EFI Connection versus TorqHead 24x Systems

#1

Staging Lane

Thread Starter

EFI Connection versus TorqHead 24x Systems

A little background:

I originally purchased my EFI Connection 24x kit, complete, from a friend. The kit was one of the first generations with the double row 24x reluctor wheel and crank trigger sensor, which was originally for a 7.0L vortec engine (which will be referred to as the “gold sensor” from now on). When I installed the kit originally everything worked as intended. It was a great year with the car and my best time down the ¼ mile was 11.400 @ 120.XXmph… Not bad for a N/A LT1 car.

Well, disaster struck late in the season when my hub for my balancer spun on the crank and literally bashed my 24x reluctor wheel. The hub broke the wheel’s slot in addition to mushrooming out the base. During removal there was no way to remove the reluctor wheel without damaging it. It is now a nice $150 ornament for my Christmas tree this year.

So, this year I ordered a new reluctor wheel from EFI Connection. When it arrived I was surprised to see that it was a single row instead of the dual row. I emailed EFI Connection’s tech support and was instructed to buy a new sensor from a 1996-2002 5.7L Vortec (which will be referred to as the “black sensor” from now on). EFI Connection also provided an exchange system for the newly designed cam sensor housing free of charge (which was a very nice and cool thing to do). So, I purchased the sensor off of EFI Connection and my new items arrived very quickly, as they always do.

During installation I had an issue with the sensor reading RPM. I later found out that the air gap between the reluctor wheel and crank sensor was too large. This was because I ended up powder coating my timing cover which provided just enough thickness to bring the sensor out of range from the reluctor wheel. After I mated the sensor with a bare surface on the timing cover the car fired right up! I was extremely excited… Unfortunately, it wasn’t the end.

I spent the first few days afterward driving the car like a “normal” person to drain the fuel and change the oil. Once I did that it was time to see what it could do at wide open throttle (WOT). When I hit the gas at about 5,500 RPM there was a big problem; the car would miss and break up, and it sounded as if my car was two stepping. At the time I didn’t think it was the 24x kit but something new entirely.

Here are the things I checked and/or replaced myself:

- Consistent fuel pressure

- Spark plug wire resistance

- New spark plugs

- MAF curve

- Timing

- Injector Duty Cycle

- Coils

It was after all these checks I decided it had to be related to the new single row and black sensor EFI Connection system. I shot EFI Connections an email and we discussed further checks. We wanted to check out the sensor scope, however I didn’t have that equipment so a friend found a selection in HPT logger that reads sensor signal. We data logged that in addition to RPM. What we found is what we assumed we might find. When the car would break up we found variations of RPM jumping from 5,500rpm down to 3,000rpm within fractions of a second. During those RPM spikes we also saw that the sensor signal would spike. It was time to dig deeper into the issue. In order to do the rest of the checks, I decided it was best to disassemble the engine back to the timing chain again so I could get proper measurements more easily. EFI Connection recommended checking:

Proper air gap between sensor and 24x wheel of .045 max to .030 minimum

Runout of the crank snout

Again, I was within tolerance of the air gap… I could shave .007 off but I was skeptical that would work. The crank snout was straight as an arrow, which is good because a bent crank would mean a new build.

At this point I was lost and no one else had other ideas to check. Through social media, I had come to know staff at Torqhead and had seen the 24x kit they had been developing, so I shot an email to them explaining the problem. What we came up with as my most likely best option was switching to a kit with the dual row reluctor wheel and gold sensor that had worked flawlessly with my car (until something unrelated broke it of course) in previous seasons. Sadly, EFI Connection no longer produces the wheel that worked for me, so that wasn’t an option. I ordered the TorqHead system and gave it a shot.

Here I want to discuss the difference between these two wheels and two sensors:

The single row with the black sensor only has teeth for ON and thus the sensor only reads ON. It seems the gap tolerance has to be near perfect for it to work. However, the sensor and wheel can be slightly off center and the sensor can still get a solid read. I personally wasn’t willing to shave off .007 and put it back together to see if it worked or not; I simply did not have the time to meet a deadline for an event I planned on racing. So, I can’t say for sure that this was even my issue. If you want to see tests of this wheel and sensor, EFI Connection has a few videos on their Facebook testing the wave length of the wheel and sensor (all the way up to 12,000rpm).

This brings us to the double row reluctor wheel matched with the gold sensor. What makes this wheel unique, and what I think a better design, is that one row of teeth is trigger for OFF and the other row of teeth is trigger for ON. The gold sensor is unique (as well as double the price as the black sensor) because it uses two posts instead of one post like the black sensor. One post reads OFF while the other posts reads ON. This means that the PCM knows exactly where the ignition timing is at all times. The only down side to this sensor is that it must be perfectly centered with the reluctor wheel to work. Since the teeth are so much thinner on the wheel, and the two posts are gapped a specific way on the sensor, any variance off from center will lose signal between the wheel and sensor.

A little background:

I originally purchased my EFI Connection 24x kit, complete, from a friend. The kit was one of the first generations with the double row 24x reluctor wheel and crank trigger sensor, which was originally for a 7.0L vortec engine (which will be referred to as the “gold sensor” from now on). When I installed the kit originally everything worked as intended. It was a great year with the car and my best time down the ¼ mile was 11.400 @ 120.XXmph… Not bad for a N/A LT1 car.

Well, disaster struck late in the season when my hub for my balancer spun on the crank and literally bashed my 24x reluctor wheel. The hub broke the wheel’s slot in addition to mushrooming out the base. During removal there was no way to remove the reluctor wheel without damaging it. It is now a nice $150 ornament for my Christmas tree this year.

So, this year I ordered a new reluctor wheel from EFI Connection. When it arrived I was surprised to see that it was a single row instead of the dual row. I emailed EFI Connection’s tech support and was instructed to buy a new sensor from a 1996-2002 5.7L Vortec (which will be referred to as the “black sensor” from now on). EFI Connection also provided an exchange system for the newly designed cam sensor housing free of charge (which was a very nice and cool thing to do). So, I purchased the sensor off of EFI Connection and my new items arrived very quickly, as they always do.

During installation I had an issue with the sensor reading RPM. I later found out that the air gap between the reluctor wheel and crank sensor was too large. This was because I ended up powder coating my timing cover which provided just enough thickness to bring the sensor out of range from the reluctor wheel. After I mated the sensor with a bare surface on the timing cover the car fired right up! I was extremely excited… Unfortunately, it wasn’t the end.

I spent the first few days afterward driving the car like a “normal” person to drain the fuel and change the oil. Once I did that it was time to see what it could do at wide open throttle (WOT). When I hit the gas at about 5,500 RPM there was a big problem; the car would miss and break up, and it sounded as if my car was two stepping. At the time I didn’t think it was the 24x kit but something new entirely.

Here are the things I checked and/or replaced myself:

- Consistent fuel pressure

- Spark plug wire resistance

- New spark plugs

- MAF curve

- Timing

- Injector Duty Cycle

- Coils

It was after all these checks I decided it had to be related to the new single row and black sensor EFI Connection system. I shot EFI Connections an email and we discussed further checks. We wanted to check out the sensor scope, however I didn’t have that equipment so a friend found a selection in HPT logger that reads sensor signal. We data logged that in addition to RPM. What we found is what we assumed we might find. When the car would break up we found variations of RPM jumping from 5,500rpm down to 3,000rpm within fractions of a second. During those RPM spikes we also saw that the sensor signal would spike. It was time to dig deeper into the issue. In order to do the rest of the checks, I decided it was best to disassemble the engine back to the timing chain again so I could get proper measurements more easily. EFI Connection recommended checking:

Proper air gap between sensor and 24x wheel of .045 max to .030 minimum

Runout of the crank snout

Again, I was within tolerance of the air gap… I could shave .007 off but I was skeptical that would work. The crank snout was straight as an arrow, which is good because a bent crank would mean a new build.

At this point I was lost and no one else had other ideas to check. Through social media, I had come to know staff at Torqhead and had seen the 24x kit they had been developing, so I shot an email to them explaining the problem. What we came up with as my most likely best option was switching to a kit with the dual row reluctor wheel and gold sensor that had worked flawlessly with my car (until something unrelated broke it of course) in previous seasons. Sadly, EFI Connection no longer produces the wheel that worked for me, so that wasn’t an option. I ordered the TorqHead system and gave it a shot.

Here I want to discuss the difference between these two wheels and two sensors:

The single row with the black sensor only has teeth for ON and thus the sensor only reads ON. It seems the gap tolerance has to be near perfect for it to work. However, the sensor and wheel can be slightly off center and the sensor can still get a solid read. I personally wasn’t willing to shave off .007 and put it back together to see if it worked or not; I simply did not have the time to meet a deadline for an event I planned on racing. So, I can’t say for sure that this was even my issue. If you want to see tests of this wheel and sensor, EFI Connection has a few videos on their Facebook testing the wave length of the wheel and sensor (all the way up to 12,000rpm).

This brings us to the double row reluctor wheel matched with the gold sensor. What makes this wheel unique, and what I think a better design, is that one row of teeth is trigger for OFF and the other row of teeth is trigger for ON. The gold sensor is unique (as well as double the price as the black sensor) because it uses two posts instead of one post like the black sensor. One post reads OFF while the other posts reads ON. This means that the PCM knows exactly where the ignition timing is at all times. The only down side to this sensor is that it must be perfectly centered with the reluctor wheel to work. Since the teeth are so much thinner on the wheel, and the two posts are gapped a specific way on the sensor, any variance off from center will lose signal between the wheel and sensor.

#2

Staging Lane

Thread Starter

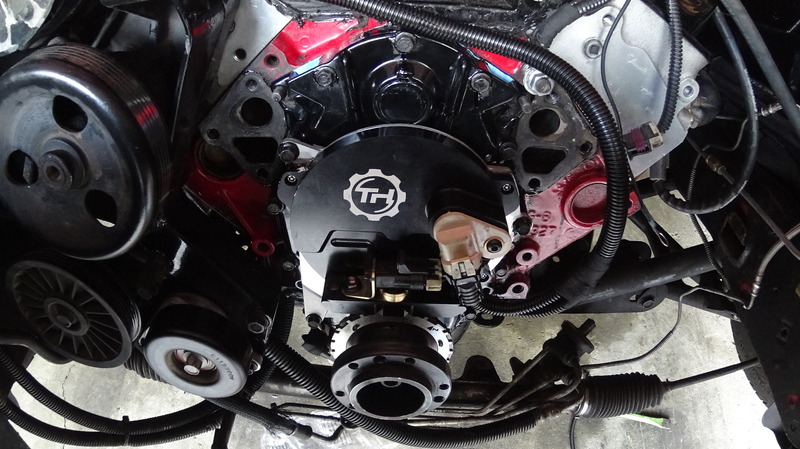

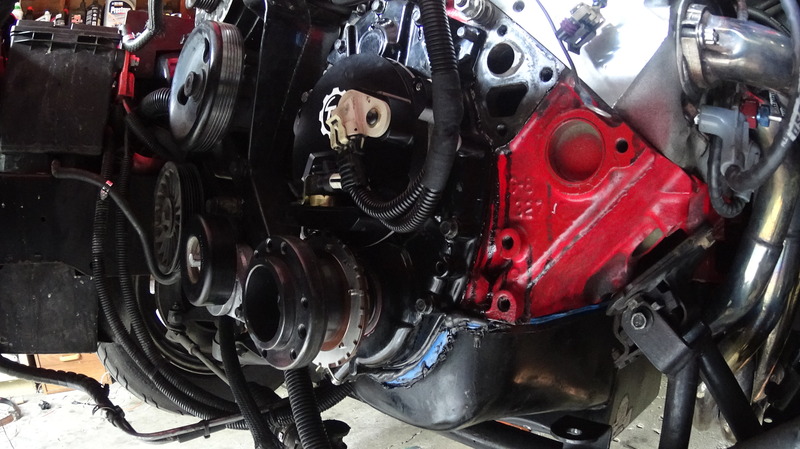

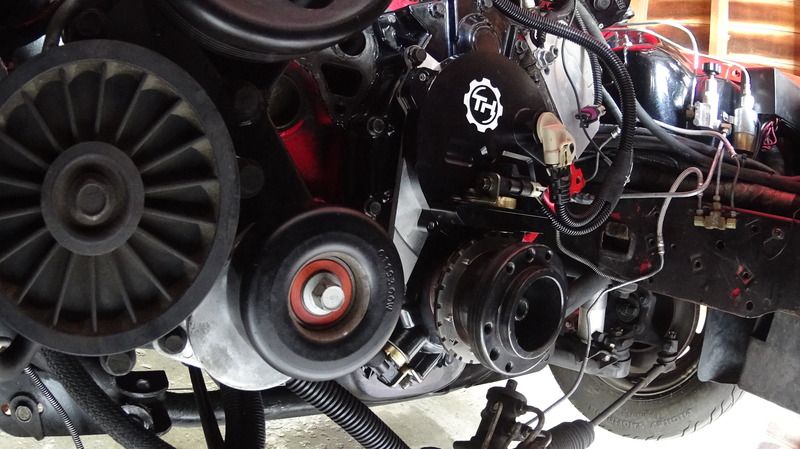

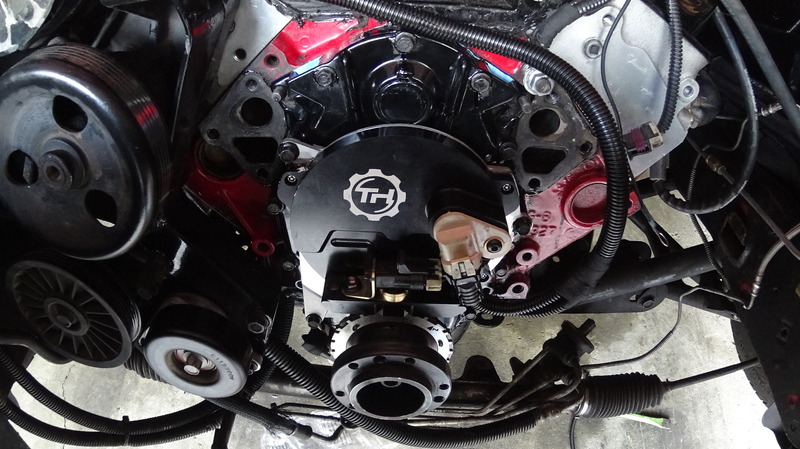

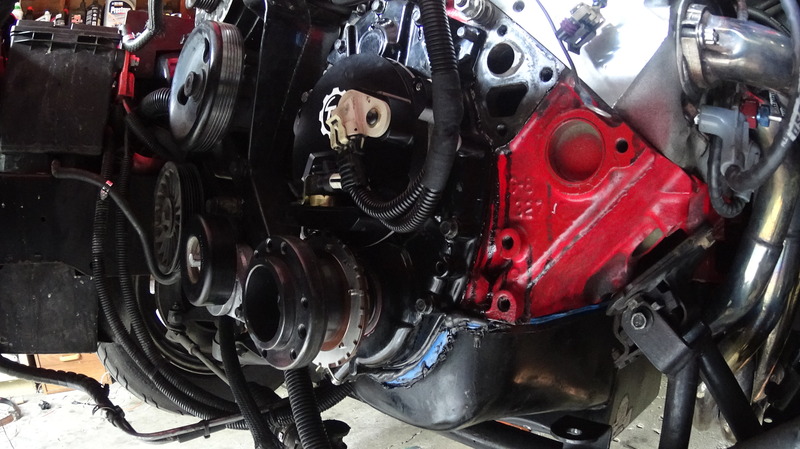

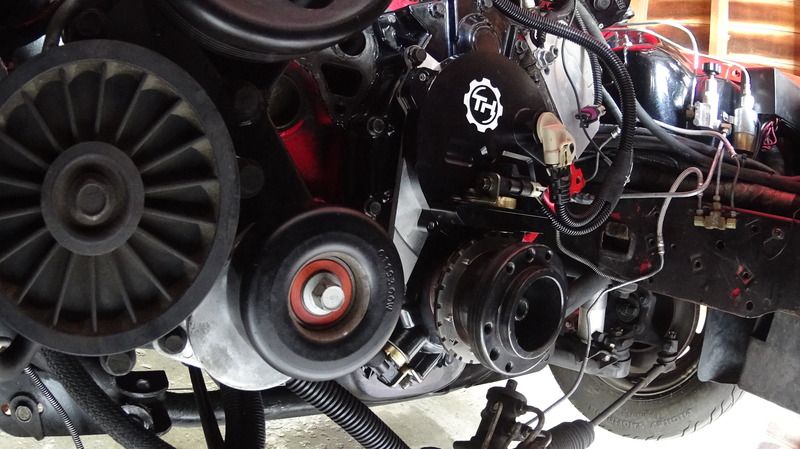

Let’s finally talk about the TorqHead 24x ignition kit. Have you replaced Optisparks in the past and find now that it is like second nature to you? If you answer yes to this question, I’ll bet you’re excited for this kit because you’ll never have to replace an Optispark again, plus you will love that the install is very similar. If you answer no, that’s not too bad of a problem. I purchased the base kit so I can’t comment any further on the PCM or pigtail harness install but all of that seems straight forward on the TorqHead site as well. What is required is to essentially read the instructions that are included with your kit:

- Remove your water pump (yay coolant)

- Remove your hub

- Adding a crank spacer if needed

- Installing the new TorqHead housing (same install procedure as an optispark)

- Installing the hub

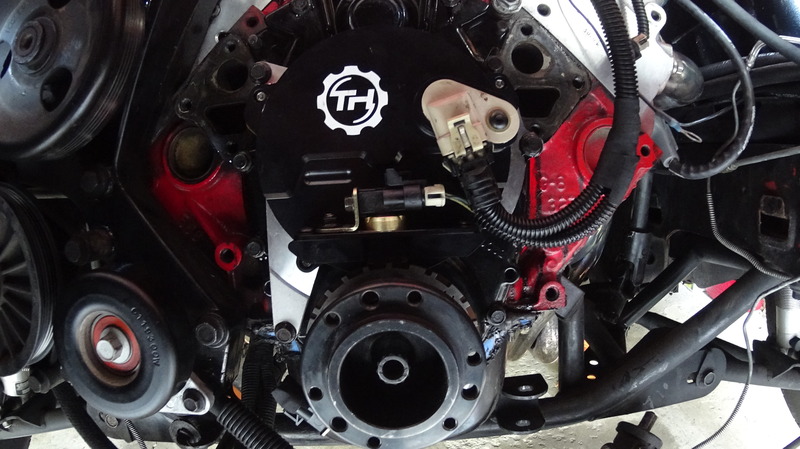

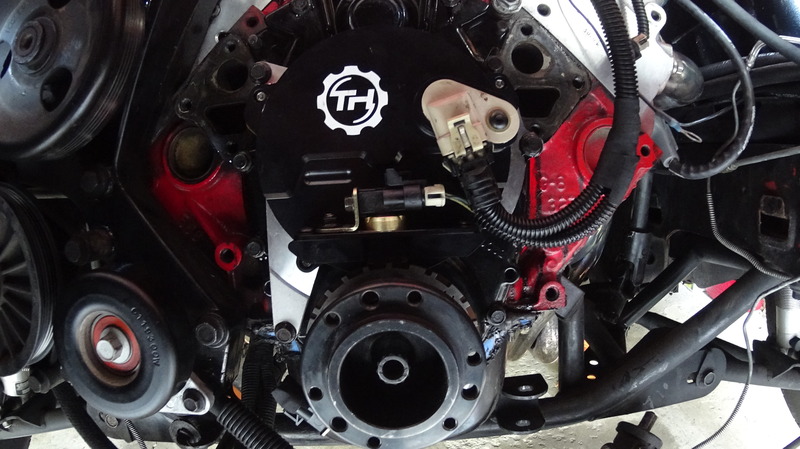

- Centering up the gold sensor to the reluctor wheel

- Finding perfect air gap with included shims and measuring device

- I recommend a test fire at this point

- Once it fires install everything else in reverse order

Do I think this kit is “better” than the EFI Connection kit? Yes, primarily because TorqHead seems to have taken out the real life variables by designing to restrict and avoid them. Some users of the EFI Connection kit had issues with the dual row reluctor and sensor because they couldn’t center the sensor to the reluctor wheel perfectly, and/or achieve a desired air gap between the sensor and reluctor wheel. To compensate for this, TorqHead designed an adjustable element with their kit. The kit comes with an alignment tool that is used to make sure the sensor is in line with the reluctor wheel. There is a lot of adjustability here so most, if not all, chain and timing cover combinations will work.

The kit, as previously mentioned, comes with multiple shims and an air gap measuring strip. Once the center is set you essentially shim up the sensor until the strip can pass the air gap between the reluctor wheel and sensor. I used 4 out of the 5 shims to achieve a slight drag of the strip between the two components.

Another semi-common issue with the EFI Connection kits is the 1x cam sensor, wheel, and housing. This will cause a no start or rough start condition that can be extremely frustrating. I personally have not had this problem, thankfully, but I know of some people who have. Once again, TorqHead designed this variable out with their product. They use what seems to be an OptiSpark base to mount their custom housing on. This custom housing holds the 1x reluctor wheel and reads off of the 1x cam sensor. These ship in a static position and will never change, again, eliminating any variables with timing chain and cover combinations.

An important element to anyone buying expensive parts is the quality of the part itself. I can say that I am very impressed with the quality pieces that TorqHead is manufacturing. I have grown up in machine and CNC shops my whole life. I am also currently working at a machine facility where quality of our product is key. Yet, I was still impressed with what I received. The main housing component is a beautiful billet CNC piece that is anodized black with a TorqHead brand in the upper right corner. All of the corners are politely chamfered so you don’t nick your knuckles. I was impressed with the near mimicry of the ATI hub, which fit perfectly with my ATI balancer. It was also interesting to see how the 24x dual row was integrated into the TorqHead hub and indexed so a case learn isn’t needed in most applications. For the cost of this kit, I was extremely impressed to see such quality.

The quality control of the Torqhead system is great as well. Each system is matched and tested before being shipped to the customer. Thankfully, because of the nature of this design, it is extremely easy to make sure the reluctor wheels and sensors are working properly. This is a great feature with ordering this kit and eliminates the possibilities of a bad detail being shipped to the customer.

What I really look into when doing research on a company is customer service. TorqHead customer service was one of the best I have ever worked with. Questions were promptly answered and at first they even gave suggestions to get my EFI Connection system working properly. However, once I abandoned the idea of the EFI Connection system and put in my order for the TorqHead system I received daily updates, pictures of the kit, and pictures of it boxed up. I was on an extreme time crunch, they knew this, and they delivered without a single hiccup. During the installation process I had a couple of quick questions and I received answers quickly, even on a Saturday morning!

So after all the checks, measuring, and general automotive diagnosis that I performed for those three weeks I made a single change to my set up. I received the TorqHead 24x base kit on Friday and began my install, which lasted roughly from 5pm-10pm. Keep in mind, I had my car torn apart farther than most people buying this kit will ever have to do. I proceeded to finish up the installation the next day from roughly 9am to 1pm. This was the only change I did to the car so I was extremely nervous that this may not be my problem and the issue would persist. I took the car out to my test spot and I let her loose. The car went through all 3 gears all the way up to the 7,000 RPMs and didn’t skip a beat! Finally, it works like it used to.

- Remove your water pump (yay coolant)

- Remove your hub

- Adding a crank spacer if needed

- Installing the new TorqHead housing (same install procedure as an optispark)

- Installing the hub

- Centering up the gold sensor to the reluctor wheel

- Finding perfect air gap with included shims and measuring device

- I recommend a test fire at this point

- Once it fires install everything else in reverse order

Do I think this kit is “better” than the EFI Connection kit? Yes, primarily because TorqHead seems to have taken out the real life variables by designing to restrict and avoid them. Some users of the EFI Connection kit had issues with the dual row reluctor and sensor because they couldn’t center the sensor to the reluctor wheel perfectly, and/or achieve a desired air gap between the sensor and reluctor wheel. To compensate for this, TorqHead designed an adjustable element with their kit. The kit comes with an alignment tool that is used to make sure the sensor is in line with the reluctor wheel. There is a lot of adjustability here so most, if not all, chain and timing cover combinations will work.

The kit, as previously mentioned, comes with multiple shims and an air gap measuring strip. Once the center is set you essentially shim up the sensor until the strip can pass the air gap between the reluctor wheel and sensor. I used 4 out of the 5 shims to achieve a slight drag of the strip between the two components.

Another semi-common issue with the EFI Connection kits is the 1x cam sensor, wheel, and housing. This will cause a no start or rough start condition that can be extremely frustrating. I personally have not had this problem, thankfully, but I know of some people who have. Once again, TorqHead designed this variable out with their product. They use what seems to be an OptiSpark base to mount their custom housing on. This custom housing holds the 1x reluctor wheel and reads off of the 1x cam sensor. These ship in a static position and will never change, again, eliminating any variables with timing chain and cover combinations.

An important element to anyone buying expensive parts is the quality of the part itself. I can say that I am very impressed with the quality pieces that TorqHead is manufacturing. I have grown up in machine and CNC shops my whole life. I am also currently working at a machine facility where quality of our product is key. Yet, I was still impressed with what I received. The main housing component is a beautiful billet CNC piece that is anodized black with a TorqHead brand in the upper right corner. All of the corners are politely chamfered so you don’t nick your knuckles. I was impressed with the near mimicry of the ATI hub, which fit perfectly with my ATI balancer. It was also interesting to see how the 24x dual row was integrated into the TorqHead hub and indexed so a case learn isn’t needed in most applications. For the cost of this kit, I was extremely impressed to see such quality.

The quality control of the Torqhead system is great as well. Each system is matched and tested before being shipped to the customer. Thankfully, because of the nature of this design, it is extremely easy to make sure the reluctor wheels and sensors are working properly. This is a great feature with ordering this kit and eliminates the possibilities of a bad detail being shipped to the customer.

What I really look into when doing research on a company is customer service. TorqHead customer service was one of the best I have ever worked with. Questions were promptly answered and at first they even gave suggestions to get my EFI Connection system working properly. However, once I abandoned the idea of the EFI Connection system and put in my order for the TorqHead system I received daily updates, pictures of the kit, and pictures of it boxed up. I was on an extreme time crunch, they knew this, and they delivered without a single hiccup. During the installation process I had a couple of quick questions and I received answers quickly, even on a Saturday morning!

So after all the checks, measuring, and general automotive diagnosis that I performed for those three weeks I made a single change to my set up. I received the TorqHead 24x base kit on Friday and began my install, which lasted roughly from 5pm-10pm. Keep in mind, I had my car torn apart farther than most people buying this kit will ever have to do. I proceeded to finish up the installation the next day from roughly 9am to 1pm. This was the only change I did to the car so I was extremely nervous that this may not be my problem and the issue would persist. I took the car out to my test spot and I let her loose. The car went through all 3 gears all the way up to the 7,000 RPMs and didn’t skip a beat! Finally, it works like it used to.

#3

So you are running their "modified" LT1 PCM? My concern is that people start having PCM issues and that TH is the only place you can get help from.

With the EFI kit, if the PCM screws up you can simply source a new 411 PCM anywhere.

I see benefits to both kits. And I could understand the frustration with the EFI kit. Having to get into the timing cover every time for issues.

I'm also curious about the method of reading the cam signal. Like you said it is similar to a Optispark. Does it use the same kind of disc inside as an OEM Opti? I believe it was the LT1 PCM's issue with reading the signal at high RPM and not the actual Opti itself correct? You mentioned spinning to 7000rpm with no issues...I never see that happening on a LT1 PCM/Opti setup...at least I never hear of it.

Great review. I'll be keeping tabs on this!

With the EFI kit, if the PCM screws up you can simply source a new 411 PCM anywhere.

I see benefits to both kits. And I could understand the frustration with the EFI kit. Having to get into the timing cover every time for issues.

I'm also curious about the method of reading the cam signal. Like you said it is similar to a Optispark. Does it use the same kind of disc inside as an OEM Opti? I believe it was the LT1 PCM's issue with reading the signal at high RPM and not the actual Opti itself correct? You mentioned spinning to 7000rpm with no issues...I never see that happening on a LT1 PCM/Opti setup...at least I never hear of it.

Great review. I'll be keeping tabs on this!

#4

TECH Regular

This is the only thing that keeps me from going this route. If they could build adapter harnesses with the LT1 PCM connections on one side, and 411 PCM connections on the other, it'd be perfect.

#6

Staging Lane

Thread Starter

So you are running their "modified" LT1 PCM? My concern is that people start having PCM issues and that TH is the only place you can get help from.

With the EFI kit, if the PCM screws up you can simply source a new 411 PCM anywhere.

I see benefits to both kits. And I could understand the frustration with the EFI kit. Having to get into the timing cover every time for issues.

With the EFI kit, if the PCM screws up you can simply source a new 411 PCM anywhere.

I see benefits to both kits. And I could understand the frustration with the EFI kit. Having to get into the timing cover every time for issues.

However, I am using an OEM 0411 PCM with the EFI Connection harness that I used previously. So, it's very possible to use an OEM PCM and separate harness if that is a concern. Really the base hard kit is what matters. Everything else is easily sourced by the user if need be.

I'm also curious about the method of reading the cam signal. Like you said it is similar to a Optispark. Does it use the same kind of disc inside as an OEM Opti? I believe it was the LT1 PCM's issue with reading the signal at high RPM and not the actual Opti itself correct? You mentioned spinning to 7000rpm with no issues...I never see that happening on a LT1 PCM/Opti setup...at least I never hear of it.

Great review. I'll be keeping tabs on this!

Great review. I'll be keeping tabs on this!

I'm sorry... I do not recall ever mentioning the Optispark except for installation comparison to the TorqHead system. EFI Connection and TorqHead systems are not similar to the Optispark ignition system at all... In fact, the Optispark is completely removed never to be used again.

The Opti disc has numerous slots into a very thin disc that is read by an optical sensor. The 24x crank reluctor wheel has teeth, the reluctor looks like a gear, that is read with a magnetic reluctor type sensor. On an oscilloscope, the sensor signal produces an analog waveform that the PCM reads.

That all being said... I was spinning up to 7k RPM with my Optispark for 3 season before I started to see a break up above 6,000 RPM. When my Optispark was failing was when my friend was selling his EFI Connection kit, so I bought it instead of buying a new Optispark.

Thank you.

#7

Thank you. I wasn't very clear in my questions. Basically I'm curious what is inside the TH unit. If it works similar to how the OEM Opti would read cam signals using a disc with holes in it.

I do like the fact that things are external which can be seen/measured to fine tune the setup.

If money is no object, I would go with the TH unit, factory 411 PCM and a reworked harness.

I do like the fact that things are external which can be seen/measured to fine tune the setup.

If money is no object, I would go with the TH unit, factory 411 PCM and a reworked harness.

Trending Topics

#9

Out of curiosity, could some of your issues be the mix of old/new kit hardware and variables in things like the timing cover?

Would their billet timing cover, the recommended timing set, and new style 24x system have also worked to alleviate your issues and reduce the margin of error that older versions were plagued with?

Just making sure we are comparing the old style kit, and not the newer 24x setup which supposedly eliminates a lot of room for error.

I purchased the newer style 24x setup w/ billet timing cover for double roller, but can definitely appreciate both setups and what each one brings to the table.

Would their billet timing cover, the recommended timing set, and new style 24x system have also worked to alleviate your issues and reduce the margin of error that older versions were plagued with?

Just making sure we are comparing the old style kit, and not the newer 24x setup which supposedly eliminates a lot of room for error.

I purchased the newer style 24x setup w/ billet timing cover for double roller, but can definitely appreciate both setups and what each one brings to the table.

#10

Staging Lane

Thread Starter

I was successful with the old gen1 double reluctor wheel and gold sensor with 97 OEM timing chain cover.

I was not successful with the new gen 2 single reluctor wheel and black sensor with the 97 OEM timing chain cover.

It is possible that the billet cover would help but I'm not sure.

I was not successful with the new gen 2 single reluctor wheel and black sensor with the 97 OEM timing chain cover.

It is possible that the billet cover would help but I'm not sure.

#11

What are you doing for knock sensing? I see the TH kit can come wit two knock sensors.

Factory fbody camaro only has 1. Is the addition of the second knock sensor utilized through HP Tuners?

Factory fbody camaro only has 1. Is the addition of the second knock sensor utilized through HP Tuners?

#13

Staging Lane

Thread Starter

Dual knock sensor kit is for B-body and a single knock sensor is for the Fbody. They are optional. Again, I'm using the EFI connection wire harness so the harness itself was plug and play. You would have to contact TorqHead for further information on the knock sensors option.

#14

Teching In

iTrader: (1)

Join Date: Jan 2007

Location: Ohio

Posts: 49

Likes: 0

Received 0 Likes

on

0 Posts

There is some interesting information here and what xdetroitmetalx brought up in his original post is the same exact issue I ran into with my kit after installation last summer.

After getting the EFI kit installed, the very first pull on the dyno resulted in the car falling on its face at 5500rpm. Through troubleshooting, my tuner found that it had to be crank sensor related and after shaving down the bran new billet timing cover crank sensor plug surface about .020, it would pull to 7k.

The next issue and still the current issue, is drive-ability around 2k-3.5k. It would miss really bad through that RPM range and to the point where I didn't even want to drive it. I went back to measuring air gap on the crank sensor and even though it was within spec, I decided to add (if memory serves me right) a .010 factory GM crank sensor shim. Once that was done, almost all of the missing/hesitation from 2k through 3.5k RPM went away. To this day there is still some hesitation, but I can live with it and continue to drive it. I even took the car back to the tuner thinking maybe it was the tune, but he quickly proved me wrong by changing the timing as we drove down the rode while it was hesitating and it never made a different no matter what he changed in the tune.

Overall, I am still happy with the kit and glad to see the opti gone, but would be nice if the car ran at 100% rather then at 90%. It makes more power now then it ever has, so can't complain about that.

After getting the EFI kit installed, the very first pull on the dyno resulted in the car falling on its face at 5500rpm. Through troubleshooting, my tuner found that it had to be crank sensor related and after shaving down the bran new billet timing cover crank sensor plug surface about .020, it would pull to 7k.

The next issue and still the current issue, is drive-ability around 2k-3.5k. It would miss really bad through that RPM range and to the point where I didn't even want to drive it. I went back to measuring air gap on the crank sensor and even though it was within spec, I decided to add (if memory serves me right) a .010 factory GM crank sensor shim. Once that was done, almost all of the missing/hesitation from 2k through 3.5k RPM went away. To this day there is still some hesitation, but I can live with it and continue to drive it. I even took the car back to the tuner thinking maybe it was the tune, but he quickly proved me wrong by changing the timing as we drove down the rode while it was hesitating and it never made a different no matter what he changed in the tune.

Overall, I am still happy with the kit and glad to see the opti gone, but would be nice if the car ran at 100% rather then at 90%. It makes more power now then it ever has, so can't complain about that.

#19

I give a thumbs up to EFI Connections 24X setup. Mine started up first try. I did have some issues with it missing but that turned out to be my wiring harness from FAST needed to have 4 wires swapped. After that she purred like a kitten. They have GREAT customer service. The install was pretty straight forward. You have to be sure to measure how much thicker your timing chain and reluctor wheel will move the hub forward because you will have to compensate for that with your accessories. If you need help just shoot me a PM. Rob.

#20

I believe the instructions said.100, stefs fabrication sells a bag of washers that thick, what i used to space mine out