pushrod length checker

#1

Teching In

Thread Starter

Join Date: Feb 2011

Location: outside of kansas city ks.

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

J am almost done rebuilding my engine only thing left to do is find out what size pushrods I need because I have a 608 lift on int. And 615 on exh. So I am asking how I use an adjustable pushrod length checker

#2

TECH Fanatic

iTrader: (35)

You set the lobe you are checking on its base circle (zero lift ) and the put the checker in like a normal pushrod, then screw it out until you hit zero lash, then remove the checker, count how many turns you put in it. Each turn is .050, once you have that amount figured out, add it to the length of the tool,,i believe its 6.800. Once you add those two numbers you get pushrod length at zero lash. Now you need to add in lifter preload, usually .050-.100 depends on who you ask. So for example, you got 8 full turns on the checker, that would be .400 add that to the 6.8 and you get 7.2 now add in your preload of say .050 and the length you would need is a 7.250 . Do it on multiple lobes so you know you are doing it right, and coming up with the same number. Hope this helps

#5

#6

Teching In

Thread Starter

Join Date: Feb 2011

Location: outside of kansas city ks.

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

OK I got the lobe on bottom rocker arm on nd snug then twisted the checker till I got zero lash and got 7.350 now wht is preload I have nvr heard about it

Trending Topics

#8

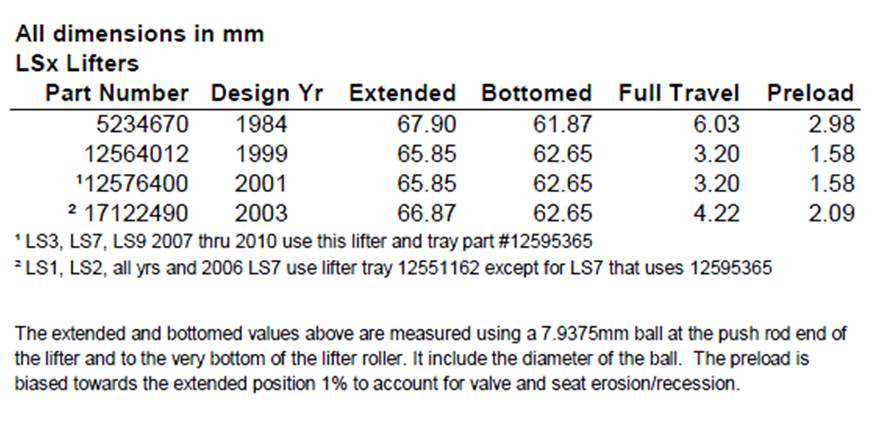

So now you need to add the amount of lifter pre-load to your zero lash pushrod lenght of 7.350" to pre-load the lifters correctly - that will be the length of pushrods you'll need to install. What lifters are you running?

#10

#11

12 Second Club

iTrader: (26)

SO is this done with a "dry" lifter? In other words, I soaked my lifters in oil overnite before installing them but I have had the motor assembeled for about 2 or 3 months waiting on other car parts. Do you have to get the hyrdaulic lifters pumped up with oil before checking them for rod length? Or do you check them dry, so to speak?

Chad

Chad

#12

TECH Fanatic

iTrader: (5)

Join Date: Sep 2008

Location: Salem/Keizer

Posts: 1,120

Likes: 0

Received 0 Likes

on

0 Posts

SO is this done with a "dry" lifter? In other words, I soaked my lifters in oil overnite before installing them but I have had the motor assembeled for about 2 or 3 months waiting on other car parts. Do you have to get the hyrdaulic lifters pumped up with oil before checking them for rod length? Or do you check them dry, so to speak?

Chad

Chad

#13

TECH Fanatic

iTrader: (5)

i thought he was using a different method to find proper pushrod length: the method i thought he was using is described below:

"From Shane at Thunder Racing.

The TDC method is NOT always accurate. Try the EO/IC method to check pushrod length. I have posted directions on this forum numerous times... Here it is again:

FWIW, EVERY cam install I have done using the LS7 lifter with a cam with greater than .600" lift (read smaller base circle) AND stock heads w/GM MLS gaskets has taken 7.425" pushrods for ~.050"-.060" preload. We measure lifter preload on each and every cam install we do. I have never had a lifter failure nor do we end up with the dreaded "sewing machine" noise.

Its very simple, If you change ANY of the following:

valve sizes, valve job, head milling, thinner/thicker head gaskets, decked block, cam with an altered base circle, etc... YOU MUST CHECK FOR PROPER PUSHROD LENGTH.

I have helped countless numbers of individuals with this process over the phone, via email, and PM's. I've posted the process on at least 3 occasions.

Here it is again in a nutshell:

1. Using the EO/IC method, get the lifter to the base circle of the cam.

2. Using a known length pushrod (7.400" is a good start with stock rockers) run the rocker arm bolt down to zero lash. This is easily done with your fingers "wiggling" the rocker, the point at which the "slack" is just gone is zero lash.

3. Set your torque wrench to 22 lb./ft. Tighten the rocker to full torque and count the number of turns it takes to get there. 1 full turn wtih a stock 8mm X 1.25 bolt is ~.047" preload as measured at the pushrod/rocker interface.

4. I normally shoot for 1 1/4 to 1 3/4 turns with stock type lifters like Comp 850's, LS1, LS7 etc.

For an example, if you use a 7.400" pushrod and come up with 3/4 of a turn, you will need at least .025" longer pushrod to get into range. If you end up with 2 1/4 turns, you will need one .025" shorter...

I might not know everything but I will tell you that this method has worked for me year after year cam swap after cam swap. We average 3 cam swaps a week here so you can do the math.

If you are not familiar with the EO/IC method for determining valve events in a 4 stroke engine, its very simple:

For a given cylinder as the Exhaust valve is Opening, the intake lifter will be on the base circle of the cam and lash/preload should be checked for that intake valve.

For a given cylinder as the Intake valve is Closing, the exhaust lifter will be on the base circle of the cam and lash/preload should be checked for that exhaust valve.

THIS METHOD ALWAYS WORKS!!!

Check it using the above method and see where you are.

Thanks,

Shane"

i was under the impression this was the method he was using, my bad for miss reading

"From Shane at Thunder Racing.

The TDC method is NOT always accurate. Try the EO/IC method to check pushrod length. I have posted directions on this forum numerous times... Here it is again:

FWIW, EVERY cam install I have done using the LS7 lifter with a cam with greater than .600" lift (read smaller base circle) AND stock heads w/GM MLS gaskets has taken 7.425" pushrods for ~.050"-.060" preload. We measure lifter preload on each and every cam install we do. I have never had a lifter failure nor do we end up with the dreaded "sewing machine" noise.

Its very simple, If you change ANY of the following:

valve sizes, valve job, head milling, thinner/thicker head gaskets, decked block, cam with an altered base circle, etc... YOU MUST CHECK FOR PROPER PUSHROD LENGTH.

I have helped countless numbers of individuals with this process over the phone, via email, and PM's. I've posted the process on at least 3 occasions.

Here it is again in a nutshell:

1. Using the EO/IC method, get the lifter to the base circle of the cam.

2. Using a known length pushrod (7.400" is a good start with stock rockers) run the rocker arm bolt down to zero lash. This is easily done with your fingers "wiggling" the rocker, the point at which the "slack" is just gone is zero lash.

3. Set your torque wrench to 22 lb./ft. Tighten the rocker to full torque and count the number of turns it takes to get there. 1 full turn wtih a stock 8mm X 1.25 bolt is ~.047" preload as measured at the pushrod/rocker interface.

4. I normally shoot for 1 1/4 to 1 3/4 turns with stock type lifters like Comp 850's, LS1, LS7 etc.

For an example, if you use a 7.400" pushrod and come up with 3/4 of a turn, you will need at least .025" longer pushrod to get into range. If you end up with 2 1/4 turns, you will need one .025" shorter...

I might not know everything but I will tell you that this method has worked for me year after year cam swap after cam swap. We average 3 cam swaps a week here so you can do the math.

If you are not familiar with the EO/IC method for determining valve events in a 4 stroke engine, its very simple:

For a given cylinder as the Exhaust valve is Opening, the intake lifter will be on the base circle of the cam and lash/preload should be checked for that intake valve.

For a given cylinder as the Intake valve is Closing, the exhaust lifter will be on the base circle of the cam and lash/preload should be checked for that exhaust valve.

THIS METHOD ALWAYS WORKS!!!

Check it using the above method and see where you are.

Thanks,

Shane"

i was under the impression this was the method he was using, my bad for miss reading

Last edited by 3rdCoastPowerSports; 11-11-2011 at 10:56 PM. Reason: wording

#19

TECH Senior Member