Oil pump priming tool won't fit

#1

Staging Lane

Thread Starter

iTrader: (5)

Join Date: Jan 2010

Location: Fort Lauderdale, FL

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Hi all (again)

After getting the oil pan pan on and verifying the clearance on my modified dipstick tube (for 4-bolt splayed mains), I went ahead and started priming the motor.

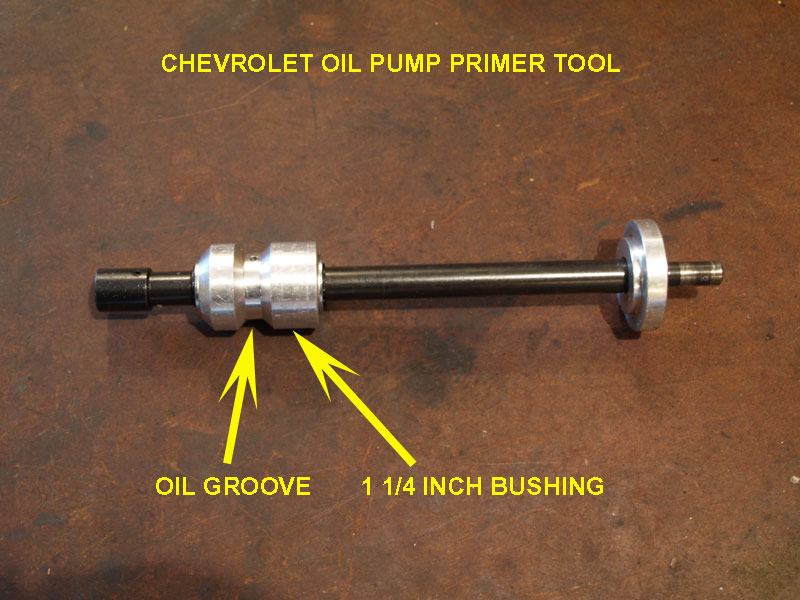

I am using a Generic (OEM brand) SBC priming tool (with a sleeve) to prime my oil pump. the tool slides down the hole in the block and meets with the oil pump drive shaft, but it appears that the sleeve on the tool (the one that seals up the big opening to provide oil pressure to both sides of the motor) is bottoming out on the cam gear and not allowing the spline on the tool to fully seat on the notch on the oil pump drive shaft. When i run the drill on the tool, it keeps jumping out of the notch on the oil pump drive shaft (since its not fully seated in there).

Is it just the tool I am using? I noticed that most use the proform tool. I just want to confirm before I go buying another tool. Any ideas? Thanks in advance!

After getting the oil pan pan on and verifying the clearance on my modified dipstick tube (for 4-bolt splayed mains), I went ahead and started priming the motor.

I am using a Generic (OEM brand) SBC priming tool (with a sleeve) to prime my oil pump. the tool slides down the hole in the block and meets with the oil pump drive shaft, but it appears that the sleeve on the tool (the one that seals up the big opening to provide oil pressure to both sides of the motor) is bottoming out on the cam gear and not allowing the spline on the tool to fully seat on the notch on the oil pump drive shaft. When i run the drill on the tool, it keeps jumping out of the notch on the oil pump drive shaft (since its not fully seated in there).

Is it just the tool I am using? I noticed that most use the proform tool. I just want to confirm before I go buying another tool. Any ideas? Thanks in advance!

#4

TECH Regular

iTrader: (6)

Join Date: Aug 2010

Location: Baton Rouge, LA

Posts: 401

Likes: 0

Received 0 Likes

on

0 Posts

I bet you go through a few batteries on those cordless drills. I just primed my motor last week and had to spin it for 20+ minutes before the last rocker had oil. My uncle has a primer tool on a corded drill. I know he didn't buy it....pretty sure he made it from an old sbc distributor.

#6

Staging Lane

Thread Starter

iTrader: (5)

Join Date: Jan 2010

Location: Fort Lauderdale, FL

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

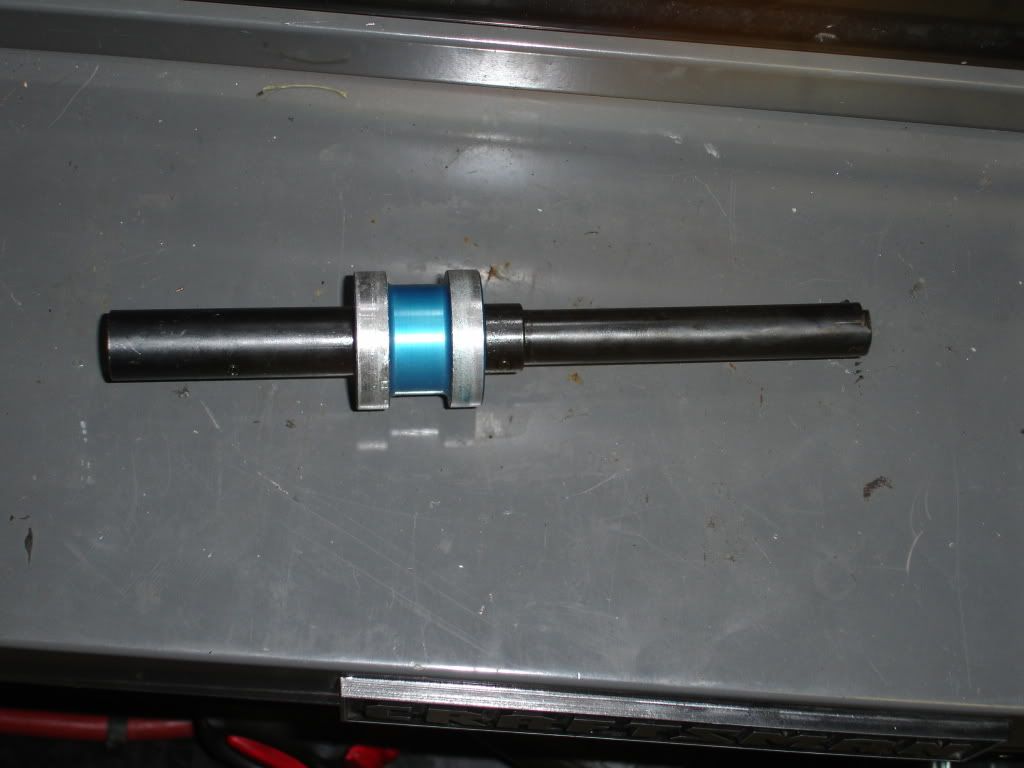

The picture you show has a beveled bushing. Mine is just straight. Here is a pic of the tool I am using

#7

Village Troll

iTrader: (2)

I take it the bushing is fixed? Remove it if you can. It will work fine. I used a right angle drill. Depending on the size of the drill you may have to cut the shaft down in order for it all to fit under the cowl.

Trending Topics

#8

TECH Veteran

Mine looks like that and worked fine. If the bushing is removed, you won't get any pressure.

#10

TECH Veteran

#11

Staging Lane

Thread Starter

iTrader: (5)

Join Date: Jan 2010

Location: Fort Lauderdale, FL

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Problem solved! Turns out the spline at the bottom of the tool was just a tad wide and didn't fully slide into the notch on the oilp pump drive shaft. Ground it down a hair and works perfectly now!

Thanks for the help!

Thanks for the help!