just got my 9" need install help

#1

i just got my 9" from TTP and i need some install help. ive swapped rears before, but never put together a 9"

basically i need to know what needs to me done by a shop, like what bearings get pressed onto what and so forth. dont i need to get the bearings, axles, and backing plates pressed together???

also a basic run down of the assembling the 9" would be great

from what ive heard basically i need to remove the old rear, take out the axles, remove the backing plates, get the backing plates+new bearings+new axles pressed together, install the center, than install the axle/bearing/backingplate assemblies, than just reinstall everything?

thanks

basically i need to know what needs to me done by a shop, like what bearings get pressed onto what and so forth. dont i need to get the bearings, axles, and backing plates pressed together???

also a basic run down of the assembling the 9" would be great

from what ive heard basically i need to remove the old rear, take out the axles, remove the backing plates, get the backing plates+new bearings+new axles pressed together, install the center, than install the axle/bearing/backingplate assemblies, than just reinstall everything?

thanks

Last edited by Tally TransAm; 09-07-2004 at 08:02 PM.

#3

TECH Apprentice

iTrader: (2)

Join Date: Apr 2002

Location: Vancleave, MS

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

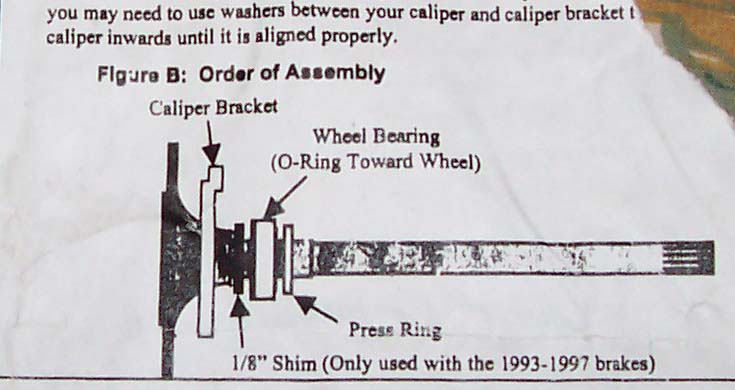

If you have the moser, there is a little diagram in one of the packages that shows you how the parts go onto the axle. The order is backing plate, wheel bearing with O-ring closest to the backing plate, and then the press ring. Make sure you don't mix up the backing plates or put them on backwards. If so you will be getting a new set of bearings pressed on.

Short side is on the drivers side. It is easy to check right now since you don't have the axle bearings pressed on. Install the chunk in the housing and test fit the axles to check the fit.

Make sure you clean out the housing real good before doing this. I used a couple cans of brake clean, 1/2 roll of paper towels and a mop handle to clean the oily film and crap out of the housing.

What gear/carrier/center section did you get?

Short side is on the drivers side. It is easy to check right now since you don't have the axle bearings pressed on. Install the chunk in the housing and test fit the axles to check the fit.

Make sure you clean out the housing real good before doing this. I used a couple cans of brake clean, 1/2 roll of paper towels and a mop handle to clean the oily film and crap out of the housing.

What gear/carrier/center section did you get?

Trending Topics

#11

ok so i was looking at it some more today.

new questions: once i get the whole axle/backing plate/bearing assembly together, how do i get it in the housing cause the wheel bearing is a REAL tight fit in the housing end and wont go in more than a cm. do i just get it started and hammer away at it until i can pull it flush with the four bolts??? if thats the case, how will i ever get the axle out if i need too.

also with the seals, do i put the seals on the axle and slide it in, or do i install the the seals in the housing and then slide the axle in.

thanks again

new questions: once i get the whole axle/backing plate/bearing assembly together, how do i get it in the housing cause the wheel bearing is a REAL tight fit in the housing end and wont go in more than a cm. do i just get it started and hammer away at it until i can pull it flush with the four bolts??? if thats the case, how will i ever get the axle out if i need too.

also with the seals, do i put the seals on the axle and slide it in, or do i install the the seals in the housing and then slide the axle in.

thanks again

#12

TECH Apprentice

iTrader: (2)

Join Date: Apr 2002

Location: Vancleave, MS

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

I installed the oil seals in the housing first then the axles.

I just used a big *** socket and put that over the oil seals and tapped them into place. There is a lip in the housing that they go up against. Look at that lip so you have a good idea of how far in they go. You might damage them if you aren't careful. I just took my time and slowly worked them in by tapping on the end of the socket.

I had a harder time with the axles. The driver side axle went in pretty easy. I just got the axle bearing started into the housing and then put a piece of wood against the end of the axle and tapped it into place. Once you get it into pretty close, you can use the tbolts to snug it on up into place. The passenger side didn't want to go. I ended taking it out several times and sanding the housing and checking the fit. I finally just used the hammer and piece of wood and hit it pretty frigging hard. It went on in then. Once I got it close, I snugged it up with the Tbolts.

I just used a big *** socket and put that over the oil seals and tapped them into place. There is a lip in the housing that they go up against. Look at that lip so you have a good idea of how far in they go. You might damage them if you aren't careful. I just took my time and slowly worked them in by tapping on the end of the socket.

I had a harder time with the axles. The driver side axle went in pretty easy. I just got the axle bearing started into the housing and then put a piece of wood against the end of the axle and tapped it into place. Once you get it into pretty close, you can use the tbolts to snug it on up into place. The passenger side didn't want to go. I ended taking it out several times and sanding the housing and checking the fit. I finally just used the hammer and piece of wood and hit it pretty frigging hard. It went on in then. Once I got it close, I snugged it up with the Tbolts.

#13

TECH Apprentice

iTrader: (2)

Join Date: Apr 2002

Location: Vancleave, MS

Posts: 367

Likes: 0

Received 0 Likes

on

0 Posts

One other thing. Make sure that you loctite the tbolt nuts. Some people have had trouble with them coming loose. If that happens, your axle can come out and bad things will happen.

I only have about 150 miles on my 9" and I heard a vibration from the rear and I checked the tbolts when I got home. They were still tight though. It seems that the frigging piece of rubber hose that I put on the top of the passenger side spring has come loose and now the spring is making noise.

I think I am going to try and shave about 1/2" off the stock upper spring mount and reinstall it this weekend.

I only have about 150 miles on my 9" and I heard a vibration from the rear and I checked the tbolts when I got home. They were still tight though. It seems that the frigging piece of rubber hose that I put on the top of the passenger side spring has come loose and now the spring is making noise.

I think I am going to try and shave about 1/2" off the stock upper spring mount and reinstall it this weekend.