**UPDATED for cut-outs**Going from 250 to 350 shot gains 2 tenths?

#1

Cleaned Nitrous filter and switched the 4an line from the filter to solenoid to a 6an. I'm now running 6an from the bottles straight through to the solenoid. The car just won't pick up any speed once I go past a .088 jet. 300 gains me a tenth or 2 and 350 jets gain me 2 tenths or so. Only a couple of mph difference between 250 jets and 350 jets. I logged run last night and was at 6500 rpm through traps at 132 for converter slippage of approximately 10% which I thought was not too bad? The first plug on the .093 jets looked great but time was terrible for that size jet. I immediately switched to a .088 jet to see what would happened and even though that plug was rich as heck virtually no difference. I eventually leaned the .088 jet with a .034 fuel and pulling 12 to get best time of 10.3541 @ 132.04. I'm stumped as to what to look at next - something is holding me bacxk??? Thoughts on what to do next anyone?

Edit: I also just measured the exhaust which is catless flowing from 1 and 7/8 headers to 2 X 2 and 1/2 inch pipes merging into one 3" pipe into a Borla Catback. I'm wondering if this is the issue. I know uncorking would give me more HP but would having this restriction actually limit the HP on NOS when using the appropriate jetting?

.093 and .042 pulling 14 from 25. (Running a #11 plug) 10.43 @ 131.95

.088 and .036 pulling 13 from 25 (running a #11 plug) 10.49 @ 132.00

.088 and .034 pulling 12 from 25 (running a #11 plug) 10.35 @ 132.04

.088 and .034 pulling 11 from 25 (#11 plug) 10.34 @ 131.94

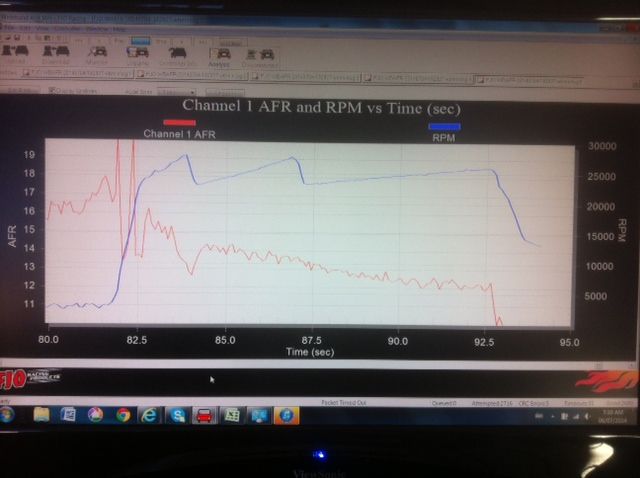

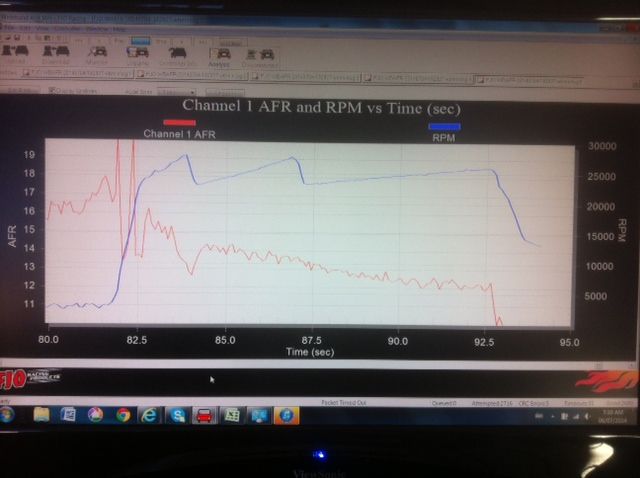

Data Log of 10.34 run with .1 delay and .2 ramp starting at 65% (Need to divide RPM by 4 - issue with datalogger)

EDIT: Added picture of solenoid (Nitrous Outlet Part#00-5004 - .125 Nitrous Solenoid new in Sept 2013). 6an or 1/2 inch to solenoid with 7/16th line to N2O plate fitting and 1/4 inch to fuel fitting.

Edit: I also just measured the exhaust which is catless flowing from 1 and 7/8 headers to 2 X 2 and 1/2 inch pipes merging into one 3" pipe into a Borla Catback. I'm wondering if this is the issue. I know uncorking would give me more HP but would having this restriction actually limit the HP on NOS when using the appropriate jetting?

.093 and .042 pulling 14 from 25. (Running a #11 plug) 10.43 @ 131.95

.088 and .036 pulling 13 from 25 (running a #11 plug) 10.49 @ 132.00

.088 and .034 pulling 12 from 25 (running a #11 plug) 10.35 @ 132.04

.088 and .034 pulling 11 from 25 (#11 plug) 10.34 @ 131.94

Data Log of 10.34 run with .1 delay and .2 ramp starting at 65% (Need to divide RPM by 4 - issue with datalogger)

EDIT: Added picture of solenoid (Nitrous Outlet Part#00-5004 - .125 Nitrous Solenoid new in Sept 2013). 6an or 1/2 inch to solenoid with 7/16th line to N2O plate fitting and 1/4 inch to fuel fitting.

Last edited by CanadianEh!; 08-02-2014 at 06:28 AM.

#4

This is a plate system so have you thought about looking into what it can flow? Plates spray fuel into the intake which takes up volume. This volume is less air the motor can ingest being taken up by fuel. So from my experiments on my setup (fast intake opened up to a 95 and ported) after a 300 I pick up jack ****. Now with a super vic setup or something similar its a different story. I had 2 stages on the car a plate and direct port. I removed the plate and made up for that stage with the direct port and it makes a huge difference. I picked up 5 mph in the 1/8th on a **** track with using the direct port only. This was my case and might be the same for you.

#6

TECH Fanatic

iTrader: (2)

I suspect the solenoid isn't keeping up with the demand. Your mph is virtually the same indicating to me that you're not really making any more power with the jet change. You're going to need a bottom exit solenoid for that amount of nitrous.

Last edited by WE TODD DID; 07-06-2014 at 09:30 PM.

Trending Topics

#14

The exhaust is not the problem. I ran STOCK Ti pipes for a long time. That said, obviously more exhaust flow = better.

So what does your car run N/A? I see 132mph on 250-350 shot. You are probably using around 175hp of nitrous,just guessing based on what your N/A mph might be. I would highly suggest you back the jetting down and maximize a smaller shot. Maybe you have done this already? Also, watch individual plugs above 200 shot. You will likely see cylinders that don't look the same w/plate w/regard to AFR.

Your AFR chart shows lean across the board, richest point 12.0, but only at the last part of the run. You should be richer than that. Most of your run is way leaner than I would like to see. I like around 11.5ish. Granted plug reading is best, but your plugs look too lean for me too. You can not make power with nitrous unless there is fuel avail.

slightly rich = best option w/LOW spark values, at least 2 deg per 50hp.

Note, how your graph starts real lean, then goes richer towards the end of your pass.

A sign of possible nitrous solenoid failure, unless thats how your N/A motor passes look too. Personally, I would replace that solenoid, relay and move on. A weak nitrous solenoid may close as your headed down the track and likely not the fuel, since its low pressure at and below 60psi. Make sure bottle valve is pointed down. Is bottle pressure 1050?

So what does your car run N/A? I see 132mph on 250-350 shot. You are probably using around 175hp of nitrous,just guessing based on what your N/A mph might be. I would highly suggest you back the jetting down and maximize a smaller shot. Maybe you have done this already? Also, watch individual plugs above 200 shot. You will likely see cylinders that don't look the same w/plate w/regard to AFR.

Your AFR chart shows lean across the board, richest point 12.0, but only at the last part of the run. You should be richer than that. Most of your run is way leaner than I would like to see. I like around 11.5ish. Granted plug reading is best, but your plugs look too lean for me too. You can not make power with nitrous unless there is fuel avail.

slightly rich = best option w/LOW spark values, at least 2 deg per 50hp.

Note, how your graph starts real lean, then goes richer towards the end of your pass.

A sign of possible nitrous solenoid failure, unless thats how your N/A motor passes look too. Personally, I would replace that solenoid, relay and move on. A weak nitrous solenoid may close as your headed down the track and likely not the fuel, since its low pressure at and below 60psi. Make sure bottle valve is pointed down. Is bottle pressure 1050?

#15

#16

TECH Fanatic

iTrader: (2)

Your AFR chart shows lean across the board, richest point 12.0, but only at the last part of the run. You should be richer than that. Most of your run is way leaner than I would like to see. I like around 11.5ish. Granted plug reading is best, but your plugs look too lean for me too. You can not make power with nitrous unless there is fuel avail.

slightly rich = best option w/LOW spark values, at least 2 deg per 50hp.

Note, how your graph starts real lean, then goes richer towards the end of your pass.

A sign of possible nitrous solenoid failure, unless thats how your N/A motor passes look too. Personally, I would replace that solenoid, relay and move on. A weak nitrous solenoid may close as your headed down the track and likely not the fuel, since its low pressure at and below 60psi. Make sure bottle valve is pointed down. Is bottle pressure 1050?

#18

FormerVendor

iTrader: (2)

Outside diameter of line from nitrous solenoid to plate is 5/16 inch on both ends. Pic of Plate end fitting below. Also using a NOS .093 and .099 jet verses NX style jet on smaller shots. Not sure why this would be an issue but I'll throw it out there (smaller shaft size on the NOS style but I'm assuming a .093 or .099 is the same size on either style?).

There's your problem. You're only moving about 175HP. Maybe more but certainly not 350. You will need what we call a "Race" hose. It is a 4an hose with a 3an nut on the plate side. Feel free to give me a call and Ic an set you up with one. I would start over with the jetting once you get this hose.

#19

May have found the gremlin thanks to Brandon at Nitrous Outlet! Discovered the line from the N2O solenoid is 3AN to 3AN and needs to be 4AN to 3AN! Also, as per lean spike at start of run - going to shorten fuel line from dedicated and relocate solenoid closer to plate. Thanks to everyone for the feedback!

#20

Slightly rich is not the best option. Nor is 2 degrees per 50hp of nitrous. When tuning a nitrous engine, there is no optimal air/fuel ratio. That is relative to each combination, and is not a straight across the board thing. I will tell you though, if you're running stuff at 11.5-1 a/f, you have a lot of room for improvement. Running stuff rich and over timed is a ticking time bomb. Whatever your optimal a/f ratio is on the engine, will be in the ball park of a close tune-up for the nitrous as well. Again like the op has been doing, pulling and cutting the plugs apart is the correct way of going about things. And judging by the fuel ring on the porcelain, he has too much fuel in it already, or NOT enough nitrous which is where his problem lies. The start of the run is susceptible to being leaner than the end of the run due to bottle pressure dropping. It's the nature of the beast with nitrous.