While doing rod bolts I checked out my bearings and now I'm wondering

#1

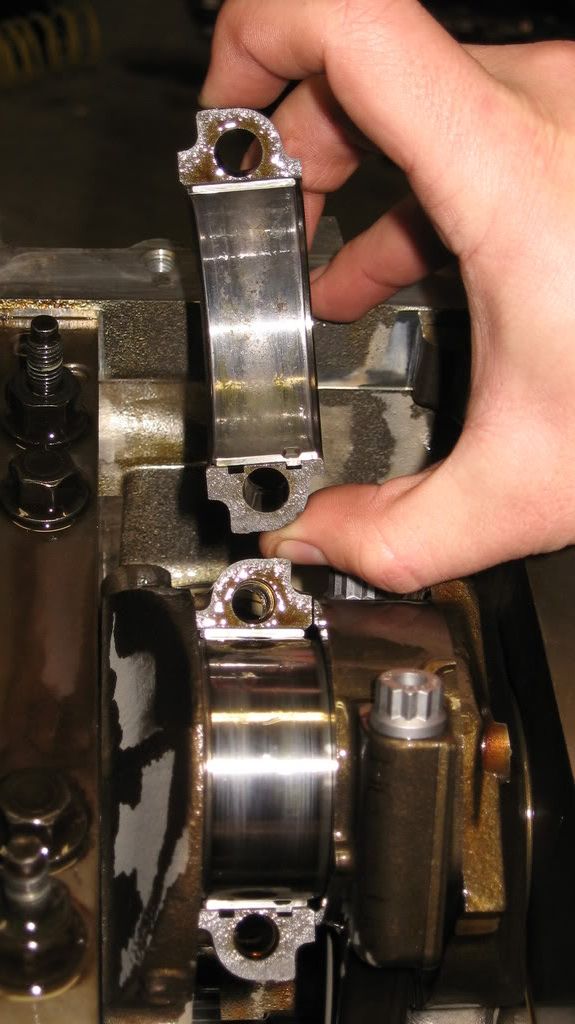

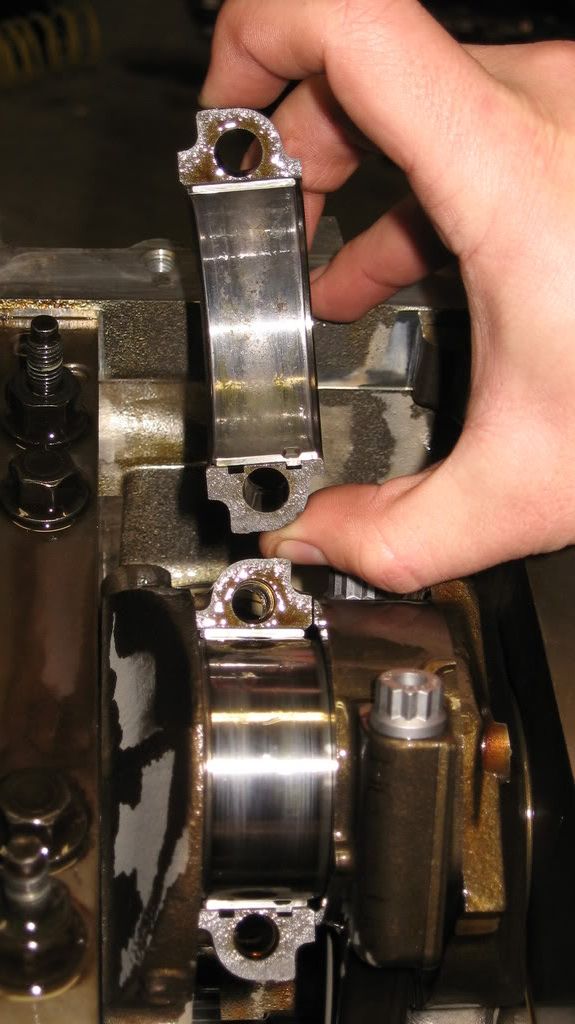

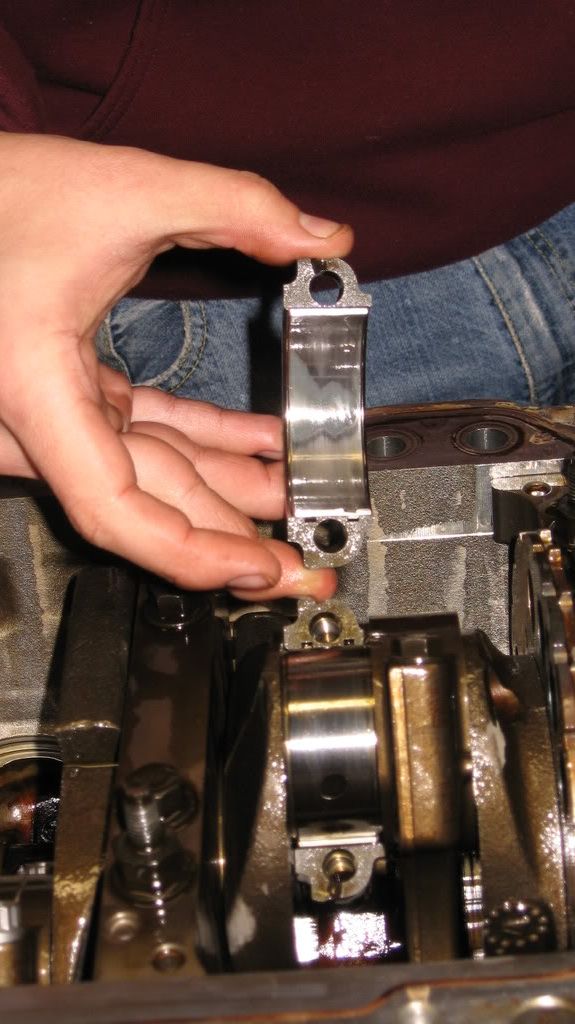

Okay well I took a look at all the bearings as I was doing my rod bolts and here's what I found: All the bearings looked like this:

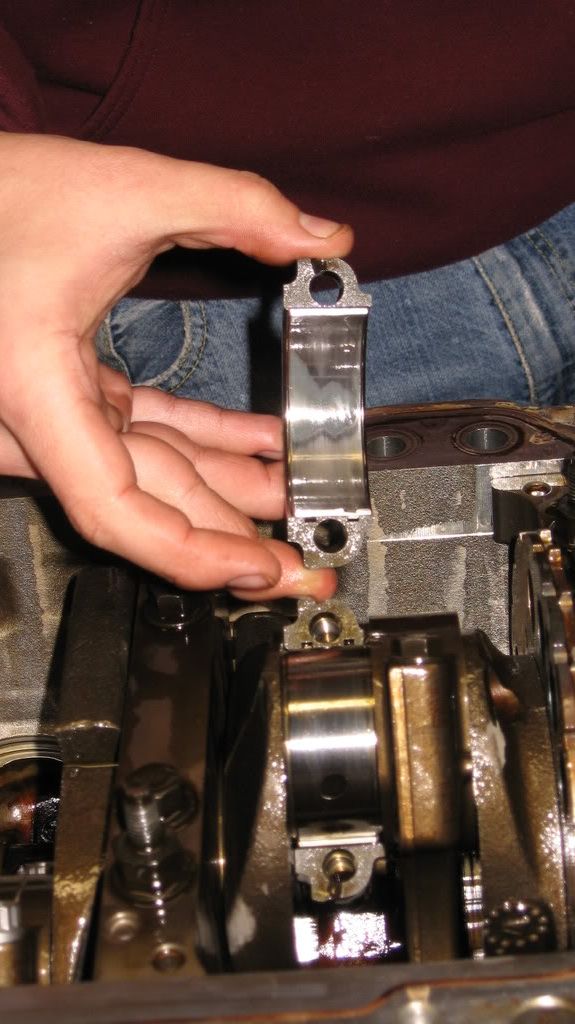

Until I got to the # 7 (I think that it's number 7, it was the second to last) and I found this:

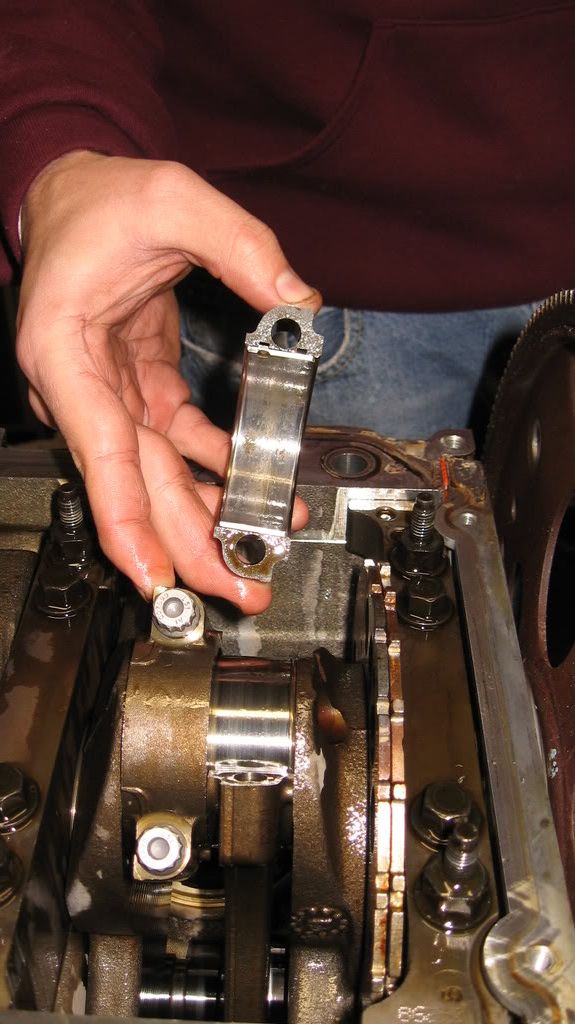

That was the back side of the bearing, it didn't spin and there was no metal shavings anywhere in the motor or in the filter, nor did the motor make any noise, only piston slap when cold then it quieted down. The other side (The side contacting the crank journal is pictured below:

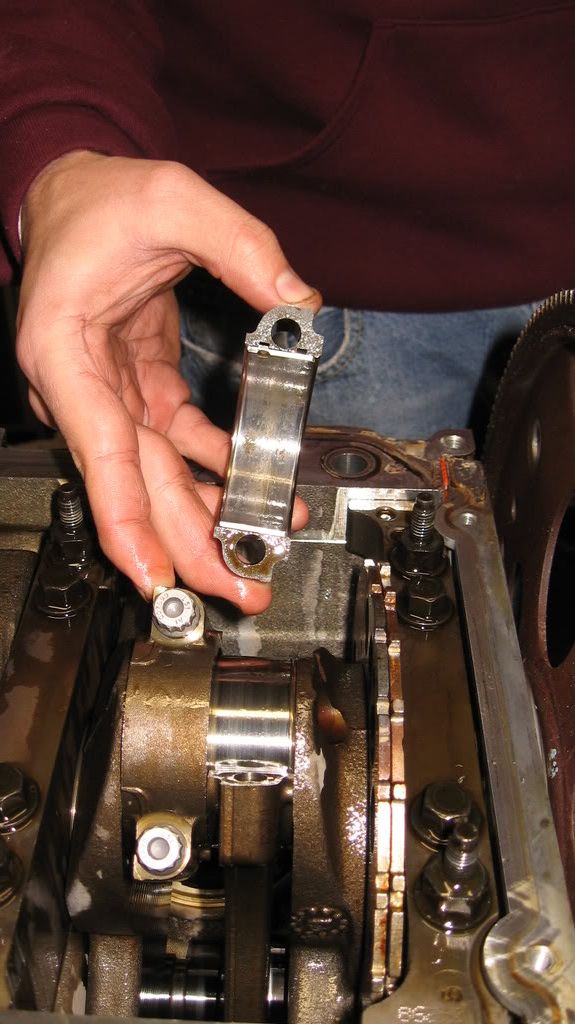

And here is the number 8 right next to it:

So what do you guys think? I replaced the oil pump about 2k miles ago because pressure dropped to around 20psi and just sat there fluctuating. Now I have about 50psi hot and at all times. Like I said, it didn't spin but I'm not sure if there's anything I can do about that right now, or if I should be concerned about it. I think it might just be a little bit of something left over from when I had the oil pump problem before...

Until I got to the # 7 (I think that it's number 7, it was the second to last) and I found this:

That was the back side of the bearing, it didn't spin and there was no metal shavings anywhere in the motor or in the filter, nor did the motor make any noise, only piston slap when cold then it quieted down. The other side (The side contacting the crank journal is pictured below:

And here is the number 8 right next to it:

So what do you guys think? I replaced the oil pump about 2k miles ago because pressure dropped to around 20psi and just sat there fluctuating. Now I have about 50psi hot and at all times. Like I said, it didn't spin but I'm not sure if there's anything I can do about that right now, or if I should be concerned about it. I think it might just be a little bit of something left over from when I had the oil pump problem before...

#3

So you think I should just swap the bearings out and let it go? I don't mind doing it, I mean it wont take long, I just get nervous about messing with that stuff down there, it seems finicky on our cars, and the bearing surfaces really didn't look too bad, even on the one in question. I am very open to you guys' opinions right now!

#4

TECH Addict

iTrader: (66)

I would definately replace that bearing. As long as it didnt score your crank any you should be able to go with a standard size bearing. Make sure you check the clearance once you install it, but I would bet it should be close. Might also want to check a main bearing while your at it....

#5

TECH Junkie

iTrader: (4)

my first time for me to see pics of the bearings... interesting...

so guys. Give me some input on this. What exactly are we looking at being bad on these bearings? I know what the bearing is, but what's wrong with it... i really don't see anything but what looks like a burn mark on the one bearing, and even so, what would that hurt?

explain it like you were talking to a child

so guys. Give me some input on this. What exactly are we looking at being bad on these bearings? I know what the bearing is, but what's wrong with it... i really don't see anything but what looks like a burn mark on the one bearing, and even so, what would that hurt?

explain it like you were talking to a child

#7

Restricted User

iTrader: (18)

Join Date: Apr 2007

Location: Fayetteville, NC

Posts: 1,515

Likes: 0

Received 0 Likes

on

0 Posts

Those bearings should all look like the journal in the first picture. Think about it this way soulTKR, "the only metal to metal contact in the entire engine should be the top piston ring" Everything else should have a thin coat of oil in between them. Since you already have the motor out of the car it would be very easy to change those bearings AND replace the rod bolts which I already see you doing. Those look like the ARP rod bolts so here's a tip since you already have 'em out. Do it the right way and get a rod bolt stretch gauge and make sure they're w/in ARP's specs. That should give you peace of mind.

Trending Topics

#8

Actually they are Katech. And I will change the bearings while there. I'm pretty sure those bearings look that way due to the oil pump problem that I had previously. My question is this: What bearing should I go with and can I remove and reuse the Katechs that I just installed?

Thank you

Thank you

#10

Restricted User

iTrader: (18)

Join Date: Apr 2007

Location: Fayetteville, NC

Posts: 1,515

Likes: 0

Received 0 Likes

on

0 Posts

you should be alright. If anything, call Katech and ask.

Get GM stock bearings. They'll be fine if your lube problem is fixed and your rod bolts have been upgraded.

Do you spin your motor past 7K?

Get GM stock bearings. They'll be fine if your lube problem is fixed and your rod bolts have been upgraded.

Do you spin your motor past 7K?

#12

TECH Fanatic

iTrader: (9)

The picture of the bearing that shows the back of the bearing, were it is in contact with the rod, that is normal. I personaly am more conserned with the wear on the jornal side of the bearing as well as the crank journal itself. I would mic the journals, and if they mic good, clean them up and replace the rod bearings. I would also check the main bearing journals and replace the main bearings. The cap side of the rod bearing is the half of the bearing that sees little loading. The rod side is the side that sees the high loads, look at them. The cap side of the main bearings is the side that sees the high loading, check them too. I have never been in the practice of going to an aftermarket rod bolt or main bolt without also checking the bore of the rod or main cap. Most of the time you will have to have the rods re-sized, and the line bore of the mains re-sized as well. You might not have a problem, but I personaly would never do it without checking it. Change the rod and main bearings, and if you have the engine out of the car, also pull the cam and check the cam bearings, I would change them as well. Remember if you pull a piston out of the bore, use a new ring set and hone the bore before you reinstall the piston. Also mic the bore and piston and check all the clearances.

Last edited by Texas_WS6; 02-03-2008 at 11:59 AM.

#13

TECH Senior Member

You should have never touched those bearings or caps. You should have changed the bolts one at a time on the rod with one still tight.

Now you screwed yourself as the bearings are unseated.

Options:

1-Take a chance and just put them back on and pray

2- Replace all bearings and have your crank miced

Now you screwed yourself as the bearings are unseated.

Options:

1-Take a chance and just put them back on and pray

2- Replace all bearings and have your crank miced

#14

TECH Fanatic

iTrader: (9)

Looking at the pictures, it looks like you do have the engine out of the car. I would go ahead and remove the pistons, check the piston to bore clearences, have the big end of the rods checked/re-sized with the new bolts, replace the rod and main bearings as well as the cam bearings. If the bores are still good and the pistons/bores all mic to specs, hone the bores slightly to make the NEW ring sets seal and put it back together.

No actually I lied. I would personaly buy a new LSX Block, L92 heads, new 4barrel intake, new 4.100" strock crank, new Lunati rods, Bore the block to 0.030 " under max, and finish the build with the finest parts around. OH well, what we wish for sometimes .

.

Get it all checked out and replace what is needed and you will be fine.

No actually I lied. I would personaly buy a new LSX Block, L92 heads, new 4barrel intake, new 4.100" strock crank, new Lunati rods, Bore the block to 0.030 " under max, and finish the build with the finest parts around. OH well, what we wish for sometimes

.

.Get it all checked out and replace what is needed and you will be fine.

#15

You should have never touched those bearings or caps. You should have changed the bolts one at a time on the rod with one still tight.

Now you screwed yourself as the bearings are unseated.

Options:

1-Take a chance and just put them back on and pray

2- Replace all bearings and have your crank miced

Now you screwed yourself as the bearings are unseated.

Options:

1-Take a chance and just put them back on and pray

2- Replace all bearings and have your crank miced

I know you know your **** and I'm not arguing with you, it's just to me I feel more comfortable knowing that everything is fresh on the bottom end and that I in fact did check everything out while I was there and didn't just hope that it was all okay.

#16

TECH Enthusiast

iTrader: (4)

Join Date: Mar 2007

Location: SoCal

Posts: 512

Likes: 0

Received 0 Likes

on

0 Posts

Throwing new bearings in is a no brainer, since your this far

The thing I would be worried about is the big end of the rods being out of round when you re-install the caps. They really should be re-sized whenever you take them apart like that. Thats the reason you are suppose to do the rod bolts one at a time.

Thats the theory at least

The thing I would be worried about is the big end of the rods being out of round when you re-install the caps. They really should be re-sized whenever you take them apart like that. Thats the reason you are suppose to do the rod bolts one at a time.

Thats the theory at least

#17

TECH Fanatic

iTrader: (17)

Join Date: Sep 2006

Location: dayton ohio

Posts: 1,638

Likes: 0

Received 0 Likes

on

0 Posts

I had Katechs put in around mid june 07,and put in Cleveite77 bearings in. No problems at all. I was concerned with it too,but my friend(shop owner) said it would be fine. Some of my bearings looked ALOT worse than yours.I have a 98 as well

#18

TECH Junkie

iTrader: (4)

since when does anyone change bearings and not have the crank checked/polished? to do it right - anything beyond removing/inspecting a bearing requires crank removal and a trip to the machine shop (for most of us, not everyone has the aforementioned tools on hand). i have checked many bearings in these engines during the rod bolt swap procedure with no problems. these are otherwise stock shortblock engines with 50k+ miles on them now spinning 7k+ and have been for awhile. assuming you get the bearing back where it was when you removed it, you won't have any problems.

bottom line - if you're going to put new bearings in it, do it right. remove the crank, have it checked/polished, then put new main and rod bearings both back in it.

bottom line - if you're going to put new bearings in it, do it right. remove the crank, have it checked/polished, then put new main and rod bearings both back in it.

#19

TECH Senior Member

Should have never touched them? Seeing as to what I found I'm glad I did. I was going to do what you said and leave one rod bolt tight and just change them out but I started a thread a while back and asked if I should check the bearings while I'm right there seeing as how I DID have an oil pump problem in the past, and the answer was an overwhelming YES! So I am now changing out all of the bearings and am using the Katech rod bolts and the oil pressure problem is all good now. So I guess I just don't see the problem....

I know you know your **** and I'm not arguing with you, it's just to me I feel more comfortable knowing that everything is fresh on the bottom end and that I in fact did check everything out while I was there and didn't just hope that it was all okay.

I know you know your **** and I'm not arguing with you, it's just to me I feel more comfortable knowing that everything is fresh on the bottom end and that I in fact did check everything out while I was there and didn't just hope that it was all okay.

You simply do not just crack open rods, fiddle with them and put it back together. Bearings are seated on the crank journal and should not be displaced unless by some magic you can repalce them at the same exact location they were before. Put your crank journals and bearing under a microscope and you'll understand what I mean.

Make sure you take the Ferrules out when swapping the Katech's, my favorite bolts BTW.

#20

Yes should have never touched them unless you ARE replacing them. What if they were in top shape? You still would have to replace all.

You simply do not just crack open rods, fiddle with them and put it back together. Bearings are seated on the crank journal and should not be displaced unless by some magic you can repalce them at the same exact location they were before. Put your crank journals and bearing under a microscope and you'll understand what I mean.

Make sure you take the Ferrules out when swapping the Katech's, my favorite bolts BTW.

You simply do not just crack open rods, fiddle with them and put it back together. Bearings are seated on the crank journal and should not be displaced unless by some magic you can repalce them at the same exact location they were before. Put your crank journals and bearing under a microscope and you'll understand what I mean.

Make sure you take the Ferrules out when swapping the Katech's, my favorite bolts BTW.

Like I said before, I wasn't arguing with you, I respect your knowledge when it comes to things like this, I just didn't understand, but now I do.

Also, is there anything I should know when going back together with it, I checked all of my clearances with plastigauge and they all checked out within factory spec. All were right around .067mm +/- .003mm. So it was a little loose but was still within spec. Also, I made sure to lube all of the bearings between the crank journal and bearing surface and all rod bolts were torqued down to 50ft/lbs. I double checked and triple checked the torque just to be sure. Is there anything else that I should be doing? Or should everything be okay?

Thanks

Last edited by 98RedBird; 02-04-2008 at 05:44 PM.