Polish the oil Gallery

#1

Teching In

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I've been grinding the casting off my LS3 block before painting it. I was wondering if I should remove the casting off the valley while I'm at it. Would there be any down side to removing the casting in the oil gallery and deburing the block?

Thanks for any advice!

Thanks for any advice!

#2

Teching In

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I guess not a very popular mod base on the overwhelming response, LOL. Does anybody have any reason why I might not want to do, as it might be harmful in any way. Any suggestion would be greatly appreciated.

#4

I think that was more popular with the old small block and even then it wasnt really worth the effort. Better off to paint it with some glyptal to help with oil drain back issues which didnt really exist in the first place. Oh and there called oil galleys and those werent fucked with anyway except to tap and replace the expansion plug with a pipe plug so it could be removed to clean them out

#7

TECH Fanatic

iTrader: (10)

Join Date: Mar 2011

Location: Miami gardens FL 33055

Posts: 1,023

Likes: 0

Received 0 Likes

on

0 Posts

Ruff expensive toys, so i take 4 to 5 hours smoothing and de-ruffing/ deburring my blocks, every Conner, sharp edge and overcasting, as well as sandy casting spots have to go.

Trending Topics

#8

12 Second Club

iTrader: (49)

The point to deburring something is not to make it look pretty, or keep your supple hands from becoming disfigured, but to remove stress risers.

Stress risers are very thin and can crack easily, leading to a larger crack.

I'm not sure what oil galleries your talking about, (yes they are called galleries, a galley is a place you would eat on a ship.) But smoothing all drain backs is always a good idea, but don't mess with any pressurized oil ports.

Stress risers are very thin and can crack easily, leading to a larger crack.

I'm not sure what oil galleries your talking about, (yes they are called galleries, a galley is a place you would eat on a ship.) But smoothing all drain backs is always a good idea, but don't mess with any pressurized oil ports.

#10

My LS3 block had pretty nasty casting and I spent over 6 hours deburring it. I also went through and ported oil passages in block and oil pan areas, I'm surprised GM dosent have more warranty problems with high spinning LS7 motors based on the blockage I observed in my LS3 dry sump pan. If your not planning on extended high RPMs the block is OK. I am contemplating painting interior with Glyptol as the sand castins are pretty nasty.

#11

ModSquad

iTrader: (6)

I used to spend 40 hours polishing the inside of my dry sump sbc engines. It was a good way to see what you actually have under the rough stuff, and it helped with oil control. They were so smooth, you could have mistaken them for aluminum engines on the inside. NASCAR late models, and yes, this was illegal. Shame on me.

#12

TECH Enthusiast

iTrader: (19)

There are small benefits to smoothing out the oil galleries. You need to know where to work but all that's being done is blending transitions. If you look closely you will find some areas that have a sharp edge or partial blockage. These areas can use some blending. Be very careful and do not alter the overall size of the gallery. LS engines don't have as much oil drainback from the intake valley like older pushrod engines so there is no gain there. LS engines do aerate the oil @ higher rpms and blending the galleries do help but if you need serious oil control then you need to go to a dry sump.

#13

Staging Lane

Join Date: Jun 2012

Location: Riverside ca

Posts: 51

Likes: 0

Received 0 Likes

on

0 Posts

I have limited room under the oil pan. We should have gone with the gto pan before we started fabbing up the rear cage in the sandrail. We experience high g force & oil control is always an issue. I would love to get a dry sump but its just not in the budget. What do you guys think about an oil accumulator?

NEVER MIND, im taking my own advice, lol

NEVER MIND, im taking my own advice, lol

- stop thread jacking

- use the search function

- start a new thread if I feel the need to discuss it further

#14

Teching In

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

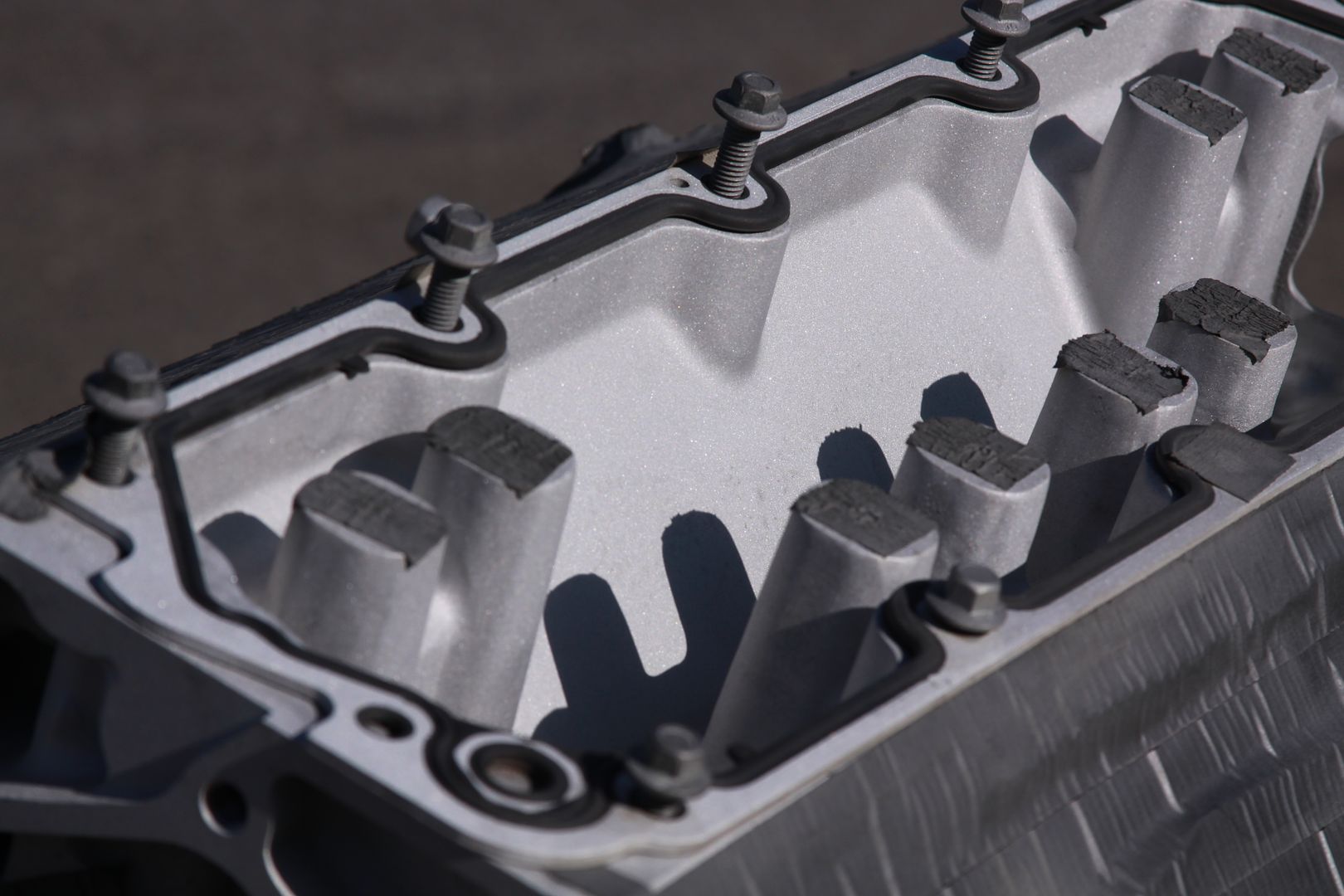

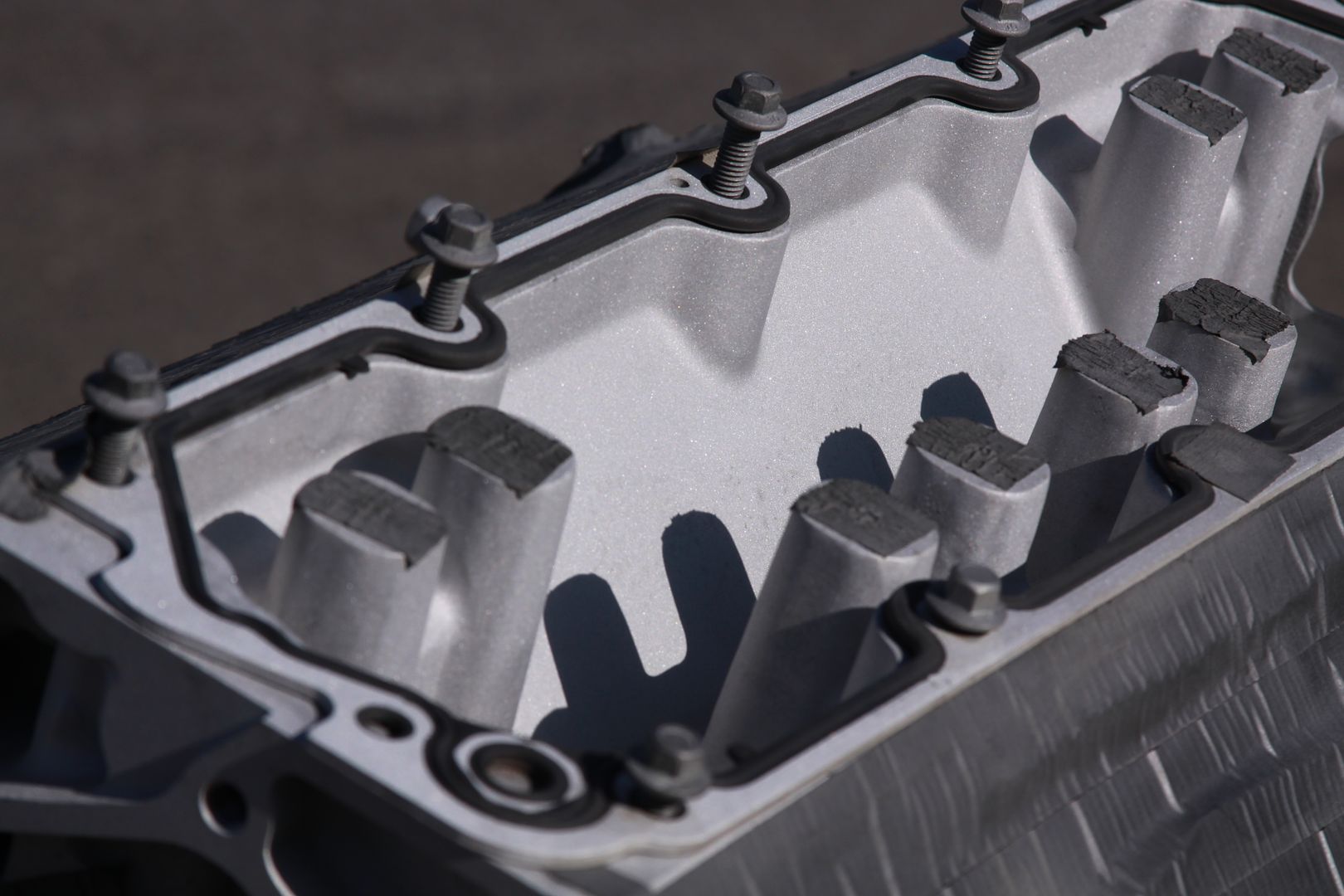

As for an up date, I ended removing all the casting off the block. Both inside and out, front and back and completely deburing it. Probably spent 60 hours working on it. Than I had it media blasted. Next will come the machine work and assembly of a 418 forge setup. And finally paint.

This is an in progress shot.

For complete details on my build thread, I'm documenting it here http://www.camaro5.com/forums/showthread.php?t=188393

This is an in progress shot.

For complete details on my build thread, I'm documenting it here http://www.camaro5.com/forums/showthread.php?t=188393

#15

ModSquad

iTrader: (6)

You blasted it after you polished it?

#17

And get abrasive dust all over the inside of the engine. Clean & flush it thoroughly and be sure to keep the cylinder liners oiled so they don't rust.

#18

Teching In

Thread Starter

iTrader: (1)

Join Date: Nov 2011

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the tip. I am definitely cleaning and re-cleaning the block, all thread holes, etc. I'm having the cylinders honed but I will lube with oil in the mean time.

I got a Pure Power oil filter just cause I want to make sure this engine run as clean as possible!