Pics of powdercoating I did

#1

TECH Enthusiast

Thread Starter

Join Date: Sep 2004

Location: Clarksville,Tn

Posts: 595

Likes: 0

Received 0 Likes

on

0 Posts

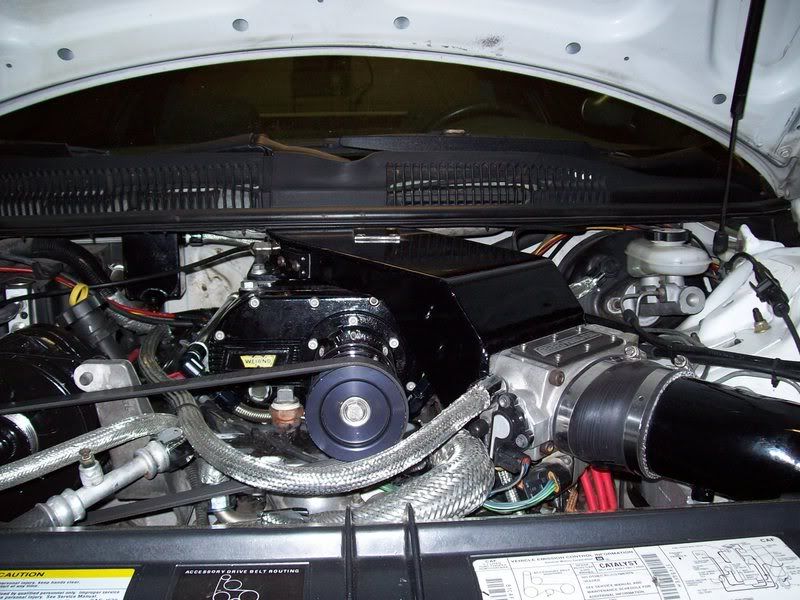

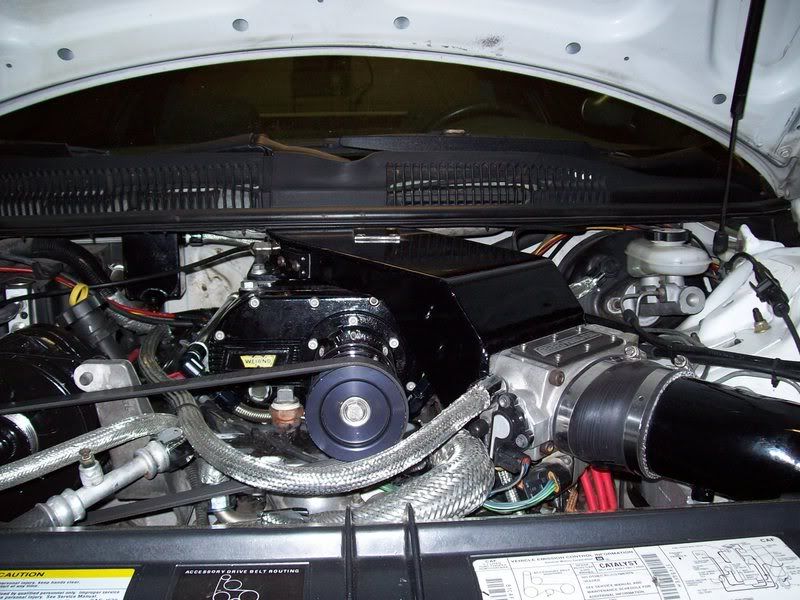

I finally got a new dig cam and thought I'd post some pics of the powdercoating I did a couple weeks ago. Aluminum is a pain, the powder wouldn't stick to it very well. The engine bay still looks like crapola but I'm getting it there little by little.

The camera takes good vid too but I gotta pull the trans out this week and do the viper mainshaft upgrade, I twisted the splines on the mainshaft. Soon as I get that done I'll get some track times and dyno numbers and see what this blower will do and post some vid up of that. Hopefully within the next month I'll start making my first kit too.

The camera takes good vid too but I gotta pull the trans out this week and do the viper mainshaft upgrade, I twisted the splines on the mainshaft. Soon as I get that done I'll get some track times and dyno numbers and see what this blower will do and post some vid up of that. Hopefully within the next month I'll start making my first kit too.

#2

TECH Senior Member

iTrader: (3)

Join Date: Oct 2006

Location: Decatur, TN (N-W of Athens)

Posts: 7,564

Likes: 0

Received 3 Likes

on

3 Posts

Can't you acid wash the aluminum to help the powder stick better? I know NAPA sells a spray bottle acid wash.

Anyways, looks good, but i probably would've left the alternator alone heh

Anyways, looks good, but i probably would've left the alternator alone heh

#5

TECH Enthusiast

Thread Starter

Join Date: Sep 2004

Location: Clarksville,Tn

Posts: 595

Likes: 0

Received 0 Likes

on

0 Posts

Preshate it guys.

The alternator looked like crapped natural next to the powdercoating, stuck out like a sore thumb. I think the prob with aluminum is you might need a different voltage and the gun I had wasn't adjustable, not real sure tho.

It's coming slowly but surely. Like I said I gotta basically rebuild the trans before I can go any further and I hope to start on the first kit within a month or so. I'm dying to get the thing to the track and see what it will do. Not expecting a whole lot due to it being a bone stock motor but with a lil alkie injection or E85 it comes to life big time.

The alternator looked like crapped natural next to the powdercoating, stuck out like a sore thumb. I think the prob with aluminum is you might need a different voltage and the gun I had wasn't adjustable, not real sure tho.

Damn thats bad ***.

How is it all coming along?

How is it all coming along?

#7

Village Troll

iTrader: (2)

Love your set up. This is something I think I would like to do later on instead of a LSx swap. Do you have any kind of write up about this or is it something you'd rather not disclose?

Trending Topics

#13

TECH Enthusiast

Thread Starter

Join Date: Sep 2004

Location: Clarksville,Tn

Posts: 595

Likes: 0

Received 0 Likes

on

0 Posts

#14

TECH Fanatic

+1 about never seeing a LT1 roots type. Sweeet! 2 years in the works?? Hopefully you finish up soon. I am very interested...

As for the powdercoating,... looks llike a good job (very shiny, very neat) although, its A LOT of black in there.

As for the powdercoating,... looks llike a good job (very shiny, very neat) although, its A LOT of black in there.

#15

Looks good.

Try putting aluminum parts in the oven for a couple of hours before coating. It also helps to coat the part right after you remove it from the oven...it'll stick! Coating hot parts is not as "easy" as coating a room temp part, so be careful not to apply too much powder.

Try putting aluminum parts in the oven for a couple of hours before coating. It also helps to coat the part right after you remove it from the oven...it'll stick! Coating hot parts is not as "easy" as coating a room temp part, so be careful not to apply too much powder.

Last edited by Mr.Whitey; 05-07-2008 at 07:06 PM.

#16

TECH Enthusiast

Thread Starter

Join Date: Sep 2004

Location: Clarksville,Tn

Posts: 595

Likes: 0

Received 0 Likes

on

0 Posts

Looks good.

Try putting aluminum parts in the oven for a couple of hours before coating. It also helps to coat the part right after you remove it from the oven...it'll stick! Coating hot parts is not as "easy" as coating a room temp part, so be careful not to apply too much powder.

Try putting aluminum parts in the oven for a couple of hours before coating. It also helps to coat the part right after you remove it from the oven...it'll stick! Coating hot parts is not as "easy" as coating a room temp part, so be careful not to apply too much powder.

By the way, yer engine bay looks immaculate but if I had to keep it clean it would drive me nuts. lol

#17

TECH Addict

iTrader: (9)

Join Date: Nov 2004

Location: Kzoo, MI

Posts: 2,289

Likes: 0

Received 0 Likes

on

0 Posts

MPE fab has had a roots blower kit for the LT1 for probably 3-4 years now. The only thing was they only made 5 kits, then started to concentrate on their TT setups and haven't made any kits since.

NXS looking good btw.

#18

I preheated all the parts and it worked great on the steel parts, soon as the powder hits it it melts. That way you can tell if you've got enough on it or not, takes the guess work out of it. The aluminum parts just didn't wanna cooperate but maybe I didn't preheat them long enough (15 minutes), aluminum cools quicker than steel. I'll try a longer preheat next time.

By the way, yer engine bay looks immaculate but if I had to keep it clean it would drive me nuts. lol

By the way, yer engine bay looks immaculate but if I had to keep it clean it would drive me nuts. lol

#19

TECH Enthusiast

Thread Starter

Join Date: Sep 2004

Location: Clarksville,Tn

Posts: 595

Likes: 0

Received 0 Likes

on

0 Posts

The blower and the upper intake on top of the blower. The powder just would not stick to them on the underside, that's why I was wondering if it was the voltage from the gun. It didn't help that I had a cheapo gun from harbor freight, that was part of the problem, it didn't wanna spray real good if you tilted the gun up.

#20

The blower and the upper intake on top of the blower. The powder just would not stick to them on the underside, that's why I was wondering if it was the voltage from the gun. It didn't help that I had a cheapo gun from harbor freight, that was part of the problem, it didn't wanna spray real good if you tilted the gun up.