Which cam should I use for turbo?(dyno # update)

#1

I have a comp cam that has been in my car since it was an all motor setup. Since then it was a rear mount setup, spun a bearing in the motor rebuilt it all forged with 9.5:1 compression and 317 hand ported heads with edelbrock aluminum intake. Then I built my own front mount kit. With the 4l80e and 3.08 rear gear the car has little low end power and slow to spool a tc76 turbo. Is the cam I have in the car really holding me back and should I stick the stock 2000 f body cam back in it? I do plan on getting a custom turbo cam but after I upgrade to am s475 t6 turbo and redo my hotside piping, which wont be for a year or so. So do I keep whats in there or go back to stock cam? Trying to push the turbo to the limit looking for 800rwhp or as close to it as possible which will probably more like 650rwhp.

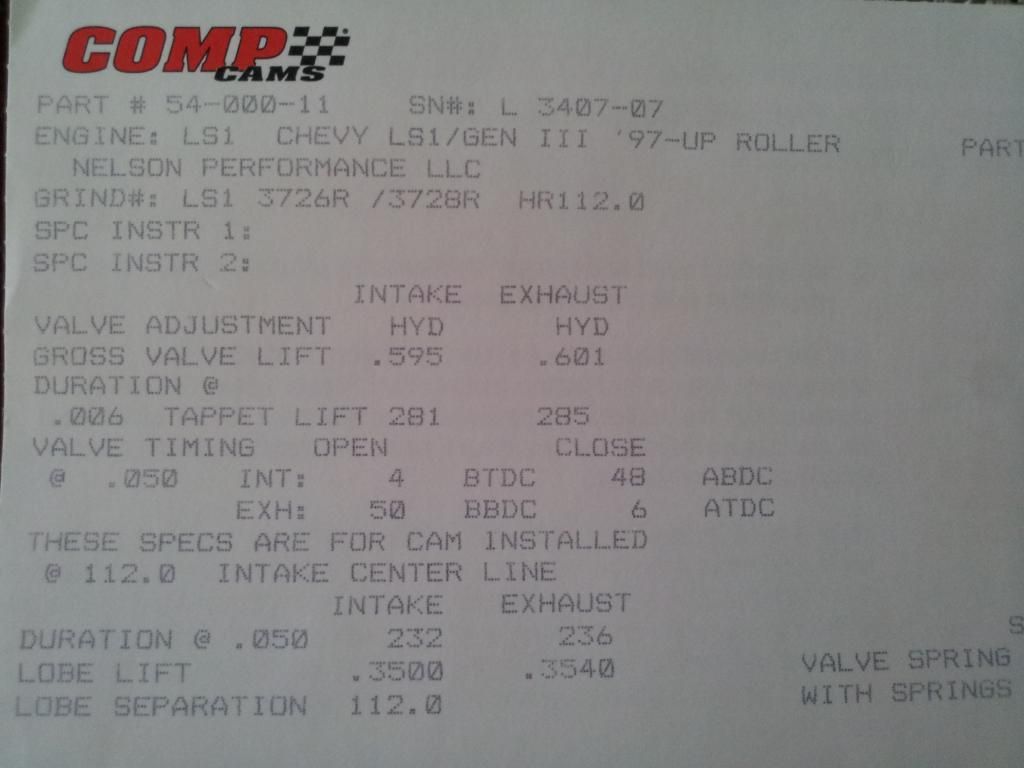

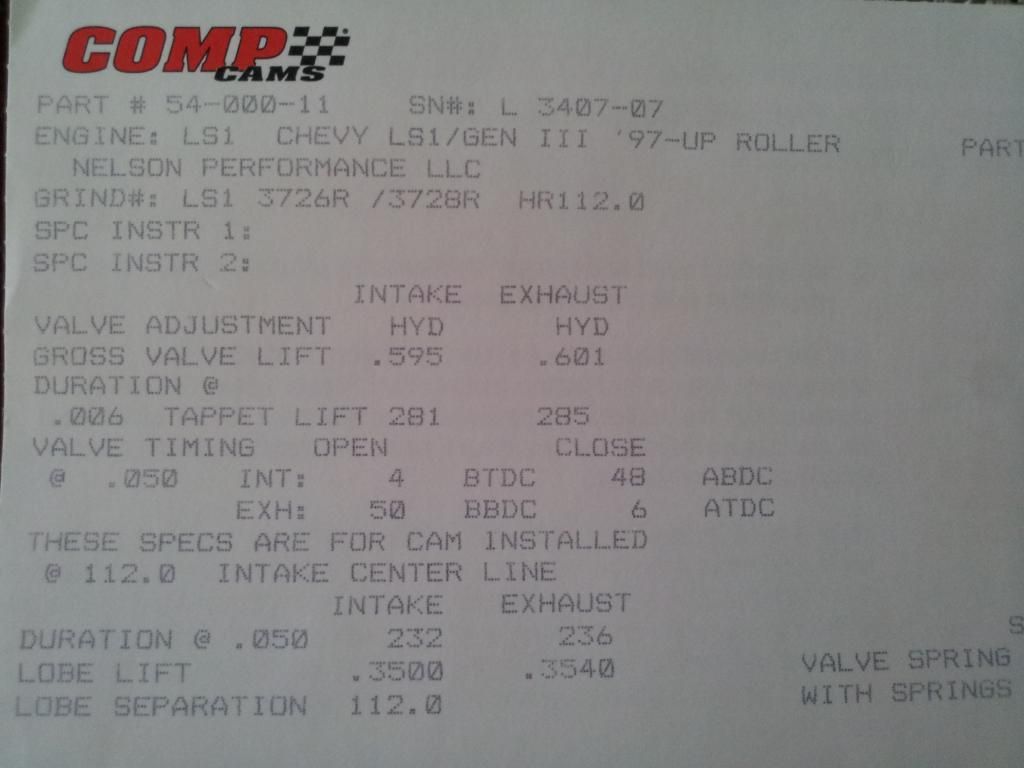

Here is the specs of the cam I have in the car at the moment.

Here is the specs of the cam I have in the car at the moment.

Last edited by Silver_TransAm; 12-11-2012 at 09:28 PM.

#2

FormerVendor

iTrader: (3)

It has too much overlap for my taste with the size turbo you have.

If a 347 is slow to spool a TC76 or 78 then I would look at the stall converter or tune as they may be off causing the slow spooling. Too rich an AFR or not enough timing can cause a car to build boost slowly.

If a 347 is slow to spool a TC76 or 78 then I would look at the stall converter or tune as they may be off causing the slow spooling. Too rich an AFR or not enough timing can cause a car to build boost slowly.

#3

It has too much overlap for my taste with the size turbo you have.

If a 347 is slow to spool a TC76 or 78 then I would look at the stall converter or tune as they may be off causing the slow spooling. Too rich an AFR or not enough timing can cause a car to build boost slowly.

If a 347 is slow to spool a TC76 or 78 then I would look at the stall converter or tune as they may be off causing the slow spooling. Too rich an AFR or not enough timing can cause a car to build boost slowly.

By the way I do plan on getting a custom cam by you since I have seen and heard really good things.

#4

#5

10 Second Club

iTrader: (27)

Join Date: Sep 2008

Location: Lake Tapps, WA

Posts: 2,229

Likes: 0

Received 0 Likes

on

0 Posts

wow it should have awesome spool and if anything fall flat on top. Your only using a 68mm turbine wheel. 4yrs ago a had a tc76 build and anytime you rolled into the throttle you could hear the turbo spooling. Like Martin said could be the tune, I would do a search and there's some threads about how to spool the turbo, basically not pulling timing or dropping the afr's until your already going into boost.

#6

FormerVendor

iTrader: (3)

Thanks Alex, I can't wait to see your car finally run. We've spent a long time planning it all out and it's getting close now!

wow it should have awesome spool and if anything fall flat on top. Your only using a 68mm turbine wheel. 4yrs ago a had a tc76 build and anytime you rolled into the throttle you could hear the turbo spooling. Like Martin said could be the tune, I would do a search and there's some threads about how to spool the turbo, basically not pulling timing or dropping the afr's until your already going into boost.

I believe and have found that overlap can and will dictate spool time more than other events in the camshaft's profile. I do think EVO and then EVC are important in that order, but not as important as matching overlap to the turbine and housing size. With a lot of overlap and good cylinder pressure, the turbo should spool very quickly. Even with lower dynamic cylinder pressure and the same amount of overlap I have found and believe that excess unburnt fuel and air from the overlap period add to drive pressure that moves the turbine wheel and creates boost pressure.

You say quick spool is great, right? Of course! To an extent....I think there is a fine balance of cylinder pressure, overlap and valve events in a turbo engine along with matching the turbine and AR housing to the engine size being used and the compressor wheel to the cylinder head flow, rpm range and power potential of the engine it's to be used on. With too much overlap, you drive the turbine extremely quickly to a point where you begin to create drive pressure in a ratio that far exceeds boost pressure. At this point it begins to drive the compressor wheel off it's higher efficiency islands, power peaks too early and falls off.

When you can balance overlap with drive pressure and the boost pressure it creates while keeping the compressor happy and in it's highest efficiency islands possible for the longest amount of time possible you go faster and quicker. A turbo engine is not operating at the same pressures a N/A motor is and thus doesn't need to be treated like one. Overlap is needed to an extent, but it can be abused and overused even in N/A set-ups.

I too think that in this case it's probably in the tune or stall speed as a 68mm turbine and a .96 AR housing on your motor should spool very quickly, especially with that much overlap.

#7

Let's just say power is not where it should be either I think. At 13psi I'm dead even with my dad's stockish auto TA (p1sc@5psi headers).

Tune is pretty solid looking at afr and timing( 11.6 in boost with 16 degrees of timing). I'm thinking back pressure is really high or cam is just not efficient with boost hence why I asked if stock cam would be better.

Tune is pretty solid looking at afr and timing( 11.6 in boost with 16 degrees of timing). I'm thinking back pressure is really high or cam is just not efficient with boost hence why I asked if stock cam would be better.

Trending Topics

#8

FormerVendor

iTrader: (3)

I think the IVC event is way to late and that it's killing cylinder pressure which is also killing spool time.

How much timing does it have in it before boost? You need N/A timing and N/A AFR up to around 1-3psi of boost and then quickly ramp it out and fuel enrichment in.

How much timing does it have in it before boost? You need N/A timing and N/A AFR up to around 1-3psi of boost and then quickly ramp it out and fuel enrichment in.

#9

I think the IVC event is way to late and that it's killing cylinder pressure which is also killing spool time.

How much timing does it have in it before boost? You need N/A timing and N/A AFR up to around 1-3psi of boost and then quickly ramp it out and fuel enrichment in.

How much timing does it have in it before boost? You need N/A timing and N/A AFR up to around 1-3psi of boost and then quickly ramp it out and fuel enrichment in.

Seems to have lots of mid range then just feels choked up. I have full 3inch exhaust from turbo to axle then splits into dual 2.5 inch no muffler. I put a cutout about 2.5ft from turbo which seemed to help spool see boost at at 2800 and full 13 at 3500rpms now with cutout.

It was tuned by nelson performance here in san Antonio tx.

#10

FormerVendor

iTrader: (3)

Has 22degrees up to boost and mid to low 13.xx afr untill about 2-3 psi.

Seems to have lots of mid range then just feels choked up. I have full 3inch exhaust from turbo to axle then splits into dual 2.5 inch no muffler. I put a cutout about 2.5ft from turbo which seemed to help spool see boost at at 2800 and full 13 at 3500rpms now with cutout.

Seems to have lots of mid range then just feels choked up. I have full 3inch exhaust from turbo to axle then splits into dual 2.5 inch no muffler. I put a cutout about 2.5ft from turbo which seemed to help spool see boost at at 2800 and full 13 at 3500rpms now with cutout.

Your description of how it feels choked up coincides perfectly with what I have seen and found with turbo camshafts. Too much overlap can and will choke the motor up top by causing drive pressure to stack up in the exhaust housing and send turbo shaft speed into orbit. A lot of people seem to forget that the turbine wheel and compressor wheel spin at the same speed on the same shaft and that what happens to the turbine happens to the compressor.

Your current cam has 10 degrees of overlap the 232 degree intake lobe and 112 ICL is killing your dynamic compression. My stage one turbo cam would work perfect with what you have right now.

It's specs:

278/278@.006"

226/226@.050"

147/147@.200"

114LSA 111ICL 117ECL

226/226 .605"/.605" 114+3

It has -2 degrees overlap and will help, but not fix your drive pressure issue which will still be present due to the 68mm turbine wheel your turbo utilizes.

#13

10 Second Club

iTrader: (27)

Join Date: Sep 2008

Location: Lake Tapps, WA

Posts: 2,229

Likes: 0

Received 0 Likes

on

0 Posts

Try letting the car shift into 4th under light throttle and than slowly rolling into the throttle. If the car starts pulling hard in the 3-5K range and then flattens out it's a good possibility it's backpressure.

I went from a TC76 with the 68mm turbine to a 80mm W/83mm turbine and the car spooled better and pulled like it gained a 100+hp on top.

I went from a TC76 with the 68mm turbine to a 80mm W/83mm turbine and the car spooled better and pulled like it gained a 100+hp on top.

#15

Try letting the car shift into 4th under light throttle and than slowly rolling into the throttle. If the car starts pulling hard in the 3-5K range and then flattens out it's a good possibility it's backpressure.

I went from a TC76 with the 68mm turbine to a 80mm W/83mm turbine and the car spooled better and pulled like it gained a 100+hp on top.

I went from a TC76 with the 68mm turbine to a 80mm W/83mm turbine and the car spooled better and pulled like it gained a 100+hp on top.

#16

10 Second Club

iTrader: (27)

Join Date: Sep 2008

Location: Lake Tapps, WA

Posts: 2,229

Likes: 0

Received 0 Likes

on

0 Posts

My advice is bigger turbo on the turbine side, not enough attention is given to the turbine side when picking a turbo. I learned my leasson. I presently have a billet 83 w/92mm turbine on my 390. Billet 83 moves enough cfm for me but need 92 on the exhaust. You get the right combination of parts together like a good cam and torque converter and you can spool a large turbo.

#17

My advice is bigger turbo on the turbine side, not enough attention is given to the turbine side when picking a turbo. I learned my leasson. I presently have a billet 83 w/92mm turbine on my 390. You get the right combination of parts together like a good cam and torque converter and you can spool a large turbo.

#18

FormerVendor

Martin made some good points here. I do generally disagree with too much overlap equaling high rpm power drop off but with a TC76 it certainly isn't helping.

Somewhat along the same lines of thinking, I look at it like this.

How much power is the turbo capable of making and how much cam do you really need to efficiently max out the turbo?

In this case the cam is unnecessarily big for that turbocharger. I would guess that anything much bigger than low 220's at .050 would not realize any more max power.

A smaller cam that shifts NA power production lower in the rpm range will help response dramatically.

Having said all that, I still really do not like the TC series turbos.

Somewhat along the same lines of thinking, I look at it like this.

How much power is the turbo capable of making and how much cam do you really need to efficiently max out the turbo?

In this case the cam is unnecessarily big for that turbocharger. I would guess that anything much bigger than low 220's at .050 would not realize any more max power.

A smaller cam that shifts NA power production lower in the rpm range will help response dramatically.

Having said all that, I still really do not like the TC series turbos.

#19

10 Second Club

iTrader: (27)

Join Date: Sep 2008

Location: Lake Tapps, WA

Posts: 2,229

Likes: 0

Received 0 Likes

on

0 Posts

I did the same thing, If your looking for 800rwhp the Borg Warner 80mm with 83 or 87mm turbine is a good place to start. I'm not sure what they call it ST80, S483, S487 etc I'm not sure. There's some good choices, the above are just reference to the size you would need. Jose at Forced Induction has helped alot with helping me pick the right turbo for my combinations, I've learned alot from Martin at Tick on camshaft, compression and tuning from his threads. Lot's of knowledgable people on here.

The TC series is really suited to high powered 4 cyclinder motors.

The TC series is really suited to high powered 4 cyclinder motors.

#20

FormerVendor

IMO the TC series isn't really well suited to anything. Regardless of displacement this turbo will be the cause of more backpressure than necessary due to the undersized turbine.

Not sure why they even make a 78 as that's a step in the wrong direction.

I would bet that a TC70/F1 would be more efficient than a TC76/78 up until the point it was maxed out.

Not sure why they even make a 78 as that's a step in the wrong direction.

I would bet that a TC70/F1 would be more efficient than a TC76/78 up until the point it was maxed out.