Clutch, shims, measurements... something's off!

#1

Staging Lane

Thread Starter

iTrader: (1)

Join Date: May 2013

Location: Oklahoma

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

Car info: Nissan s13 (though that shouldn't have anything to do with my issue), Ls2 from an '05 Vette, CTS-V bellhousing, f-body T-56, new t-56 slave and master.

So, my clutch isn't releasing. I'm certain the new slave and new master are bled correctly. Pedal feels okay, but I can see the rear tires move after I've wrestled my freshly rebuilt trans into first, push the clutch in, and bump the starter. No bueno.

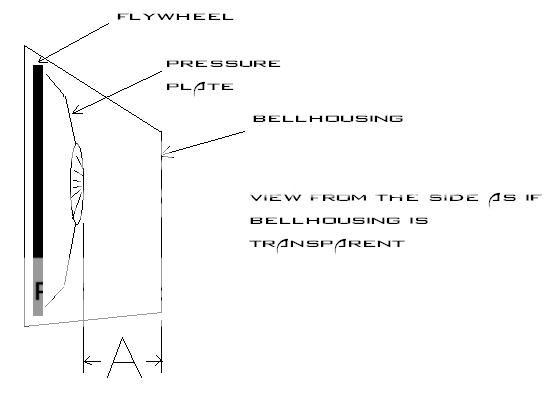

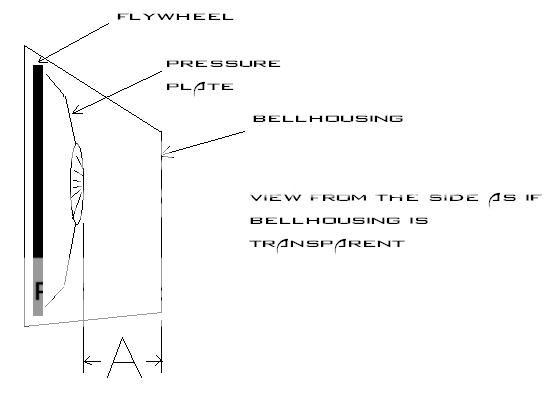

I pulled my transmission and took some measurements to see what size of shim I'd need...

Since I needed the bellhousing still on the motor to take my measurements, no sense in removing that! This was actually not too difficult to do.

I used the procedure listed here on LS1Tech.

Measurement A: (2 7/16")

Measurement B: (2")

Anyway... so, for those of you who know about this whole shim thing, you already know I've got a big issue. For those of you that don't... The math should be A > B by 0.062" to 0.125" (1/16"-1/8"). I double and triple checked myself, but my measurements come out to A > B by 0.4375", which is at least 0.3125" too much, and much larger then most shims, even the most common "3 pack" some places sell... all together! So something is way off.

Any ideas? I've got a CTS-V bellhousing... but I think that's okay... maybe not? The shifter fits good and my Sikky trans mount lines up pretty good (as you can see in the pictures), but I've heard it's a touch longer (but never confirmed)? Maybe there's a problem with the clutch and it's pressure plate fingers (since that's what you use to take your measurement from)? I'd appreciate any ideas you all have. Thanks!

So, my clutch isn't releasing. I'm certain the new slave and new master are bled correctly. Pedal feels okay, but I can see the rear tires move after I've wrestled my freshly rebuilt trans into first, push the clutch in, and bump the starter. No bueno.

I pulled my transmission and took some measurements to see what size of shim I'd need...

Since I needed the bellhousing still on the motor to take my measurements, no sense in removing that! This was actually not too difficult to do.

I used the procedure listed here on LS1Tech.

Measurement A: (2 7/16")

Measurement B: (2")

Anyway... so, for those of you who know about this whole shim thing, you already know I've got a big issue. For those of you that don't... The math should be A > B by 0.062" to 0.125" (1/16"-1/8"). I double and triple checked myself, but my measurements come out to A > B by 0.4375", which is at least 0.3125" too much, and much larger then most shims, even the most common "3 pack" some places sell... all together! So something is way off.

Any ideas? I've got a CTS-V bellhousing... but I think that's okay... maybe not? The shifter fits good and my Sikky trans mount lines up pretty good (as you can see in the pictures), but I've heard it's a touch longer (but never confirmed)? Maybe there's a problem with the clutch and it's pressure plate fingers (since that's what you use to take your measurement from)? I'd appreciate any ideas you all have. Thanks!

#2

FormerVendor

iTrader: (15)

Are you still running the large pilot bearing from the vette in the back of the crank? Also it's hard to be exact with a tape measure, when you really need a micrometer to take the measurements, but it appears from yours that you need ~.3125" of shim and probably longer bolts. I would personally try to find an F-body bellhousing, unless you know the CTSV is the same overall width as that would definitely affect your numbers and clutch disengagement. Hope that helps, Chris

#4

i never understood this procedure

would you not need to measure with the friction disk removed from the assembly? doesn't the clutch need to be fully relaxed for this?

if you measure with the friction disk in and the slave fully compressed as soon as the disk wears out a bit the fingers relax and the clutch will always be partially disengaged..

would you not need to measure with the friction disk removed from the assembly? doesn't the clutch need to be fully relaxed for this?

if you measure with the friction disk in and the slave fully compressed as soon as the disk wears out a bit the fingers relax and the clutch will always be partially disengaged..

#5

Staging Lane

Thread Starter

iTrader: (1)

Join Date: May 2013

Location: Oklahoma

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

Are you still running the large pilot bearing from the vette in the back of the crank? Also it's hard to be exact with a tape measure, when you really need a micrometer to take the measurements, but it appears from yours that you need ~.3125" of shim and probably longer bolts. I would personally try to find an F-body bellhousing, unless you know the CTSV is the same overall width as that would definitely affect your numbers and clutch disengagement. Hope that helps, Chris

i never understood this procedure

would you not need to measure with the friction disk removed from the assembly? doesn't the clutch need to be fully relaxed for this?

if you measure with the friction disk in and the slave fully compressed as soon as the disk wears out a bit the fingers relax and the clutch will always be partially disengaged..

would you not need to measure with the friction disk removed from the assembly? doesn't the clutch need to be fully relaxed for this?

if you measure with the friction disk in and the slave fully compressed as soon as the disk wears out a bit the fingers relax and the clutch will always be partially disengaged..

On your second point though, when you measure the clutch slave, it's fully compressed IN... meaning that's as far back as it goes and as "off" as possible. When the fingers relax, that's fine, because the full stroke of the slave should more than compensate for that as it moves out when you push the clutch pedal in. At least that's how it makes sense to me.

#6

There is a significant stack height difference between the LS-7 clutch/flywheel and the CTS-V clutch/flywheel so a thicker shim will inherently be needed. I know you think remeasuring is a strange request but it really will provide a much more accurate view at what you need.

As for the clutch, as the disc wears the fingers raise. But, removing the disc, would not provide an accurate measurement of the typical amount of change in finger height because without a disc the fingers will be at their max height (one that is not achievable with a functioning clutch kit). The difference that we normally shoot for is .175" to .225". I hope this helps. Let me know if you have any further questions. Thanks,

As for the clutch, as the disc wears the fingers raise. But, removing the disc, would not provide an accurate measurement of the typical amount of change in finger height because without a disc the fingers will be at their max height (one that is not achievable with a functioning clutch kit). The difference that we normally shoot for is .175" to .225". I hope this helps. Let me know if you have any further questions. Thanks,

#7

Staging Lane

Thread Starter

iTrader: (1)

Join Date: May 2013

Location: Oklahoma

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

I have no problem re-measuring, I just don't see that using my caliper will show me anything that much different than what I've already measured. I'll do it anyway, just in case.

A question I have now is... if the CTS-V bellhousing is longer (I read somewhere it's 7mm... or ~ 0.276"), should I (with an effort to try and get this done in short order, and as cheaply as possible):

A. Have the bellhousing machined a little shorter to the F-body length?

B. Space up the slave about .375" with several shims and longer bolts (though this makes me question the pilot bearing contact)?

C. Just get an f-body bellhousing?

Also... I was wrong. I have the "larger" ls2 style pilot bearing. I don't know if this is a problem or not?

A question I have now is... if the CTS-V bellhousing is longer (I read somewhere it's 7mm... or ~ 0.276"), should I (with an effort to try and get this done in short order, and as cheaply as possible):

A. Have the bellhousing machined a little shorter to the F-body length?

B. Space up the slave about .375" with several shims and longer bolts (though this makes me question the pilot bearing contact)?

C. Just get an f-body bellhousing?

Also... I was wrong. I have the "larger" ls2 style pilot bearing. I don't know if this is a problem or not?

Trending Topics

#8

FormerVendor

iTrader: (15)

If you have a F-body trans, I'd put an F-body bellhousing on it as the LS7 clutch will fit and that would work with the small pilot bearing to support the input shaft. The large pilot bearing will only work with the longer CTSV bellhousing, so you'd have to do the monster shim. Otherwise if you machine the bellhousing you still have to swap pilot bearings. Curious if this going to be a drift car?

#9

Staging Lane

Thread Starter

iTrader: (1)

Join Date: May 2013

Location: Oklahoma

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

If you have a F-body trans, I'd put an F-body bellhousing on it as the LS7 clutch will fit and that would work with the small pilot bearing to support the input shaft. The large pilot bearing will only work with the longer CTSV bellhousing, so you'd have to do the monster shim. Otherwise if you machine the bellhousing you still have to swap pilot bearings. Curious if this going to be a drift car?

Just curious or have some wisdom I could use? (by the way, your GM level 2 GTO clutch package looks awesome, so when this one burns up, I might go that route. My power goals aren't but to get 400-450 to the wheels in the foreseeable future)

#10

FormerVendor

iTrader: (15)

Yeah I'm afraid that LS7 might give you troubles with some clutch kicks, I honestly would recommend a ceramic compound that kind of stuff. Our 11" clutch is the one I usually recommend for drifters as it's lasted 3 seasons no problems with heavy abuse from guys on the circuit, it's a bit overkill maybe for yours so you could go with the Level 3 instead.

#11

Staging Lane

Thread Starter

iTrader: (1)

Join Date: May 2013

Location: Oklahoma

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

Okay, thanks for the input! When it's time to get a new clutch I will.

Also... just in case somebody looks this up in the future... I think all my research has come up with this...

1. The f-body and GTO bellhousings are 140mm (about 5.5 inches). The CTS-V is 147mm (about 5.8 inches)

2. The "large" pilot bearing isn't what you want with a t56 in an LS1 or LS2 in most cases. If you have problems seating your transmission, it's probably binding on the larger bearing, which puts pressure on the thrust washers, which means you risk an engine rebuild.

3. Shims are your friend.

Also... just in case somebody looks this up in the future... I think all my research has come up with this...

1. The f-body and GTO bellhousings are 140mm (about 5.5 inches). The CTS-V is 147mm (about 5.8 inches)

2. The "large" pilot bearing isn't what you want with a t56 in an LS1 or LS2 in most cases. If you have problems seating your transmission, it's probably binding on the larger bearing, which puts pressure on the thrust washers, which means you risk an engine rebuild.

3. Shims are your friend.

#12

Proper shimming can make this work either way. We supply a great number of kit to drift and road-race competitors so if you do wind up with questions about the best option for your needs hit me up and I will be happy to assist you. Additionally, I have a few shim thicknesses available if you need one. Let me know. Thanks!