High Torque vs High Horsepower.

#1

Launching!

Thread Starter

iTrader: (5)

Join Date: Jul 2005

Location: Corona, CA

Posts: 236

Likes: 0

Received 0 Likes

on

0 Posts

My main question is how do you produce more torque than horsepower in a mild street driven combination? (without forced induction)

2.For those of us that have heavy cars and trucks that don't see much High RPM and need a lot of grunt to get the vehicle moving what would the ideal LSX setup be?

3.Will this be a good engine for gas mileage and daily driveability?

4.Would the cam specs change if you wanted to add a mild forced induction set up later?

2.For those of us that have heavy cars and trucks that don't see much High RPM and need a lot of grunt to get the vehicle moving what would the ideal LSX setup be?

3.Will this be a good engine for gas mileage and daily driveability?

4.Would the cam specs change if you wanted to add a mild forced induction set up later?

Last edited by AmericanMuscle313; 03-07-2007 at 07:06 PM.

#4

TECH Fanatic

Join Date: Mar 2004

Location: Laguna Niguel, CA

Posts: 1,017

Likes: 0

Received 0 Likes

on

0 Posts

I think he was looking for some more serious answers. One thing that I can add is that LONG intake runners tends to help low end torque a tremendous amount, but tends to sacrafice high end HP.

If you pick up the March(?) issue of GMHTP, they have a very good write-up about the long runnered L98 and how they could make 400FT-LBS of torque and only 250HP.

It is all in the long runnners. They help to keep the air velocity up and efecitvely 'shove' more air into the cylinder when the valve is open than an equal but shorter runner. On other hand, when RPM's start to raise, the long runner starts to become a restriction and that is where the shorter runners start to shine.

For a LSx motor, there is the truck intake, which has runners that are slightly longer than the LS1 or LS6 intakes. It is a nice compromise if you are looking for more low end grunt w/o sacrficing TOO much high end HP. The truck intake won't fit in a Camaro, Firebird, or Corvette w/ stock hood and cowl.

I think the best bet would be a FI motor (roots type or whipple), they seem to be able make a lot of low end torque...

If you pick up the March(?) issue of GMHTP, they have a very good write-up about the long runnered L98 and how they could make 400FT-LBS of torque and only 250HP.

It is all in the long runnners. They help to keep the air velocity up and efecitvely 'shove' more air into the cylinder when the valve is open than an equal but shorter runner. On other hand, when RPM's start to raise, the long runner starts to become a restriction and that is where the shorter runners start to shine.

For a LSx motor, there is the truck intake, which has runners that are slightly longer than the LS1 or LS6 intakes. It is a nice compromise if you are looking for more low end grunt w/o sacrficing TOO much high end HP. The truck intake won't fit in a Camaro, Firebird, or Corvette w/ stock hood and cowl.

I think the best bet would be a FI motor (roots type or whipple), they seem to be able make a lot of low end torque...

Last edited by gun5l1ng3r; 03-07-2007 at 04:44 PM.

#5

LS1 Tech Veteran

iTrader: (1)

Join Date: Oct 2003

Location: Wichita, Ks

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Three things tune the power band for a given engine design (with a fixed bore and stroke):

1. Camshaft design

2. Intake manifold design

3. Exhaust manifold/header design

For the purposes of this thread, I will broadly classify lower-end torque as that occurring below 5,252 RPM's. By the definition of SAE type horsepower and torque measured in pounds feet, torque and horsepower are always equal at 5,252 RPM's.

Relatively longer intake runners and relatively longer and smaller exhaust primary tubes will favor lower-end torque. Tri-Y headers favor broad-band torque in the range you are talking about but the peak power (or torque) production will be less than a long tube header (which will have a narrower power band. Cams designed with relatively short duration intake and exhaust durations will favor lower-end torque.

My first aftermarket cam for my 2000 Yukon XL was a 212/218 114 LSA Comp Cam (P/N: 54-412-11). It is a great cam, but it didn't really start to come alive until about 2,800 RPM's. I then switched to a custom ground cam that I am currently running (a Comp cam that is 200/206 with a 109 LSA). This is a great cam for a daily driver that is a four wheel drive 3/4 ton vehicle weighing 6,700 pounds and that tows an 8,600 pound trailer on occasion. I get excellent mileage (again, relatively speaking) and it greatly out performs the stock cam.

I'm currently building a 408 stroker for my truck and I plan to go back to the 212/218 114 LSA cam because with the larger displacement, I will need a bigger cam to keep the power band that I want (torque maximization between 2,500 and 4,500 RPM's) plus with more displacement, I'll have more low end torque anyway.

If you want to play around with cam optimization, I'd recommend a program like DynoSim. It's a lot of fun and you can run simulations to emphasize torque or horsepower within a certain RPM range or try different cam specs and see what happens.

I hope that this helps.

Steve

1. Camshaft design

2. Intake manifold design

3. Exhaust manifold/header design

For the purposes of this thread, I will broadly classify lower-end torque as that occurring below 5,252 RPM's. By the definition of SAE type horsepower and torque measured in pounds feet, torque and horsepower are always equal at 5,252 RPM's.

Relatively longer intake runners and relatively longer and smaller exhaust primary tubes will favor lower-end torque. Tri-Y headers favor broad-band torque in the range you are talking about but the peak power (or torque) production will be less than a long tube header (which will have a narrower power band. Cams designed with relatively short duration intake and exhaust durations will favor lower-end torque.

My first aftermarket cam for my 2000 Yukon XL was a 212/218 114 LSA Comp Cam (P/N: 54-412-11). It is a great cam, but it didn't really start to come alive until about 2,800 RPM's. I then switched to a custom ground cam that I am currently running (a Comp cam that is 200/206 with a 109 LSA). This is a great cam for a daily driver that is a four wheel drive 3/4 ton vehicle weighing 6,700 pounds and that tows an 8,600 pound trailer on occasion. I get excellent mileage (again, relatively speaking) and it greatly out performs the stock cam.

I'm currently building a 408 stroker for my truck and I plan to go back to the 212/218 114 LSA cam because with the larger displacement, I will need a bigger cam to keep the power band that I want (torque maximization between 2,500 and 4,500 RPM's) plus with more displacement, I'll have more low end torque anyway.

If you want to play around with cam optimization, I'd recommend a program like DynoSim. It's a lot of fun and you can run simulations to emphasize torque or horsepower within a certain RPM range or try different cam specs and see what happens.

I hope that this helps.

Steve

Last edited by Steve Bryant; 03-07-2007 at 06:26 PM.

#6

The shortest explanation for getting high torque is, small diameter but long length pipes and big displacement. Pick your intake, exhaust, cam and heads for torque, then the rest of the equation is just like building a high horsepower engine, lightweight (but still strong) parts, good quench, compression that properly suits your camshaft. Coatings help but aren't as big a factor. stroking a motor out is a great way to increase your torque, it has a two fold effect, more displacement and (although some may argue it is negated by the increase in friction) greater leverage against the center of the crankshaft due to the further throw.

#7

Launching!

Thread Starter

iTrader: (5)

Join Date: Jul 2005

Location: Corona, CA

Posts: 236

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Guys. So for a budget setup a 6.0L with a truck intake and a small 20x/20X cam would be good for a truck or heavy car?

Steve what are you max rpm's going to be on the 408 you are building?

Steve what are you max rpm's going to be on the 408 you are building?

Trending Topics

#8

Teching In

Join Date: Dec 2006

Location: Crown Point, IN

Posts: 15

Likes: 0

Received 0 Likes

on

0 Posts

Just wait till everyone converts to metric...

You'll almost always have higher torque than power (kW and Nm FTW!)

well.. except motorcycles and F1..

but i digress...

You'll almost always have higher torque than power (kW and Nm FTW!)

well.. except motorcycles and F1..

but i digress...

#10

LS1 Tech Veteran

iTrader: (1)

Join Date: Oct 2003

Location: Wichita, Ks

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

AmericanMuscle313,

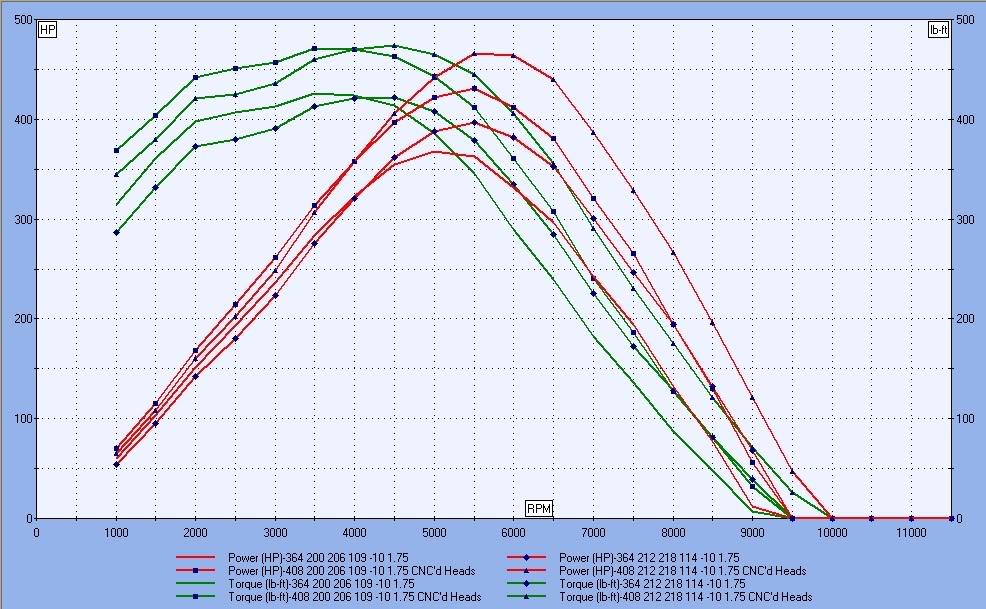

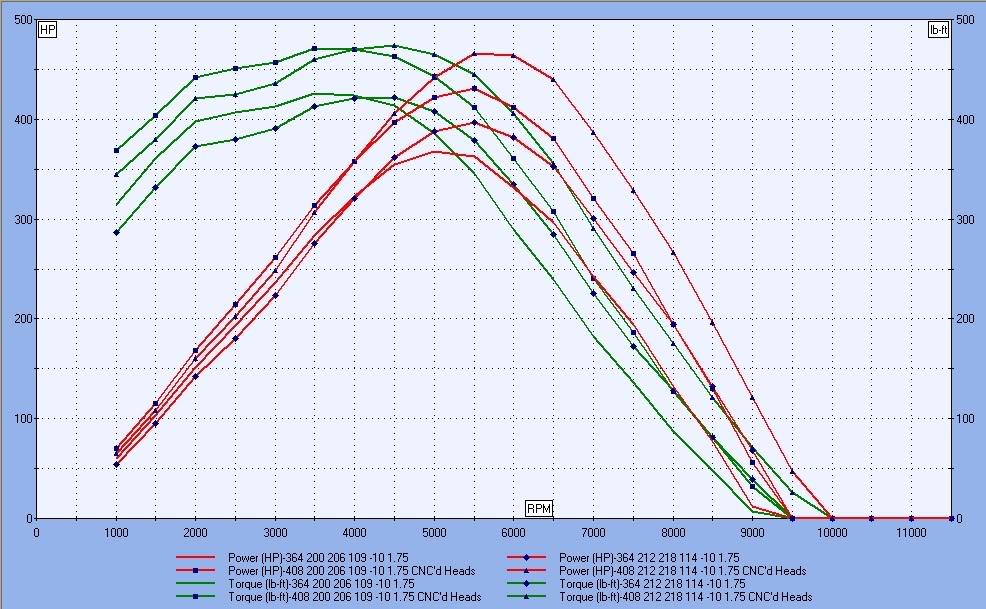

Here's a DynoSim ProTools version of my estimated gross HP and Torque. In reality, I think that the HP peak will be about 5,300 RPM's with the 4L80E automatic transmission. I plan to use the small runner Patriot Predator heads when they become available.

Something else that will improve torque and horsepower in the range you're talking about is a good set of small runner CNC'd heads. I've hand ported my cast iron heads, but I'm sure that I can make improvements with the volumetric efficiency of the heads.

Steve

Here's a DynoSim ProTools version of my estimated gross HP and Torque. In reality, I think that the HP peak will be about 5,300 RPM's with the 4L80E automatic transmission. I plan to use the small runner Patriot Predator heads when they become available.

Something else that will improve torque and horsepower in the range you're talking about is a good set of small runner CNC'd heads. I've hand ported my cast iron heads, but I'm sure that I can make improvements with the volumetric efficiency of the heads.

Steve

#12

Originally Posted by gun5l1ng3r

It is all in the long runnners. They help to keep the air velocity up and efecitvely 'shove' more air into the cylinder when the valve is open than an equal but shorter runner. On other hand, when RPM's start to raise, the long runner starts to become a restriction and that is where the shorter runners start to shine.

Just wait till everyone converts to metric...

You'll almost always have higher torque than power (kW and Nm FTW!)

well.. except motorcycles and F1..

but i digress...

You'll almost always have higher torque than power (kW and Nm FTW!)

well.. except motorcycles and F1..

but i digress...

Al

#13

Teching In

Join Date: Dec 2006

Location: Crown Point, IN

Posts: 15

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by ProdriveMS

Until 10,000 rpm when they cross.

Al

(sorry, had to do it.. seeing as how accurate LS1 Techies are..

Oh, and i know... i rounded.. sorry)

Oh, and i know... i rounded.. sorry) Last edited by XBR24; 03-08-2007 at 07:41 PM.

#15

TECH Addict

iTrader: (6)

Originally Posted by LiENUS

stroking a motor out is a great way to increase your torque, it has a two fold effect, more displacement and (although some may argue it is negated by the increase in friction) greater leverage against the center of the crankshaft due to the further throw.