Self Rebuilt 4L60E Problem Only When Hot

#1

Hi guys, I'm a Corvette Forum Member......wish we had a transmission forum...this is great. Thought I'd share my rebuild link below, read and enjoyed the recent rebuild one of your members shared.

I have a 99 Rally Red on Tan Stock Convertible C5, and a 95 Black on Black Coupe 383 Stroker w/ Headers, GM Hotcam, Ported Heads and 3" SS Exhaust.

The problem is with my Black 95 Hot Rod Vette Coupe. I got tired of paying out over $2,700 a rebuild, so I did the third one myself. Just got it back on the road wi the following problem:

My problem is that when tranny temp gets above 206 F the forward clutch appears to disengage...slip somewhat at idle in Drive when stopped (like in stop and go traffic), then it pops back in when the throttle is opened a little wider. Only happens when tranny is above 206F.......

Doesn't do this below 206F, seems to work fine then. Haven't been able to check line pressure at that temp yet though

OK, checked line pressure at 165 F Tranny temp 80 to 85 psi at idle (850 rpm) in P, D or R. Note line pressure does not increase when placed in park at idle.

150 psi at approximately 1,500 rpm.

Filled with Royal Purple Max ATF Synthetic to the 190F Line in P hot w/engine running.

Some of the many mods:

2,800 stall protorque lockup converter, LT-1 383 w/ GM Hot Cam, Ported & Polished Heads, 850 RPM idle. Have an added tranny cooler + dual core alum radiator.

13 vane pump that I rebuilt.

Transgo HD-2 shift kit. Raptor Torque Drive Input Drum and timken bearing reaction shaft carrier. Beast Shell. .030"Low Reverse piston hole drilled and reverse check ball removed from rear of case.

All new solenoids and wire harness.

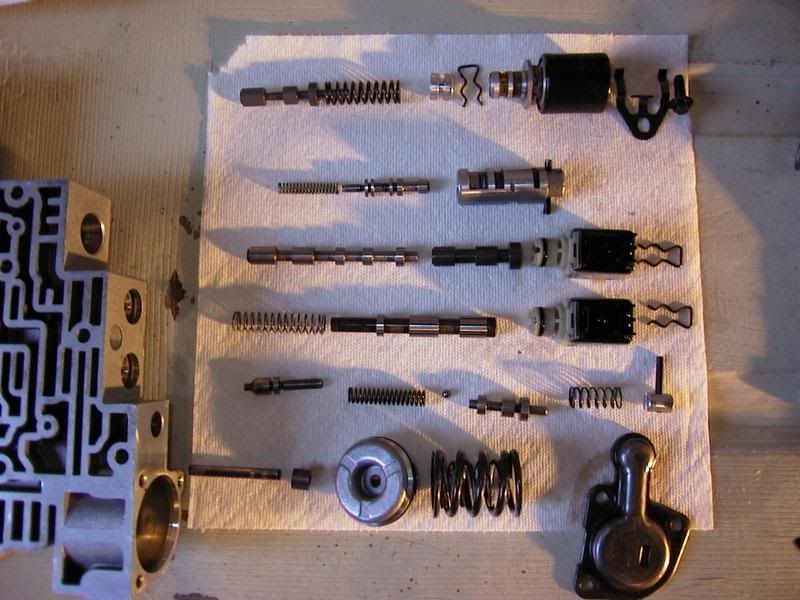

Link to my Corvette Forum Rebuild Tranny photos:

http://forums.corvetteforum.com/show....php?t=1566877

Any ideas what could be causing this?

What a PIA this is

I'm betting it's the Transgo super strong 14 anti-centifugal springs I put in the input drum so the forward clutch won't apply by itself at high RPM. This comes with the Transgo kit in a little box.

I bet they're just strong enough along with the slightly smaller forward clutch piston (modified by PATC to fit over the input shaft steel retained band) to overcome the piston apply force at idle pump line pressure.

Also, probably the pump halves being aluminum expand enough at 206F to allow for excess clearance between the steel pump rotor and blades and the casing. I'm thinking the guy who sold me the ebuilt pump case just polished the inside wear faces...I should have checked the pump side clearance with a feeler gage and straight edge...Oh well, lessons learned....hindsight is best sight...., etc. etc. etc. But my pump readings don't look that bad which is puzzling to me.

OK, spoke to Larry at Transgo.

Seems like when I tore things apart a second timeto put the Helicoil inserts in the case (past builder stripped pne of my 6mm valve body case threads), I decided to put the anti-centrifugal spring kit in the input shell assembly. Took out the 3-4, forward and overrun clutch packs, then using spring compressor the retainer clip, and spring retainer...changed these.....that's the problem, I closed it all back up changing only these springs to stronger ones. Larry says the 3-4 return springs below the forward and overrun clutch assembly work with these as a balanced set and need to be istalled. So, I'll be taking the tranny out again to install the stiffer performance 3-4 springs I didn't install earlier. While I have it apart, I'm also going to check the pump insternal side clearances and also am going to send my protorque out to have it's lock up clutch and bearings freshened up.

looked at my GM service manual specifically the input drum cross section that shows all the clutches, pistons, etc.

The stiffer forward/overrun clutch return springs I put in don't in any way interact with the 3-4 return springs that I can see

There is an extended rim at the base of the forward piston that bottoms on the center hub of the input drum so it can push on the 3-4 clutch piston. The 3-4 clutch return springs are smaller and weaker so they don't push up and unseat the forward piston housing.

Sorry, I disagree with Larry of Transgo...don't think that's my problem and these guys are supposed to be the experts!

I think I'm going to tweak my LT-1 edit program to get a slightly higher line pressure at zero throttle opening before I tear this thing apart again....I will evetually tear it down, but just want to experiment a little first

But that lack of increase of line pressure in reverse at idle concerns me after what I read on this site about line pressure.

Come on guys, can't I get a little feedback on this

I have a 99 Rally Red on Tan Stock Convertible C5, and a 95 Black on Black Coupe 383 Stroker w/ Headers, GM Hotcam, Ported Heads and 3" SS Exhaust.

The problem is with my Black 95 Hot Rod Vette Coupe. I got tired of paying out over $2,700 a rebuild, so I did the third one myself. Just got it back on the road wi the following problem:

My problem is that when tranny temp gets above 206 F the forward clutch appears to disengage...slip somewhat at idle in Drive when stopped (like in stop and go traffic), then it pops back in when the throttle is opened a little wider. Only happens when tranny is above 206F.......

Doesn't do this below 206F, seems to work fine then. Haven't been able to check line pressure at that temp yet though

OK, checked line pressure at 165 F Tranny temp 80 to 85 psi at idle (850 rpm) in P, D or R. Note line pressure does not increase when placed in park at idle.

150 psi at approximately 1,500 rpm.

Filled with Royal Purple Max ATF Synthetic to the 190F Line in P hot w/engine running.

Some of the many mods:

2,800 stall protorque lockup converter, LT-1 383 w/ GM Hot Cam, Ported & Polished Heads, 850 RPM idle. Have an added tranny cooler + dual core alum radiator.

13 vane pump that I rebuilt.

Transgo HD-2 shift kit. Raptor Torque Drive Input Drum and timken bearing reaction shaft carrier. Beast Shell. .030"Low Reverse piston hole drilled and reverse check ball removed from rear of case.

All new solenoids and wire harness.

Link to my Corvette Forum Rebuild Tranny photos:

http://forums.corvetteforum.com/show....php?t=1566877

Any ideas what could be causing this?

What a PIA this is

I'm betting it's the Transgo super strong 14 anti-centifugal springs I put in the input drum so the forward clutch won't apply by itself at high RPM. This comes with the Transgo kit in a little box.

I bet they're just strong enough along with the slightly smaller forward clutch piston (modified by PATC to fit over the input shaft steel retained band) to overcome the piston apply force at idle pump line pressure.

Also, probably the pump halves being aluminum expand enough at 206F to allow for excess clearance between the steel pump rotor and blades and the casing. I'm thinking the guy who sold me the ebuilt pump case just polished the inside wear faces...I should have checked the pump side clearance with a feeler gage and straight edge...Oh well, lessons learned....hindsight is best sight...., etc. etc. etc. But my pump readings don't look that bad which is puzzling to me.

OK, spoke to Larry at Transgo.

Seems like when I tore things apart a second timeto put the Helicoil inserts in the case (past builder stripped pne of my 6mm valve body case threads), I decided to put the anti-centrifugal spring kit in the input shell assembly. Took out the 3-4, forward and overrun clutch packs, then using spring compressor the retainer clip, and spring retainer...changed these.....that's the problem, I closed it all back up changing only these springs to stronger ones. Larry says the 3-4 return springs below the forward and overrun clutch assembly work with these as a balanced set and need to be istalled. So, I'll be taking the tranny out again to install the stiffer performance 3-4 springs I didn't install earlier. While I have it apart, I'm also going to check the pump insternal side clearances and also am going to send my protorque out to have it's lock up clutch and bearings freshened up.

looked at my GM service manual specifically the input drum cross section that shows all the clutches, pistons, etc.

The stiffer forward/overrun clutch return springs I put in don't in any way interact with the 3-4 return springs that I can see

There is an extended rim at the base of the forward piston that bottoms on the center hub of the input drum so it can push on the 3-4 clutch piston. The 3-4 clutch return springs are smaller and weaker so they don't push up and unseat the forward piston housing.

Sorry, I disagree with Larry of Transgo...don't think that's my problem and these guys are supposed to be the experts!

I think I'm going to tweak my LT-1 edit program to get a slightly higher line pressure at zero throttle opening before I tear this thing apart again....I will evetually tear it down, but just want to experiment a little first

But that lack of increase of line pressure in reverse at idle concerns me after what I read on this site about line pressure.

Come on guys, can't I get a little feedback on this

Last edited by redvet99; 03-14-2007 at 07:06 AM.

#2

FormerVendor

iTrader: (1)

Have you checked the forward accumulator piston? The factory one is made from plastic and is known for cracking. This is located in the valve body and can be checked in the car. The only other thought that I have is that you could have a cracked forward clutch piston. I looked at your pictures, are you using the aluminum forward clutch piston? This could be a problem as well. Good luck, Vince.

#3

I tore this entire tranny apart from stem to stern over the last 2 months and cleaned everything. Changed the forward accumlator (that's the horizonatlly mounted one in the side of the valve body with the three screws retaining it, right?) to a Sonnax pinless billet aluminum with dual seals. I have to see if it shows in my photos....may have to post more as I haven't finished uploading everything yet.

What do you think of my line pressure idea tweak?

Also, will be taking more pressure readings...noted when goin to 1/2 throttle the needle gets up in the 175 range and then starts violently shaking back and forth in a 40 psi range of movement

What do you think of my line pressure idea tweak?

Also, will be taking more pressure readings...noted when goin to 1/2 throttle the needle gets up in the 175 range and then starts violently shaking back and forth in a 40 psi range of movement

#4

FormerVendor

iTrader: (1)

Well your just band aiding the problem with the increased pressure. I think you can try it but how long will it last? I don't know. With the erratic gauge readings it sounds like you have a pump issue. We do sell pumps built to our spec's if you are interested. Please give Chuck a call if you decide to go that route or shoot him an Email through the link in my signature. Vince

#5

Originally Posted by Vince @ FLT

Well your just band aiding the problem with the increased pressure. I think you can try it but how long will it last? I don't know. With the erratic gauge readings it sounds like you have a pump issue. We do sell pumps built to our spec's if you are interested. Please give Chuck a call if you decide to go that route or shoot him an Email through the link in my signature. Vince

Put it on my lift and drained the fluid after work, dropped the pan, looks really clean

Turned up my adjustable force motor about 1/4 turn clockwise and locked down the locknut. Reinstalled my pan with a little new red silicone sealant over reused new gasket that was still on tranny case

I'll torque up the pan bolts later tonight, fill it and check the line pressure.

Did note in my assembly notes when I dissassembled the valve body that part #373 the 1-2 accumulator valve bore plug was missing when I dissassembled it. I didn't put in a new one since I figured it had driven fine without it before.

#7

So you think that missing part is what's causing my problem Vince?

Would you recommend I put in that accumulator valve #373 the 1-2 accumulator valve bore plug before I do another thing?

I thougt I'd try uploading my revised A4 transmission milliampere vs %TPS table edited using my Lt-1 Edit software tomorrow morning. I just lowered the milliampere setting at 0% throttle opening so I get some more line pressure at idle.

I still have to check my line pressure, but will probably just drive it to work tomorrow and get it good and hot to see if my problem occurs again.

If it does I'll tear it apart and my next stop will definately be the pump.

Would you recommend I put in that accumulator valve #373 the 1-2 accumulator valve bore plug before I do another thing?

I thougt I'd try uploading my revised A4 transmission milliampere vs %TPS table edited using my Lt-1 Edit software tomorrow morning. I just lowered the milliampere setting at 0% throttle opening so I get some more line pressure at idle.

I still have to check my line pressure, but will probably just drive it to work tomorrow and get it good and hot to see if my problem occurs again.

If it does I'll tear it apart and my next stop will definately be the pump.

Last edited by redvet99; 03-14-2007 at 10:19 PM.

Trending Topics

#8

FormerVendor

iTrader: (1)

I was just looking at my atsg book. The #373 part that I believe you are making referrence to is from an early valve body. The later valve bodies do not use this style 1-2 accumulator valve setup. The bore plug was removed and the sleeve was changed as well. The later setup is all one piece and I believe this is what you have. I'm not sure if the 95 VB has the early or late setup. I guess if you can see the valve from outside the valve body bore you will require the bore plug. Vince

Last edited by FLT; 03-15-2007 at 08:35 AM.

#10

So I reprogrammed my ECM tonight with LT-1 Edit. Lowered the zero throttle tranny milliamps settings above 56 C (132 F...I wanted a little insurance ahead of my 206F problem temperature) from 1074 to 918 see chart below (the first row is the column header which is % throttle opening, all the other numbers are the programmed force motor milliamp settings):

% Throttle 0___ 6__ 12__ 18__ 24 30 36 42 48 54 60 66 72 78 84 90 96

-40 Deg C 1074 879 879 879 840 801 781 742 684 645 605 547 488 410 332 215 215

-28 Deg C 1074 918 898 879 840 801 781 723 684 645 605 547 488 410 332 215 215

-16 Deg C 1074 918 898 879 840 801 781 742 703 645 605 547 488 430 352 254 254

-4 Deg C 1074 918 898 879 840 801 781 742 684 645 605 547 488 410 332 234 234

8 Deg C 1074 918 898 879 840 801 762 723 684 645 586 527 469 410 332 215 215

20 Deg C 1074 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

32 Deg C 1074 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

44 Deg C 1074 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

56 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

68 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

80 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

92 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

104 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

116 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

128 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

140 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

152 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

Note that I only lowered the ma numbers to 918 (in bold) in the 0% thottle settings 56 degrees centigrade and higher tranny temperature.

Only time will tell.

% Throttle 0___ 6__ 12__ 18__ 24 30 36 42 48 54 60 66 72 78 84 90 96

-40 Deg C 1074 879 879 879 840 801 781 742 684 645 605 547 488 410 332 215 215

-28 Deg C 1074 918 898 879 840 801 781 723 684 645 605 547 488 410 332 215 215

-16 Deg C 1074 918 898 879 840 801 781 742 703 645 605 547 488 430 352 254 254

-4 Deg C 1074 918 898 879 840 801 781 742 684 645 605 547 488 410 332 234 234

8 Deg C 1074 918 898 879 840 801 762 723 684 645 586 527 469 410 332 215 215

20 Deg C 1074 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

32 Deg C 1074 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

44 Deg C 1074 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

56 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

68 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

80 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

92 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

104 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

116 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

128 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

140 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

152 Deg C 918 820 781 742 703 645 605 566 508 430 371 313 234 137 59 59 59

Note that I only lowered the ma numbers to 918 (in bold) in the 0% thottle settings 56 degrees centigrade and higher tranny temperature.

Only time will tell.

Last edited by redvet99; 03-16-2007 at 08:10 AM.

#14

Only HOT @ IDLE, when the pump is putting out the bare minimum.

I changed the forward clutch return springs to stiffer ones from Transgo, used all 14 springs for a high performance setup......never had this problem before.....seems to work fine when giving it just a little gas, say around 1,100 rpm. I'm also running the Raptor Torque Drive Input drum which has a larger forward clutch piston center opening to clear the steel reinforcing band they install. This makes the forward piton apply area smaller than stock. that along with the stronger springs may be casusing my problem.

On the other hand, I'm wondering if it's the pump. Whjat do you think of my pressure readings? Unfortunately they were taken at 165F and not 206F when I have the problem. I don't have any probl4ems below 206F.

Bought a rebuilt with "Diamond Machines" pump shell side faces from CTPowertrain of California. However, I used my former 13 vane performnce pump rotor and vanes (they looked fine...no wear to speak of), new high rev rings, Transgo high performance pump spring, new teflon pump bushing and seal. Also took out the boost valve and replaced with Transgo Boost Valve, TCC Valve (replaced with Sonnax), and removed pump pressure relief ball and spring before reassembly....flushed everything including the pump case galleries down with solvent and blew dry prior to reassembly.

Dumb thing I didn't do was check the pump vane and rotor to new case halves side clearance. Wondering if the pump cutting made the side clearances too loose and I'm loosing pressure when the aluminum pump case expands more than the steel rotor and vanes when it gets hot. Have you ever seen this happen?

I changed the forward clutch return springs to stiffer ones from Transgo, used all 14 springs for a high performance setup......never had this problem before.....seems to work fine when giving it just a little gas, say around 1,100 rpm. I'm also running the Raptor Torque Drive Input drum which has a larger forward clutch piston center opening to clear the steel reinforcing band they install. This makes the forward piton apply area smaller than stock. that along with the stronger springs may be casusing my problem.

On the other hand, I'm wondering if it's the pump. Whjat do you think of my pressure readings? Unfortunately they were taken at 165F and not 206F when I have the problem. I don't have any probl4ems below 206F.

Bought a rebuilt with "Diamond Machines" pump shell side faces from CTPowertrain of California. However, I used my former 13 vane performnce pump rotor and vanes (they looked fine...no wear to speak of), new high rev rings, Transgo high performance pump spring, new teflon pump bushing and seal. Also took out the boost valve and replaced with Transgo Boost Valve, TCC Valve (replaced with Sonnax), and removed pump pressure relief ball and spring before reassembly....flushed everything including the pump case galleries down with solvent and blew dry prior to reassembly.

Dumb thing I didn't do was check the pump vane and rotor to new case halves side clearance. Wondering if the pump cutting made the side clearances too loose and I'm loosing pressure when the aluminum pump case expands more than the steel rotor and vanes when it gets hot. Have you ever seen this happen?

Last edited by redvet99; 03-17-2007 at 02:37 PM.

#15

I have not had this happen to me, but I have seen this before when the rotor/slide clearance is too much, so when hot it can do this. Rotor should be about .002 - .0025, and the slide .0025 - .003. I use the TransGo steel rings and matching primer spring here very successfully, along with the HI-Rev spring setup in the input drum.

#16

Thanks for the feedback,

When it gets a little nicer out I'll drive it to work again and let it get really hot.

If it does it again, I'll pull the tranny back out and attack the pump

PITA, but a good lesson learned

When it gets a little nicer out I'll drive it to work again and let it get really hot.

If it does it again, I'll pull the tranny back out and attack the pump

PITA, but a good lesson learned

#17

Well finally had some time to work on this again. It's been sitting up on my lift since the last time I posted. I've changed out my leaky headers to new ones with copper gaskets, installed new PS pump, rack and hoses, new TPS. Also purchased a GM Tech 1 scan test tool w/ memory module.

Also cleared all DTC's and retaught my TPS with my tech 1

So, hooked up my tranny pressure gage this morning and as per the GM service manual, connected my tech 1 scantool and ran the PCS control program that steps the PCS. At idle in park at 70F tranny temp everything looks great, pressure steps properly per the chart in the service manual as the miliamperes go down. Also at highest miliamp reading pump puts out a steady 75 psi. Also put tranny in reverse and boost works OK as pressure goes up to about 150 at idle and back to 75 in other positions P,N,D, etc.

So then I notice tranny temp is at about 107F...not hot at all, and I try the step procedure again and the pressure pretty much stays at 75 psi, I did notice that the actual milliamps tend to be somewhat higher than the called for. I wonder if the new PCS motor is defective? Also when shifting into reverse no more boost

I can't see how only a difference of 27F would cause the pump output to drop so drastically. I'm wondering if the AFL valve could be binding up when the valve body warms?

Any insight on this would be helpful from the experts...thanks in advance

Also cleared all DTC's and retaught my TPS with my tech 1

So, hooked up my tranny pressure gage this morning and as per the GM service manual, connected my tech 1 scantool and ran the PCS control program that steps the PCS. At idle in park at 70F tranny temp everything looks great, pressure steps properly per the chart in the service manual as the miliamperes go down. Also at highest miliamp reading pump puts out a steady 75 psi. Also put tranny in reverse and boost works OK as pressure goes up to about 150 at idle and back to 75 in other positions P,N,D, etc.

So then I notice tranny temp is at about 107F...not hot at all, and I try the step procedure again and the pressure pretty much stays at 75 psi, I did notice that the actual milliamps tend to be somewhat higher than the called for. I wonder if the new PCS motor is defective? Also when shifting into reverse no more boost

I can't see how only a difference of 27F would cause the pump output to drop so drastically. I'm wondering if the AFL valve could be binding up when the valve body warms?

Any insight on this would be helpful from the experts...thanks in advance

#20

OK, replaced the PCS it with my saved GM stock unit. Didn't have a new tranny pan gasket so waiting for the red RTV gasket sealand to set up before refilling and testing

Sounds like you found your problem! I kinda figured you had a pressure problem or a major leak. Nice work. Vince

Sounds like you found your problem! I kinda figured you had a pressure problem or a major leak. Nice work. Vince