SPEC LS9/ZR-1 Super Twin Billet Multidisc Clutch and Flywheel Assemblies

#1

FormerVendor

Thread Starter

iTrader: (2)

Join Date: Feb 2007

Posts: 2,507

Likes: 0

Received 0 Likes

on

0 Posts

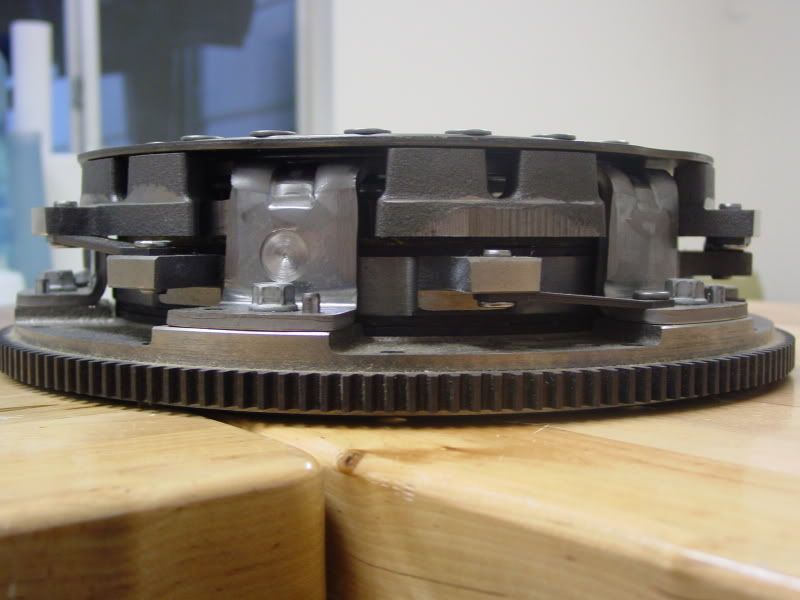

SPEC, Inc Clutches and Flywheels introduces their Super-Twin for street and track use in the LS9 Corvette ZR1. SPEC also offers Super Twin fitments for LS9 to T56 conversion applications.

Until now, there has been a drivability, maintenance and longevity trade-off with clutches built to handle 700-1700 ft.-lbs. tq. The revolutionary new SPEC Super Twin has set a new standard by offering near-stock drivability, tremendous life expectancy, bolt-in installation with no shimming or setup needed and maintenance free operation. These units are upgradeable, downgradeable and rebuildable for ultimate versatility.

SPEC Super-Twin's are constructed with aircraft grade aluminum and high carbon billet steel milled to an industry leading .001 inch for perfect balance and actuation. All billet construction allows these units to be smooth and quiet in operation. Friction is provided by one of four disc types ranging a Hybrid Kevlar/Carbon Graphite Puck to full-metallic (Sintered Iron) option.

Torque capacities upwards of 1700 ft.-lbs. can be realized depending on the disc type specified. Flywheel and track-spec hardware are included in each kit.

Pricing for the SC10 Series Super-Twin is:

SC10SST $1549

SC10PT $1749

SC10ST $2049

SC10ET $2149

To find a SPEC distributor in your area, call 205-491-8581 or visit www.specclutch.com.

#5

FormerVendor

Thread Starter

iTrader: (2)

Join Date: Feb 2007

Posts: 2,507

Likes: 0

Received 0 Likes

on

0 Posts

Also hard to do when the geometry of the kits is completely different. The LS9 flywheel is almost 3 times thicker than the LS1 flywheel and thus the total geometry, along with the difference in crank pattern, would not allow you to take an stock LS9 part and istall is into your LS1/T56 car.

Trending Topics

#8

FormerVendor

iTrader: (15)

Also hard to do when the geometry of the kits is completely different. The LS9 flywheel is almost 3 times thicker than the LS1 flywheel and thus the total geometry, along with the difference in crank pattern, would not allow you to take an stock LS9 part and istall is into your LS1/T56 car.

If you can't find them Jeremy I've got three setting here, I'll be more than happy to get those pics for you. Nice multi-disc btw, very nice!

#10

FormerVendor

Thread Starter

iTrader: (2)

Join Date: Feb 2007

Posts: 2,507

Likes: 0

Received 0 Likes

on

0 Posts

I am referencing the difference in stack-height. This is the distance from the crank-mounting surface on the rear of the flywheel to the diaphragm finger peak. The LS9 clutch assembly is not like anything else used by GM in the Vette or Camaro in the past. I haven't had time to get the pics...it has been wild around here this week. But I will try to get them posted shortly. Or SNL can post them too...as stock parts are stock parts! Thanks for the complements on the kit by the way. Let me know if you guys need anything else. Thanks,

#15

FormerVendor

Thread Starter

iTrader: (2)

Join Date: Feb 2007

Posts: 2,507

Likes: 0

Received 0 Likes

on

0 Posts

Yep...room limitations are a major factor. Of course...having seen the stock ZR1 part and knowing that it utilizes an organic disc material...I don't think that it is as ideal as many believe it to be. Remember, organic discs, especially those using a marcel spring, will have a tenency to compress and this can greatly affect the clutches engagement point and long-term durability.

I know that there will always be those that want to use alternative OE options on their cars because "OE parts are great"...but in many instances there are better, more durable, higher capacity options available from aftermarket manufactures that offer a better value to boot. I know...I am biased...but I am also speaking from experience and as an enthusiast. Let me know if you all have any further questions. Thanks,

I know that there will always be those that want to use alternative OE options on their cars because "OE parts are great"...but in many instances there are better, more durable, higher capacity options available from aftermarket manufactures that offer a better value to boot. I know...I am biased...but I am also speaking from experience and as an enthusiast. Let me know if you all have any further questions. Thanks,

#16

FormerVendor

iTrader: (15)

Yep...room limitations are a major factor. Of course...having seen the stock ZR1 part and knowing that it utilizes an organic disc material...I don't think that it is as ideal as many believe it to be. Remember, organic discs, especially those using a marcel spring, will have a tenency to compress and this can greatly affect the clutches engagement point and long-term durability.

I know that there will always be those that want to use alternative OE options on their cars because "OE parts are great"...but in many instances there are better, more durable, higher capacity options available from aftermarket manufactures that offer a better value to boot. I know...I am biased...but I am also speaking from experience and as an enthusiast. Let me know if you all have any further questions. Thanks,

I know that there will always be those that want to use alternative OE options on their cars because "OE parts are great"...but in many instances there are better, more durable, higher capacity options available from aftermarket manufactures that offer a better value to boot. I know...I am biased...but I am also speaking from experience and as an enthusiast. Let me know if you all have any further questions. Thanks,

LOL, LS7 *cough*cough*

I know what you mean, organic material with a coefficient of .25 is no match for a cerametallic material with a .38... it is what it is though, some will never agree with us.

#17

TECH Apprentice

iTrader: (8)

Join Date: Jan 2004

Location: McKinney, TX.

Posts: 313

Likes: 0

Received 0 Likes

on

0 Posts

Well I can see where you guys are coming from because you both sell a direct replacement for what we're now talking about. And I'm sure your companies both sell a good product. That being said, us normal guys sometimes like the feeling we get from an OEM part and also the fact that they are a great value in most people's opinion.

#20

FormerVendor

Thread Starter

iTrader: (2)

Join Date: Feb 2007

Posts: 2,507

Likes: 0

Received 0 Likes

on

0 Posts

Slow...I hate that you were unhappy with the part you purchased. I do not remember talking with you about this...of course I am not sure of the timeframe since purchase or any other details...and as you can imagine I talk to hundreds of people each day (with the great majority being quite pleased with the products we provide). Did you request an RMA and subsequently send the unit back to us for assessment?