Is this the correct way......

#1

On The Tree

Thread Starter

iTrader: (6)

Join Date: Jul 2006

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

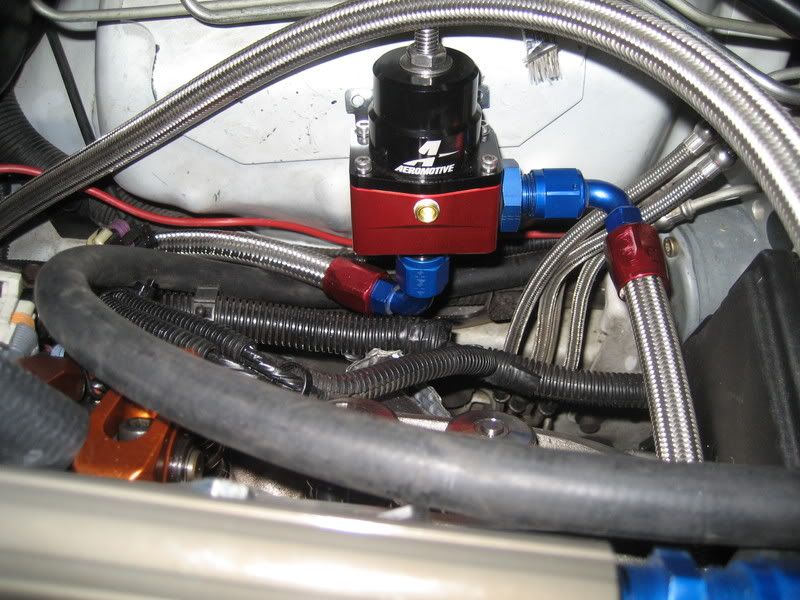

This is my first time building a fuel system and want to make sure all is well.

First off I am going to be making around 750 to the wheels. At first its going to be a mild tune with low boost (7to 8 pounds). I am running twin walbro in the tank.

[IMG] [/IMG]

[/IMG]

I have the two pumps running into a t-fitting and into one line up to the fuel supply nipples on the bottom of the top of the fuel bucket.

Then I got those quick connects that I was told to get

Then it runs into -8an lines to a fuel filter under the car and into the drivers side of the fuel rail.

[IMG] [/IMG]

[/IMG]

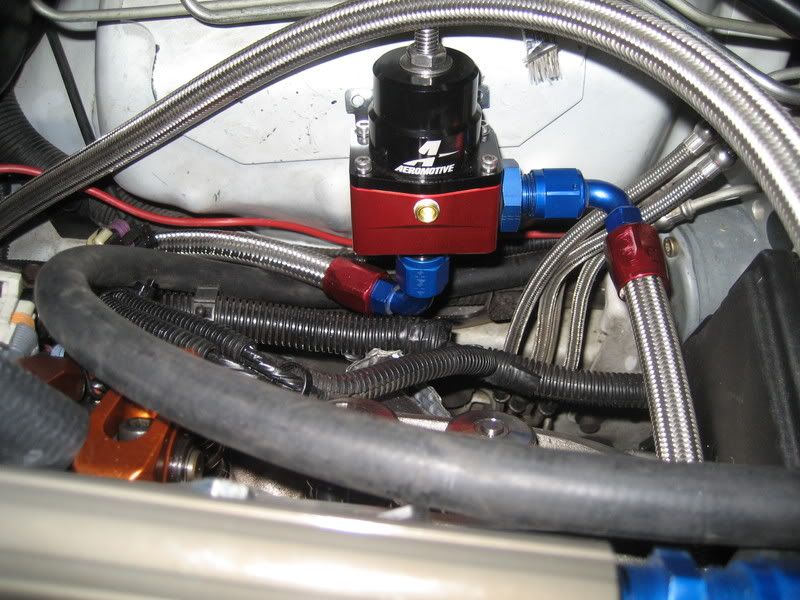

The fuel rails on the back are connected with -8an lines(not shown)

Then the return line comes out of the pass side of the fuel rail into the fuel pressure regulator. One side of the regulator is going to be plugged. THen a -8 an line out the bottom of the fuel pressure regulator back to the tank

Does this look correct to have enough fuel to support 750 rwhp

I am affraid that having the two pump running into a t fitting is going to cause a restrticion and not work properly.

The inectors are 60lbs.

THanks

Chris J

First off I am going to be making around 750 to the wheels. At first its going to be a mild tune with low boost (7to 8 pounds). I am running twin walbro in the tank.

[IMG]

[/IMG]

[/IMG]I have the two pumps running into a t-fitting and into one line up to the fuel supply nipples on the bottom of the top of the fuel bucket.

Then I got those quick connects that I was told to get

Then it runs into -8an lines to a fuel filter under the car and into the drivers side of the fuel rail.

[IMG]

[/IMG]

[/IMG]The fuel rails on the back are connected with -8an lines(not shown)

Then the return line comes out of the pass side of the fuel rail into the fuel pressure regulator. One side of the regulator is going to be plugged. THen a -8 an line out the bottom of the fuel pressure regulator back to the tank

Does this look correct to have enough fuel to support 750 rwhp

I am affraid that having the two pump running into a t fitting is going to cause a restrticion and not work properly.

The inectors are 60lbs.

THanks

Chris J

#3

Teching In

Join Date: Oct 2003

Location: Western Nebraska

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

In my opinion, you have two issues. Just like you mentioned, restriction at the "T" and also getting through the stock 90 deg top of the fuel module. Those are like 5/16 bore diameter. The 2nd issue I see is I dont think 60's will deliver enough for a 750rwhp FI motor. I would put a hole where the pressure sensor is and install a bulkhead fitting through there, plumb one pump through the orgininal and one through the bulkhead fitting, then Y them togather after the tank with a an Y. Are you going to run both pumps all the time or are you planning a hobbs switch? I would suggest the 2nd, wire the 2nd fuel pump to come on with boost, that way you are not overheating the fuel. I would feel good about the setup you have to maybe 550-600rwhp, after that, I would be afraid of leaning out. Good Luck with your project!

#4

FormerVendor

iTrader: (33)

Join Date: Feb 2002

Location: Lake in the Hills, IL

Posts: 5,052

Likes: 0

Received 0 Likes

on

0 Posts

Your fuel line setup is fine (don't like the cut out in the bucket but you should work) we have not seen any restrictions in tests with the stock neck. And boost referenced your 60# have made over 800rwhp.

Nate

Nate

#5

On The Tree

Thread Starter

iTrader: (6)

Join Date: Jul 2006

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

The whole in the side of the bucket was cut before i had the car. I did not know it was cut up like that till i pulled out the bucket.

I am running a hobbs switch for the second pump.

I will keep this setup and see how it does when i go dyno the car. I will post up what happens. I am only looking for 600 to the wheels as of right now. I need to get use to the power and it will give me room to make more so i do not get bored with the hp to fast.

I am running a hobbs switch for the second pump.

I will keep this setup and see how it does when i go dyno the car. I will post up what happens. I am only looking for 600 to the wheels as of right now. I need to get use to the power and it will give me room to make more so i do not get bored with the hp to fast.

#6

On The Tree

Thread Starter

iTrader: (6)

Join Date: Jul 2006

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

In my opinion, you have two issues. Just like you mentioned, restriction at the "T" and also getting through the stock 90 deg top of the fuel module. Those are like 5/16 bore diameter. The 2nd issue I see is I dont think 60's will deliver enough for a 750rwhp FI motor. I would put a hole where the pressure sensor is and install a bulkhead fitting through there, plumb one pump through the orgininal and one through the bulkhead fitting, then Y them togather after the tank with a an Y. Are you going to run both pumps all the time or are you planning a hobbs switch? I would suggest the 2nd, wire the 2nd fuel pump to come on with boost, that way you are not overheating the fuel. I would feel good about the setup you have to maybe 550-600rwhp, after that, I would be afraid of leaning out. Good Luck with your project!

I am going to fix a couple parts of the system and see how it all works out.