Cam install questions

#1

Banned

Thread Starter

iTrader: (14)

Join Date: Apr 2005

Location: Keller

Posts: 1,701

Likes: 0

Received 0 Likes

on

0 Posts

got a few questions before i tear into this. im goin by the ls1howto.com thread on how to do this. im gonna use the magnet trick pen to hold up the lifters install of the jrp tool cus its just to much. and as far as the valve spring compressor i got the flat manual thing from orielys to compress each one, im obvisously gonna cut it to make it fit, ive heard of this breakin off in the rocker bolt spot tho? should i worry about it or just get the MORE tool.

thanks again.

thanks again.

#3

TECH Regular

iTrader: (1)

Join Date: Oct 2003

Location: Bloomington, MN

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

You can use 5/16" wooden dowel rod instead of the JRP tool. I used the crane valve spring tool. I think you might have a hell of a time with the flat style.

http://i80.photobucket.com/albums/j1...a/IMG_0004.jpg

http://i80.photobucket.com/albums/j1...a/IMG_0004.jpg

#6

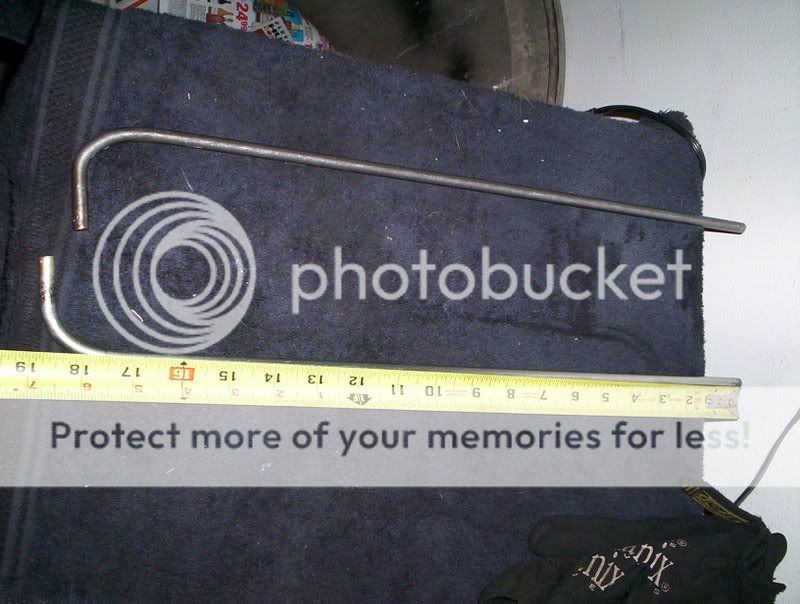

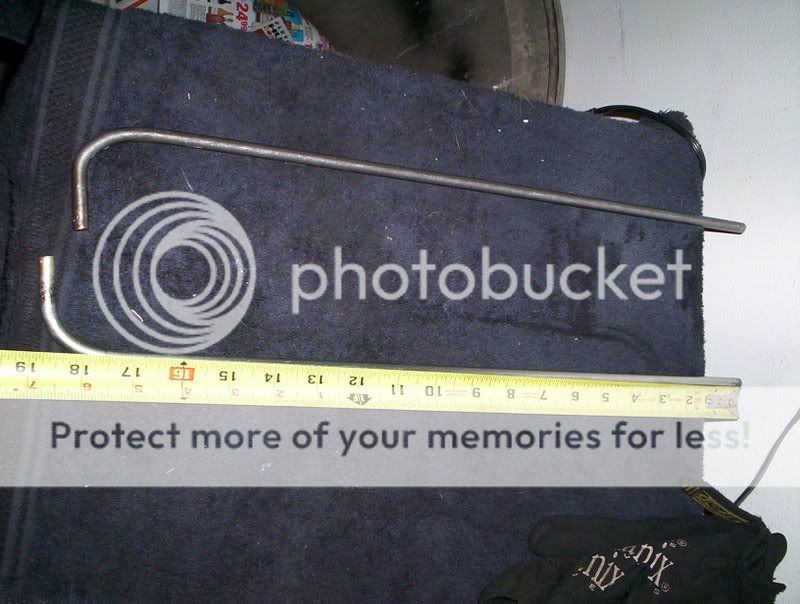

I used two 5/16 metal dowles from lowes bent the ends and then cut them off 17-3/4" to 18" from the inner bend(they are supposed to clear by a good 1 to 1-1/2 inch but I cut mine longer just to be sure). I did have to d-shape the passenger side(with a dremel) to fit, I also used oil on them before use just to be safe, they worked great. Good luck -Dave

#7

TECH Addict

iTrader: (1)

If you're going to spend money on a spring tool do it right the first time and buy the vinci/crane tool. It costs 3 times as much as the Tim's tool, but it does 2 at a time. I bought the Tim's tool first and there is nothing wrong with it if you have the time to remove 16 springs and then install 16 new ones. The Crane tool does two at a time which is a significant time sayings if you don't mind spending $100.00 plus shipping for a spring tool.

Trending Topics

#9

Banned

Thread Starter

iTrader: (14)

Join Date: Apr 2005

Location: Keller

Posts: 1,701

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 98RedZone

I can send you my crane if you want to use it.

thanks guys/

#14

Banned

Thread Starter

iTrader: (14)

Join Date: Apr 2005

Location: Keller

Posts: 1,701

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by kyles2000z

you dont have to make them a D shape. just get a 4 ft. piece, and cut it in half. with each piece being 2 ft. long, the whole piece wont fit in and get stuck.

#18

TECH Enthusiast

iTrader: (7)

Join Date: Jul 2006

Location: Fenway

Posts: 623

Likes: 0

Received 0 Likes

on

0 Posts

i just did mine this weekend and used 5/16th wooden dowels. cut them to about 22 inches, and used a dremel with sanding barrel to flaten the passenger side one down a little on one side. I also used the crane tool which i HIGHLY recommend.

and i used a custom tool from a friend for the springs

and i used a custom tool from a friend for the springs