View Poll Results: Does anyone have an engine with a L76 intake with a peak HP above 6350RPM.

Yes

4

33.33%

No

8

66.67%

Voters: 12. You may not vote on this poll

SDPC 416 L92 Out of Air @ 6100 RPM

#1

On The Tree

Thread Starter

Join Date: Dec 2006

Location: Indianapolis, IN

Posts: 126

Likes: 0

Received 0 Likes

on

0 Posts

I'm looking for help. My engine is out of air at 6100 RPM, but it should make power to at least 6500 RPM. My current guesses for bottlenecks are my SLP Headers W/Cats & my stock LS2 fuel pump. My injectors were at 85% at WOT, so the pump may not be it. I can e-mail my HPTuners scan of my dyno pull if you PM me with your e-mail.

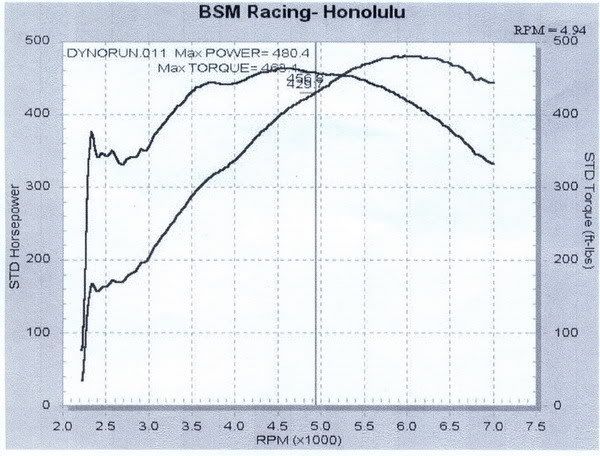

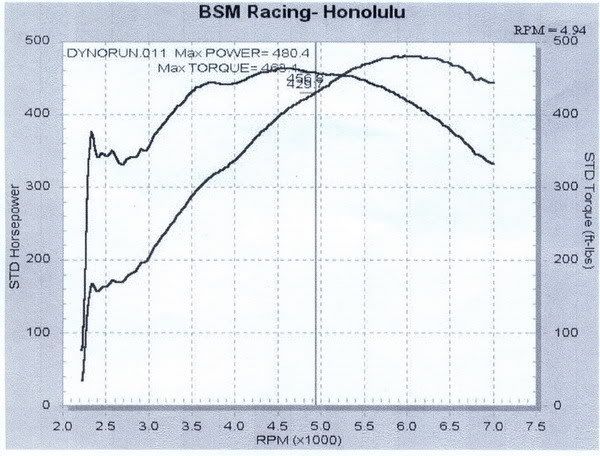

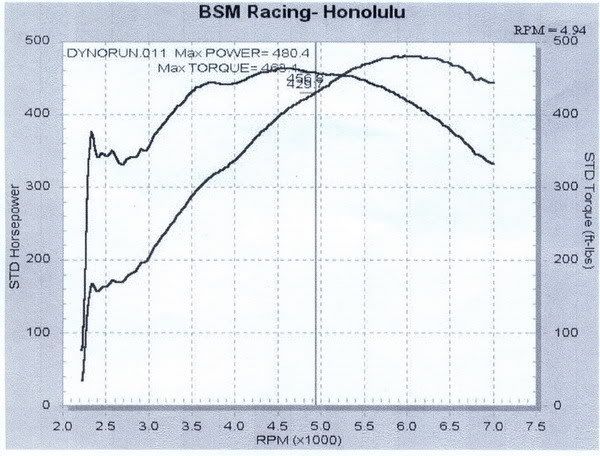

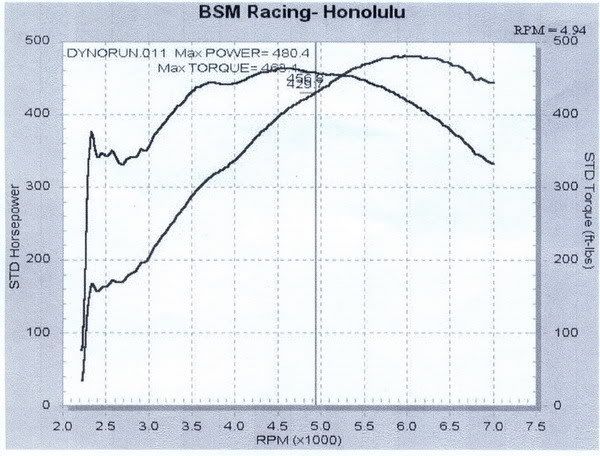

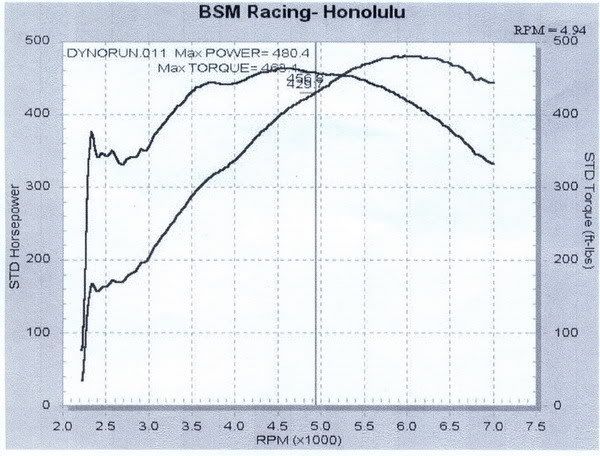

My Dyno is as follows; 480 RWHP @ 6100 RPM and 468 RWTQ at 4500 RPM.

My Dyno is as follows; 480 RWHP @ 6100 RPM and 468 RWTQ at 4500 RPM.

Last edited by cybernco; 04-13-2007 at 05:59 PM. Reason: Remove SDPC from the Negative Title

#4

On The Tree

Join Date: Apr 2004

Location: Brampton, Ontario

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by cybernco

I'm looking for help. My engine is out of air at 6100 RPM, but it should make power to at least 6500 RPM. My current guesses for bottlenecks are my SLP Headers W/Cats & my stock LS2 fuel pump. My injectors were at 85% at WOT, so the pump may not be it. I can e-mail my HPTuners scan of my dyno pull if you PM me with your e-mail.

My Dyno is as follows; 480 RWHP @ 6100 RPM and 468 RWTQ at 4500 RPM.

My Dyno is as follows; 480 RWHP @ 6100 RPM and 468 RWTQ at 4500 RPM.

My 447ci had a very similar HP curve.

I'd wager it's the LSx style intake and 90mm t/b that's restricting the air your cubes need at that rpm. Drop a sheet metal intake, and your power would keep on increasing past 6K, but at the sacrifice of substantial low end torque. I've heard from a tuner that a comparison showed an increase of 15rwhp at the top rpm, but at the sacrifice of 30rwtq in the midrange.

IMO, unless your willing to spin your motor over 7K, and a drag only car, the sacrifice of mid torque you'd likely experience won't make up for the mid range torque loss of a sheet metal intake. And remember, torque is ET, HP is mph.

So to sum it all up, your making great power. But with today's technology, the LSx style intakes create great bottom end power, but do tend to choke a big cube motor. The alternative changes the power of a motor to a very specific and focused requirement.

If you want more, go with a small shot of NOS.

#5

TECH Senior Member

iTrader: (15)

Join Date: Nov 2001

Location: Grand Prairie, TX

Posts: 5,109

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by tlaselva

400+ci motors seem to run out of steam at 6K.

My 447ci had a very similar HP curve.

I'd wager it's the LSx style intake and 90mm t/b that's restricting the air your cubes need at that rpm. Drop a sheet metal intake, and your power would keep on increasing past 6K, but at the sacrifice of substantial low end torque. I've heard from a tuner that a comparison showed an increase of 15rwhp at the top rpm, but at the sacrifice of 30rwtq in the midrange.

IMO, unless your willing to spin your motor over 7K, and a drag only car, the sacrifice of mid torque you'd likely experience won't make up for the mid range torque loss of a sheet metal intake. And remember, torque is ET, HP is mph.

So to sum it all up, your making great power. But with today's technology, the LSx style intakes create great bottom end power, but do tend to choke a big cube motor. The alternative changes the power of a motor to a very specific and focused requirement.

If you want more, go with a small shot of NOS.

My 447ci had a very similar HP curve.

I'd wager it's the LSx style intake and 90mm t/b that's restricting the air your cubes need at that rpm. Drop a sheet metal intake, and your power would keep on increasing past 6K, but at the sacrifice of substantial low end torque. I've heard from a tuner that a comparison showed an increase of 15rwhp at the top rpm, but at the sacrifice of 30rwtq in the midrange.

IMO, unless your willing to spin your motor over 7K, and a drag only car, the sacrifice of mid torque you'd likely experience won't make up for the mid range torque loss of a sheet metal intake. And remember, torque is ET, HP is mph.

So to sum it all up, your making great power. But with today's technology, the LSx style intakes create great bottom end power, but do tend to choke a big cube motor. The alternative changes the power of a motor to a very specific and focused requirement.

If you want more, go with a small shot of NOS.

#6

Its funny,

All this arm chair quarter backing and no one is looking at the data he has.

MAP data from the dyno run will reveal a lot and end some speculation.

If you find your Map (vacuum) is increasing at RPMs then the is infact an TB/intake issue. If not, maybe you camshaft selection is not optimized to run to that RPM.

Dave

All this arm chair quarter backing and no one is looking at the data he has.

MAP data from the dyno run will reveal a lot and end some speculation.

If you find your Map (vacuum) is increasing at RPMs then the is infact an TB/intake issue. If not, maybe you camshaft selection is not optimized to run to that RPM.

Dave

Trending Topics

#9

Originally Posted by Louis

My MAP on the L92/L76 is a consistent 97-99, never falling off. It pulls clean to 6600, and never falls off. Cam selection is a large part.

I'm sure you've thought of it, but testing for exhaust restriction is as simple as dropping out the cats for one pull, and the wideband O2 data will tell you if your fuel pump is leaning you out, assuming the dynojet operator uses a wideband O2.

#10

TECH Senior Member

iTrader: (14)

I'm gonna have to say the intake isn't your restriction at this point. My graph looks sorta the same as it starts dropping off after 6k, but I have a LS6 intake so that's my excuse. Your combo won't restrict you that much at your hp level. It's gotta be a cam issue. Your tq commits suicide at 5k.

#11

TECH Apprentice

I trhought cam as well but would be inclined to close the intake earlier and reduce pumping losses, maybe freeing up some extra rpm's? Could be wrong though

Boosted.

Boosted.

#12

To really understand how intake, exhaust, and cam work together in a high-performance engine, download the user's manual for Dynomation:

http://www.proracingsim.com/download...sersManual.pdf

and read the section called Wave-Dynamics Analysis, beginning on page 231. It sums up much of the important information from my Internal Combustion Engine theory course 25 years ago, but in a much more accessible form.

Unfortunately, it's a 44MB download, so beware.

And if you or your engine guru are particularly ambitious, buy the Dynomation program itself and model your engine. You can experiment much more quickly and cheaply in software than by testing a dozen new cams ...

http://www.proracingsim.com/download...sersManual.pdf

and read the section called Wave-Dynamics Analysis, beginning on page 231. It sums up much of the important information from my Internal Combustion Engine theory course 25 years ago, but in a much more accessible form.

Unfortunately, it's a 44MB download, so beware.

And if you or your engine guru are particularly ambitious, buy the Dynomation program itself and model your engine. You can experiment much more quickly and cheaply in software than by testing a dozen new cams ...

#13

On The Tree

Join Date: Jul 2003

Location: Kaneohe, Hawaii

Posts: 159

Likes: 0

Received 0 Likes

on

0 Posts

Any follow up CYBERNCO? Was the problem with your tune? Did you take the car back for a second run? If you don't mind me asking about the price on your engine (SDPC, right?). Thanks!

#15

Originally Posted by Louis

BTW- are you using LS2 injectors, or the L76 units that came with the intake?

Louis, how does the curve on the G5X4 cam look on a 402+engine?

#16

On The Tree

Join Date: Jan 2002

Location: Aloha, Oregon

Posts: 120

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 99Fbody99

Its funny,

All this arm chair quarter backing and no one is looking at the data he has.

MAP data from the dyno run will reveal a lot and end some speculation.

If you find your Map (vacuum) is increasing at RPMs then the is infact an TB/intake issue. If not, maybe you camshaft selection is not optimized to run to that RPM.

Dave

All this arm chair quarter backing and no one is looking at the data he has.

MAP data from the dyno run will reveal a lot and end some speculation.

If you find your Map (vacuum) is increasing at RPMs then the is infact an TB/intake issue. If not, maybe you camshaft selection is not optimized to run to that RPM.

Dave

Last edited by nitrousc5; 04-09-2007 at 06:30 AM.

#19

LS1TECH Sponsor

iTrader: (10)

Originally Posted by cybernco

I'm looking for help. My engine is out of air at 6100 RPM, but it should make power to at least 6500 RPM. My current guesses for bottlenecks are my SLP Headers W/Cats & my stock LS2 fuel pump. My injectors were at 85% at WOT, so the pump may not be it. I can e-mail my HPTuners scan of my dyno pull if you PM me with your e-mail.

My Dyno is as follows; 480 RWHP @ 6100 RPM and 468 RWTQ at 4500 RPM.

My Dyno is as follows; 480 RWHP @ 6100 RPM and 468 RWTQ at 4500 RPM.

#20

On The Tree

Thread Starter

Join Date: Dec 2006

Location: Indianapolis, IN

Posts: 126

Likes: 0

Received 0 Likes

on

0 Posts

Wow, I'm sorry I let this go so long without a reply.

I have Stock L92 heads with the 40Lb injectors that came with the L92 416 from SDPC.

I'm not sure how to post the HPTuners scan file from my Dyno run on this forum.

Like several of you, I too think my cam is a very likely culprit of the upper RPM limitation. I think that the L92/L76 setup was just too new, when I ordered the engine in November last year. Not enough was known (Publicly) of what kind of cam the L92/L76 setup would really respond to.

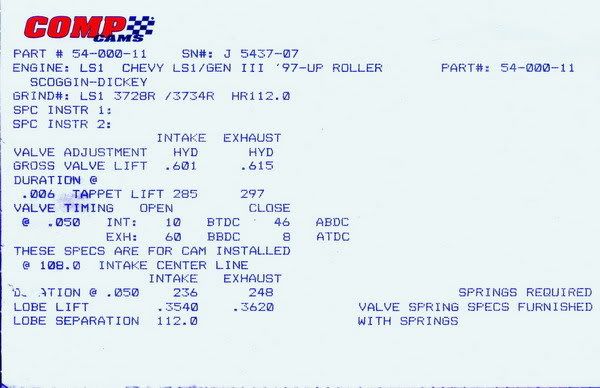

Here are the specs on my cam:

I wish someone would design a better intake with shorter runners for the L92. F.A.S.T. are you listening???

GHL Crossover... Hmmm, I looked at the Borla and it has a small crossover section too. I'm curious about this one. Did you go to straight pipe on your car and eliminate your crossover completely?

I do plan on a 75 HP shot of NOS after Iíve installed in a better fuel pump and am confident of my tune.

You know, from 3000-5500 RPM's the car is a rocket ready to rip out the drive train. You gotta love torque!!!

I have Stock L92 heads with the 40Lb injectors that came with the L92 416 from SDPC.

I'm not sure how to post the HPTuners scan file from my Dyno run on this forum.

Like several of you, I too think my cam is a very likely culprit of the upper RPM limitation. I think that the L92/L76 setup was just too new, when I ordered the engine in November last year. Not enough was known (Publicly) of what kind of cam the L92/L76 setup would really respond to.

Here are the specs on my cam:

I wish someone would design a better intake with shorter runners for the L92. F.A.S.T. are you listening???

GHL Crossover... Hmmm, I looked at the Borla and it has a small crossover section too. I'm curious about this one. Did you go to straight pipe on your car and eliminate your crossover completely?

I do plan on a 75 HP shot of NOS after Iíve installed in a better fuel pump and am confident of my tune.

You know, from 3000-5500 RPM's the car is a rocket ready to rip out the drive train. You gotta love torque!!!

Last edited by cybernco; 04-13-2007 at 03:57 AM.