Boring Motor News

#1

10 Second Club

Thread Starter

iTrader: (4)

Join Date: Feb 2004

Location: Marysville, WA

Posts: 9,448

Likes: 0

Received 0 Likes

on

0 Posts

I went out to Don's last night to replace my main bolts & check the windage tray clearance. I paid to have ARP studs installed, but the engine arrived with factory bolts. They sent me a set Thursday & I had an itch to get started....

Anyway, Don showed me how to check the main bearing gap (damn these guys in Monroe are thourough!) so I amused myself for a few hours. Disclaimer - a couple hours were spent on some much needed drinking of Mikes & smoking of cigars first. Then I had to go to Ellis's to get my parts. And then...well it was almost time to go home.

Anyway, I got 3 of the main cap bolt sets replaced. All of the bearing gaps were just about identical, # 1 was just under .002", 2 was just over .002", 3 was just under .002". Don wasn't sure about blown LS1 applications, but said a SBC should run around .0015", so it might be a tad loose, but it's consistent.

And as I was finishing up on #3 the wrench slipped off the bolt @ 60 ft lbs & my knuckles became good friends with the bottom surface of the block. DAMN that metal is sharp! Took my middle finger right down to the white stuff. Since there was no skin left, it wouldn't stop bleeding so I cleaned up & went home.

Took my middle finger right down to the white stuff. Since there was no skin left, it wouldn't stop bleeding so I cleaned up & went home.

After I get off work today I will go get the correct sockets to torque 12 pt main bolts & head back out to finish the job. Like I said - boring, but some of you seem interested in my progress.

And get this, Linda went with to watch & help.

Anyway, Don showed me how to check the main bearing gap (damn these guys in Monroe are thourough!) so I amused myself for a few hours. Disclaimer - a couple hours were spent on some much needed drinking of Mikes & smoking of cigars first. Then I had to go to Ellis's to get my parts. And then...well it was almost time to go home.

Anyway, I got 3 of the main cap bolt sets replaced. All of the bearing gaps were just about identical, # 1 was just under .002", 2 was just over .002", 3 was just under .002". Don wasn't sure about blown LS1 applications, but said a SBC should run around .0015", so it might be a tad loose, but it's consistent.

And as I was finishing up on #3 the wrench slipped off the bolt @ 60 ft lbs & my knuckles became good friends with the bottom surface of the block. DAMN that metal is sharp!

Took my middle finger right down to the white stuff. Since there was no skin left, it wouldn't stop bleeding so I cleaned up & went home.

Took my middle finger right down to the white stuff. Since there was no skin left, it wouldn't stop bleeding so I cleaned up & went home.

After I get off work today I will go get the correct sockets to torque 12 pt main bolts & head back out to finish the job. Like I said - boring, but some of you seem interested in my progress.

And get this, Linda went with to watch & help.

#5

10 Second Club

Thread Starter

iTrader: (4)

Join Date: Feb 2004

Location: Marysville, WA

Posts: 9,448

Likes: 0

Received 0 Likes

on

0 Posts

You know Eric, nurses are some of the most caring, loving people on the planet. Unless you are married to them. Then it's "Hell, it anit squirting ya big sissy. Put a band-aid on it & quit your crying!" Luckily it quit bleeding by the time I got home or she would have gotten out her sewing box.

Thanks Ellis! I was just perusing the engine forum & guys like Harlan say that is normal, and the ~.025 side-to-side on the rods is OK too. So I've done 3 mains, but Don is out of plasti-gauge. Where can I get more for him (& do I need to do all 5?) Oh, and I got more $ for you....

Thanks Ellis! I was just perusing the engine forum & guys like Harlan say that is normal, and the ~.025 side-to-side on the rods is OK too. So I've done 3 mains, but Don is out of plasti-gauge. Where can I get more for him (& do I need to do all 5?) Oh, and I got more $ for you....

#6

10 Second Club

iTrader: (8)

I have some but I think it is un-necassary(sp). You paid the builder to build the motor right? Either you trust him or you don't  If you don't trust him WHY did you buy the motor

If you don't trust him WHY did you buy the motor  You have already checked 60% of his work and it was fine. My fear is you are going to not get the thrust back on correctly

You have already checked 60% of his work and it was fine. My fear is you are going to not get the thrust back on correctly  it can be tricky on some motors and will ruin a good crank fast.

it can be tricky on some motors and will ruin a good crank fast.

Either way I have plasigauge here and I can grab a stick from the machinest, which I trust completely, when I drop off the gaskets for him to port your heads today

If you don't trust him WHY did you buy the motor

If you don't trust him WHY did you buy the motor  You have already checked 60% of his work and it was fine. My fear is you are going to not get the thrust back on correctly

You have already checked 60% of his work and it was fine. My fear is you are going to not get the thrust back on correctly  it can be tricky on some motors and will ruin a good crank fast.

it can be tricky on some motors and will ruin a good crank fast.Either way I have plasigauge here and I can grab a stick from the machinest, which I trust completely, when I drop off the gaskets for him to port your heads today

#7

TECH Addict

I always check every single bearing, ring gap, cylinder wall clearance etc. just for piece of mind. I guess I don't trust anybody  It doesn't really cost anything more than time, and peace of mind is easy to sleep with

It doesn't really cost anything more than time, and peace of mind is easy to sleep with

It doesn't really cost anything more than time, and peace of mind is easy to sleep with

It doesn't really cost anything more than time, and peace of mind is easy to sleep with

Trending Topics

#8

10 Second Club

iTrader: (8)

Originally Posted by Racehead

I always check every single bearing, ring gap, cylinder wall clearance etc. just for piece of mind. I guess I don't trust anybody  It doesn't really cost anything more than time, and peace of mind is easy to sleep with

It doesn't really cost anything more than time, and peace of mind is easy to sleep with

It doesn't really cost anything more than time, and peace of mind is easy to sleep with

It doesn't really cost anything more than time, and peace of mind is easy to sleep with

Like I said...why are you paying some one else to do it

In the past I have done it over and over and Then one day I realized time is money

I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?

I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?  So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game.

So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game. Either you have them or you don't

The rest is a waste of time and money

The rest is a waste of time and money

#9

TECH Addict

Originally Posted by TwoFast4Lv

Like I said...why are you paying some one else to do it

In the past I have done it over and over and Then one day I realized time is money I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?

I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?  So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game.

So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game.

Either you have them or you don't The rest is a waste of time and money

The rest is a waste of time and money

In the past I have done it over and over and Then one day I realized time is money

I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?

I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?  So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game.

So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game. Either you have them or you don't

The rest is a waste of time and money

The rest is a waste of time and money

I certainly understand why someone would pay someone else to assemble a motor and throw it in and run it. As you say "time is money", I just couldn't do that myself

#10

Originally Posted by TwoFast4Lv

Like I said...why are you paying some one else to do it

In the past I have done it over and over and Then one day I realized time is money I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?

I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?  So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game.

So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game.

Either you have them or you don't The rest is a waste of time and money

The rest is a waste of time and money

In the past I have done it over and over and Then one day I realized time is money

I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?

I had to ask my self..."Why did I just pay some one else to put my motor together if I was going to spend 4-6 hours tearing it back apart to make sure he did it right?  So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game.

So I make sure I find reliable people to put it together. If I am worried I will pop a few parts and check. If I find a problem I find a new source. Reliable suppliers are the name of the game. Either you have them or you don't

The rest is a waste of time and money

The rest is a waste of time and money

There is only one time we ever bought a crated motor - we didn't even bother to check with a fine hair since its why we bought it that way to start with. *shrug*

Santa: I thought I was the worst at mutilating myself! Had to get a tetanus shot yesterday because I slammed two staples into my left hand (½" construction). Never bothered to take the glove off to look, just pulled em' out and continued working.

Steri-strips. Best alternative to stitches nowadays

So when is this monster going to be up and running? You hitting the last run of the season or just getting a jump on the winter mod list?

#11

10 Second Club

Thread Starter

iTrader: (4)

Join Date: Feb 2004

Location: Marysville, WA

Posts: 9,448

Likes: 0

Received 0 Likes

on

0 Posts

I agree with what you are saying Ellis. And I will NEVER pull the tranny out after you work on it, I PROMISE!  But since we were pulling the main bolts out to install the ARP bolts the Skogging Dickey should have, Don thought we might just as well look. And now that all 5 measured .002 +/- a hair I feel better.

But since we were pulling the main bolts out to install the ARP bolts the Skogging Dickey should have, Don thought we might just as well look. And now that all 5 measured .002 +/- a hair I feel better.

So yesterday I finished the mains, got the windage tray on, checked the oil pan for clearance & prepped the lifters. Today I hope to get the rear cover, oil pump & pan installed, and set the heads on. (Ellis went to pick them up late last night....what a guy!) I will post pics tonight.

Ellis - can I assume straight up on the cam? I'll need to put the crank sprocket on to install the oil pump.

1/2" staples Amy? You are a kinky girl....

But since we were pulling the main bolts out to install the ARP bolts the Skogging Dickey should have, Don thought we might just as well look. And now that all 5 measured .002 +/- a hair I feel better.

But since we were pulling the main bolts out to install the ARP bolts the Skogging Dickey should have, Don thought we might just as well look. And now that all 5 measured .002 +/- a hair I feel better.So yesterday I finished the mains, got the windage tray on, checked the oil pan for clearance & prepped the lifters. Today I hope to get the rear cover, oil pump & pan installed, and set the heads on. (Ellis went to pick them up late last night....what a guy!) I will post pics tonight.

Ellis - can I assume straight up on the cam? I'll need to put the crank sprocket on to install the oil pump.

1/2" staples Amy? You are a kinky girl....

#13

10 Second Club

Thread Starter

iTrader: (4)

Join Date: Feb 2004

Location: Marysville, WA

Posts: 9,448

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Steve Goodwin

How are you adapting to working on an engine that is not under the cowl??

#15

Originally Posted by WAHUSKER

Well, it certainly makes rolling it over to work on the top/bottom easier!

Yeah - it must just suck to not be trying to dig into the cowl to work on it.

pppppppppfffffffffffttttttttttttttttttttttt

#16

Originally Posted by WAHUSKER

Well, it certainly makes rolling it over to work on the top/bottom easier!

#18

TECH Fanatic

Join Date: Feb 2002

Location: Monroe, Washington

Posts: 1,209

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Ryan K

Just mocking things up?

And what on earth are you doing to those poor heads?

And what on earth are you doing to those poor heads?

<--That's Ellis after looking at them...

<--That's Ellis after looking at them...

#19

10 Second Club

Looks good, Glad to here the bearings were spot on, but I sort of agree with elis but since you were changing mian studs it was a good thing to check, cause sometimes the clamping force will cause the main line hone to be out of check.

Those main nu,bers sound more like a nitrous motor to me, BUt that is old school small block.

And make shure you check the trust again very well as it is a bitch sometimes to get right on.

Those main nu,bers sound more like a nitrous motor to me, BUt that is old school small block.

And make shure you check the trust again very well as it is a bitch sometimes to get right on.

#20

TECH Addict

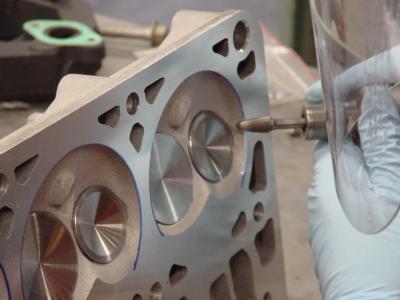

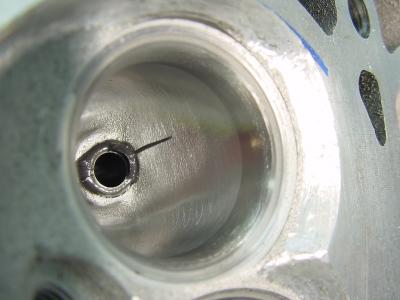

Guys, testing by the likes of AFR, Brodix, etc as well as many of the best head porters in the world, have consistantly shown that a completely polished combustion chamber, and piston top IF need be, will consistantly show a 4-6% increase in power output. 2 desirable traits occur when you polish your combustion chambers.

1. You reduce the possibility of, and raise the threshold of detonation because a polished chamber has much less surface area thru which to conduct heat into the head, and you no longer have little microscopic "peaks" to start glowing, which as you already know is the beginning of the end.

2. The less heat that is lost thru the heads/pistons/cylinder walls, the more power you'll make. A polished chamber "reflects" the heat back into the chamber. More heat = more hp. The fancy coatings that they use do the exact same things.

3. The heads have been quickly gone over once with a cartridge roll, but are not yet done, and haven't yet started to be polished and so they do look rough. The intake/exhaust ports have not been touched at all and will be left as is.

1. You reduce the possibility of, and raise the threshold of detonation because a polished chamber has much less surface area thru which to conduct heat into the head, and you no longer have little microscopic "peaks" to start glowing, which as you already know is the beginning of the end.

2. The less heat that is lost thru the heads/pistons/cylinder walls, the more power you'll make. A polished chamber "reflects" the heat back into the chamber. More heat = more hp. The fancy coatings that they use do the exact same things.

3. The heads have been quickly gone over once with a cartridge roll, but are not yet done, and haven't yet started to be polished and so they do look rough. The intake/exhaust ports have not been touched at all and will be left as is.