What causes boost to fall off as RPM's rise? (BAD ASSES INSIDE PLEASE!)

#1

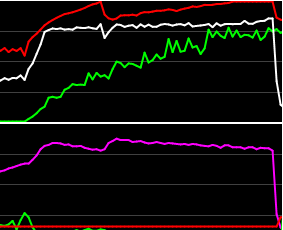

I'm seeing a strange issue with my turbo fox. With 20psi on top of the waste gate from my controller I see the following:

@ 5000 rpm I make 250kpa

@ 5700 rpm I make 235kpa

@ 6500 rpm I make 220kpa

It does this in low gear and high gear every pass. It's a linear fall as RPM's rise.

Combo is a 370ci, stock 317's, ls6 mani, box stock s475 (1.32AR T6), manifold kit, open 5" downpipe, twin 38mm gates, boost least co2 controller (no leaks), 3" cold side, pump gas and meth, powerglide.

What could cause this? Everyone assures me it's not the turbo running out of steam, but what else could it be?

@ 5000 rpm I make 250kpa

@ 5700 rpm I make 235kpa

@ 6500 rpm I make 220kpa

It does this in low gear and high gear every pass. It's a linear fall as RPM's rise.

Combo is a 370ci, stock 317's, ls6 mani, box stock s475 (1.32AR T6), manifold kit, open 5" downpipe, twin 38mm gates, boost least co2 controller (no leaks), 3" cold side, pump gas and meth, powerglide.

What could cause this? Everyone assures me it's not the turbo running out of steam, but what else could it be?

#3

TECH Fanatic

iTrader: (16)

are you sure the wastegates arent cracking open when they shouldnt (if there really arent any leaks)? im using a manual controll and it starts at 12lbs and tapers to 9.5lbs (which is what the spring is rated for). it just cant put enough pressure back on top of the gate.

#4

230/230 .612/.608 115+2lsa comp xfi

I'm using co2 on the top of the gate. No leaks I can find, just tapers off through the rpm band.

are you sure the wastegates arent cracking open when they shouldnt (if there really arent any leaks)? im using a manual controll and it starts at 12lbs and tapers to 9.5lbs (which is what the spring is rated for). it just cant put enough pressure back on top of the gate.

Trending Topics

#9

7 Second Club

iTrader: (7)

Swap in a spring or set of springs that gets it up to around 14-15 psi on spring pressure alone, then feed pressure to the top of it to hit your target and see if it stays steadier. If it doesn't you are probably out of turbo at that point if everything pressure tests fine. I suppose it could be valve float, what valve springs are you running with that cam?

#10

TECH Fanatic

iTrader: (16)

Swap in a spring or set of springs that gets it up to around 14-15 psi on spring pressure alone, then feed pressure to the top of it to hit your target and see if it stays steadier. If it doesn't you are probably out of turbo at that point if everything pressure tests fine.

#11

Swap in a spring or set of springs that gets it up to around 14-15 psi on spring pressure alone, then feed pressure to the top of it to hit your target and see if it stays steadier. If it doesn't you are probably out of turbo at that point if everything pressure tests fine. I suppose it could be valve float, what valve springs are you running with that cam?

i'm running the lunati .650 springs

#17

7 Second Club

iTrader: (7)

Those Lunati duals are good so I doubt they would have a problem controlling the valve train.

Onfire touched on something too, since it seems you have a fancy boost controller you should have the ability to put more pressure to the top of the gate in the higher RPM/speeds to counter it?

#18

7 Second Club

iTrader: (7)

My GTO used to have a similar effect with my old camshaft. I knew my hotside backpressure was through the roof on my setup because my turbos are just too small so I had somebody spec me another camshaft to try to deal with the large amount of backpressure and keep it pulling up in the higher RPMs. I didn't think it would make much of a difference but I'll be damned if my boost stays nice and steady now instead of dropping a couple psi by redline. But I really don't think it's your problem here seeing as how you have a large turbine wheel on that thing with a T6 flange and wide open downpipe.

#19

powerglide using a pulse width generator. the output is a little sporadic.

i use a 2 step and a boost controller. i have a launch psi and then as soon as i let off the brake it starts stages to get me to full boost. i can't really use it the way you are saying since it is time based, not speed or rpm based, so if i tried to trick it i could potentially way over boost it if the run isn't perfectly on time.

ya, its a giant turbine housing, and a 5" downpipe. i need to pressure test the cold side and make sure i don't have a leak somewhere causing the turbo to run out of steam.

I guess I just control my launch boost pressure with my 2 step RPM but if you don't have a 2 step I don't suppose that would work for you. Either way it would just be a test so you could just launch off idle if you wanted to since it's just to see if pressure is anymore steady.

Those Lunati duals are good so I doubt they would have a problem controlling the valve train.

Onfire touched on something too, since it seems you have a fancy boost controller you should have the ability to put more pressure to the top of the gate in the higher RPM/speeds to counter it?

Those Lunati duals are good so I doubt they would have a problem controlling the valve train.

Onfire touched on something too, since it seems you have a fancy boost controller you should have the ability to put more pressure to the top of the gate in the higher RPM/speeds to counter it?

My GTO used to have a similar effect with my old camshaft. I knew my hotside backpressure was through the roof on my setup because my turbos are just too small so I had somebody spec me another camshaft to try to deal with the large amount of backpressure and keep it pulling up in the higher RPMs. I didn't think it would make much of a difference but I'll be damned if my boost stays nice and steady now instead of dropping a couple psi by redline. But I really don't think it's your problem here seeing as how you have a large turbine wheel on that thing with a T6 flange and wide open downpipe.