L92's Turbo & blown Copper head gaskets...

#1

TECH Senior Member

Thread Starter

iTrader: (6)

Join Date: Jul 2005

Location: Decatur, AL

Posts: 5,276

Likes: 0

Received 0 Likes

on

0 Posts

Ok, the specs on this engine at the time of failure is:

370 ci

9.0:1 comp, 223/218 114 cam

front mount PT76-gts FMIC

L92 heads stock

6psi

16* timing

10.5:1 afr

ARP studs tqed to 70lbs with arp moly lube

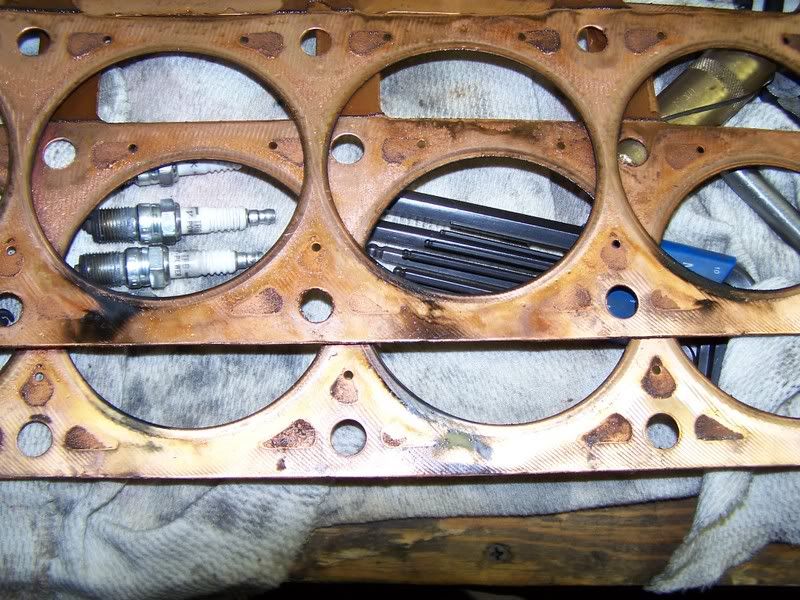

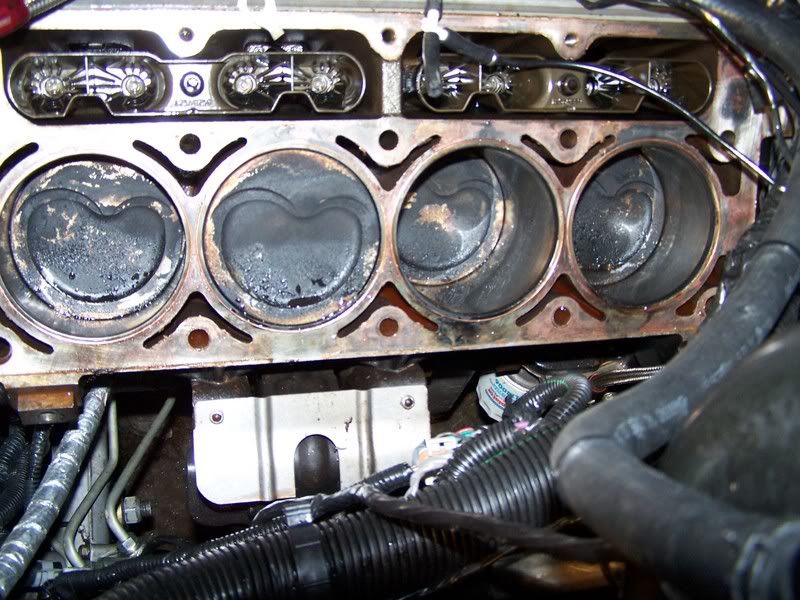

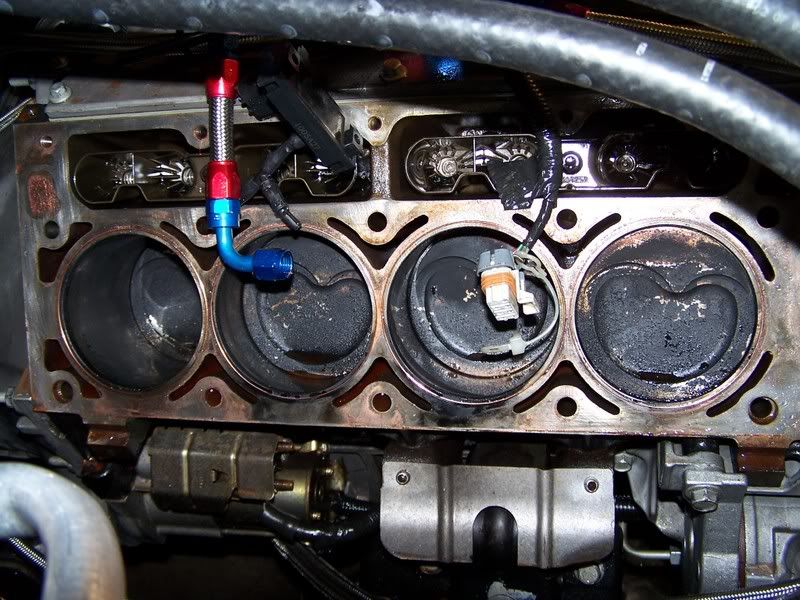

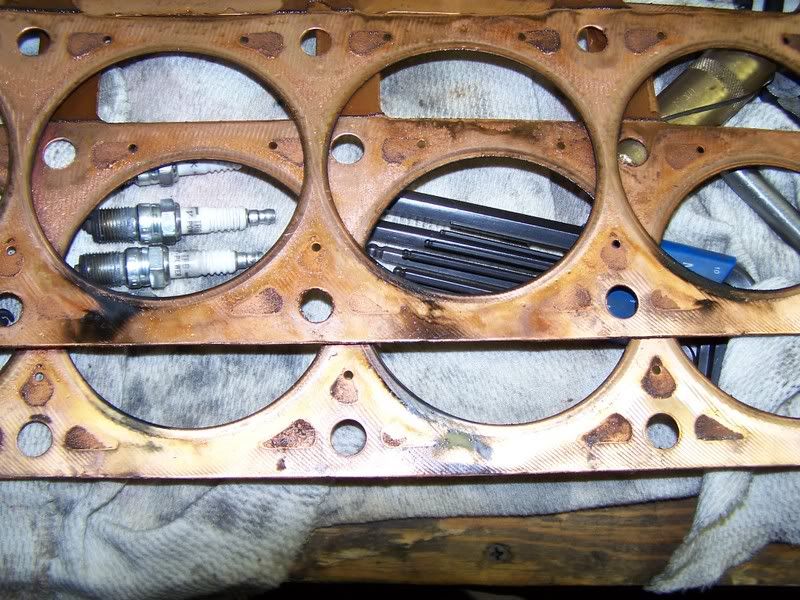

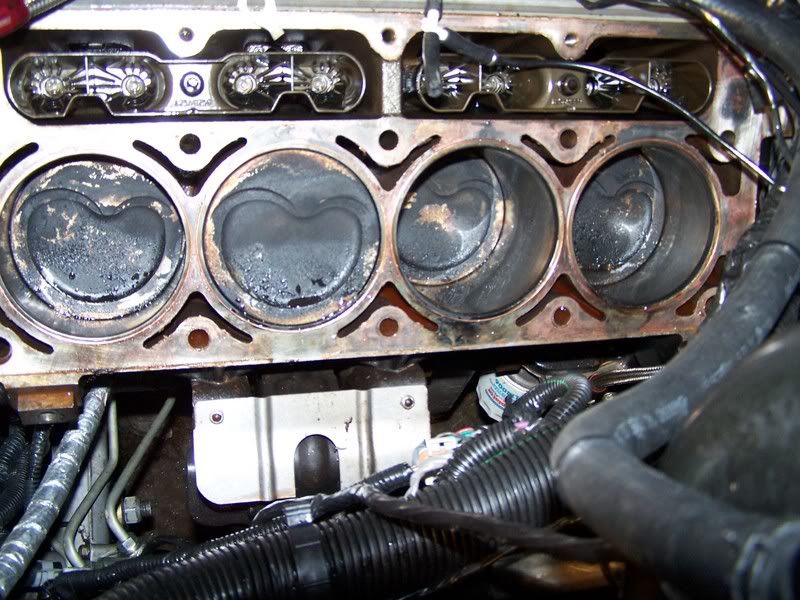

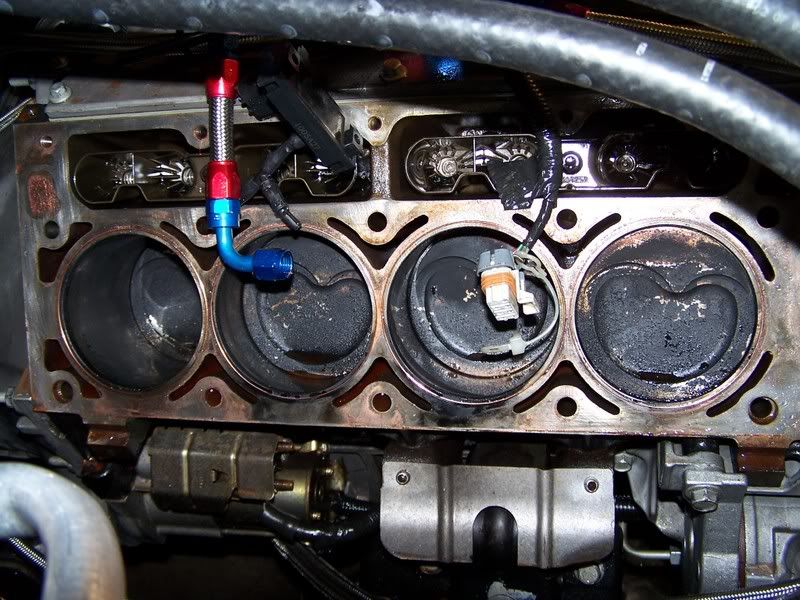

Only about 1000 miles on engine, O-ringed block, and SCE solid copper .040" gaskets. From the markings it looks like they have been blowing by more than once.

Heads and block were checked flat and hand stoned before assembly and oringing.

As a note, previously I had 317 heads with all the same specs above but 13psi and 11.7:1 afr and when I pulled the heads they factory MLS gaskets had been blowing by on the center two cyls as well with ARP bolts.

Does this look like a common problem with factory heads that only have a 3/8" deck? Is the only fix for this aftermarket heads with a 3/4" deck? I'm plum fed up.

370 ci

9.0:1 comp, 223/218 114 cam

front mount PT76-gts FMIC

L92 heads stock

6psi

16* timing

10.5:1 afr

ARP studs tqed to 70lbs with arp moly lube

Only about 1000 miles on engine, O-ringed block, and SCE solid copper .040" gaskets. From the markings it looks like they have been blowing by more than once.

Heads and block were checked flat and hand stoned before assembly and oringing.

As a note, previously I had 317 heads with all the same specs above but 13psi and 11.7:1 afr and when I pulled the heads they factory MLS gaskets had been blowing by on the center two cyls as well with ARP bolts.

Does this look like a common problem with factory heads that only have a 3/8" deck? Is the only fix for this aftermarket heads with a 3/4" deck? I'm plum fed up.

#7

Looks like there were a couple of things i would be weary of, it looks like those heads still have the swirl marks from the decking, if so they dont have a smooth enough finish for the gaskets to seal. Second did you retorque those head gaskets after the first heat cycle? Those kinds of gaskets should be retorqued. Other than that everything looks right but those are the most common spots for any head gasket to blow i wouldnt chalk it uo to just an l92 problem.

Trending Topics

#8

TECH Senior Member

Thread Starter

iTrader: (6)

Join Date: Jul 2005

Location: Decatur, AL

Posts: 5,276

Likes: 0

Received 0 Likes

on

0 Posts

The factory facing marks were somewhat noticable. I stoned the hell out of them and the divits or waves you may see I would estimate to be no more than .0005" deep if that. There is just enough there for discoloring and you can't hardly feel them with your nail. I doubt they affected the seal of the oring. There is more variences in the oring from dinks or marks when the wire was installed.

#13

TECH Senior Member

Thread Starter

iTrader: (6)

Join Date: Jul 2005

Location: Decatur, AL

Posts: 5,276

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by cncbird

head surfaces really do look too rough--you can even see swirl marks from the heads on the gaskets

#16

TECH Senior Member

Thread Starter

iTrader: (6)

Join Date: Jul 2005

Location: Decatur, AL

Posts: 5,276

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by LASTLS1

Did you re torque the heads after the first heat cycle?????

#17

TECH Senior Member

Thread Starter

iTrader: (6)

Join Date: Jul 2005

Location: Decatur, AL

Posts: 5,276

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by black98ws6ta

How much does the wire protrude ? Did the gaskets blow on both side of the gasket or just one(block/head side)

#18

TECH Addict

iTrader: (77)

The wire should only be protruding no more then 25% of the total thickness of the copper gasket. If your boost/timing is where you say it was and there arent any backpressure issues or anything I cant understand why your old or new set-up should be blowing. If you have a .015-.020 and a .040 gasket, you need to go to a thicker gasket for them to be used correctly.

#19

6 Second Club Moderator

iTrader: (7)

Join Date: Sep 2002

Location: Lombard .IL

Posts: 3,682

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by TurboGibbs

I spot checked a few I could get to and none of them budged at 70lbs. ARP recommended 65 with their lube, I torqued to 70 initially.

If you mark each nut before you loosen it you will be suprised how much further they will turn.

Ill even pick it up from your

Ill even pick it up from your