Vibrating my teeth at 75+

#1

Ok, so I just put in the LT1 + T56 + new 10bolt with 4.10s.

So, I head out on the road, 1, 2, 3...about 70-80ish I get a really bad vibration. Put the car up figure out the clamshell on the tailshaft of the transmission isn't bolted together, so I bolted it together and checked the pinion angle while I'm at it.

Now I was kinda low on sleep/stressed, when adjusting the TA I think I saw a +1 on the rearend and a -1 on the driveshaft(looking from the drivers side). Doesn't that mean I have a 0 degrees pinion angle. Shouldn't it be -1(+)?

Anyone have any ideas? Btw, before I took the car off the road I had JUST got the aluminum driveshaft balanced and the wheels also. So I really don't think that's the problem...

I'm lost...

So, I head out on the road, 1, 2, 3...about 70-80ish I get a really bad vibration. Put the car up figure out the clamshell on the tailshaft of the transmission isn't bolted together, so I bolted it together and checked the pinion angle while I'm at it.

Now I was kinda low on sleep/stressed, when adjusting the TA I think I saw a +1 on the rearend and a -1 on the driveshaft(looking from the drivers side). Doesn't that mean I have a 0 degrees pinion angle. Shouldn't it be -1(+)?

Anyone have any ideas? Btw, before I took the car off the road I had JUST got the aluminum driveshaft balanced and the wheels also. So I really don't think that's the problem...

I'm lost...

#2

TECH Addict

iTrader: (14)

Join Date: May 2005

Location: Simi Valley, CA.

Posts: 2,727

Likes: 0

Received 0 Likes

on

0 Posts

M6 likes a more negative angle. I had mine set to -2 and it would vibrate a lil at high speed. I changed it to -3.5 and it went away. Funny how such a lil change could make such a big diff.

#3

10 Second Club

iTrader: (22)

Join Date: Feb 2006

Location: coastal N.C.

Posts: 536

Likes: 0

Received 0 Likes

on

0 Posts

it sounds like -2 to me (+1 and -1). It makes it easier for me to not worry about the + or the - when reading a protractor, in this regard. It only makes things confusing. It's easier to just count the amnt. of degrees between the 2 measurements ... just make sure you pinion is pointed down as opposed to the driveshaft. Just remember, your axle needs room to "wrap" upward, toward a "0" pinion angle upon hard acceleration.

#4

TECH Addict

iTrader: (14)

Join Date: May 2005

Location: Simi Valley, CA.

Posts: 2,727

Likes: 0

Received 0 Likes

on

0 Posts

Not trying to be condesending at all, but have you thought about the balance on your wheels? I only say this because I had a terrible vibration at ~75mph also and I thouhgt it was something else...turned out the guy who did my tire rotation left off a locking lugnut on the passenger side rear and threw off my wheel balance. Just take a look to be safe. Hope you figure it out.

Oh and as far as measuring the Pinion angle i use Madman's method. Just one measurement off the T/A plate.

98 dergees = -2 degrees

96.5 degrees = -3.5 degrees.

#6

TECH Fanatic

iTrader: (1)

Join Date: Apr 2006

Location: Edgewater, MD

Posts: 1,507

Likes: 0

Received 0 Likes

on

0 Posts

When you say the torque arm plate do you mean the lower side of the part mounting onto the rear?

#7

tomorrow i will be resetting the pinion angle again. i gave UMI a call. yet again another glory story with their customer service. the tech (I assume Ryan or other) was busy, the lady took down my number and called me back within 30-45 minutes and helped me out with some good info. thanks UMI!

if that's not the problem i'm going to work backwards, driveshaft, wheels then alignment. i just got the car aligned and it's the drivetrain that shutters...so who knows...hopefully i can get it fixed soon, i wanna get on the dyno!

Trending Topics

#8

Although your adjustable torque arm may be a possibility, I'm leaning toward the driveshaft. I noted that you had it balanced... I wonder what balancing procedure they used.

When I installed 3.73's in my 94 Z28 (from 3.23's) with a steel shaft it acquired a major vibration at the same speed. I purchased a Lingenfelter internally balanced 3.5" aluminum shaft and the problem was fixed.

Just food for thought...

Good luck

When I installed 3.73's in my 94 Z28 (from 3.23's) with a steel shaft it acquired a major vibration at the same speed. I purchased a Lingenfelter internally balanced 3.5" aluminum shaft and the problem was fixed.

Just food for thought...

Good luck

#9

Although your adjustable torque arm may be a possibility, I'm leaning toward the driveshaft. I noted that you had it balanced... I wonder what balancing procedure they used.

When I installed 3.73's in my 94 Z28 (from 3.23's) with a steel shaft it acquired a major vibration at the same speed. I purchased a Lingenfelter internally balanced 3.5" aluminum shaft and the problem was fixed.

Just food for thought...

Good luck

When I installed 3.73's in my 94 Z28 (from 3.23's) with a steel shaft it acquired a major vibration at the same speed. I purchased a Lingenfelter internally balanced 3.5" aluminum shaft and the problem was fixed.

Just food for thought...

Good luck

#10

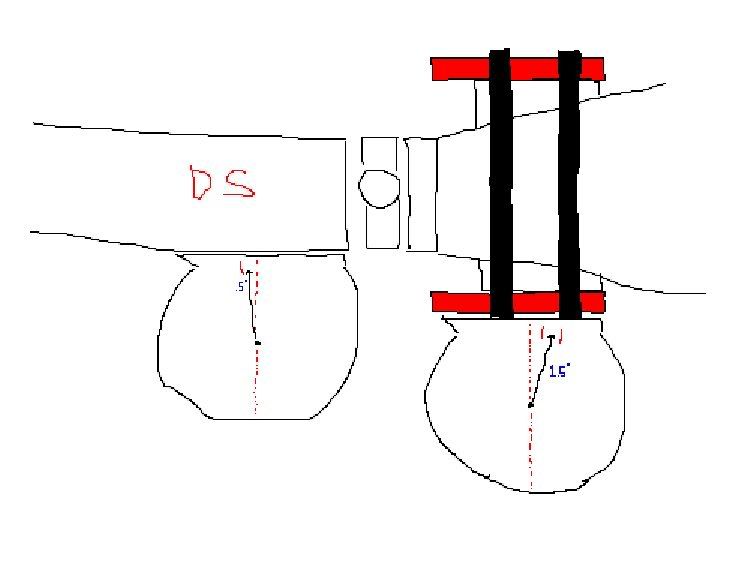

I checked the pinion angle again last night. The rearend was at -1.5* and the driveshaft was at .5*.

By my calculations that's a -1*.

I did notice however that the driveshaft was pushed all the way into the transmission...I remember when putting in the rearend that I had to shove it forwards to get it to align with the LCAs. Also, the clam shell on the transmission, where it holds the TA it was tough to get bolted down because it was shoved all the way forward.

Could this by chance cause the vibration?

I am going to take out the aluminum driveshaft tonight and put in a steel one and see if that fixes the problem. No matter how much I DON'T think it will. It's worth a try atleast to eliminate it from the problem.

By my calculations that's a -1*.

I did notice however that the driveshaft was pushed all the way into the transmission...I remember when putting in the rearend that I had to shove it forwards to get it to align with the LCAs. Also, the clam shell on the transmission, where it holds the TA it was tough to get bolted down because it was shoved all the way forward.

Could this by chance cause the vibration?

I am going to take out the aluminum driveshaft tonight and put in a steel one and see if that fixes the problem. No matter how much I DON'T think it will. It's worth a try atleast to eliminate it from the problem.

#14

10 Second Club

iTrader: (22)

Join Date: Feb 2006

Location: coastal N.C.

Posts: 536

Likes: 0

Received 0 Likes

on

0 Posts

I've seen it in helicopters (and other high weight, high rpm rotating assy) .. granted we're not talking the same rpm's or weight but still, harmonics come in phases (cycles) of vibration. Like an out of balance tire .. the whoom whoom whoom sound. I'm skeptical of the driveshaft 1st, wheels second because of the rotating mass in ea. ... swap the drive shaft, for ***** and giggles, and see what that does. Got a friend wiht the proper size drive shaft?

#15

10 Second Club

iTrader: (22)

Join Date: Feb 2006

Location: coastal N.C.

Posts: 536

Likes: 0

Received 0 Likes

on

0 Posts

I just noticed something! I had seen it on a post in here before: take the rear cover off of your NEW 10 bolt and check everything out (bolts to the ring gear esp.). I've seen it where the ring gear bolts began backing out.

#16

The car is on the lift now. I am going to replace the aluminum DS with the steel one I had in there before and see how it goes.

junior28570, when I installed the rearend into my car I did not mess at all with it. It came out of another car with 5k miles on it, I did however take off the cover and weld the axle tubes then put it all back on. The only thing that sticks out in my mind though is that I did NOT adjust the axle stops(the two screws that are supposed to hold the rearend from deflecting). I just put them back on with the assumption that they were already in the right place.

Do you think that could cause anything?

junior28570, when I installed the rearend into my car I did not mess at all with it. It came out of another car with 5k miles on it, I did however take off the cover and weld the axle tubes then put it all back on. The only thing that sticks out in my mind though is that I did NOT adjust the axle stops(the two screws that are supposed to hold the rearend from deflecting). I just put them back on with the assumption that they were already in the right place.

Do you think that could cause anything?

#17

Well I ended up getting the car in the air and finding one of the bolts on the driveshaft was loose. Also, I went back and checked the TA cover, retightened all the bolts to 30ft-lbs and then hand tightened the preload bolts and got those situated. I never replaced the driveshaft because I hoped what I had done had fixed the problem.

WRONG. A little better...still there. Tomorrow, steel driveshaft(I'll take the aluminum to get rebalanced) and I'll bring the pinion angle to 0*. This is getting on my last freaking nerve.

WRONG. A little better...still there. Tomorrow, steel driveshaft(I'll take the aluminum to get rebalanced) and I'll bring the pinion angle to 0*. This is getting on my last freaking nerve.

#18

TECH Fanatic

iTrader: (5)

you dont want to bring the pinion angle to 0...when you put the drivetrain under load the pinion will want to raise up hence the reason why you should run a negative angle. You are at -2 right now which is good for street driving. Mine is set at -2.5. I have a feeling making your angle 0 will not help at all

#19

OK, my 2cents. I have had these vibration problems, most recently on my 3rd gen but also 2 years ago on my 98. Here is what I learned the hard way:

1. There are several versions around concerning "pinion angle". One is what appears to be cited in this thread where it is simply the angle between the driveshaft and the pinion shaft. Another version is that it is the angle between the crankshaft and the pinion shaft.

What I have found to reduce the vibration (mine was horrible at 60+) is to keep the driveshaft working angles (both front and rear) less than 3deg - they also need to be opposite (one positive, one negative). It is also important (from a vibration standpoint) that they be nearly equal. Also, you do not want working angles of zero - this is what I hear from my circle track buddies.

For both my F bodies where I have altered the suspension, I have had trouble reducing these working angles. The line of the crankshaft is typically below the line of the pinion shaft which says that under hard acceleration my working angles increase rather than decrease. On my third gen I had cut the rear springs about 1/2 coil (Eibach's) to get the stance right - I totally screwed up the driveshaft alignment having working angles of around 4.5 degrees. Adjusting the pinion to point down reduced the rear angle but increased the front DS angle - little effect on vibration. I had to buy a new set of springs to get back to ~3 deg working angles.

1. There are several versions around concerning "pinion angle". One is what appears to be cited in this thread where it is simply the angle between the driveshaft and the pinion shaft. Another version is that it is the angle between the crankshaft and the pinion shaft.

What I have found to reduce the vibration (mine was horrible at 60+) is to keep the driveshaft working angles (both front and rear) less than 3deg - they also need to be opposite (one positive, one negative). It is also important (from a vibration standpoint) that they be nearly equal. Also, you do not want working angles of zero - this is what I hear from my circle track buddies.

For both my F bodies where I have altered the suspension, I have had trouble reducing these working angles. The line of the crankshaft is typically below the line of the pinion shaft which says that under hard acceleration my working angles increase rather than decrease. On my third gen I had cut the rear springs about 1/2 coil (Eibach's) to get the stance right - I totally screwed up the driveshaft alignment having working angles of around 4.5 degrees. Adjusting the pinion to point down reduced the rear angle but increased the front DS angle - little effect on vibration. I had to buy a new set of springs to get back to ~3 deg working angles.

#20

12 Second Club

iTrader: (4)

Join Date: Aug 2003

Location: NorCal

Posts: 1,618

Likes: 0

Received 0 Likes

on

0 Posts

Yeah you dont want it at 0*...... if you set it to 0* then when driving under load it will be +X*... you dont want that. The reason people set them at say -2* is so when you get on it, or even regular cruising load, the actual driving angle moves towards 0*. The goal is 0* while driving or under load. Thats why cars with rod end suspension you can get away with -1*, because there is less "give" in the components. Cars with poly end suspension need more - * because is has more "give" then the rod ends. Lastly.. stock rubber suspensions need even more - *.

If its not right youll have vibration.. and possibly eat up U joints. Did you check your U joints after finding the loose bolts? You should, you may have damaged it... causing vibration even after you tighten it.

If its not right youll have vibration.. and possibly eat up U joints. Did you check your U joints after finding the loose bolts? You should, you may have damaged it... causing vibration even after you tighten it.