i need input, lots of it!

#1

TECH Fanatic

Thread Starter

iTrader: (2)

Join Date: Aug 2006

Location: Bryant, AR

Posts: 1,008

Likes: 0

Received 0 Likes

on

0 Posts

Okay so some may remeber about two weeks ago i installed my cam. prior to the cam install the car worked fine, however i did notice that the clutch was slipping prior to the cam install but besides that the car worked GREAT for daily driving.

here's what was changed with the cam install

Underdrive pully was taken off

LT4 Hotcam

New lifters

Rockers were locked down using the engine running method, 1/2 turn after no clack

tune from Madz28

New keyed pully/hub assembly.

After all of this was commenced and done, the car idled GREAT. Sounded awesome too. however, the car just didnt move like it should. this is a full bolton car, and it just doesnt go. This could be contributed to the failing clutch but thats besides the true issue. The poblem i was having is that when driving, the oil pressur would surge to 45 Psi and as i started to drive regularly throughout my neighbor hood the PSi would start to drop lower and lower. Also, the car would die at any stop, whether its a stop sign or stop light, or stopping to make a turn.

Could this be because the cam isnt "broken in" yet?

would my O2's have anything to do with this?

I've cleaned my IAC and it still does this.

Like stated above, the car ran fine prior to the cam install.

Im coming back home for labor day ( im at college right now ) and i plan to tackle the car for a day or two. what would yall suggest i do? Ion set my idle at 700 but has since sent me a tune for a stock idle of 800 that ima install to see if that works.

Any ideas are accepted, leave a reasoning with them please though.

here's what was changed with the cam install

Underdrive pully was taken off

LT4 Hotcam

New lifters

Rockers were locked down using the engine running method, 1/2 turn after no clack

tune from Madz28

New keyed pully/hub assembly.

After all of this was commenced and done, the car idled GREAT. Sounded awesome too. however, the car just didnt move like it should. this is a full bolton car, and it just doesnt go. This could be contributed to the failing clutch but thats besides the true issue. The poblem i was having is that when driving, the oil pressur would surge to 45 Psi and as i started to drive regularly throughout my neighbor hood the PSi would start to drop lower and lower. Also, the car would die at any stop, whether its a stop sign or stop light, or stopping to make a turn.

Could this be because the cam isnt "broken in" yet?

would my O2's have anything to do with this?

I've cleaned my IAC and it still does this.

Like stated above, the car ran fine prior to the cam install.

Im coming back home for labor day ( im at college right now ) and i plan to tackle the car for a day or two. what would yall suggest i do? Ion set my idle at 700 but has since sent me a tune for a stock idle of 800 that ima install to see if that works.

Any ideas are accepted, leave a reasoning with them please though.

#2

Well first i would make sure the car is running as good as you think it is at idle with a vacuum gauge. if your reading on the vacuum gauge ends up being below par you probably have your rockers set too tight, or your tune is off but i doubt ion or anybody else would miss with a hotcam.

Otherwise i just go back to my suggestion to you earlier, i'm not talking out of my *** here, i drive my heads/cam/355 over 100 miles 3 days a week to college myself. i had the dying problem just like yours, 1/2 a turn out on the tb stop screw and the problem vanished. even with the air on and the wheel at full lock it wont die now. hell just try holding the gas open just a hair with your foot and see if it still tries to stumble and die while stopping or even if you try turning the screw... its TOTALY reversable so you wont lose jack crap if you try it.

none of your symptoms can be because your cam isnt broken in yet, there is no breakin on roller cams.

as for your oil pressure problem it is perfectly natural for engine oil pressure to drop as the engine oil becomes warmed up to temp. my engine starts off cold with 75psi at idle, and at hot idle about 180 degrees it will be 30psi. is it possible that when you were doing your cam swap that you bumped the oil press sensor in the back of the motor and damaged it with intake while either installing or removing it? what were your pressures like before you did the cam swap?

Otherwise i just go back to my suggestion to you earlier, i'm not talking out of my *** here, i drive my heads/cam/355 over 100 miles 3 days a week to college myself. i had the dying problem just like yours, 1/2 a turn out on the tb stop screw and the problem vanished. even with the air on and the wheel at full lock it wont die now. hell just try holding the gas open just a hair with your foot and see if it still tries to stumble and die while stopping or even if you try turning the screw... its TOTALY reversable so you wont lose jack crap if you try it.

none of your symptoms can be because your cam isnt broken in yet, there is no breakin on roller cams.

as for your oil pressure problem it is perfectly natural for engine oil pressure to drop as the engine oil becomes warmed up to temp. my engine starts off cold with 75psi at idle, and at hot idle about 180 degrees it will be 30psi. is it possible that when you were doing your cam swap that you bumped the oil press sensor in the back of the motor and damaged it with intake while either installing or removing it? what were your pressures like before you did the cam swap?

#3

TECH Fanatic

Thread Starter

iTrader: (2)

Join Date: Aug 2006

Location: Bryant, AR

Posts: 1,008

Likes: 0

Received 0 Likes

on

0 Posts

how do i adjust that stop screw? cause i know that a pair of pliers doesnt do the trick.

how do i do a vacuum test and what number am i looking for on a vacuum test?

how do i do a vacuum test and what number am i looking for on a vacuum test?

#4

12 Second Club

iTrader: (2)

Join Date: Oct 2004

Location: Easton, Md

Posts: 222

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by ckyconan2003

how do i adjust that stop screw? cause i know that a pair of pliers doesnt do the trick.

how do i do a vacuum test and what number am i looking for on a vacuum test?

how do i do a vacuum test and what number am i looking for on a vacuum test?

The TB idle set screw has a nut on the back side and the head of the screw is usually a Torx bit. Just hold the screw inplace with your Torx and losen the nut a bit, then make your half turn adjustment and retighten the nut making sure your still holding it in place w the Torx.

Use a vacum gage to test vacum. If you don't have one, go to your nearest auto parts store and purchase one. A good set that has multiple connectors will only be about $25.00. Pull the small vacum line off of the drivers side of the intake just above your PCV. Attach vacum gage and record readings at idle. Not 100% sure of what the reading should be for your set up, but I would guess your readings should be in the range of 15 to 20 lbs. Anything less than 15, I would suggest that your rockers are too tight. Vacum on my car is 16 to 16.5 and I have a 502 cc w 1.6 rr.

#5

TECH Fanatic

Thread Starter

iTrader: (2)

Join Date: Aug 2006

Location: Bryant, AR

Posts: 1,008

Likes: 0

Received 0 Likes

on

0 Posts

can you show me a pciture of this screw. because i never noticed a screw. so i would like to make sure that we are talking about the same screw.

Im thinking about the screw that the TB butterfly lever hits, instead of hitting the actual TB.

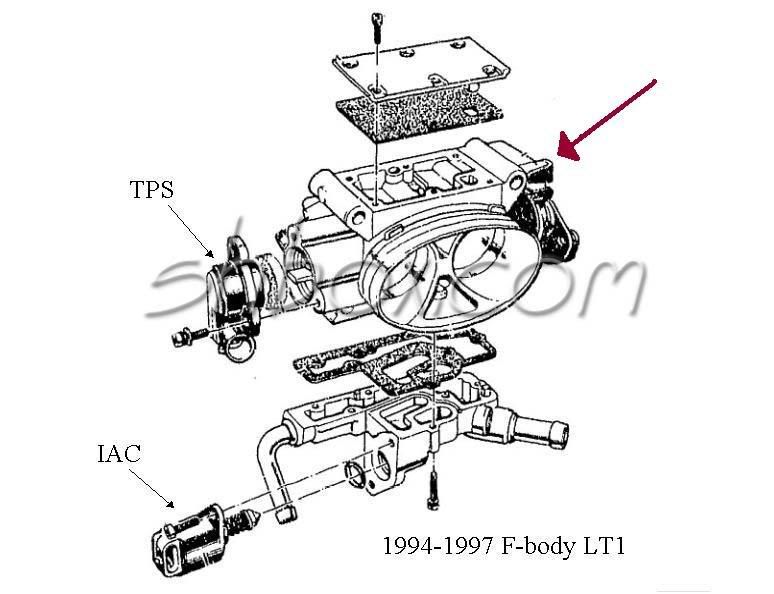

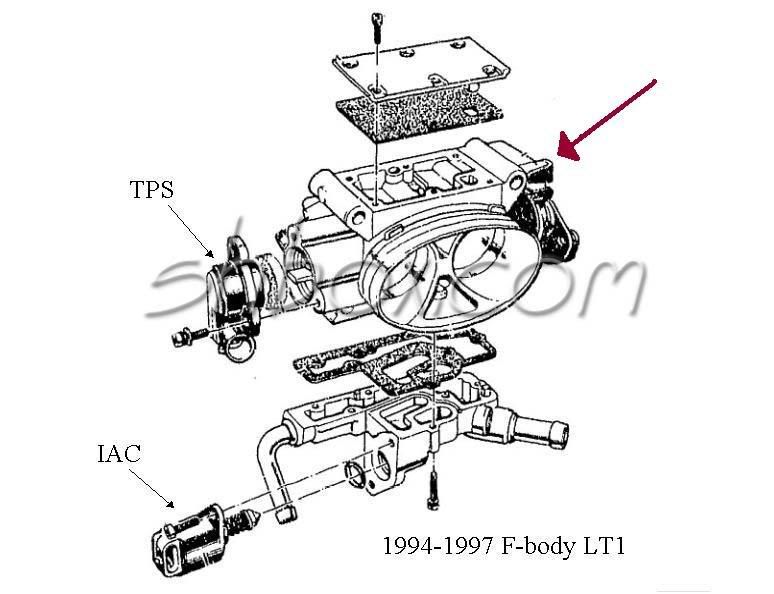

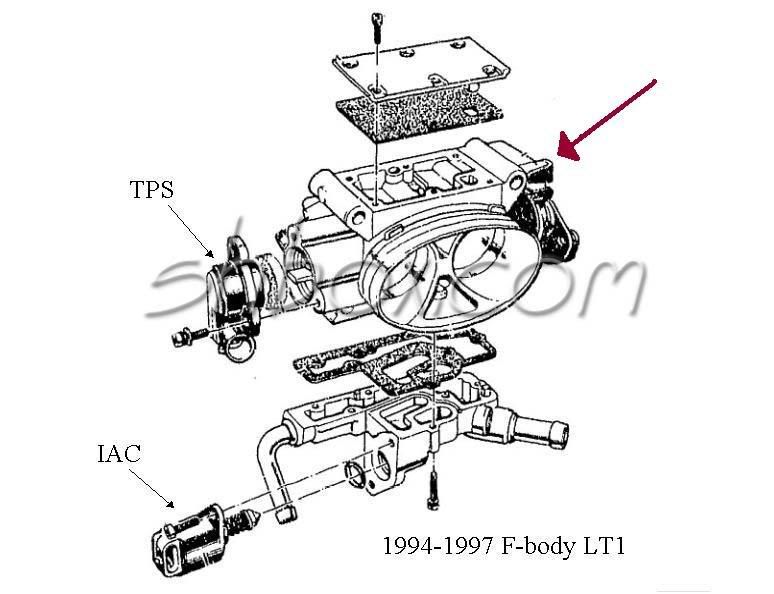

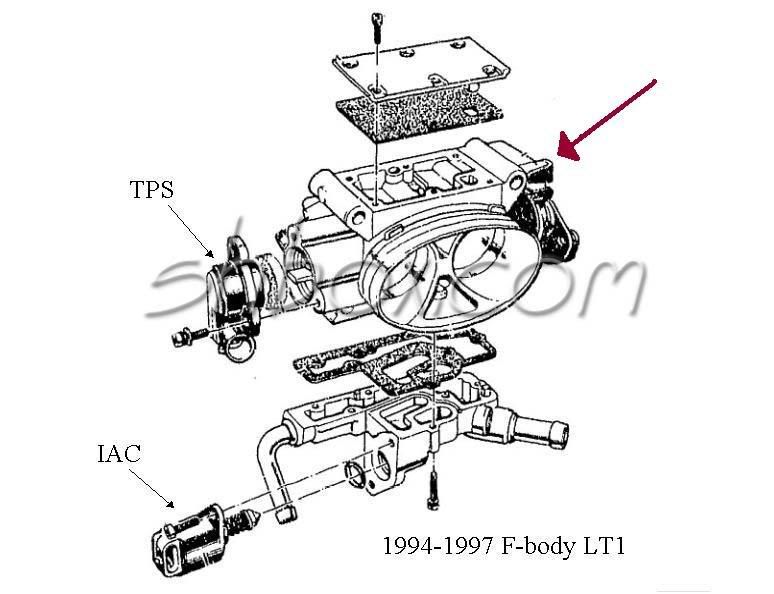

the arrow points to where the screw that im thinking of is located.

Im thinking about the screw that the TB butterfly lever hits, instead of hitting the actual TB.

the arrow points to where the screw that im thinking of is located.

#6

thats the one i mean, on the back side of the tb you can access it with a torx bit. sometimes you can grab it from the front side though and turn it a little with pliers. otherwise my suggestion is to remove the tb from the car and screw the thing all the way out and then screw it in from the front side with the torx facing out for easy adjustment. and just for your reference measure where you are at from the factory so you can return it to that position (length) if you wish.

on the vac gauge reading i would say you should be looking for about 15" or 16" of vacuum with your setup, assuming you have stock compression or above.

on the vac gauge reading i would say you should be looking for about 15" or 16" of vacuum with your setup, assuming you have stock compression or above.

#7

12 Second Club

iTrader: (2)

Join Date: Oct 2004

Location: Easton, Md

Posts: 222

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by ckyconan2003

can you show me a pciture of this screw. because i never noticed a screw. so i would like to make sure that we are talking about the same screw.

Im thinking about the screw that the TB butterfly lever hits, instead of hitting the actual TB.

the arrow points to where the screw that im thinking of is located.

Im thinking about the screw that the TB butterfly lever hits, instead of hitting the actual TB.

the arrow points to where the screw that im thinking of is located.