A Little Dyno Time Today

#22

TECH Enthusiast

Thread Starter

Join Date: Jul 2008

Location: Miles City Mt

Posts: 734

Likes: 0

Received 0 Likes

on

0 Posts

Ok, I was told that the RPM Sensor on the Dyno acts up and its hard to get a constant reading. He said this was what its putting to the ground at the rollers and the TRQ Numbers were multiplied through the Diff or something of that nature. He started to explain everything and we got interrupted by another instructor who needed something. I am going to discuss this further with him tomorrow. Not sure if that clears things up or makes it more confusing.

Ty McBride

Team Leader/Owner

McBride Motorsports

Ty McBride

Team Leader/Owner

McBride Motorsports

#23

Banned

iTrader: (1)

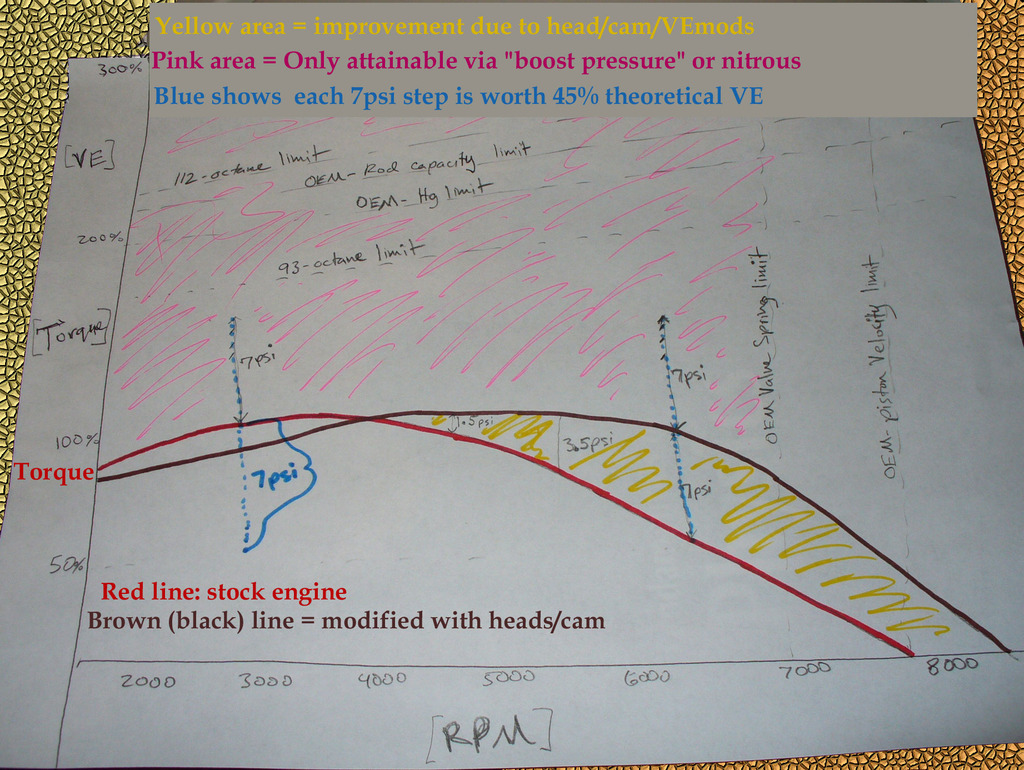

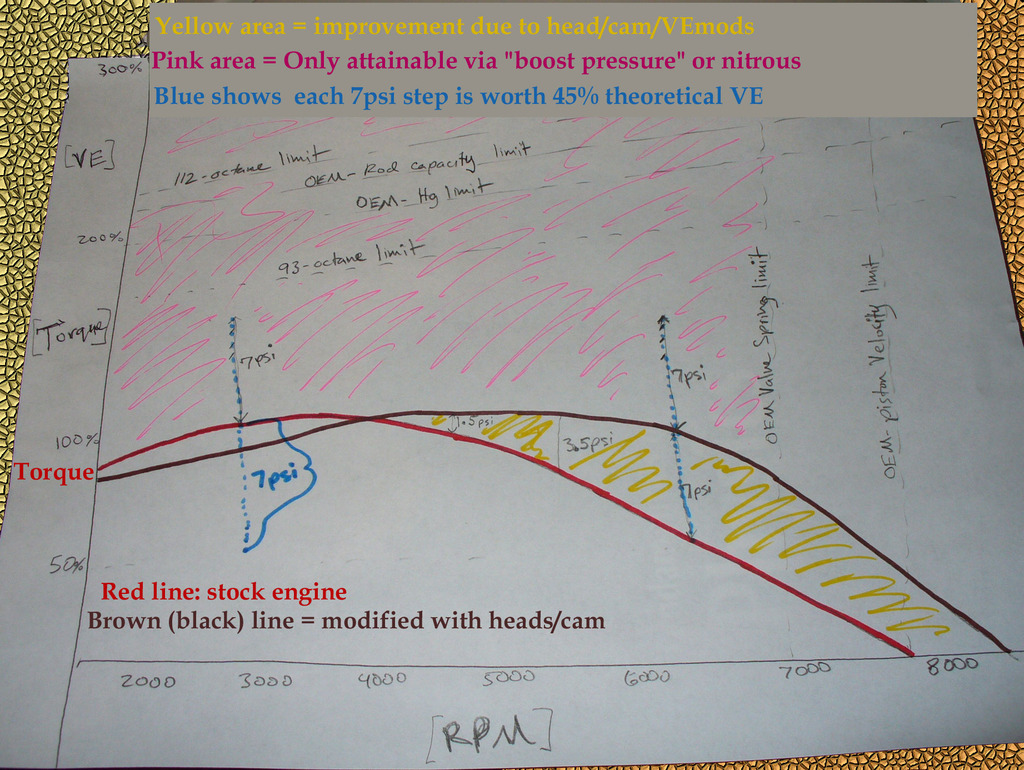

If you are on an OEM bottom end, I would pickup a turbo before I went into the head. To me, a running OEM engine is a beautiful thing, and if we avoid opening it, well, it will stay exactly like it is: running reliably. You can get the same if not more power by adding a turbo, without opening the engine, and especially without raising the RPM limit.

Here is an illustration

Notice how all of that upper area is inaccessible to us without forced induction, and yet, is perfectly compatible with our horrible fuel like 91 or 93.

camshaft modification gives us a shift, that portion on the end- and at the cost of raising our engine RPM if we really want to take full advantage of it, something I avoid doing at all costs on an OEM bearing with thin oil and a tight clearance.

The head is the center piece, but it can only take us so far, around 100%VE. It depends how bad your current heads are, when the final decision is made, turbo or head first. For example if you had an old engine 1985 Iron head, I would definetely be saying get a modern aluminum head on it with some brand new valvetrain equipment. But if the head you have is already fairly modern, with fairly low mileage equipment, then my rec leans to the turbocharger, no question.

Here is an illustration

Notice how all of that upper area is inaccessible to us without forced induction, and yet, is perfectly compatible with our horrible fuel like 91 or 93.

camshaft modification gives us a shift, that portion on the end- and at the cost of raising our engine RPM if we really want to take full advantage of it, something I avoid doing at all costs on an OEM bearing with thin oil and a tight clearance.

The head is the center piece, but it can only take us so far, around 100%VE. It depends how bad your current heads are, when the final decision is made, turbo or head first. For example if you had an old engine 1985 Iron head, I would definetely be saying get a modern aluminum head on it with some brand new valvetrain equipment. But if the head you have is already fairly modern, with fairly low mileage equipment, then my rec leans to the turbocharger, no question.

#25

TECH Addict

Ok, I was told that the RPM Sensor on the Dyno acts up and its hard to get a constant reading. He said this was what its putting to the ground at the rollers and the TRQ Numbers were multiplied through the Diff or something of that nature. He started to explain everything and we got interrupted by another instructor who needed something. I am going to discuss this further with him tomorrow. Not sure if that clears things up or makes it more confusing.

Ty McBride

Team Leader/Owner

McBride Motorsports

Ty McBride

Team Leader/Owner

McBride Motorsports

#26

TECH Addict

If you are on an OEM bottom end, I would pickup a turbo before I went into the head. To me, a running OEM engine is a beautiful thing, and if we avoid opening it, well, it will stay exactly like it is: running reliably. You can get the same if not more power by adding a turbo, without opening the engine, and especially without raising the RPM limit.

Here is an illustration

Notice how all of that upper area is inaccessible to us without forced induction, and yet, is perfectly compatible with our horrible fuel like 91 or 93.

camshaft modification gives us a shift, that portion on the end- and at the cost of raising our engine RPM if we really want to take full advantage of it, something I avoid doing at all costs on an OEM bearing with thin oil and a tight clearance.

The head is the center piece, but it can only take us so far, around 100%VE. It depends how bad your current heads are, when the final decision is made, turbo or head first. For example if you had an old engine 1985 Iron head, I would definetely be saying get a modern aluminum head on it with some brand new valvetrain equipment. But if the head you have is already fairly modern, with fairly low mileage equipment, then my rec leans to the turbocharger, no question.

Here is an illustration

Notice how all of that upper area is inaccessible to us without forced induction, and yet, is perfectly compatible with our horrible fuel like 91 or 93.

camshaft modification gives us a shift, that portion on the end- and at the cost of raising our engine RPM if we really want to take full advantage of it, something I avoid doing at all costs on an OEM bearing with thin oil and a tight clearance.

The head is the center piece, but it can only take us so far, around 100%VE. It depends how bad your current heads are, when the final decision is made, turbo or head first. For example if you had an old engine 1985 Iron head, I would definetely be saying get a modern aluminum head on it with some brand new valvetrain equipment. But if the head you have is already fairly modern, with fairly low mileage equipment, then my rec leans to the turbocharger, no question.

You can't reliably boost an LT1 without working on the bottom half. That's why most of us go NA. Because we have to build the bottom half any way to boost it reliably. And the power difference between a boosted stock LT1 and a modified NA LT1 favors the NA LT1, not the other way around.

#27

Banned

iTrader: (1)

Are you Cardo0? Or related?..... Please learn more about the LT1.

You can't reliably boost an LT1 without working on the bottom half. That's why most of us go NA. Because we have to build the bottom half any way to boost it reliably. And the power difference between a boosted stock LT1 and a modified NA LT1 favors the NA LT1, not the other way around.

You can't reliably boost an LT1 without working on the bottom half. That's why most of us go NA. Because we have to build the bottom half any way to boost it reliably. And the power difference between a boosted stock LT1 and a modified NA LT1 favors the NA LT1, not the other way around.

The way you talk... you are inferring the bottom end if weak. And if so, it has a weakness to torque output. So 400 torque from FI vs 400 torque from Head/cam ... is the same thing (actually boost is supposed to be a little safer as the incoming pressure tends to buffet the piston as it is slowing near TDC). So how exactly are you correlating your data to the "bottom end needs work", because it would need work regardless of how you get your torque.

#28

TECH Addict

This is unprecidented. I have never heard this. The size of the "bang" in the combustion chamber is where you get the torque and so increasing it via forced induction vs head/cam work is usually a no brainer. Is the compression ratio insanely high or something? I am new to the new "LT1" you are absolutely correct. However, I can't possibly imagine that you could tell me that this or any other V8 engine would respond poorly to 7psi of intercooled boost on E85 or methanol injection LESS favorably than it would to a head/cam swap. `

The way you talk... you are inferring the bottom end if weak. And if so, it has a weakness to torque output. So 400 torque from FI vs 400 torque from Head/cam ... is the same thing (actually boost is supposed to be a little safer as the incoming pressure tends to buffet the piston as it is slowing near TDC). So how exactly are you correlating your data to the "bottom end needs work", because it would need work regardless of how you get your torque.

The way you talk... you are inferring the bottom end if weak. And if so, it has a weakness to torque output. So 400 torque from FI vs 400 torque from Head/cam ... is the same thing (actually boost is supposed to be a little safer as the incoming pressure tends to buffet the piston as it is slowing near TDC). So how exactly are you correlating your data to the "bottom end needs work", because it would need work regardless of how you get your torque.

Most boosted guys you see run a forged setup. Their individual specs will vary, but forged is needed to reliably make good power.

When you look at stock guys running boost they stay under 7 psi typically. Assuming an impossible 100% efficiency from that 7 psi of boost in a stock LT1 we can conclude that it would produce roughly 430 flywheel horsepower (360rwhp). A turbo kit for an LT1 installed would run at least $6k (likely more).

Compare that to a head/cam build with a forged bottom half (except for a stock crank), those routinely push over 400rwhp. I built mine for $4.5k. Hell, some guys on the stock bottom half push that to the wheels. Tightening quench and still with minimal detonation issues.That would run less than $4k With only minimal savy shopping needed.

See where this is going?

Now. If you built a forged boosted LT1 ($$$$$$$), you'd make some great power reliably. But that would cost as much as a head/cam full build and the turbo kit.

Last edited by hrcslam; 01-19-2016 at 11:39 PM.

#29

Banned

iTrader: (1)

You're catching on. The LT1 has powdered metal rods and hypereutectic pistons with a stock SCR of 10.4:1. Too make things a bit more difficult the stock quench is a mind boggling 0.076". It is reverse cooled which helps a ton, as would e85 (availability is an issue). But what you are recommending is a situation that would be pushing those stock pistons to the limit.

Most boosted guys you see run a forged setup. Their individual specs will vary, but forged is needed to reliably make good power.

When you look at stock guys running boost they stay under 7 psi typically. Assuming an impossible 100% efficiency from that 7 psi of boost in a stock LT1 we can conclude that it would produce roughly 430 flywheel horsepower (360rwhp). A turbo kit for an LT1 installed would run at least $6k (likely more).

Compare that to a head/cam build with a forged bottom half (except for a stock crank), those routinely push over 400rwhp. I built mine for $4.5k. Hell, some guys on the stock bottom half push that to the wheels. Tightening quench and still with minimal detonation issues.That would run less than $4k With only minimal savy shopping needed.

See where this is going?

Now. If you built a forged boosted LT1 ($$$$$$$), your make some great power reliably. But that would cost as much as a head/cam full build and the turbo kit.

Most boosted guys you see run a forged setup. Their individual specs will vary, but forged is needed to reliably make good power.

When you look at stock guys running boost they stay under 7 psi typically. Assuming an impossible 100% efficiency from that 7 psi of boost in a stock LT1 we can conclude that it would produce roughly 430 flywheel horsepower (360rwhp). A turbo kit for an LT1 installed would run at least $6k (likely more).

Compare that to a head/cam build with a forged bottom half (except for a stock crank), those routinely push over 400rwhp. I built mine for $4.5k. Hell, some guys on the stock bottom half push that to the wheels. Tightening quench and still with minimal detonation issues.That would run less than $4k With only minimal savy shopping needed.

See where this is going?

Now. If you built a forged boosted LT1 ($$$$$$$), your make some great power reliably. But that would cost as much as a head/cam full build and the turbo kit.

Alright, so let me explain where I am coming from. We are both on the same page now.

First, I would never pay someone to install anything on my car. if you can't handle fabrication and installing your own turbocharger, then forget it. I do not advocate modifications for individuals without mechanical/tuning knowledge to troubleshoot (there will be trouble to shoot) unless the pocket is limitless, and if that is the case, you will not flinch at 6k or 12k etc...

Second, turbo is still a viable option in this perspective, because

A: A rear mount setup properly done can "stay in place" as you remove/change engines and/or components while still delivering "dialable" performance

B: you can run 0psi of boost or 2psi of boost, or 8 or 10 or 15, etc... In other words, you can use as much as you need, no reason to say "turbo is too much power" since we have wastegates and boost controllers. Thus, if the engine is only safe to 5psi then so be it.

C: the turbo will add torque (as much as you want) to places that a head/cam will not (see the pink area above in my graph). As long as you do not overpower the OEM bottom end with boost, this is a great way to get extra torque without opening the engine

D: Although it may cost more up front, the adjustability and plastic performance is not set in stone the way a camshaft profile is, and the engine does not need to be opened up which may save headache.

Third,

You are right that it appears to get the most out of the setup a forged bottom end is necessary. If this is the case, I would not get stuck on an LT1. In other words, there are other applicable engines with similar displacements available that (may or may not) fit your vehicle, with similarly forged bottom ends (having one built) that should cost less. It sounds like the LT1 is a very expensive, newish engine, and so everything is over priced. I can understand that, so this is my view when it comes to new over priced engines: get a cheaper engine platform.

Four,

I Know that someone with 10,000 miles on a brand new LT1 engine is not going to want to buy a fully forged bottom end in another engine type and rip theirs out of their new vehicle etc... I am not suggesting that.

What I AM pointing out is this: the piston limit is the piston limit, whether boosted, nitrous, or N/A. You can add "5psi of boost" or "5psi worth of VE" and wind up with the same exact torque output with the same fragile piston. I agree the head/cam and staying N/A is CHEAPER as an option for stock bottom ends and avoids the hassles of turbocharging etc... and is perfect for this situation. However, it is still a dead end. You still need to dig into the piston to bring in more reliable power, regardless of whether you are using nitrous, turbo, or a million dollar induction system. The only line of thought this makes sense in, is if you do the head/cam first, then years later, the bottom end and turbo. But even then, you are looking at removing those new heads and camshaft AGAIN (doing it twice) to get to the bottom end and do machine work. So it becomes a losing situation if you ever intend to replace the piston.

#30

12 Second Club

iTrader: (3)

Kingtal0n, the stock pistons do not like detonation. They crack, or break a ring land with too much boost or nitrous. They do not like heat or detonation, cast metals do not like to bend or deform. Forged metals can absorb the detonation or heat, and when you spec a piston for boost you widen the ring gap so they don't touch and break a ring land. People HAVE pushed stock bottom end lt1s and especially stock bottom end 4.8/5.3/6.0 LS motors to 700-1000hp, but you are dancing a fine line especially with the LT platform. A heads/cam lt1 can easily do 400rwhp. The lt1 weak link is the rod bolts when it comes to rpm, but resizing the rods for ARP bolts puts you solid to 7000 rpm. Boosting a stock bottom end is dangerous, as you are fucked if you get detonation. The tune and fuel system have to be DEAD ON, one thing goes wrong and you break a piston, and worst case, send a shard through the exhaust valve and into your turbo, ******* your turbo and your bottom end. 400rwhp is fine for a stock boosted bottom end, but it costs a ton more than a heads/cam swap and gives the same output.

#32

TECH Addict

Alright, so let me explain where I am coming from. We are both on the same page now.

First, I would never pay someone to install anything on my car. if you can't handle fabrication and installing your own turbocharger, then forget it. I do not advocate modifications for individuals without mechanical/tuning knowledge to troubleshoot (there will be trouble to shoot) unless the pocket is limitless, and if that is the case, you will not flinch at 6k or 12k etc...

Second, turbo is still a viable option in this perspective, because

A: A rear mount setup properly done can "stay in place" as you remove/change engines and/or components while still delivering "dialable" performance

B: you can run 0psi of boost or 2psi of boost, or 8 or 10 or 15, etc... In other words, you can use as much as you need, no reason to say "turbo is too much power" since we have wastegates and boost controllers. Thus, if the engine is only safe to 5psi then so be it.

C: the turbo will add torque (as much as you want) to places that a head/cam will not (see the pink area above in my graph). As long as you do not overpower the OEM bottom end with boost, this is a great way to get extra torque without opening the engine

D: Although it may cost more up front, the adjustability and plastic performance is not set in stone the way a camshaft profile is, and the engine does not need to be opened up which may save headache.

Third,

You are right that it appears to get the most out of the setup a forged bottom end is necessary. If this is the case, I would not get stuck on an LT1. In other words, there are other applicable engines with similar displacements available that (may or may not) fit your vehicle, with similarly forged bottom ends (having one built) that should cost less. It sounds like the LT1 is a very expensive, newish engine, and so everything is over priced. I can understand that, so this is my view when it comes to new over priced engines: get a cheaper engine platform.

Four,

I Know that someone with 10,000 miles on a brand new LT1 engine is not going to want to buy a fully forged bottom end in another engine type and rip theirs out of their new vehicle etc... I am not suggesting that.

What I AM pointing out is this: the piston limit is the piston limit, whether boosted, nitrous, or N/A. You can add "5psi of boost" or "5psi worth of VE" and wind up with the same exact torque output with the same fragile piston. I agree the head/cam and staying N/A is CHEAPER as an option for stock bottom ends and avoids the hassles of turbocharging etc... and is perfect for this situation. However, it is still a dead end. You still need to dig into the piston to bring in more reliable power, regardless of whether you are using nitrous, turbo, or a million dollar induction system. The only line of thought this makes sense in, is if you do the head/cam first, then years later, the bottom end and turbo. But even then, you are looking at removing those new heads and camshaft AGAIN (doing it twice) to get to the bottom end and do machine work. So it becomes a losing situation if you ever intend to replace the piston.

First, I would never pay someone to install anything on my car. if you can't handle fabrication and installing your own turbocharger, then forget it. I do not advocate modifications for individuals without mechanical/tuning knowledge to troubleshoot (there will be trouble to shoot) unless the pocket is limitless, and if that is the case, you will not flinch at 6k or 12k etc...

Second, turbo is still a viable option in this perspective, because

A: A rear mount setup properly done can "stay in place" as you remove/change engines and/or components while still delivering "dialable" performance

B: you can run 0psi of boost or 2psi of boost, or 8 or 10 or 15, etc... In other words, you can use as much as you need, no reason to say "turbo is too much power" since we have wastegates and boost controllers. Thus, if the engine is only safe to 5psi then so be it.

C: the turbo will add torque (as much as you want) to places that a head/cam will not (see the pink area above in my graph). As long as you do not overpower the OEM bottom end with boost, this is a great way to get extra torque without opening the engine

D: Although it may cost more up front, the adjustability and plastic performance is not set in stone the way a camshaft profile is, and the engine does not need to be opened up which may save headache.

Third,

You are right that it appears to get the most out of the setup a forged bottom end is necessary. If this is the case, I would not get stuck on an LT1. In other words, there are other applicable engines with similar displacements available that (may or may not) fit your vehicle, with similarly forged bottom ends (having one built) that should cost less. It sounds like the LT1 is a very expensive, newish engine, and so everything is over priced. I can understand that, so this is my view when it comes to new over priced engines: get a cheaper engine platform.

Four,

I Know that someone with 10,000 miles on a brand new LT1 engine is not going to want to buy a fully forged bottom end in another engine type and rip theirs out of their new vehicle etc... I am not suggesting that.

What I AM pointing out is this: the piston limit is the piston limit, whether boosted, nitrous, or N/A. You can add "5psi of boost" or "5psi worth of VE" and wind up with the same exact torque output with the same fragile piston. I agree the head/cam and staying N/A is CHEAPER as an option for stock bottom ends and avoids the hassles of turbocharging etc... and is perfect for this situation. However, it is still a dead end. You still need to dig into the piston to bring in more reliable power, regardless of whether you are using nitrous, turbo, or a million dollar induction system. The only line of thought this makes sense in, is if you do the head/cam first, then years later, the bottom end and turbo. But even then, you are looking at removing those new heads and camshaft AGAIN (doing it twice) to get to the bottom end and do machine work. So it becomes a losing situation if you ever intend to replace the piston.

Yes, the stock pistons are limiting, then the rod bolts. There are a few other limitations, but it is always cheaper and easier to do an NA built LT1 than a boosted one. The boosted one will have more potential. But $ for hp NA wins with the old LT1. Other engines could be a different story.

#33

TECH Addict

#34

Banned

iTrader: (1)

Kingtal0n, the stock pistons do not like detonation. They crack, or break a ring land with too much boost or nitrous. They do not like heat or detonation, cast metals do not like to bend or deform. Forged metals can absorb the detonation or heat, and when you spec a piston for boost you widen the ring gap so they don't touch and break a ring land. People HAVE pushed stock bottom end lt1s and especially stock bottom end 4.8/5.3/6.0 LS motors to 700-1000hp, but you are dancing a fine line especially with the LT platform. A heads/cam lt1 can easily do 400rwhp. The lt1 weak link is the rod bolts when it comes to rpm, but resizing the rods for ARP bolts puts you solid to 7000 rpm. Boosting a stock bottom end is dangerous, as you are fucked if you get detonation. The tune and fuel system have to be DEAD ON, one thing goes wrong and you break a piston, and worst case, send a shard through the exhaust valve and into your turbo, ******* your turbo and your bottom end. 400rwhp is fine for a stock boosted bottom end, but it costs a ton more than a heads/cam swap and gives the same output.

Last edited by kingtal0n; 01-20-2016 at 12:21 PM.

#35

Banned

iTrader: (1)

I'm not talking about the new gen 5 LT-1. I'm talking about the gen 2 LT1 (no dash). The ones that are 20 + years old. Those are a different animal.

Yes, the stock pistons are limiting, then the rod bolts. There are a few other limitations, but it is always cheaper and easier to do an NA built LT1 than a boosted one. The boosted one will have more potential. But $ for hp NA wins with the old LT1. Other engines could be a different story.

Yes, the stock pistons are limiting, then the rod bolts. There are a few other limitations, but it is always cheaper and easier to do an NA built LT1 than a boosted one. The boosted one will have more potential. But $ for hp NA wins with the old LT1. Other engines could be a different story.

A: not opening an engine (since you are not doing pistons why take any chances at all)

B: headroom to grow (you do pistons later and have the turbo already installed)

C: economy/efficiency associated with turbochargers

Oh and, I do not prefer the OLD LT1 engines due to their high compression and optispark. I would recommend anyone with that kind of engine jump on the LS bandwagon. Just IMO.

#36

TECH Addict

Then we agree completely, turbo is more expensive, and both N/A AND turbo applications can provide just enough power to be safe. Its just that a turbo allows room to grow (without opening the engine) and will find torque in area that a head/cam will not, and it also improves fuel economy. But yes it is more expensive. It is just as important that your "fuel and tune be dead on" whether making 400 from a turbo or head configuration.

You're confusing Boost with FE. The reality is that the FE comes when you're OFF of boost. So you take a smaller engine and boost it to move the air (power) of a larger one, but when you're not using that boost it's only using the air of the smaller engine. Hence improved fuel economy when you're OFF boost. But worse fuel efficiency when you're on it.

Stock pistons are limiting in nearly all OEM applications. But 400 horses from N/A and 400 horses from turbo is nearly the same thing (just as likely to squeeze a ring shut or fracture a piston) this is simply due to the fact that [airflow = horsepower = airflow], it doesn't matter how we get that airflow (turbo or head). My whole position revolves around

A: not opening an engine (since you are not doing pistons why take any chances at all)

B: headroom to grow (you do pistons later and have the turbo already installed)

C: economy/efficiency associated with turbochargers

Oh and, I do not prefer the OLD LT1 engines due to their high compression and optispark. I would recommend anyone with that kind of engine jump on the LS bandwagon. Just IMO.

A: not opening an engine (since you are not doing pistons why take any chances at all)

B: headroom to grow (you do pistons later and have the turbo already installed)

C: economy/efficiency associated with turbochargers

Oh and, I do not prefer the OLD LT1 engines due to their high compression and optispark. I would recommend anyone with that kind of engine jump on the LS bandwagon. Just IMO.

Why would you waste $7K (Rear mount Turbo system) to limit your boost to 5-6 PSI only for less RWHP than a H/C/I set up? Only to have to later rebuild the engine (pistons, rods, head work, cam, etc.) so you can run 14PSI (new turbo) and add another $6-10K to your build? Of course that's ignoring you'd HAVE to replace the rear axle ($3K) and build up the transmission ($3K, clutch/internals or stall/internals). That would get you close to 700RWHP. I don't know about you, but most of us do alright with only 400+RWHP for less cost than just a Turbo......

See above for the economy thing. Boosted engines while boosted turn lower BSFC than NA, period. Something about classical physics that applies to this......

Oh and, you're in the LT1 section. You may want to double check your posting location before you go around giving advice about an engine you know nothing about, but have a disdain for.....

#37

Banned

iTrader: (1)

Um, you have more researching to do. The reality is that the FE comes when you're OFF of boost. So you take a smaller engine and boost it to move the air (power) of a larger one, but when you're not using that boost it's only using the air of the smaller engine. Hence improved fuel economy when you're OFF boost. But worse fuel efficiency when you're on it.

Hence improved fuel economy when you're OFF boost.

Fuel economy goes out the window when you want power.

Again, not how it all works together. It is not recommended to boost a none forged piston engine no matter what year or generation or manufacturer.

You'll be opening it up to do it right. Or you can do it wrong and gamble.

Why would you waste $7K (Rear mount Turbo system) to limit your boost to 5-6 PSI only for less RWHP than a H/C/I set up? Only to have to later rebuild the engine (pistons, rods, head work, cam, etc.) so you can run 14PSI (new turbo) and add another $6-10K to your build? Of course that's ignoring you'd HAVE to replace the rear axle ($3K) and build up the transmission ($3K, clutch/internals or stall/internals). That would get you close to 700RWHP.

I don't know about you, but most of us do alright with only 400+RWHP for less cost than just a Turbo......

Oh and, you're in the LT1 section. You may want to double check your posting location before you go around giving advice about an engine you know nothing about, but have a disdain for.....

#38

TECH Enthusiast

Thread Starter

Join Date: Jul 2008

Location: Miles City Mt

Posts: 734

Likes: 0

Received 0 Likes

on

0 Posts

I have seen some valid arguments and opinions on NA vs FI and I love both types of routes for increasing power to the wheels always have. But I have one thing to say about it all, as a car enthusiast how can anyone "Not Want" to open up the engine, get in there with your hands and create HP through Hard Work, Blood Sweat and Tears. I have no problem opening up my motor, and enjoy nothing more then seeing, hearing and driving the finished product. To me, when someone says they "dont" want to tear into the motor it sounds like someone who builds a 600WHP car and then trailers it every place never putting the power and wheels to the track or to the car shows. I'm always in firm discussion about this with Drivability Techs and Instructors at school about this. But to each his own.

Ty McBride

Team Leader/Owner

McBride Motorsports

PS. The LS is an awesome motor, swap isn't in the plan unless I had the $ to make a new gen LT1 fit under the hood.

Ty McBride

Team Leader/Owner

McBride Motorsports

PS. The LS is an awesome motor, swap isn't in the plan unless I had the $ to make a new gen LT1 fit under the hood.

#39

Banned

iTrader: (1)

[QUOTE=ninjai_ruken;19122271 I have one thing to say about it all, as a car enthusiast how can anyone "Not Want" to open up the engine, get in there with your hands and create HP through Hard Work, Blood Sweat and Tears.[/QUOTE]

The first time you open an engine as a novice you are rolling the dice.

Anyone without experience using an FSM and torque specs is at serious risk.

I don't recommend you experiment with an engine you care about, if you are a novice.

And last, even if you are a trained professional, there is still an enormous risk handing your engine block to a machine shop. Time has been wasted because of one tiny error at the machine shop, that isn't caught sometimes for months (you get 5k miles out of the engine and it fails). This is all too common and one more reason "not to open the engine" if you do not directly own the machine shop and can supervise the process. It isn't that you don't trust yourself to do the work; it is the work done that you cannot see or control that screws you in the end. machine shop will just shrug their shoulders (its been six months what do you want?)

This post not directed at anybody, it only states my target audience for these recommendations (beginners)

The first time you open an engine as a novice you are rolling the dice.

Anyone without experience using an FSM and torque specs is at serious risk.

I don't recommend you experiment with an engine you care about, if you are a novice.

And last, even if you are a trained professional, there is still an enormous risk handing your engine block to a machine shop. Time has been wasted because of one tiny error at the machine shop, that isn't caught sometimes for months (you get 5k miles out of the engine and it fails). This is all too common and one more reason "not to open the engine" if you do not directly own the machine shop and can supervise the process. It isn't that you don't trust yourself to do the work; it is the work done that you cannot see or control that screws you in the end. machine shop will just shrug their shoulders (its been six months what do you want?)

This post not directed at anybody, it only states my target audience for these recommendations (beginners)

Last edited by kingtal0n; 01-24-2016 at 12:16 PM.

#40

TECH Enthusiast

Thread Starter

Join Date: Jul 2008

Location: Miles City Mt

Posts: 734

Likes: 0

Received 0 Likes

on

0 Posts

The first time you open an engine as a novice you are rolling the dice.

Anyone without experience using an FSM and torque specs is at serious risk.

I don't recommend you experiment with an engine you care about, if you are a novice.

And last, even if you are a trained professional, there is still an enormous risk handing your engine block to a machine shop. Time has been wasted because of one tiny error at the machine shop, that isn't caught sometimes for months (you get 5k miles out of the engine and it fails). This is all too common and one more reason "not to open the engine" if you do not directly own the machine shop and can supervise the process. It isn't that you don't trust yourself to do the work; it is the work done that you cannot see or control that screws you in the end. machine shop will just shrug their shoulders (its been six months what do you want?)

Anyone without experience using an FSM and torque specs is at serious risk.

I don't recommend you experiment with an engine you care about, if you are a novice.

And last, even if you are a trained professional, there is still an enormous risk handing your engine block to a machine shop. Time has been wasted because of one tiny error at the machine shop, that isn't caught sometimes for months (you get 5k miles out of the engine and it fails). This is all too common and one more reason "not to open the engine" if you do not directly own the machine shop and can supervise the process. It isn't that you don't trust yourself to do the work; it is the work done that you cannot see or control that screws you in the end. machine shop will just shrug their shoulders (its been six months what do you want?)

I am far from being a novice Ive spent my entire childhood at the track and in the shop building Circle Track Cars and Engines with my father. Trust me when I say I am not worried. Just because I'm attending Lincoln Tech in the Automotive Program don't assume Ive never rebuilt a motor. This is far from being my first rodeo. And when it comes to machine shop's I listen to the people who have worked with and have experience with that shop. There is one locally if I ever decided to use them I would. The guys knows his stuff and multiple people I have talked to recommend his work. All that aside though, Thank you for your input. Its always good to hear other peoples experiences and concerns.

Ty McBride

Team Leader/Owner

McBride Motorsports