Cam bearing installation tools/honing tools

#1

Got a quote for $45 to install cam bearings, but I'd like to do it myself and keep the tools. Do any of you have experience with either this one from Allstar performance

http://www.summitracing.com/parts/aa...FWNgMgodGC0A-A

Or this summit one

http://m.summitracing.com/parts/sum-...FYxaMgodwR4ATw

Or this proform one

http://www.jegs.com/i/Proform/778/66...FScSMwodlHAA4g

Or is this something I should leave up to a machinist

And for honing, there's this pretty cool brush research one I've seen a few times on YouTube and in a bunch or articles

http://www.brushresearch.com/cylinder_hones.php

Or go with a normal old fashioned style one not necessarily from harbor freight

http://www.harborfreight.com/4-inch-...one-97164.html

Bowtienut said his cylinders were out of round by as much as 0.002" on only 80k mile engine, mine has 110k, I'd like to just do a ball hone myself and new rings rather than the $80 "take it back to round" I was quoted, I know it's dumb to bitch about $80 but tons of running engines have been fine with just a ball hone and I'm trying to do as much as I can myself for the learning experience and "I did it" factor.

http://www.summitracing.com/parts/aa...FWNgMgodGC0A-A

Or this summit one

http://m.summitracing.com/parts/sum-...FYxaMgodwR4ATw

Or this proform one

http://www.jegs.com/i/Proform/778/66...FScSMwodlHAA4g

Or is this something I should leave up to a machinist

And for honing, there's this pretty cool brush research one I've seen a few times on YouTube and in a bunch or articles

http://www.brushresearch.com/cylinder_hones.php

Or go with a normal old fashioned style one not necessarily from harbor freight

http://www.harborfreight.com/4-inch-...one-97164.html

Bowtienut said his cylinders were out of round by as much as 0.002" on only 80k mile engine, mine has 110k, I'd like to just do a ball hone myself and new rings rather than the $80 "take it back to round" I was quoted, I know it's dumb to bitch about $80 but tons of running engines have been fine with just a ball hone and I'm trying to do as much as I can myself for the learning experience and "I did it" factor.

Last edited by bufmatmuslepants; 10-08-2013 at 06:06 AM.

#2

TECH Fanatic

iTrader: (10)

Installing cam bearings is easy, just a little time consuming. Especially if you miss the hole alignment. But investing in a good tool would be worth it if you plan on doing it alot. Otherwise its easier to have a have a shop do it.

As for a cylinder being out of round?? Were those measurements taken without a torque plate on?A plate will make a big difference when its bolted to the block. That's why they're used for boring, honing and why a good shop will ask if you're using bolts or studs. If using studs, they will want the studs you'll be using. The clamping force is different and has an effect on the bore when machining.

A bottle or ball hone is used just mainly for knocking off a glaze for new rings to seat in. They are still retty abrasive so use alot of lubricant. Preferrably spraying WD40 while your honing. 4-6 swipes up and down the bore is suffice using the 240 grit.

As for a cylinder being out of round?? Were those measurements taken without a torque plate on?A plate will make a big difference when its bolted to the block. That's why they're used for boring, honing and why a good shop will ask if you're using bolts or studs. If using studs, they will want the studs you'll be using. The clamping force is different and has an effect on the bore when machining.

A bottle or ball hone is used just mainly for knocking off a glaze for new rings to seat in. They are still retty abrasive so use alot of lubricant. Preferrably spraying WD40 while your honing. 4-6 swipes up and down the bore is suffice using the 240 grit.

#3

I'm reusing stock head bolts, so did bowtienut, I'm 90% sure I'm going to do the hone myself if my dial indicators don't indicate anything over 0.003 out of round, my machinist said most cases require an overbore and I don't want to get new pistons, which require balancing, and then I might as well get rods and now were snowballing. I just want to deglaze the walls for new stock replacement rings.

#4

TECH Resident

iTrader: (12)

I own and use the cam bearing install tool from lisle. I think it is a great investment and has payed for itself many times over the initial cost throughout the years. Well worth the money. Be sure to chamfer the edges on the bearings and make sure the bores are clean. Get an extra set of bearings in case you mess up on the first try.

#6

TECH Enthusiast

iTrader: (4)

I own and use the cam bearing install tool from lisle. I think it is a great investment and has payed for itself many times over the initial cost throughout the years. Well worth the money. Be sure to chamfer the edges on the bearings and make sure the bores are clean. Get an extra set of bearings in case you mess up on the first try.

I have the same tool. It works great. I praticed with the old bearings in another block first.

Trending Topics

#8

TECH Resident

I did my own cam bearings as well.

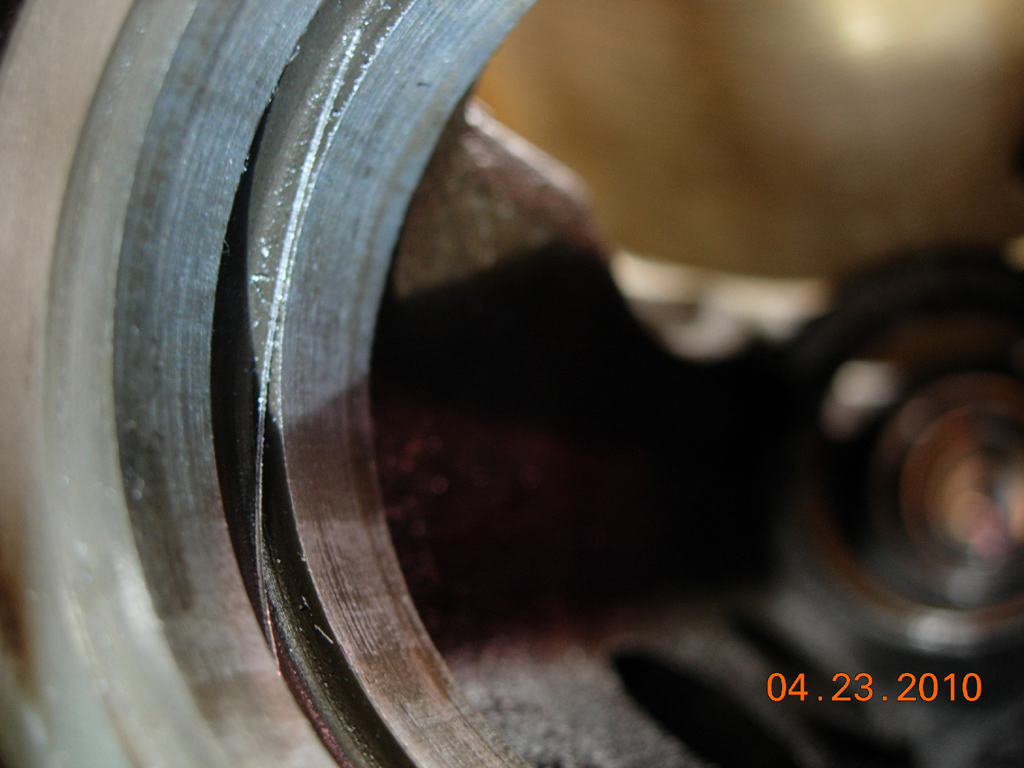

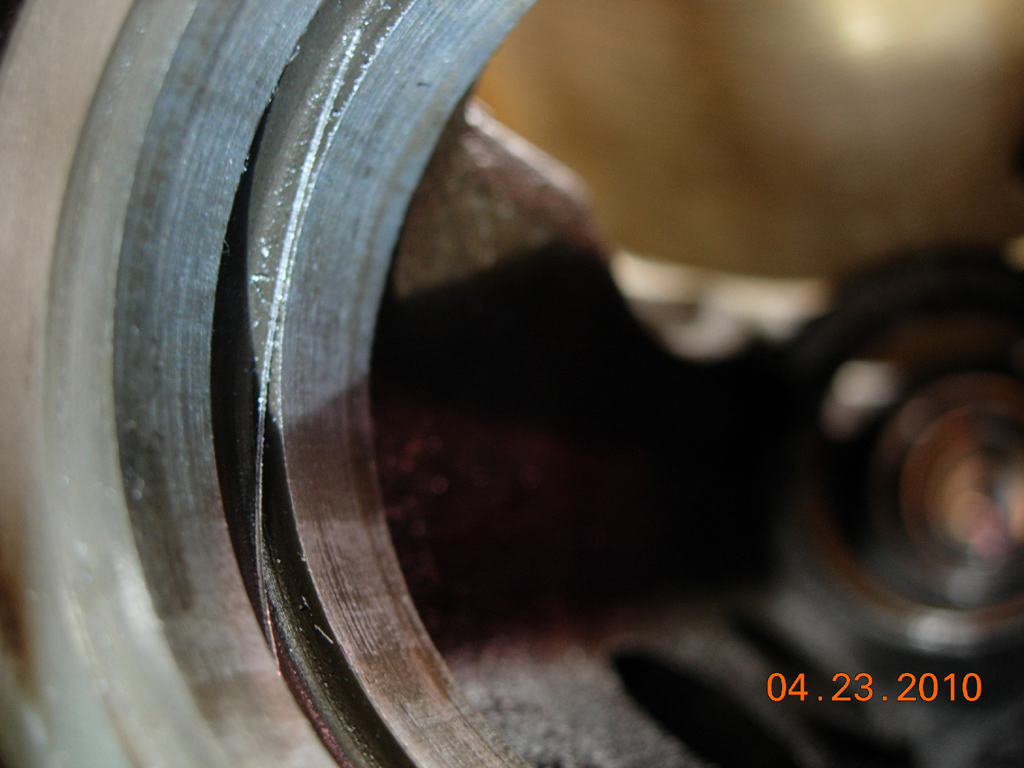

You need to be careful of the sharp ridges that may be on the inside of the cam bores in the oil passages. The edges were so sharp in my block that I had to "break" them. The edges were shaving off quite a bit of bearing material upon install and leaving huge shards in the oil passages.

This also forced me to wash down the block before installing the bearings after I got done breaking the edges. I had to use a scotch brite dremel wheels with a dremel attachement to break the edges.

Scotch brite material is small enough to pass through an oil filter. If one does not wash the block, rifle brush the oil galleys(knocking out all plugs), etc.... then it can tear your new bearings all to pieces as the material flows with the oil through the engine..just like liquid sand paper.

It was a great learning experience and I got a ton of great advice from another board(it's almost dead now...the tech section is limping along ok though...).

Just be aware that it may more work than you think. It was for me, but I'm glad I did it. Pics of the shards before the work and the tools I used to fix the problem below them.

Oh, get two or three sets of bearings. You will need to practice to get a feel for how to install them. Install 1 and 2 from the back side, install 3, 4, and 5 from the front. This way, you get to use the alignment of the tool to center them and you have less of a chance to hammer them in crooked. I do advise a cam bearing tool with a full soft face to the bearing surface. I have a tool with just an o-ring....it will work, but you have to be very careful when removing it or you will scuff and scratch the bearing surface.

Information on clocking the bearings...

http://www.mellingdurabond.com/Porta...20Bulletin.pdf

I'll also try to pull together my threads from the other board. If may help to read what I had to do a few years ago.

You need to be careful of the sharp ridges that may be on the inside of the cam bores in the oil passages. The edges were so sharp in my block that I had to "break" them. The edges were shaving off quite a bit of bearing material upon install and leaving huge shards in the oil passages.

This also forced me to wash down the block before installing the bearings after I got done breaking the edges. I had to use a scotch brite dremel wheels with a dremel attachement to break the edges.

Scotch brite material is small enough to pass through an oil filter. If one does not wash the block, rifle brush the oil galleys(knocking out all plugs), etc.... then it can tear your new bearings all to pieces as the material flows with the oil through the engine..just like liquid sand paper.

It was a great learning experience and I got a ton of great advice from another board(it's almost dead now...the tech section is limping along ok though...).

Just be aware that it may more work than you think. It was for me, but I'm glad I did it. Pics of the shards before the work and the tools I used to fix the problem below them.

Oh, get two or three sets of bearings. You will need to practice to get a feel for how to install them. Install 1 and 2 from the back side, install 3, 4, and 5 from the front. This way, you get to use the alignment of the tool to center them and you have less of a chance to hammer them in crooked. I do advise a cam bearing tool with a full soft face to the bearing surface. I have a tool with just an o-ring....it will work, but you have to be very careful when removing it or you will scuff and scratch the bearing surface.

Information on clocking the bearings...

http://www.mellingdurabond.com/Porta...20Bulletin.pdf

I'll also try to pull together my threads from the other board. If may help to read what I had to do a few years ago.

Last edited by ACE1252; 10-09-2013 at 12:44 PM.