Speedometer delayed......

#41

Village Troll

iTrader: (2)

You have the weirdest **** happen to you. I am beginning to think you have some sort of broad harmonic issue going that is breaking things. I shifted at 7200rpm with my still factory stock alternator/stock pulleys with no issue, as well as a 10+ y/o steering pump using the stock bolts. Are you sure the pulley and p/s bolts were tight before this happened?

#42

TECH Addict

Thread Starter

You have the weirdest **** happen to you. I am beginning to think you have some sort of broad harmonic issue going that is breaking things. I shifted at 7200rpm with my still factory stock alternator/stock pulleys with no issue, as well as a 10+ y/o steering pump using the stock bolts. Are you sure the pulley and p/s bolts were tight before this happened?

Yes. The pulley sheared. I'll try and get those pics up so you can see what I mean. You're probably right about a harmonic issue, but my **** was triple plane balanced to I forget what, I think 0.5g at 1500rpms.....

The ps bolts were definitely tight. I checked my belt alignment and all that looks straight. I'm not chucking belts.

With all that and the alternator cutting out, I'm leaning to overspeed of my accessories. I've seen some ls1 guys post up overspeed issues with their alternators too.

It could be the alternator, but I'm not sure replacing it will fix the issue as the new one might do the same thing. And the last alternator I had didn't cut out over 6k, but it did Chuck the pulley over 6k.

Last edited by hrcslam; 01-18-2016 at 07:42 PM.

#43

Village Troll

iTrader: (2)

Again. Weird ****. It doesn't make sense how those two things would just up and break without some sort of vibration going on, whether they're loose or vibrating themselves to death. Also, it's RPM. Not RPMssssssss. Give the readers a little credit in the ability to distinguish the difference.

#44

TECH Addict

Thread Starter

I will say I cheaped out on the AC though after the pulley sheared. Money was tight so I got the cheapest kit available on Rock Auto. I'm running an AC delete pulley for now. Come spring I'll put in a name brand one. But by then I'll have the underdrive pulley in too.

Also, it's RPM. Not RPMssssssss. Give the readers a little credit in the ability to distinguish the difference.

Last edited by hrcslam; 01-19-2016 at 01:43 PM.

#46

Man-Crush Warning

iTrader: (1)

Yes. The pulley sheared. I'll try and get those pics up so you can see what I mean. You're probably right about a harmonic issue, but my **** was triple plane balanced to I forget what, I think 0.5g at 1500rpms.....

The ps bolts were definitely tight. I checked my belt alignment and all that looks straight. I'm not chucking belts.

With all that and the alternator cutting out, I'm leaning to overspeed of my accessories. I've seen some ls1 guys post up overspeed issues with their alternators too.

It could be the alternator, but I'm not sure replacing it will fix the issue as the new one might do the same thing. And the last alternator I had didn't cut out over 6k, but it did Chuck the pulley over 6k.

The ps bolts were definitely tight. I checked my belt alignment and all that looks straight. I'm not chucking belts.

With all that and the alternator cutting out, I'm leaning to overspeed of my accessories. I've seen some ls1 guys post up overspeed issues with their alternators too.

It could be the alternator, but I'm not sure replacing it will fix the issue as the new one might do the same thing. And the last alternator I had didn't cut out over 6k, but it did Chuck the pulley over 6k.

A CS144 "should" output power well past 6k rpm. I do not think it has the smarts to de-energize its field so if I had to take a guess I would say the springs can't hold the brushes on shaft.

#47

TECH Addict

Thread Starter

Stock red line would put max alternator rpm at just under 18k. I'm maxing it out at just under 21k.

It could very well be the brushes loosing accuracy from too much rpm. The fix is the same regardless though, underdrive pulley. Instead of doing just the alternator though, I'm doing the crank to reduce overspeed on my AC and PS too. I don't care about any power it'll save me, I just want my accessories to live.

Also, I have 24k miles on my engine since rebuild. These issues may be showing up, that others may not see, because of how much I drive my car.

Last edited by hrcslam; 01-22-2016 at 07:23 PM.

#48

TECH Addict

Thread Starter

Garhh!!! The under drive pulley didn't work. This has me stumped. It cuts out at the exact same place, the exact same way. With the under drive pulley my max Alternator RPM is 13,800 RPM. That would be like my engine at 4,500 RPM before the pulley (where I saw no voltage drop). So it's likely not the Alternator. Now what? I don't think it's belt slip, I'm running a Gatorback 4060600 belt (60"). Plus it just drops out instantly and completely, it's not gradual as RPM rises. I could try a 59.5" belt, but I honestly don't think it'll make a difference.

It seems like it's commanded by the PCM, but I see no place in the tune to do that. Maybe I should try the Lamp in the L wire mod from a IGN lead?

It seems like it's commanded by the PCM, but I see no place in the tune to do that. Maybe I should try the Lamp in the L wire mod from a IGN lead?

Last edited by hrcslam; 02-06-2016 at 09:27 AM.

#49

TECH Addict

Thread Starter

Speaking of the weirdish **** happening to me.....

So today I decided to check out the alternator signal wire to see if maybe somehow at 6K RPM it was loosing contact. It checked out o.k. But wiring in an alternate signal wire (with bulb) should be easy.

Anywho, while poking around under the hood I noticed my brand new serpentine belt was missing a rib, throughout the entire length. I noticed that the belt was running good on all pulleys (aft 5 ribs of it anyway) except on the AC Bypass pulley where it was running on the 5 front ribs. Hmm. Misalignment maybe?

Turns out the plastic AC bypass pulley had worn around the base where it sits around the bearing, the metal bearing. This gave it play that caused it to wobble. Which in turn cut my belt and wrapped the last missing (no longer missing, cause I found it) rib around the aft side of the pulley (not sure how it ended up there. ARGH! New belt and pulley will be installed tomorrow (I was lucky enough to find this before my local store closed and they could get it in by tomorrow). It also cut halfway through one of my heater hoses, the one that routes in front of the Power Steering pulley. So I'll be fixing that tomorrow too.

I'm happy I found it when I did, and not after completely cutting through the heater hose, or chucking that pulley too, while on the highway. But, man, WTF?!

So today I decided to check out the alternator signal wire to see if maybe somehow at 6K RPM it was loosing contact. It checked out o.k. But wiring in an alternate signal wire (with bulb) should be easy.

Anywho, while poking around under the hood I noticed my brand new serpentine belt was missing a rib, throughout the entire length. I noticed that the belt was running good on all pulleys (aft 5 ribs of it anyway) except on the AC Bypass pulley where it was running on the 5 front ribs. Hmm. Misalignment maybe?

Turns out the plastic AC bypass pulley had worn around the base where it sits around the bearing, the metal bearing. This gave it play that caused it to wobble. Which in turn cut my belt and wrapped the last missing (no longer missing, cause I found it) rib around the aft side of the pulley (not sure how it ended up there. ARGH! New belt and pulley will be installed tomorrow (I was lucky enough to find this before my local store closed and they could get it in by tomorrow). It also cut halfway through one of my heater hoses, the one that routes in front of the Power Steering pulley. So I'll be fixing that tomorrow too.

I'm happy I found it when I did, and not after completely cutting through the heater hose, or chucking that pulley too, while on the highway. But, man, WTF?!

#50

Man-Crush Warning

iTrader: (1)

If you wanna get crazy, setup some probe to verify you have an AC voltage prior to bridge and DC in at field energizer. Damn tough to do at WOT though. A field collapse would def be a on/off sort of thing but IDK if the bridge is smart enough to do that on its on. IF its the alternator doing all this.

#51

TECH Addict

Thread Starter

If you wanna get crazy, setup some probe to verify you have an AC voltage prior to bridge and DC in at field energizer. Damn tough to do at WOT though. A field collapse would def be a on/off sort of thing but IDK if the bridge is smart enough to do that on its on. IF its the alternator doing all this.

#52

Man-Crush Warning

iTrader: (1)

Tons of info if you are bored

http://www.pirate4x4.com/tech/billavista/Wiring/Part2/

I bought the pigtail in the idea to do a remote POR at battery but have yet to get around to it. Prob will also see if I can wire in a pin L excitation setup.

Last edited by Shownomercy; 02-07-2016 at 10:29 AM.

#53

TECH Addict

Thread Starter

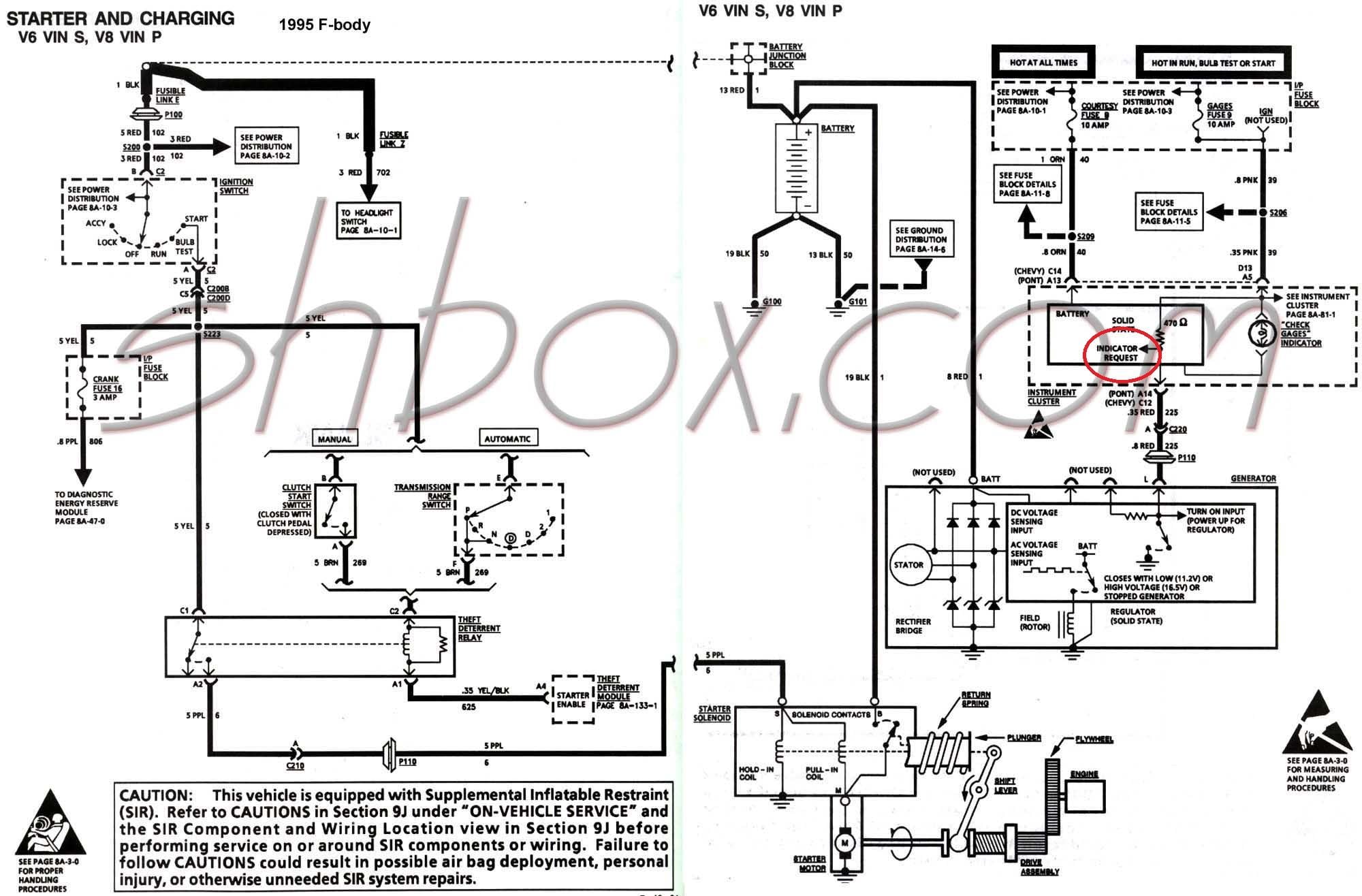

Easy enough, think its a 470ohmn resistor inline to switched 12v hot.

Tons of info if you are bored

http://www.pirate4x4.com/tech/billavista/Wiring/Part2/

I bought the pigtail in the idea to do a remote POR at battery but have yet to get around to it. Prob will also see if I can wire in a pin L excitation setup.

Tons of info if you are bored

http://www.pirate4x4.com/tech/billavista/Wiring/Part2/

I bought the pigtail in the idea to do a remote POR at battery but have yet to get around to it. Prob will also see if I can wire in a pin L excitation setup.

#54

TECH Addict

Thread Starter

A little more info, I was going to do the free A/C By pass pulley mod by using my old AC compressor. That would've given me a metal pulley at OEM specs to use. But, it turns out I sheared that pulley too! @@$)*#@$)%(@#! Sheared the exact same way as the last one. Only this one had more points to break and it did it anyway. I'm going to look through my tune and lower my A/C cutoff points under PE modes. But, that can wait until I get a new A/C Compressor in March/April (most likely March, I live in Phoenix LOL).

O.K, so I did a little more thinking about this while I'm waiting on new parts. IIRC, the Bypass pulley needs to be spaced out a bit to have proper alignment. It's a cheap Dorman unit, so not sure if it was designed for the LT1 or not (probably not). Last time I had this delete pulley in I did space it out, this time I did not. Like an idiot, this probably caused my failure. My bad. I'll space out the new one when I get it.

Anywho, when I first installed the underdrive pulley, it still did the voltage drop, but it did it at a higher RPM and not nearly as bad. It would drop over 6500 on the tach and only to about 12V instead of into the red. I think it was belt slip. I did order a new belt and that will be in today. A little more info on this. I bought the ASP Underdrive Pulley Kit, that came with the Alternator and Crank Pulleys (not harmonic balancer) and belt. ASP recommends a 60.5" belt for this kit with both pulleys. I only installed the Crank pulley. The kit I got (used on Ebay) came with a 60" Belt. ASP recommends a 59.8" belt for just the Crank pulley installed, I figured it should work..... 59.5" belt in route.

That leads to this failure. I THINK with the belt losing a rib and wrapping that around the base of the pulley, the pulleys would spin fine until I hit high RPM. Add in belt slip, only 5 ribs, and a wrapped up pulley and I could see how it would lead to sudden voltage drop due to the belt slipping completely at a certain RPM point.

I'm likely wrong on this, but I'm going to hold off on doing the Lamp mod to the L wire for a bit. I'm going to get this stuff fixed first and check it out. My Alternator is also starting to squeal. So I'm going to replace that (making sure I get OEM this time) and check it again. If it's still doing it after that, then I'll try the Lamp wire mod.

Got the heater hose fixed though.

O.K, so I did a little more thinking about this while I'm waiting on new parts. IIRC, the Bypass pulley needs to be spaced out a bit to have proper alignment. It's a cheap Dorman unit, so not sure if it was designed for the LT1 or not (probably not). Last time I had this delete pulley in I did space it out, this time I did not. Like an idiot, this probably caused my failure. My bad. I'll space out the new one when I get it.

Anywho, when I first installed the underdrive pulley, it still did the voltage drop, but it did it at a higher RPM and not nearly as bad. It would drop over 6500 on the tach and only to about 12V instead of into the red. I think it was belt slip. I did order a new belt and that will be in today. A little more info on this. I bought the ASP Underdrive Pulley Kit, that came with the Alternator and Crank Pulleys (not harmonic balancer) and belt. ASP recommends a 60.5" belt for this kit with both pulleys. I only installed the Crank pulley. The kit I got (used on Ebay) came with a 60" Belt. ASP recommends a 59.8" belt for just the Crank pulley installed, I figured it should work..... 59.5" belt in route.

That leads to this failure. I THINK with the belt losing a rib and wrapping that around the base of the pulley, the pulleys would spin fine until I hit high RPM. Add in belt slip, only 5 ribs, and a wrapped up pulley and I could see how it would lead to sudden voltage drop due to the belt slipping completely at a certain RPM point.

I'm likely wrong on this, but I'm going to hold off on doing the Lamp mod to the L wire for a bit. I'm going to get this stuff fixed first and check it out. My Alternator is also starting to squeal. So I'm going to replace that (making sure I get OEM this time) and check it again. If it's still doing it after that, then I'll try the Lamp wire mod.

Got the heater hose fixed though.

Last edited by hrcslam; 02-07-2016 at 03:10 PM.

#55

TECH Resident

The indicator request is most likely electrical "requests" to turn on the check gauges lamp. Nothing to worry about.

Terminal L is voltage for the regulator which in turn places an AC voltage on the rotor. There is some internal detection for AC voltage in the stator once the engine is started...which then provides pulse width modulation to the rotor field depending on voltage level/load.

At least, according to the factory manual.

I agree with Super Simmons. You have some weird s**t happen to you.

I don't think it's an over or under voltage issue. Your voltmeter never moves prior to it dropping. Also, if the alternator cuts off the regulator for such conditions, it's suppose to light the "check gauges" lamp....which it never does....unless your lamp is burnt out.

I'm not sure what might be causing that without doing some testing. A DMM with voltage min/max recording would help. DC amp clamp for load checks with min/max recording....and of course an oscilloscope.

Does look like you have oil pressure issues and most certainly oil control issues. Your pressure dipping is what mine used to do prior to a different oil pickup and pan....only at a much higher reading.

Terminal L is voltage for the regulator which in turn places an AC voltage on the rotor. There is some internal detection for AC voltage in the stator once the engine is started...which then provides pulse width modulation to the rotor field depending on voltage level/load.

At least, according to the factory manual.

I agree with Super Simmons. You have some weird s**t happen to you.

I don't think it's an over or under voltage issue. Your voltmeter never moves prior to it dropping. Also, if the alternator cuts off the regulator for such conditions, it's suppose to light the "check gauges" lamp....which it never does....unless your lamp is burnt out.

I'm not sure what might be causing that without doing some testing. A DMM with voltage min/max recording would help. DC amp clamp for load checks with min/max recording....and of course an oscilloscope.

Does look like you have oil pressure issues and most certainly oil control issues. Your pressure dipping is what mine used to do prior to a different oil pickup and pan....only at a much higher reading.

#56

TECH Addict

Thread Starter

The indicator request is most likely electrical "requests" to turn on the check gauges lamp. Nothing to worry about.

Terminal L is voltage for the regulator which in turn places an AC voltage on the rotor. There is some internal detection for AC voltage in the stator once the engine is started...which then provides pulse width modulation to the rotor field depending on voltage level/load.

At least, according to the factory manual.

I agree with Super Simmons. You have some weird s**t happen to you.

I don't think it's an over or under voltage issue. Your voltmeter never moves prior to it dropping. Also, if the alternator cuts off the regulator for such conditions, it's suppose to light the "check gauges" lamp....which it never does....unless your lamp is burnt out.

I'm not sure what might be causing that without doing some testing. A DMM with voltage min/max recording would help. DC amp clamp for load checks with min/max recording....and of course an oscilloscope.

Does look like you have oil pressure issues and most certainly oil control issues. Your pressure dipping is what mine used to do prior to a different oil pickup and pan....only at a much higher reading.

Terminal L is voltage for the regulator which in turn places an AC voltage on the rotor. There is some internal detection for AC voltage in the stator once the engine is started...which then provides pulse width modulation to the rotor field depending on voltage level/load.

At least, according to the factory manual.

I agree with Super Simmons. You have some weird s**t happen to you.

I don't think it's an over or under voltage issue. Your voltmeter never moves prior to it dropping. Also, if the alternator cuts off the regulator for such conditions, it's suppose to light the "check gauges" lamp....which it never does....unless your lamp is burnt out.

I'm not sure what might be causing that without doing some testing. A DMM with voltage min/max recording would help. DC amp clamp for load checks with min/max recording....and of course an oscilloscope.

Does look like you have oil pressure issues and most certainly oil control issues. Your pressure dipping is what mine used to do prior to a different oil pickup and pan....only at a much higher reading.

I did get a good 3rd gear pull in (an STS-V wanted to have some fun, it wasn't even close, lol). Speedometer still stalls out at about 105-110. I let out halfway through 4th and never saw over 110 on the Speedo meter. The STS-V then did a ricer fly by as I was slowing down. Fun times.

I'm not worried about the oil pressure. That gauge is wrong. 20 psi on that gauge is 40 on my mechanical, and the mechanical does not drop. I have a mechanical gauge permanently installed because of that gauge.

Last edited by hrcslam; 02-09-2016 at 04:42 AM.

#57

TECH Addict

Thread Starter

So I noticed the voltage drop only happens when I rev it up quickly. If I slowly bring up the RPM it doesn't do it. But the faster I rev it the worse it does it. So accelerating in gear it gets better with every gear (1st is worse, 2nd is better, 3rd even better), but it still does it. By 2nd it doesn't drop into the red anymore. In neutral I can rev it much slower and it wont do it until I hit the limiter, then it drops in to red from bouncing of the limiter (I know, I know, don't do that).

I'm thinking belt slip. Time for a 59 inch belt. I'll be picking that up this afternoon and my alternator is under warranty; it's not the AC Delco one either, ugh, it's the Ultima brand. But, I did get the lifetime warranty. So it's a free replacement. But, that could explain the Voltage drop at high RPM with the stock pulley ratios.

I'm thinking belt slip. Time for a 59 inch belt. I'll be picking that up this afternoon and my alternator is under warranty; it's not the AC Delco one either, ugh, it's the Ultima brand. But, I did get the lifetime warranty. So it's a free replacement. But, that could explain the Voltage drop at high RPM with the stock pulley ratios.

Last edited by hrcslam; 02-10-2016 at 03:45 PM.

#58

TECH Addict

Thread Starter

New Alternator (Ultima Select, which are remanufactured Delcos) and smaller belt(pn: 590k6) voltage drop is gone.

I haven't been able to see how that has effected my speedometer yet. I'll update when I have a chance to do a good 3rd gear pull.

I also found out I got the AC bypass pulley from Oreilly Auto, limited lifetime warranty. So I'm taking my bad one back for an exchange and returning the one I got from Autozone. Another free fix!

I haven't been able to see how that has effected my speedometer yet. I'll update when I have a chance to do a good 3rd gear pull.

I also found out I got the AC bypass pulley from Oreilly Auto, limited lifetime warranty. So I'm taking my bad one back for an exchange and returning the one I got from Autozone. Another free fix!

Last edited by hrcslam; 02-10-2016 at 08:46 PM.