpressure, and all through a bigger turbine housing inlet area ratio that the single scroll turbine housing counterpart. THE CONTENT OF THE ABOVE PARAGRAPH IS A PRIMER, AND IS NOT WITHIN THE SCOPE OF THIS THREAD!!! IT TAKES ENTIRE BOOKS TO LEARN THESE CONCEPTS (OR EQUIVALENT READING ELSEWHERE) SO IF YOU SEEK TO UNDERSTAND THE THINGS I’VE MENTIONED THEN DON’T DO IT BY ASKING WITHOUT FIRST DOING SIGNIFICANT RESEARCH!!! A tip: If you want to learn about turbo science and engineering, the Mitsubishi Evolution guys (found on their top forum) tend to be the most knowledgeable around. Those cars are 100% turbo driven, and are entirely useless off boost, so it grows out of necessity. American car forums tend to be laughably misguided about twinscroll turbo science (no offense) so just skip that.

If you do not understand any or many of these concepts, it will take some outside research to understand HOW these components are working, and A LOT OF ENERGY on top of a good head to understand WHY these components cause these results. This is seriously complex stuff. If you are thinking twice, read the entirely uppercase sentences above.

Twinscroll turbo cutaway:

Twinscroll header (left), vs singlescroll header (right) for a 4-cylinder engine. Cylinder pairing for the twinscroll is 1-3 and 2-4. More on this soon.

*These are Full Race Inc. Manifolds (no relation except I have chatted with the owner about this kind of stuff). These are often regarded as the best manifolds in the world, in both design and craftsmanship (and of course price). They don't make anything for the LSx, but then there's no shortage of brilliantly designed LSx headers, at least for N/A.

If you do get the system designed properly, then you can get your turbo to do amazing things. Example: On a Subaru 2.5L engine, the Garrett GT35r turbo is considered laggy and unresponsive. However, in proper twinscroll configuration setup (even with long intercooler piping), it becomes instantly responsive, allowing for excellent gas pedal modulation. If you are a good enough driver, as in the top 1% of professional drivers, then twinscroll helps you modulate throttle this quick.

http://www.youtube.com/watch?v=rs-jAImScms

I have seen this car in person, under the hood, and I know how it is setup.

NOW ONTO THE TOPIC OF THIS THREAD:

A twinscroll turbo is a turbocharger with divided twin header pipe entries. The idea is to keep the exhaust pulses separated, to some degree, in order to improve the exhaust scavenging environment! I did not say “in order to better perform exhaust scavenging” as that is naturally aspirated long-tube equal length header territory. In order to achieve an optimal twinscroll design, you want to pair opposite cylinders PER FIRING ORDER, not location on the engine. This is a huge pain on the LSx engine, and here is why:

Firing order:

1-8-7-2-6-5-4-3

For a single turbo twin scroll, you would pair 4 cylinders joining up and eventually entering one turbo scroll, and the other 4 cylinders doing the same thing, merging up and entering the other scroll. Completely divided until they exit the turbo, at which point it doesn’t really matter. But which cylinders pair together?

1-8-7-2-6-5-4-3

The bold cylinder numbers are for side of the divided turbo flange, and the underlined numbers are for the other scroll of the turbo. Easy as that.

Why is this an epic pain in the butt? Because you’re going to have a mess of header primaries and secondaries throughout the engine bay if you actually do this. Most engine bays do not even have enough room, and are lucky to fit left bank / right bank turbo headers.

HOWEVER, a proper drag car with roomy tube frame and excellent fabricator skill and lots of time could in fact do this setup! The gains would not be staggering over a single scroll counterpart. But for some people who do everything perfect no matter what it takes, and/or are chasing that small increase in volumetric efficiency or decrease in EGT and backpressure, this may be the best possible way to go. Maybe. More on this later.

For twin turbo twinscroll:

We already know our two cylinder groupings: 1-7-6-4 and 8-2-5-3.

So we apply the every-other format: 1-7-6-4 and 8-2-5-3.

So with Turbo A, you would feed it with 1&6 on one side of the divided turbo flange, and 7&4 on the other. On the other turbo, Turbo B, it would be 8&5, then 2&3.

This configuration may prove do-able in a more generous engine bay.

This is also a configuration I am going to try and design, such that one primary from every pair runs under the oil pan, and allows two low-mount turbos to run true twinscroll.

Equal Length: The most optimal design for a twinscroll manifold (or any exhaust) is to have the mating primaries and secondaries be equal length prior to each collector merge. One clear advantage (or disadvantage to the loud folks) is equal length does wonders to smooth out exhaust pulsing and thus smooth out sound. This is simple: your V8 exhaust pulses 67 times a second at just 1000rpms. Your ear (actually brain) cannot pickup that. But you do hear an average of amplitude. If you have unequal length headers (turbo Subarus are famous for this sound) then certain exhaust pulses will be closer to overlapping others, and the result will be higher amplitude and more of a rumble. This would make a Chevy V8 real quiet. However, no one actually does it on a Chevy, as it would require pairing primaries from opposite cylinder banks. It would be a pain to plumb it, and it can be ugly (oh no) to have all that extra pipe.

Short header length: In summary, the Subaru EJ25 (2.5L) spools an identical turbo slower than a Mitsubishi Evo 4G63 (2.0L) largely because the headers on the Subaru are stupid long, and the headers on the EVO are very short. The factors at play here are:

1) Heat retention: 1500*F exhaust energy (heat) wants to move to 120*F engine bay faster than you would think. These small engine turbo guys can make their headers glow on a long WOT pull, which is a visible sign of heat energy NOT getting to the turbo and doing work. Bad.

2) Pulse has further to travel: Obviously an exhaust pulse has to cover more ground, which takes a hair more time and also leads to #1 above. This is not a big deal. The exhaust isn’t exactly crawling, especially when you make your turbo header primaries SMALLER than you think they should be when comparing with the guy who has the bigger *****, oops I mean turbo header primaries in the car next to yours at the local meet or car show.

In summary, take your wealth of N/A long-tube header design knowledge, and don't apply it to turbo header design, unless you want to do things sub-optimally.

So I do not have the correct (proven) answer, but it is entirely likely that if you compare two systems:

A) Short headers merged by cylinder bank and then feeding a singlescroll turbo or twin turbo set, or

B) Longer header primaries required to feed proper twinscroll turbo or twin turbo set,

They might end up being pretty close. I would choose twinscroll for a manual transmission open track car. I would go with the status quo for drag racing. I don’t know what would actually win though, and none of us will probably ever really know for sure. But we do know that it is just so much easier to batch a bank of tubes, that everyone does it that way for that reason and will continue to. Obviously, there is ‘ideal’ and then there is ‘reality’.

Last edited by ClimberD; 08-31-2011 at 01:42 AM.

#2

Staging Lane

Thread Starter

To add, you LSx guys (me excited to soon to be one of them) are spoiled in that your 5.3-5.7 liter V8s will spool some pretty big turbos with ease, such that you have to worry about lag less than almost any other turbo cars. BUT, if you have a pretty big turbo or two, and you think to yourself 'Hmm these turbos have made the car less enjoyable to drive because the power isn't there as low and fast as I would like,' then you should give this a second look, if only to better understand what all really matters to a turbo.

Reserved for an idea I have for divided bank twin turbo twinscroll that might actually work, if it still stands as good after I run it by some experts.

Basically, the idea is to use two twinscroll turbos with non-paired cylinders, such that the banks are kept separate, and you get some of the twinscroll benefit, just not all of it.

Driver side

Pair 1(long)&5

Pair 3&7(long)

Passenger side

Pair 2&4(long)

Pair 6(long)&8

*the idea of one primary longer and one shorter is to offset that there is an odd firing of XOOXOOOO, for each pairing. So the goal is to shift that second X over to the right a little bit...

This goes more to show how twinscroll just isn't meant to be paired with a LSx. BMW solved the problem by flipping the heads so the exhaust outlets are into the valley. Then they put two twinscroll turbos between each head, and feed them with very short exhaust runners, and bam, best turbo V8 engine design ever, minus the BMW aspect.

Reserved for an idea I have for divided bank twin turbo twinscroll that might actually work, if it still stands as good after I run it by some experts.

Basically, the idea is to use two twinscroll turbos with non-paired cylinders, such that the banks are kept separate, and you get some of the twinscroll benefit, just not all of it.

Driver side

Pair 1(long)&5

Pair 3&7(long)

Passenger side

Pair 2&4(long)

Pair 6(long)&8

*the idea of one primary longer and one shorter is to offset that there is an odd firing of XOOXOOOO, for each pairing. So the goal is to shift that second X over to the right a little bit...

This goes more to show how twinscroll just isn't meant to be paired with a LSx. BMW solved the problem by flipping the heads so the exhaust outlets are into the valley. Then they put two twinscroll turbos between each head, and feed them with very short exhaust runners, and bam, best turbo V8 engine design ever, minus the BMW aspect.

Last edited by ClimberD; 08-31-2011 at 01:39 AM.

#3

TECH Fanatic

iTrader: (7)

A twin-scroll setup isn't the main reason Block's old Subaru spooled up the way it did.

WRC cars incorporate some pretty serious anti-lag systems...Pulling timing and adding fuel off throttle, recirculating pressurized air from the into-cooler piping to the exhaust manifold pre-turbo to keep the turbine-wheel spinning, etc. It should also be noted that the budgets these guys operate on are MUCH larger than almost anyone building a turbo LS1 street car.

WRC cars incorporate some pretty serious anti-lag systems...Pulling timing and adding fuel off throttle, recirculating pressurized air from the into-cooler piping to the exhaust manifold pre-turbo to keep the turbine-wheel spinning, etc. It should also be noted that the budgets these guys operate on are MUCH larger than almost anyone building a turbo LS1 street car.

#4

Staging Lane

Thread Starter

A twin-scroll setup isn't the main reason Block's old Subaru spooled up the way it did.

WRC cars incorporate some pretty serious anti-lag systems...Pulling timing and adding fuel off throttle, recirculating pressurized air from the into-cooler piping to the exhaust manifold pre-turbo to keep the turbine-wheel spinning, etc. It should also be noted that the budgets these guys operate on are MUCH larger than almost anyone building a turbo LS1 street car.

WRC cars incorporate some pretty serious anti-lag systems...Pulling timing and adding fuel off throttle, recirculating pressurized air from the into-cooler piping to the exhaust manifold pre-turbo to keep the turbine-wheel spinning, etc. It should also be noted that the budgets these guys operate on are MUCH larger than almost anyone building a turbo LS1 street car.

As for my post, I alluded to the fact that twinscroll is more work, and work is of course paid by the hour.

Thank you for reading though and hopefully you enjoyed some part of it.

-David aka ClimberD

Owner, Hexagram Modifications

EDIT: Some credit where due though, Ford rally did basically build the Gymkhana car for Ken, and so THIS COMPLETELY DIFFERENT CAR does have anti-lag.

http://www.youtube.com/watch?v=4TshFWSsrn8

Last edited by ClimberD; 08-30-2011 at 11:10 PM.

#7

Staging Lane

Thread Starter

Basically, if your comparative setup is a properly-designed single scroll turbo or twin turbo, then the answer is most likely No. The reason is the best parts of twinscroll are driveability (making a big turbo feel smaller via much faster transient response and lower boost threshold), which is meaningless in most drag racing. You would see a reduction of exhaust gas temperatures and a reduction in exhaust backpressure (good twinscroll systems run 1:1 ratio of post-compressor pressure to pre-turbine pressure, which is freaking phenominal). However--and this is the big controversy over whether twinscroll is worth it--is it really doesn't result in your high-RPM horsepower going up much at all. So guys who only want that bragging right HP# will have no use for twinscroll. Anyways, you also have race gas (assuming some sort of high octane insurance), which further reduces the need for it. Reason being you can just advance timing a little to lower EGTs, as long as you have the built engine to handle it. That leaves some extra backpressure, but if you're only drag racing then you probably have large turbine housings to begin with, and these are easy on exhaust backpressure. If it was primarily a street car, you would want a smaller A/R so you could get the turbo(s) to spool quicker/earlier, at the expense of top end power. So on all points, the REALISTIC answer is No, stay single scroll, stay happy.

Trending Topics

#10

10 Second Club

iTrader: (27)

Join Date: Sep 2008

Location: Lake Tapps, WA

Posts: 2,229

Likes: 0

Received 0 Likes

on

0 Posts

After reading your post, I question how a rotary type exhaust barrel would work? Similiar to how 2 stroke race motors would alter the exhaust port. I'm thinking more at the manufacturer level of development to alter flow to and from a twin scroll set up.

Very interesting information, thanks for sharing.

Very interesting information, thanks for sharing.

#11

how much power are you looking to make?

what turbos are you looking to run?

what is your intended use?

spool valves will work as well if not better and are easier to package. (I'm not about debate which is better. SP and full race can battle it out.)

its a neat idea on 4cyl but on a v8 you can make plenty of power and have turbos that spool as fast as you can pres your right foot down, especially considering you have torque to begin with. When I switched from a sr20det it to me a while to get though my thick head.

what turbos are you looking to run?

what is your intended use?

spool valves will work as well if not better and are easier to package. (I'm not about debate which is better. SP and full race can battle it out.)

its a neat idea on 4cyl but on a v8 you can make plenty of power and have turbos that spool as fast as you can pres your right foot down, especially considering you have torque to begin with. When I switched from a sr20det it to me a while to get though my thick head.

#12

TECH Fanatic

iTrader: (7)

I just don't see where this would be necessary. It's cool to think about I suppose.

Maybe in road racing or similar...But there's no need for a big, laggy turbo in a road race car...It wouldn't be able to make use of that power properly to begin with.

This is good for small displacement motors...But that's just because they need so much more to catch up to a bigger v8 motor right off the bat.

The SP spool-valve would work awesome on a turbo LS1 car I bet. I'd like to see that with an 88 or 91mm turbo.

Maybe in road racing or similar...But there's no need for a big, laggy turbo in a road race car...It wouldn't be able to make use of that power properly to begin with.

This is good for small displacement motors...But that's just because they need so much more to catch up to a bigger v8 motor right off the bat.

The SP spool-valve would work awesome on a turbo LS1 car I bet. I'd like to see that with an 88 or 91mm turbo.

#13

Staging Lane

Thread Starter

I just don't see where this would be necessary. It's cool to think about I suppose.

Maybe in road racing or similar...But there's no need for a big, laggy turbo in a road race car...It wouldn't be able to make use of that power properly to begin with.

This is good for small displacement motors...But that's just because they need so much more to catch up to a bigger v8 motor right off the bat.

The SP spool-valve would work awesome on a turbo LS1 car I bet. I'd like to see that with an 88 or 91mm turbo.

Maybe in road racing or similar...But there's no need for a big, laggy turbo in a road race car...It wouldn't be able to make use of that power properly to begin with.

This is good for small displacement motors...But that's just because they need so much more to catch up to a bigger v8 motor right off the bat.

The SP spool-valve would work awesome on a turbo LS1 car I bet. I'd like to see that with an 88 or 91mm turbo.

In general I tend to agree that on a big V8 you don't "need" this much refinement of the power band. However, there is a place for everything, and there is a place for twinscroll turbo systems, probably least of all with big LSx V8s. My intention with this thread was simply to perform an analysis, however the outcome would end up. As you allude, just because it exists doesn't mean everyone should run it.

The only application I can really think of for it is a 1000hp AWD LSx that the owner wishes to keep as streetable as possible, and thus wishes to go the extra hurdles to make the engine's hard life a little easier, and to make the challenge of driving such a thing a little smoother and more linear and predictable.

On a separate note, everyone please don't tarnish this thread with the quick spool valve. Please discuss that elsewhere... [must... try... not... to...

]

] Last edited by ClimberD; 08-31-2011 at 03:57 PM.

#14

twin gt35s will make 1000 at the tire and will spool plenty fast, I think you will need to be looking at making more hp before you really need to think this hard about fast spool. build a bigger engine and get the cam right and you will have plenty of response.

But since the is just a Theory discussion, you proposed plan would work as well as any 4cyl set up. if you do twins you are basically treating the engine as two 4cyl.

packaging would be a pain in the *** but I don't see why it could not be done, also you would need to get the lengths correct.

But since the is just a Theory discussion, you proposed plan would work as well as any 4cyl set up. if you do twins you are basically treating the engine as two 4cyl.

packaging would be a pain in the *** but I don't see why it could not be done, also you would need to get the lengths correct.

#15

Staging Lane

Thread Starter

twin gt35s will make 1000 at the tire and will spool plenty fast, I think you will need to be looking at making more hp before you really need to think this hard about fast spool. build a bigger engine and get the cam right and you will have plenty of response.

But since the is just a Theory discussion, you proposed plan would work as well as any 4cyl set up. if you do twins you are basically treating the engine as two 4cyl.

packaging would be a pain in the *** but I don't see why it could not be done, also you would need to get the lengths correct.

But since the is just a Theory discussion, you proposed plan would work as well as any 4cyl set up. if you do twins you are basically treating the engine as two 4cyl.

packaging would be a pain in the *** but I don't see why it could not be done, also you would need to get the lengths correct.

On a 2.5L turbo 4cylinder in 3rd gear, you're rarely going to do better than full boost of 20psi from a single GT35r at 4000rpm. So taking the same number of cylinders, removing half the valves, and variable valve timing, and adding some displacement (aka using one LSx bank), what kind of 3rd gear peak boost RPM are people seeing with twin GT35r turbos? Because if they are only making 4psi at 2000rpm, and 10 psi at 3000 rpm (well I guess 10psi is peak boost for a lot of you) then when would they make 20psi? (those other LSx spool numbers are just total guesses). More importantly, if you rev the motor to 6000rpm while in neutral, how much boost will the needle point to?

#16

This is my analysis of setting up a 'single twinscroll turbo' or 'twin twinscroll turbo' system in the most efficient format possible on the LSx V8 engine with firing order 1-8-7-2-6-5-4-3. This firing order does NOT pair well with twinscroll turbo builds, at least not under the most efficient model of twinscroll header design, as will be explained in this post.

NOW ONTO THE TOPIC OF THIS THREAD:

A twinscroll turbo is a turbocharger with divided twin header pipe entries. The idea is to keep the exhaust pulses separated, to some degree, in order to improve the exhaust scavenging environment! I did not say “in order to better perform exhaust scavenging” as that is naturally aspirated long-tube equal length header territory. In order to achieve an optimal twinscroll design, you want to pair opposite cylinders PER FIRING ORDER, not location on the engine. This is a huge pain on the LSx engine, and here is why:

Firing order:

1-8-7-2-6-5-4-3

For a single turbo twin scroll, you would pair 4 cylinders joining up and eventually entering one turbo scroll, and the other 4 cylinders doing the same thing, merging up and entering the other scroll. Completely divided until they exit the turbo, at which point it doesn’t really matter. But which cylinders pair together?Equal Length: The most optimal design for a twinscroll manifold (or any exhaust) is to have the mating primaries and secondaries be equal length prior to each collector merge.

NOW ONTO THE TOPIC OF THIS THREAD:

A twinscroll turbo is a turbocharger with divided twin header pipe entries. The idea is to keep the exhaust pulses separated, to some degree, in order to improve the exhaust scavenging environment! I did not say “in order to better perform exhaust scavenging” as that is naturally aspirated long-tube equal length header territory. In order to achieve an optimal twinscroll design, you want to pair opposite cylinders PER FIRING ORDER, not location on the engine. This is a huge pain on the LSx engine, and here is why:

Firing order:

1-8-7-2-6-5-4-3

For a single turbo twin scroll, you would pair 4 cylinders joining up and eventually entering one turbo scroll, and the other 4 cylinders doing the same thing, merging up and entering the other scroll. Completely divided until they exit the turbo, at which point it doesn’t really matter. But which cylinders pair together?Equal Length: The most optimal design for a twinscroll manifold (or any exhaust) is to have the mating primaries and secondaries be equal length prior to each collector merge.

In a nutshell, if you slap together a good sized twinscroll setup with two wastegates and decent flowing manifold you will still reap the benefits that the smaller motors are getting.

#17

UNDER PRESSURE MOD

iTrader: (19)

If you want instant throttle response and instant boost, why not look to a centrifugal supercharger? My throttle response is phenominal and as I roll into the throttle at 2500 rpm I go from vacuum to boost in a split second as the bypas valve closes. I know the argument that a centrifugal blower robs horsepower to turn it, but if you have a big motor that makes plenty of torque to begin with, you'll never notice that loss.

I do like your outside the box thinking.

I do like your outside the box thinking.

#18

#19

9 Second Club

Twin scroll on a Subaru is very easy. Just buy a twin scroll equipped Subaru !!

Most Impreza STI turbo's from around 07+ have been fitted with twin scroll turbos and manifolds

Most Impreza STI turbo's from around 07+ have been fitted with twin scroll turbos and manifolds