No clearance!!! Help!!!

#1

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: Gardnerville, NV.

Posts: 1,037

Likes: 0

Received 0 Likes

on

0 Posts

I have no P to V clearance...what are my options? I'm trying to install an F14 cam on 62cc 5.3 heads with stock .054" gaskets.

Do I change cams? (what's a good cam for 10.7:1)

Flycut the pistons in the motor?

Where can I get a flycutting tool?

Do I change cams? (what's a good cam for 10.7:1)

Flycut the pistons in the motor?

Where can I get a flycutting tool?

#2

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: Gardnerville, NV.

Posts: 1,037

Likes: 0

Received 0 Likes

on

0 Posts

Tomorrow I'm going to check P to V with a stock head. The cam sure looks to be lined up dot to dot and everything looks right, except I have just about ZERO clearance.

I'm really thinking about overnighting a milder cam than the Futral F14, but I'm not sure how to make sure it will clear?

I'm really thinking about overnighting a milder cam than the Futral F14, but I'm not sure how to make sure it will clear?

#3

Flycut, it's really not that big of a deal

https://ls1tech.com/forums/generation-iii-internal-engine/709183-how-flycut-pistons.html

https://ls1tech.com/forums/generation-iii-internal-engine/709183-how-flycut-pistons.html

#4

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: Gardnerville, NV.

Posts: 1,037

Likes: 0

Received 0 Likes

on

0 Posts

Will the stock pistons take .080" cutting?

And..is there room to do this in the car on a F-body?????

#5

1) I'm not sure, you may be able to rent something from a local machine shop.

2) Yes they will take .080 np

3) Good question.. I don't know.

#7

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: Gardnerville, NV.

Posts: 1,037

Likes: 0

Received 0 Likes

on

0 Posts

Heads were milled .003"-.005" for cleaning.

The cam sure looks striaght up dot to dot, but I'm wondering is something is off?

When you think about it, zero clearance doesn't sound right as the .035" valve drop of the 5.3 heads and the .002" larger diameter (diregarding trigonomentic angular...) only makes me .040" MAX tighter than stock and that doesn't seem right.

All opinions welcome.

The cam sure looks striaght up dot to dot, but I'm wondering is something is off?

When you think about it, zero clearance doesn't sound right as the .035" valve drop of the 5.3 heads and the .002" larger diameter (diregarding trigonomentic angular...) only makes me .040" MAX tighter than stock and that doesn't seem right.

All opinions welcome.

Trending Topics

#8

TECH Fanatic

iTrader: (31)

Join Date: Apr 2007

Location: Dover DE

Posts: 1,207

Likes: 0

Received 0 Likes

on

0 Posts

Re'

#12

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: Gardnerville, NV.

Posts: 1,037

Likes: 0

Received 0 Likes

on

0 Posts

Okay, here's what is confusing me (more). When I rotate it through I actually hit the exhaust valve too. Right before the dots line up dot to dot the piston comes up and touches the exhaust valve. Then, in the 1-2 degrees of rotation, the exhaust clears and the intake touches. Does that sound right?

How much difference would a 228/228 cam make from a 232/234? I know it depends on ramp profile, but speaking in broad terms...4 degrees on the intake would mean 2 degrees on each side of the lobe roight? Or 6 degrees (228 to 234) would only be 3 degree change on the exhaust. I know the F14 is ground with 4 degrees advance built in, what would it do if I retarded it 2 degrees? How many degrees does one tooth equal. It looks like there's 40 teeth on the cam gear so is that 360/40/2=4.5degrees per cam tooth? I'm just curious, I could bump it one tooth and check it again just to give me some kind of an idea what 4.5 degrees means to piston to valve clearance?

How much difference would a 228/228 cam make from a 232/234? I know it depends on ramp profile, but speaking in broad terms...4 degrees on the intake would mean 2 degrees on each side of the lobe roight? Or 6 degrees (228 to 234) would only be 3 degree change on the exhaust. I know the F14 is ground with 4 degrees advance built in, what would it do if I retarded it 2 degrees? How many degrees does one tooth equal. It looks like there's 40 teeth on the cam gear so is that 360/40/2=4.5degrees per cam tooth? I'm just curious, I could bump it one tooth and check it again just to give me some kind of an idea what 4.5 degrees means to piston to valve clearance?

Last edited by ssheets; 12-04-2007 at 01:18 AM.

#13

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: Gardnerville, NV.

Posts: 1,037

Likes: 0

Received 0 Likes

on

0 Posts

So I'm thinking about a

Futral F4 -226/226 .575/.575 112

Futral F10 -228/228 .576/.576 112

Futral F11 -228/230 .576.595 112

Comp SI4 -228/228 .588/.588 112

Or I may have to go smaller like a Comp SI2 -224/224 .581/.581 112

What exactly will a 114 vs 112 LSA do to my P to V on the exhaust timing event?

Futral F4 -226/226 .575/.575 112

Futral F10 -228/228 .576/.576 112

Futral F11 -228/230 .576.595 112

Comp SI4 -228/228 .588/.588 112

Or I may have to go smaller like a Comp SI2 -224/224 .581/.581 112

What exactly will a 114 vs 112 LSA do to my P to V on the exhaust timing event?

Last edited by ssheets; 12-04-2007 at 02:15 AM.

#14

TECH Enthusiast

iTrader: (42)

if your heads haven't been milled like, it should fit!!! ppl run the tq3 with the same heads and it fits.... ppl even run the ms3 that is bigger then our f14 so you have something wrong somewhere don't give up and order another cam... that combo should be a good one... not to many on here even use that combo, if any cause i've been researching for sometime now and haven't found those heads with that cam.... i talked with tsp and they said ppl run the tq2 with those heads mill .030 and it fits, that cam is about as close as you could get to ours without the advance... so if the advance causes it not to work then thats understandable with my heads that is.... so your heads should work with no problem!!!!

#15

TECH Junkie

iTrader: (18)

You sure your pushrods aren't too long? If you are using a checker spring, you need to just tighten the rocker bolt until you have zero lash. Same you would with a solid lifter. If you tighten the rocker bolt all the way down, with the checker spring, it's probably not going to compress the lifter any which will give you .080 to .100 less clearance than you will actually have.

#16

TECH Resident

Join Date: Jan 2003

Location: AUSTIN TX

Posts: 855

Likes: 0

Received 0 Likes

on

0 Posts

I agree, something is being missed here. Did you soak the lifters for days, or pump them up in oil before you installed them? I ask because some of the older hyd lifters were reluctant to bleed back down, and if these are also, or you are checking thgem with test or no springs, then the plunger is most likely still up against the top retaining ring adding .040-.080 to the pushrod side (which would equate to .068-.102 lift at the valve), this combined with a slightly too long pushrod could be the problem. Also, you did not mention where the heads came from. Are they regular 5.3 castings that you had ported and larger valves put in, or are they a pair from TSP? I ask because TSP's CNC'd 5.3's are supposed to have the same intake valve clearance as the stock heads with even better ex clearance. I just love the way so many people post up here to check p/v clearance and then recommend the "clay method", which does not work very well at all. Really the best way to check p/v clearance is with a solid lifter and either an adjustable pushrod or adjustable valvetrain. Good luck

#17

Teching In

iTrader: (1)

Join Date: Sep 2007

Location: Texas

Posts: 24

Likes: 0

Received 0 Likes

on

0 Posts

Take the engine out of the car, tape it really good and start flycutting, you need a spare head cuz you'll junk one and the flycutting tool. It shouldn't be too much of a deal but it'll definetely take patience and time, last cilinders will be hard to work on if the engine is in. Good luck

#18

TECH Senior Member

iTrader: (4)

Measure using the check springs and the drop to piston contact rather than clay. You should have a dial indicator to do this but feeler gages can be used also but its a bit more work. It will provide you with a curve of clearance if you start at 20 degrees before the top of the overlap stroke to 20 degrees after. This way you are not relying on a single value and you will be able to see if the valves are truly getting that close and figure out what is going on. Also, with a hydraulic lifter in place, if the valve is truly contacting then you are using the valve to compress the lifter to get it to swing through the top of stroke. Not the best thing to be doing.

#19

TECH Senior Member

if your heads haven't been milled like, it should fit!!! ppl run the tq3 with the same heads and it fits.... ppl even run the ms3 that is bigger then our f14 so you have something wrong somewhere don't give up and order another cam... that combo should be a good one... not to many on here even use that combo, if any cause i've been researching for sometime now and haven't found those heads with that cam.... i talked with tsp and they said ppl run the tq2 with those heads mill .030 and it fits, that cam is about as close as you could get to ours without the advance... so if the advance causes it not to work then thats understandable with my heads that is.... so your heads should work with no problem!!!!

Sooo SSheets I told you this cam might be tight depending on your valves. If you have Ferrea, you've lost .020 right of the bat and you are not even sure of the cleanup mill.

Your idea of putting on stock heads is not a bad one, but before that I would first invest in a degree kit and degree your cam in.

That will let you know for sure if install is correct or if cam is correct.

Then make a decision after that.

Mark

#20

TECH Fanatic

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: Gardnerville, NV.

Posts: 1,037

Likes: 0

Received 0 Likes

on

0 Posts

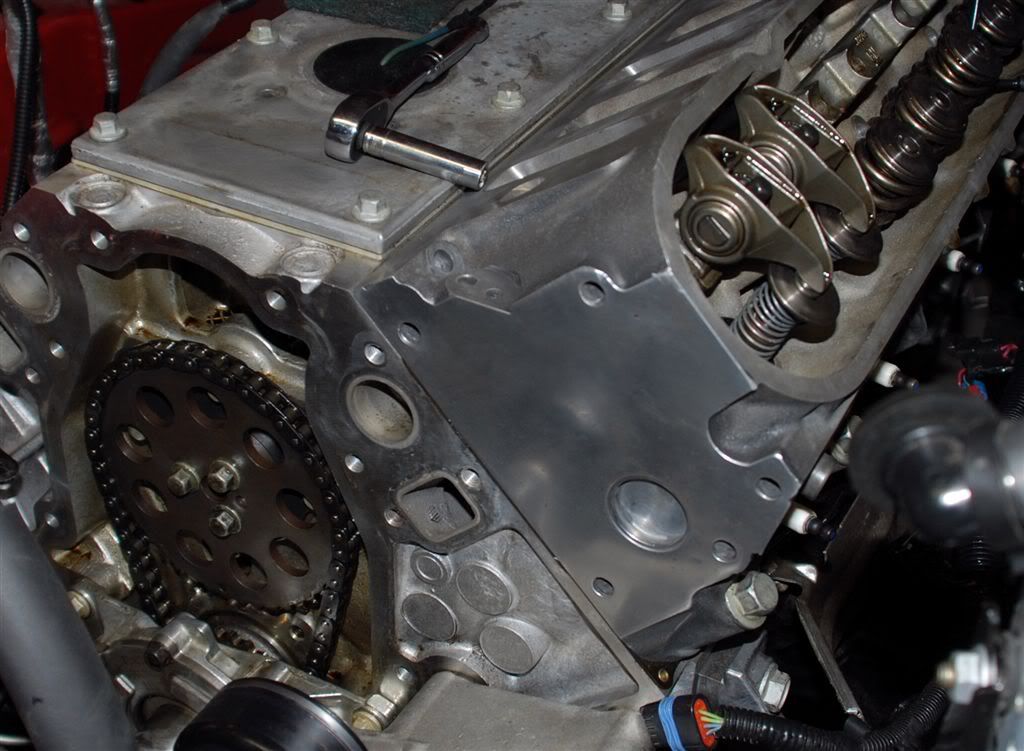

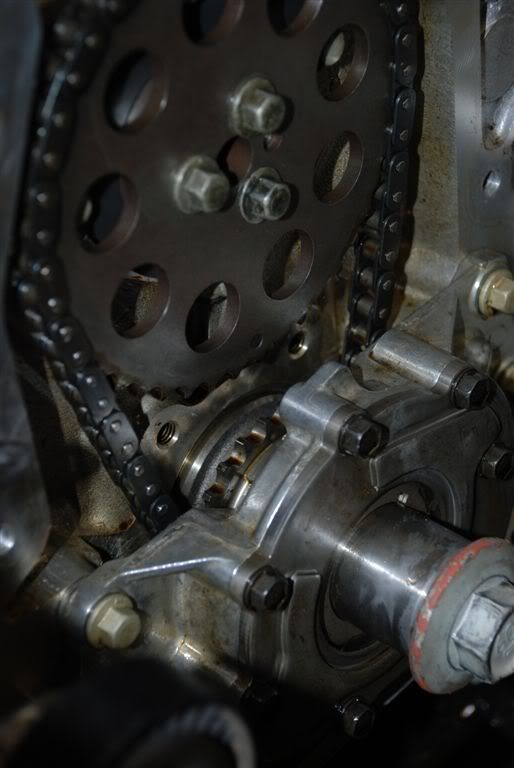

Okay, I think you guys may have found something. First the heads:

They are stock 5.3s that a friend worked. He's a good machinest and builds a ton of race motors, but that doesn't mean he's perfect, although I have a lot of faith in him. They are intnetionally worked very mildly, nothing drastic or radical done to any of the machine work.

He put in new valve seats and cut the intakes in deep. He then milled the heads to clean them up and I thought he said about .003", but it may have been as much as .005". I remember talking to him about the .035" valve drop on the 5.3s so we didn't mill much. The valves are Manley pro-flows.

Hydraulic lifters....I took them out a few days ago and laid them on the bench in the order they came out. The plungers are definetely against the retaining clip and the weak springs are not compressing them at all.

Should I clay with a set of the strong (PRC Gold) springs and see what I get?

I'll check on a degree wheel today.

Here's a picture of a chamber that shows the valve depth...I've got better ones, but I'll have to find them.

They are stock 5.3s that a friend worked. He's a good machinest and builds a ton of race motors, but that doesn't mean he's perfect, although I have a lot of faith in him. They are intnetionally worked very mildly, nothing drastic or radical done to any of the machine work.

He put in new valve seats and cut the intakes in deep. He then milled the heads to clean them up and I thought he said about .003", but it may have been as much as .005". I remember talking to him about the .035" valve drop on the 5.3s so we didn't mill much. The valves are Manley pro-flows.

Hydraulic lifters....I took them out a few days ago and laid them on the bench in the order they came out. The plungers are definetely against the retaining clip and the weak springs are not compressing them at all.

Should I clay with a set of the strong (PRC Gold) springs and see what I get?

I'll check on a degree wheel today.

Here's a picture of a chamber that shows the valve depth...I've got better ones, but I'll have to find them.